Reinforcement schemes

When building a house on your own, you do not need to carry out complex calculations for limit states in order to determine the cross-section of the reinforcement and the general need for material. Use of information from the Concrete Structural Design Manual is permitted. Using the available data, the general section of the longitudinal elements of the reinforcement cage for the foundation is specified:

- if the side of the tape does not exceed three meters, reinforcement of 10 mm in diameter is taken in an amount of 0.1% of the cross-section of the base;

- in the case when the length of one side is more than that indicated above, then the rods are taken in the same amount, but their diameter is 12 mm or more.

The placement of longitudinal rods is shown in the table:

| Conditions | Minimum installation step |

| Lower frame in one or two rows | Not less than 2.5 cm, rod diameter - maximum |

| Top frame for one or two rows | Similarly, at least 3 cm |

| Bottom reinforcement with more than two rows | Similarly, at least 5 cm |

| When compaction with vibrators | All the previous conditions are met, the step in some places is not less than 6 cm. |

Horizontal cross clamp

Such rods are assigned constructively, do not depend on the section. In this case, the loading effect of the object is taken into account. The minimum parameters of the cross-section of the transverse rod are 6 mm.

The rods are installed with a pitch equal to twenty diameters of the working rods. For example, if the cross-section of a longitudinal element is 1.4 cm, the horizontal rods are set at intervals of 28 cm.To simplify the task, this indicator is rounded up to 30 cm.

The length of the bars in the reinforcement frame for the strip footing is determined by the same parameter of the strip and the required concrete layer to create protection.

Clamp vertical

The size of the reinforcement in diameter is determined by the height of the foundation. If it does not exceed 80 cm, then rods with a cross section of 0.6 cm or more are selected. In other cases, from 0.8 cm, provided that it is not less than 0.25 of the diameter of the working rods.

If it is planned to build a large structure, the rods in the frame should be laid with a certain margin and a step similar to the transverse reinforcement. The length of the steel rods is determined taking into account the height of the foundation, from the value of which the thickness of the protective layers is subtracted.

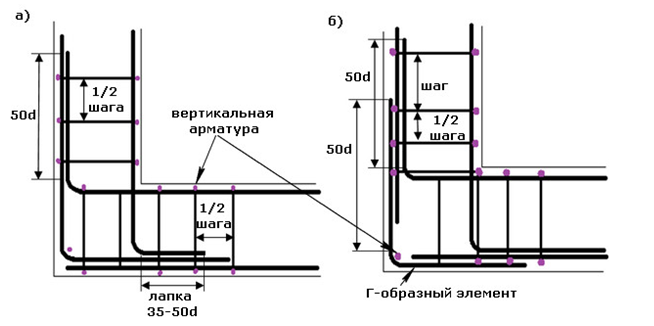

Gusset

When performing a rigid installation with an overlap and with the help of a "foot", the free ends of the rods directed in one direction are bent at ninety degrees and connected with perpendicularly located elements.

The bent "foot" should have an overlap length equal to thirty to fifty rod diameters. Clamps are installed in 3/8 increments from the height parameter of the reinforced concrete base.

The reliability of the connection of the working reinforcement is achieved by L-shaped clamps applied to the rods with an overlap equal to from fifty diameters of the longitudinal bar. The interval between the fastening clamps is 0.75 times the height of the foundation wall.

Use additional elements that look like the letter "P". A pair of such clamps is installed at each corner, the length of which corresponds to fifty diameters of the longitudinal bar. At the overlap point of such a clamp, an additional frame of vertical and transverse rods is mounted.

Obtuse corner reinforcement

It is carried out with an overlap. The outer rods are bent at the desired angle, the inner ones are attached to them with an overlap, the length of which starts from fifty rod diameters. A vertical clamp is installed at the bend of the outer element.

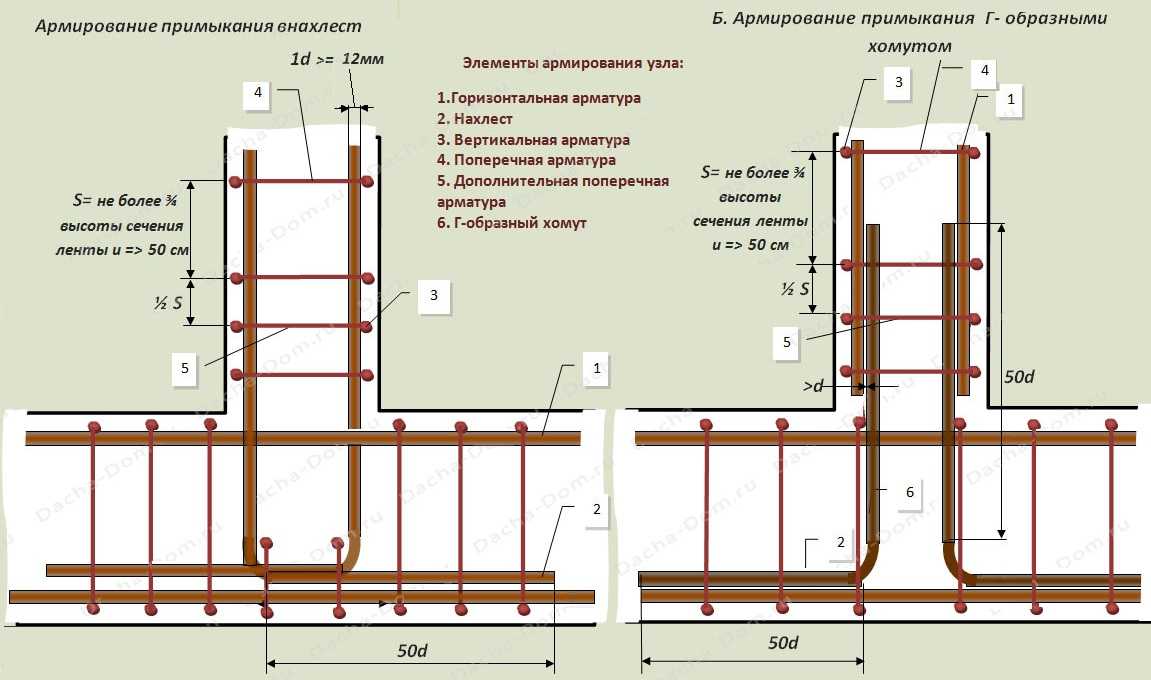

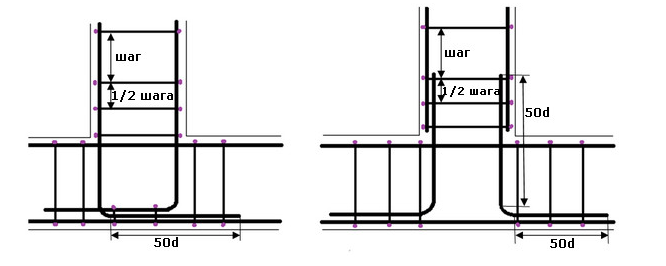

Wall abutment

Frame rods are bent, while the length of the section should not be less than 50 sections.Each of the abutment bars is connected to an outer wall bar that is perpendicular to it. The connection zone differs in the step of mounting the clamps at 0.375 from the height of the foundation tape.

If clamps are used in the form of the letter "G", then the rods are bent in such a way that both sides correspond to the length of five dozen rod diameters. The first side is fixed with the reinforcement of the adjoining wall, the second is connected to the outer working element of the tape, suitable perpendicularly. The spacing between the clamps is halved in relation to the total length of the strap.

When installing clamps "P", the abutment is performed to the outer rod using the "foot". An additional indicator of reliability is created due to the rod, curved with the letter P, while its length corresponds to two dimensions of the width of the foundation.

Non-standard way of knitting the frame

To simplify the process of creating a metal frame as much as possible, you can build a simple device from scrap materials. It will not only significantly speed up the mating, but also help to cope with it without assistance.

Stage 1. Make four blanks from boards with a length of reinforcing bars and connect them in two at a distance equal to the length of the vertical bridges.

Stage 2. Make improvised racks - stops on which you can put the resulting blanks. The main thing is that they stand on a flat surface.

Step 3. Fix the linked boards. So you got a wonderful layout of the future frame, according to which you can easily create a metal copy of it.

The procedure for performing the reinforcement of the strip foundation

The existing scheme for reinforcing the strip base for building a house implies following several mandatory rules:

- Application when carrying out reinforcement of bars of class A400

- Minimization of the use of welding when joining the rods, as this technology contributes to the weakening of the sections

- At the corners, the frame can only be tied, the use of welding at the corners is not recommended

- The protective laid layer of concrete used in a particular situation must be at least 4 centimeters to protect metal elements from negative environmental influences, corrosion

- The use of smooth reinforcement is not recommended.

- When laying concrete, it must not be able to get stuck between the rods, which will eliminate control over failure, for too frequent arrangement of metal rods

Detailed step-by-step instructions with photos and videos given for clarity will help to create a reinforcing cage. A significant advantage of reinforced strip foundations is the combination of high reliability and affordable cost. Steel and concrete are high strength materials.

This is important for creating a foundation for construction on any soil, except for the already naturally stable and reliable rocks. In other situations, any foundation reinforcement will save you from damage caused by stress.

How is formed

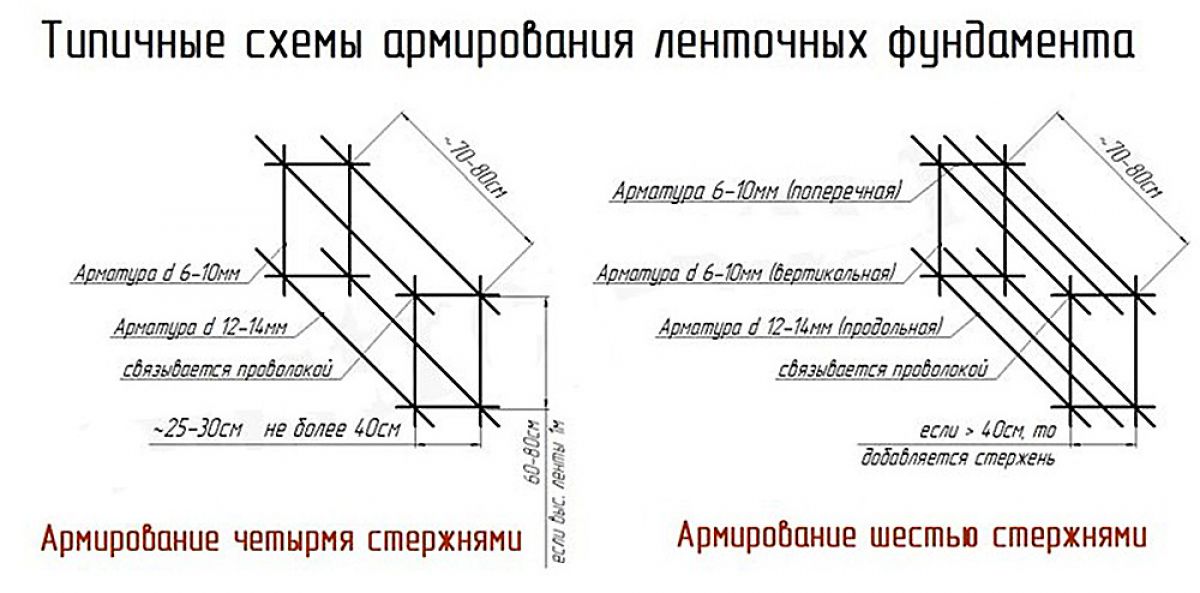

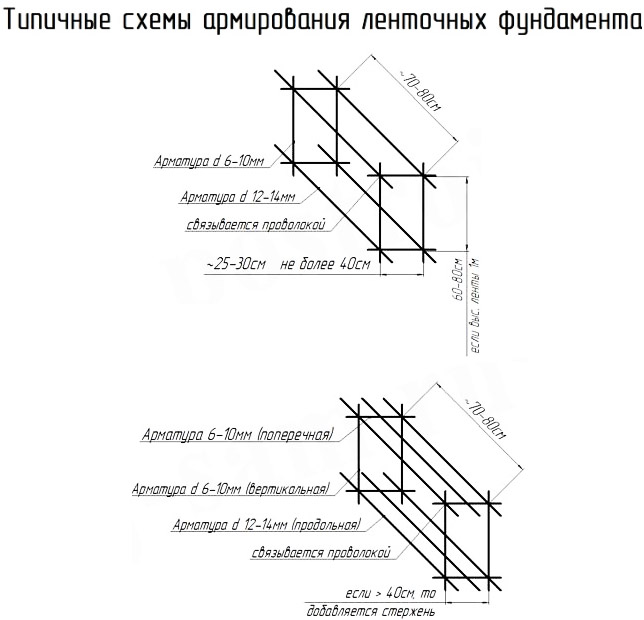

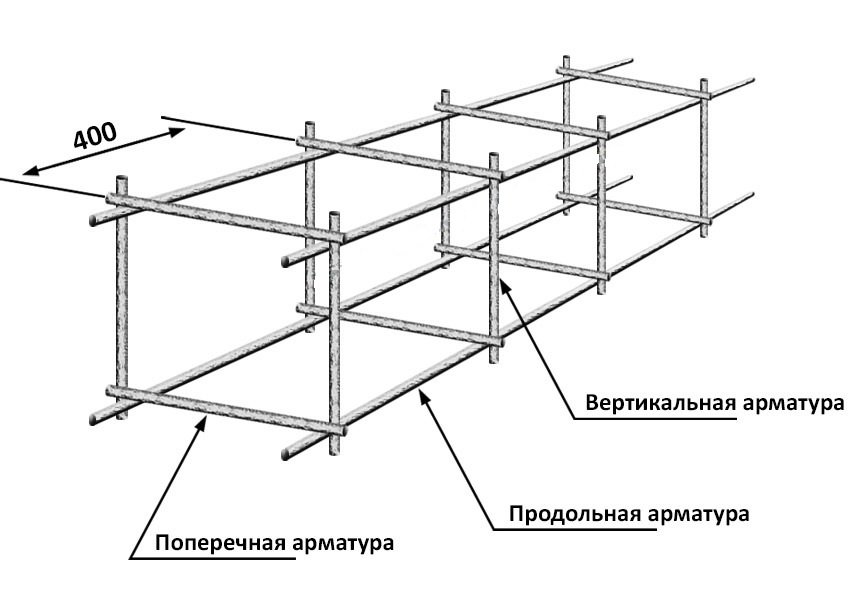

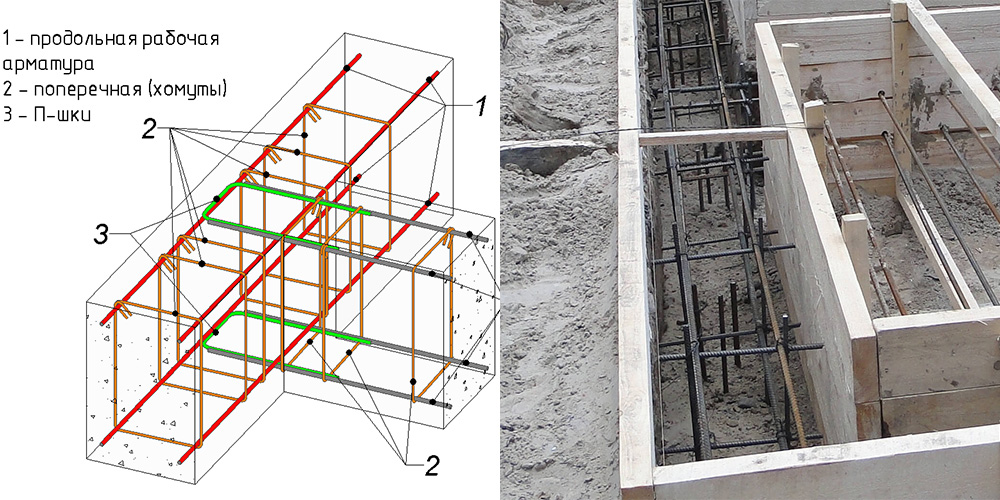

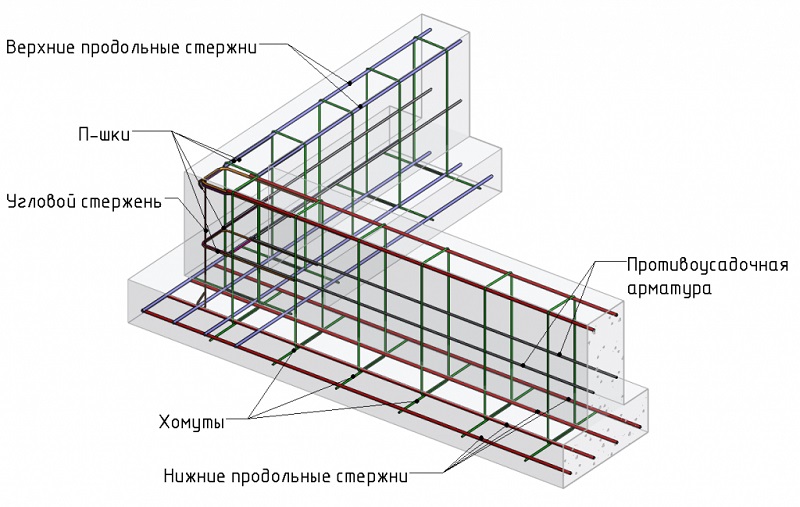

When carrying out work such as strip foundation reinforcement, drawings include three groups of rods:

- Used for laying along the belt, used working rods

- Horizontal elements located transversely

- Vertical options, transverse

The task of the transverse reinforcement is to connect all working elements into a stable in use, a single unit of reliable, innovative working rods. They are often called clamps.

An important feature of the work is the use of SNIP and other regulatory specialized documents in activities such as reinforcement of the strip foundation. The calculation uses SNiP 52-01-2203

In this regulatory document, it is easy to find all the necessary calculations to create the reinforcement of the strip foundation of a small country house.

What are the requirements for concrete determined by regulatory documents?

If you maintain the order of creating reinforcement, it is important to comply with the mandatory requirements for the concrete used in a particular job. When creating a strip foundation with your own hands at the site of future construction, it should be borne in mind that among the main characteristics of the strength of concrete structures is an indicator of resistance to axial compression, readiness to resist stretching and not respond to transverse fracture

Correction factors for reliability can vary from 1 to 1.5

When creating a strip foundation with your own hands at the site of future construction, it should be borne in mind that among the main characteristics of the strength of concrete structures is the indicator of resistance to axial compression, the readiness to resist stretching and not respond to transverse fracture. Correction factors for reliability can vary from 1 to 1.5.

Requirements for fittings

These indicators are determined by regulations and standards. Reliable foundation reinforcement uses bar-based:

- hot-rolled rebars,

- mechanically hardened fittings

- heat treated reinforcement

It is GOST that allows you to calculate the indices of the limiting submerged states, which are strictly divided into groups in it. Indicators are determined on the basis of the requirements specified in state standards, which are determined on test benches. Any regulatory and technical documentation that is used to determine the reliability of reinforcement must be approved by the official regulatory authorities.

What basic rules are important to consider when performing work?

As a rule, reinforcement during suburban and construction is carried out independently. In this case, the requirements of SNiP and GOST are not always followed so carefully.

For this reason, when considering how to reinforce a strip foundation with your own hands, it is important to adhere to some mandatory rules:

- When performing the reinforcement of the strip foundation of the future structure, including 1-2 floors, rods with a diameter of 10-24 mm are used.

- The use of welded joints is not recommended

- When creating a strip foundation with your rivers, it will be necessary to create a formwork

General recommendations

Having decided on the tool used for knitting, having prepared the necessary materials and performing the work, be guided by the following recommendations:

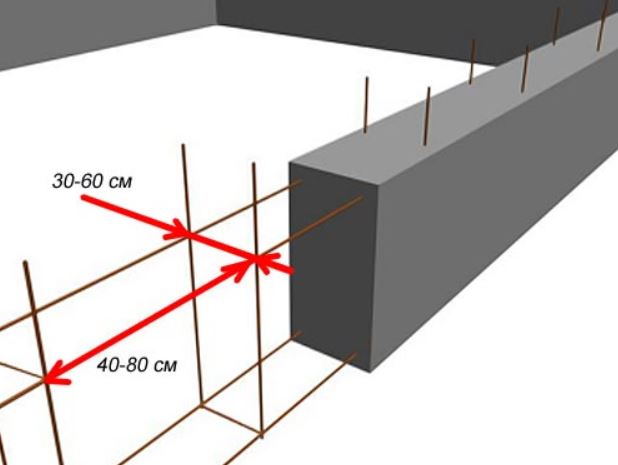

- Provide an equal distance (4-5 cm) from the horizontally positioned reinforcement frame to the ground, using wood pads or non-metallic supports. The rods should not touch the ground at the bottom of the trench;

- immobility of perpendicularly located steel rods when fixing with a wire can be ensured using a simple device that grips the ends of the rods with boards;

- do not drive vertically arranged rods designed to fix horizontal rods into the soil. Use non-metallic cupholders, which will prevent the rods from contacting the ground and reliably protect it with concrete from corrosion processes;

- check the reliability of fixing the frame elements with a wire. Errors in fixing bars - insignificantly affect the location of the reinforcement contour during manual filling. However, the use of a concrete pump supplying the composition under pressure can affect the arrangement of the elements, pushing them apart or displacing the structure;

- additionally check the reliability of the fastening of the rods in the corners of the frame, which are a vulnerable area of any foundation. The ends of the bars located at right angles, which must have bends, are not allowed;

- the criterion for correctly performed knitting work is the immobility of the spatial structure under the influence of human weight;

the provision of a reinforcement structure for the tasks set is possible with the correct selection of the assortment of rods, determination of the location and number of elements, according to preliminary calculations.

Execution of works

Step-by-step instructions will tell novice builders how to make a strip foundation and reinforce it. If a monolithic slab is reinforced with a reinforcing mesh, then the base of the building, erected with a tape, requires the creation of a high-quality reinforcing cage, for which it is necessary to follow the instructions and follow the order of work:

The preparation of the site on which construction work will be carried out consists in performing accurate markings, getting rid of excess vegetation, removing the fertile soil layer.

After completing the marking and installing the pegs with a stretched cord, they begin excavation work. These include digging ditches for the future foundation.

The next stage is the assembly and installation of the formwork

If wooden boards or shields are used to perform the work at this stage, then it is important to provide high-quality waterproofing of the structure so that moisture from the solution is not absorbed into the formwork material. For this purpose, plastic wrap is used.

Now start filling with sand and gravel

Layers of dumping are spilled with water and rammed, and a reinforcing cage is assembled next to the formwork on the soil surface.

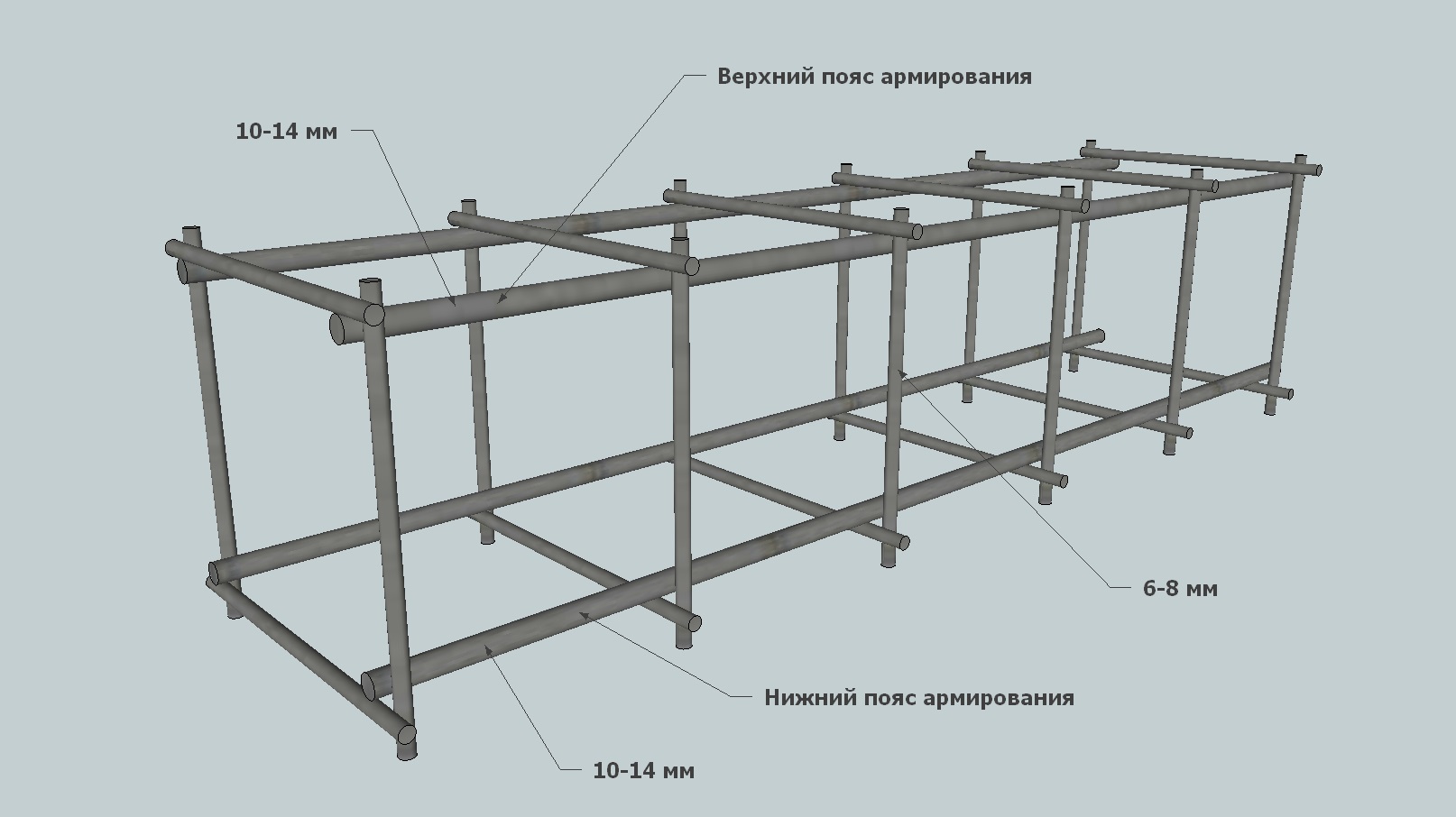

To assemble the frame, long reinforcing rods are used, which are laid in two rows (upper and lower), fastened with transverse elements, which are smooth metal rods. They are bent in the shape of the letter "P" and fixed at a set distance from each other. Fixation is carried out using knitting wire or plastic clamps. It is strictly forbidden to use welding. This will lead to the destruction of the structure due to corrosion at the weld seams.

The longitudinal parts of the frame are knitted on the ground near the future foundation, but one of the most important operations associated with strengthening the corners is carried out directly in the base tape. Correct reinforcement of the corners is the key to the strength and reliability of the entire structure.

To create a high-quality system, you must follow the rules:

- It is necessary to bend metal rods for corners so that rods with a diameter of 10 mm can be deepened into the foundation wall by at least 40 cm.

- The strength of the structure at the points where the corner reinforcement bars overlap can be increased by further fixing the longitudinal and transverse elements.

- The short rods are lengthened using "L" -shaped parts in order to achieve a full deepening into the base wall.

- The step between knots of knitting wire or plastic ties is halved.

When reinforcing corners, joints should be avoided and curved rods should be used.

A knitting wire with a diameter of 1 mm is cut into pieces with a length of at least 20 cm. For knitting, use a special hook or ordinary pliers. Many craftsmen prefer to knit wire with plastic clamps, since this process is simpler, does not require significant physical and time costs. At the same time, the quality of the work performed does not suffer.

Detailed instructions on reinforcing the corners of the frame can be obtained by watching the video.

Reinforcement of the foundation can be avoided only in conditions close to ideal, and this happens quite rarely. In an effort to erect a building that can serve for many years, first of all, you need to take care of the construction of a high-quality and reliable foundation, which is impossible to do without full reinforcement.

2 Work technology

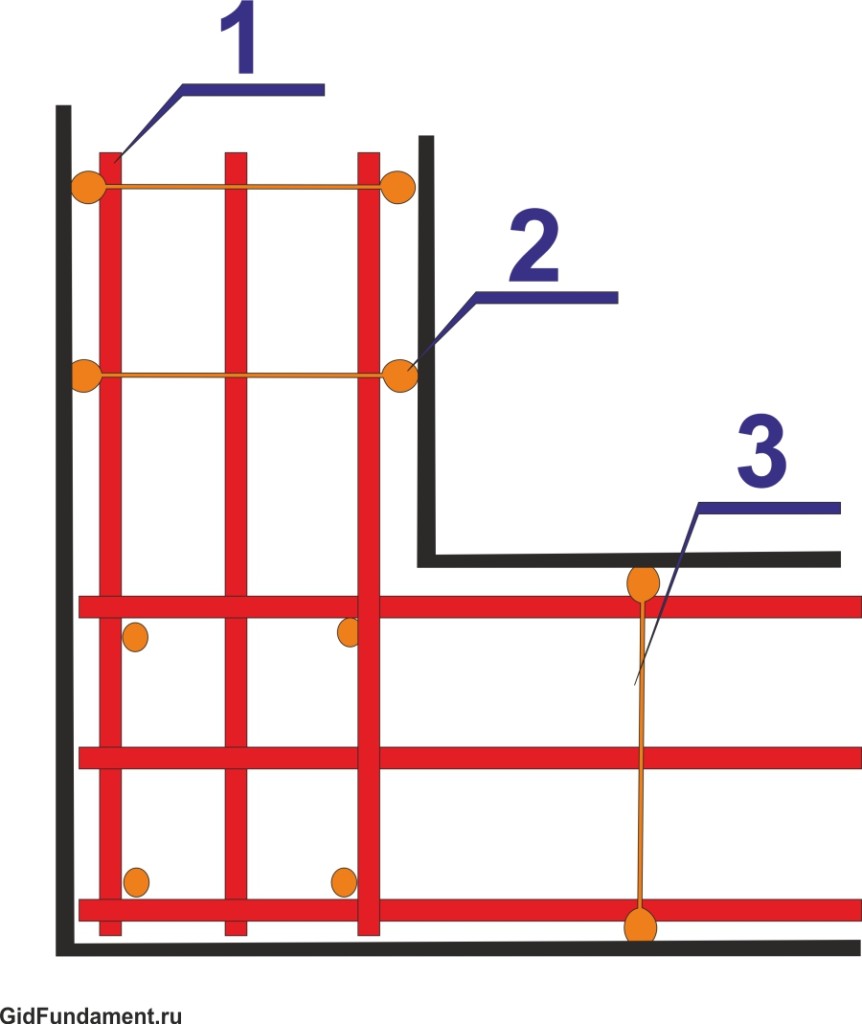

After the number of reinforcement has been determined, a strip foundation reinforcement scheme should be selected, according to which the reinforcement cage will be assembled.Straight sections of the structure are made of solid rods, while at the corner places additional reinforcement is required with a reinforcement curved in a P or L-shaped shape. The use of a perpendicular overlap of individual reinforcement bars at corners and junctions is not allowed.

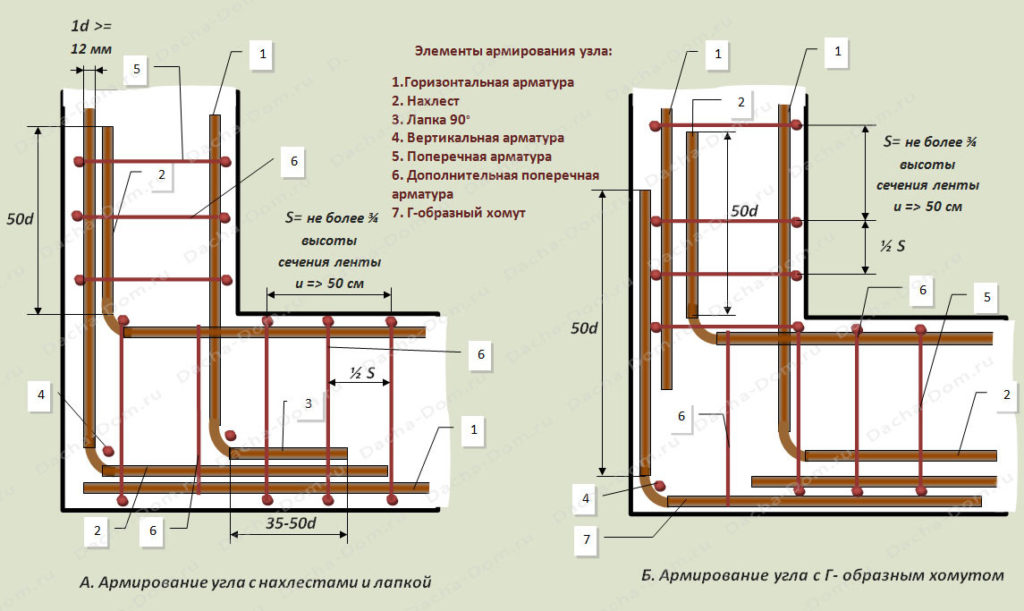

The correct reinforcement of the corners of the strip foundation is shown in the diagram:

Reinforcement of foundation corners

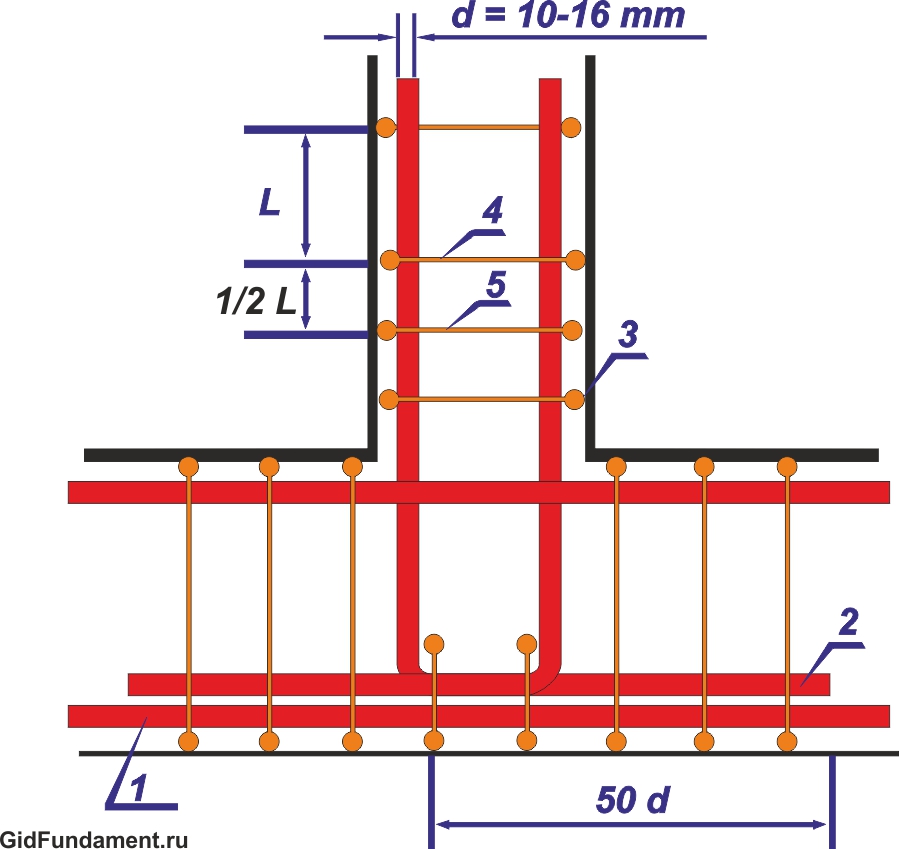

Scheme of reinforcement of the strip foundation at the junctions:

Reinforcement of abutments

Reinforcing the strip foundation with your own hands involves assembling the frame in a convenient place and then placing it inside the formwork. The technology requires bending fittings into rectangular clamps, which can be easily done at home using a homemade device.

On the 20th channel, you need to cut grooves with a grinder, into which the reinforcement is subsequently inserted, and a piece of steel pipe is put on the bar, which is used as a lever. Finished rings must be fastened by welding or tied with wire. For rods with a diameter of 10-15 mm, wire 1.2-1.5 mm is used.

The length of the bars on the longitudinal belt should be equal to the length of the side of the house. The rods are threaded inside the ring and fixed with a knitting wire at the corners of the clamp and in its central part. The step between the clamps is 30 cm. At the exit, you should have 4 component parts of the frame - 2 equal to the length and 2 smaller ones equal to the width of the house. Next, the frames are laid in the trench and connected with angled reinforcement bars in accordance with the above diagram.

Bending of clamps from reinforcement

When installing the frame inside the trench, the following rules must be observed:

- the frame must be raised above the bottom of the trench with the help of stands by 5 cm - the requirements of SNiP do not allow the use of fragments of bricks for this purpose;

- laying should be carried out strictly on a horizontal level;

- the frame must be fixed relative to the side walls of the trench with pins driven into its walls so that the reinforcement does not move during concreting.

Reinforcement of the strip foundation according to the execution technology is identical for shallow and buried bases. After installing the reinforcement cage, the concreting stage begins - concrete of the M200 brand is used for pouring. You can determine the required amount of concrete based on the volume of the foundation - you need to multiply the length, width and perimeter of the tape.

Reinforcement frame for foundation tape

Note that the technology of construction of a strip foundation requires the obligatory arrangement at the bottom of the trench of a sealing cushion made of layers of sand and crushed stone of the same thickness (thickness from 10 to 20 cm each)

A pillow is used to protect the foundation from vertical heaving loads, which is especially important when arranging a shallow foundation located in a layer of freezing soil

Reinforcement portal »Reinforcement» Strip foundation reinforcement technology

What material is better to make a reinforcing cage for a strip foundation?

Progress does not stand still, new building materials are constantly appearing. If earlier the knitting of reinforcement was strictly made of metal, then today you can see plastic reinforcement, fiberglass options and composite parts. So what is the best way to knit rebar? Let's take a closer look at the materials.

Despite the emergence of new and more modern materials, it is the time-tested metal fittings that remain popular. Its service life is about 50 years. The fittings are distinguished by their high weight, strength and reliability. Its main drawback is that it begins to rust under the influence of moisture.

To make a knitting of reinforcement for the foundation, hot-rolled construction reinforcement with a periodic profile, mechanically hardened or heat-treated, is suitable.

When choosing reinforcement, the value of the yield point must be taken into account.For the installation of longitudinal rows carrying the main load, rods of class A400 (AIII) are suitable, it is permissible to use materials of a higher class. But keep in mind that they will cost more.

It is important that the profile is ribbed, because

it adheres better to concrete and transfers the load evenly.

For lintels, smooth A1 class reinforcement is suitable, this will help reduce the cost of the foundation, while it will have sufficient strength.

For strip foundations, fittings with a diameter of 6-12 mm are suitable.

If the side of the tape is less than 3 m, then it is permissible to use rods of at least 10 mm for horizontal clamps, if more than 3 m, then at least 12 mm. For vertical clamps with a foundation height of less than 80 cm, fittings with a diameter of 6 mm and more are suitable, for more than 80 cm - from 8 mm.

Fiberglass reinforcement is 2 times stronger and 9 times lighter than metal one. An important advantage of this material is that, unlike metal, it does not corrode. Fiberglass reinforcement has a service life of about 70 years. Moreover, its price is cheaper than the metal version.

The choice of material for reinforcement must be carefully. If the reinforcement is of poor quality, then cracks may appear on the foundation, which will gradually expand, and as a result, the structure will serve you much less than it could.

You can do the knitting of the frame from the reinforcement yourself or buy a ready-made reinforcing mesh. The second option will be more expensive, but the question of how to knit a reinforcing cage will not bother you, since specialists take care of these concerns. In addition, the advantage of the finished mesh is that the rods are firmly connected to each other in the factory. This ensures that the framework does not decay over time, as it might with a homemade one. In addition, in this case, it will be easier to reinforce the foundation: you just need to put the frame in two parallel layers.

Reinforcement schemes

When building a house on your own, you do not need to carry out complex calculations for limit states in order to determine the cross-section of the reinforcement and the general need for material. Use of information from the Concrete Structural Design Manual is permitted. Using the available data, the general section of the longitudinal elements of the reinforcement cage for the foundation is specified:

- if the side of the tape does not exceed three meters, reinforcement of 10 mm in diameter is taken in an amount of 0.1% of the cross-section of the base;

- in the case when the length of one side is more than that indicated above, then the rods are taken in the same amount, but their diameter is 12 mm or more.

The placement of longitudinal rods is shown in the table:

| Conditions | Minimum installation step |

| Lower frame in one or two rows | Not less than 2.5 cm, rod diameter - maximum |

| Top frame for one or two rows | Similarly, at least 3 cm |

| Bottom reinforcement with more than two rows | Similarly, at least 5 cm |

| When compaction with vibrators | All the previous conditions are met, the step in some places is not less than 6 cm. |

Horizontal cross clamp

Such rods are assigned constructively, do not depend on the section. In this case, the loading effect of the object is taken into account. The minimum parameters of the cross-section of the transverse rod are 6 mm.

The rods are installed with a pitch equal to twenty diameters of the working rods. For example, if the cross-section of a longitudinal element is 1.4 cm, the horizontal rods are set at intervals of 28 cm.To simplify the task, this indicator is rounded up to 30 cm.

The length of the bars in the reinforcement frame for the strip footing is determined by the same parameter of the strip and the required concrete layer to create protection.

Clamp vertical

The size of the reinforcement in diameter is determined by the height of the foundation. If it does not exceed 80 cm, then rods with a cross section of 0.6 cm or more are chosen.In other cases - from 0.8 cm, subject to the condition that it will not be less than 0.25 of the diameter of the working rods.

If it is planned to build a large structure, the rods in the frame should be laid with a certain margin and a step similar to the transverse reinforcement. The length of the steel rods is determined taking into account the height of the foundation, from the value of which the thickness of the protective layers is subtracted.

Gusset

When performing a rigid installation with an overlap and with the help of a "foot", the free ends of the rods directed in one direction are bent at ninety degrees and connected with perpendicularly located elements.

The bent "foot" should have an overlap length equal to thirty to fifty rod diameters. Clamps are installed in 3/8 increments from the height parameter of the reinforced concrete base.

The reliability of the connection of the working reinforcement is achieved by L-shaped clamps applied to the rods with an overlap equal to from fifty diameters of the longitudinal bar. The interval between the fastening clamps is 0.75 times the height of the foundation wall.

Use additional elements that look like the letter "P". A pair of such clamps is installed at each corner, the length of which corresponds to fifty diameters of the longitudinal bar. At the overlap point of such a clamp, an additional frame of vertical and transverse rods is mounted.

Obtuse corner reinforcement

It is carried out with an overlap. The outer rods are bent at the desired angle, the inner ones are attached to them with an overlap, the length of which starts from fifty rod diameters. A vertical clamp is installed at the bend of the outer element.

Wall abutment

Frame rods are bent, while the length of the section should not be less than 50 sections. Each of the abutment bars is connected to an outer wall bar that is perpendicular to it. The connection zone differs in the step of mounting the clamps at 0.375 from the height of the foundation tape.

If clamps are used in the form of the letter "G", then the rods are bent in such a way that both sides correspond to the length of five dozen rod diameters. The first side is fixed with the reinforcement of the adjoining wall, the second is connected to the outer working element of the tape, suitable perpendicularly. The spacing between the clamps is halved in relation to the total length of the strap.

When installing clamps "P", the abutment is performed to the outer rod using the "foot". An additional indicator of reliability is created due to the rod, curved with the letter P, while its length corresponds to two dimensions of the width of the foundation.