A staircase is a necessary element of any house with two or more floors. Today there are several types of stairs, differing in design features, dimensions and convenience. However, whichever design you choose, the presence of a railing is a must for each of them.

Therefore, in this article we will talk about stair handrails, including materials of manufacture and design features.

Handrails for modern stairs

The SNiP requirements clearly state several rules regarding stair railings:

- All stairs with more than three steps must be equipped with handrails. If the staircase is free, that is, it does not adjoin any of the walls, then the fence should be on both sides. If it is located against the wall, then it is necessary to protect it only from the free side.

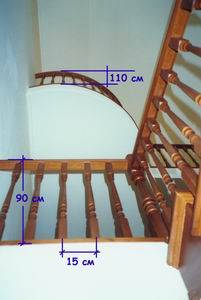

- The handrail for the stairs must be located not lower than 90 cm from the tread.

Advice! The handrail can be round, square, rectangular or curly. However, the main requirement is a size that is convenient for a hand grip, because, first of all, it is not a decorative, but a functional element.

- The distance between the balusters should be on average 150-200 mm.

Advice! If small children live in the house, then the distance should be reduced to 100 mm in order to avoid injury.

Choosing a material

Today, a handrail for stairs can be made from a variety of materials. At the same time, designers are striving to ensure that even poorly combined materials begin to look harmonious and stylish in certain models of stair railings.

If we talk about the design aspect of these structures, then it is important to achieve a combination of three main components:

- Steps of the stairs.

- Railing.

- Baluster.

If the combination of these elements is successful, the staircase will have an attractive appearance.

The material for the handrails is used:

- Wood.

- Metal (most often it is aluminum or stainless steel - materials that are easy to process).

- Stone.

- Plastic.

- Ceramics.

- Glass.

Consider the features of the most popular materials:

- Wood. Wood is a traditional material for stairs. Today, most of the structures in private houses are made of wood. Polished and varnished, the wood fits nicely in the hand, being a warm and environmentally friendly material. A wooden staircase, if desired, can be made with your own hands.

Advice! One of the indisputable advantages of wood is that wooden elements look harmoniously with any materials. Therefore, you can't go wrong when combining wood with metal, forging, ceramics or plastic.

Wooden elements are quite strong and durable, while the price of such railings can vary from budget options to luxury ones, with sophisticated carved forms. Such handrails can be easily made with your own hands, because wood is famous for its exceptional flexibility in work.

- Metal. Metal handrails for stairs are most often installed in large stores, swimming pools, sports clubs, etc. The material for such products is stainless steel and aluminum. These are smooth and lightweight structures that are not afraid of cold and temperature extremes, corrosion, dampness, maintaining their original shine for a long time.

In addition, they are characterized by ease of care - you just need to wipe such elements with a soft napkin, and they will shine in a new way.

- Stone. Old noble houses, castles, museums and some institutions of the Soviet era boast marble railings. These monumental structures showcase the scale and power of the building. Therefore, these days, such designs are often installed in luxury cottages.

In most cases, the entire structure is made of marble, including steps and handrails.

Since the material is rather light, has a porous structure and tends to absorb moisture, in the manufacture of staircase structures, fastening mixtures are used that are prepared on an anhydrous basis.

- PVC handrails for stairs most often imitate wood, however, they can be of different colors. Despite the fact that such products for the most part belong to the budget segment, they are characterized by many advantages:

- Strong enough to ensure the safety of the fence as well as a beautiful appearance.

- Such products are durable, are not afraid of dampness and moisture, and are easy to clean.

- They are very easy to install, because they use carefully "fitted" parts. The ladder handrail bracket can be easily attached to the wall, making the installation of wall structures much easier.

- Plasticity, due to which such products bend easily when using a powerful construction hair dryer. This allows such handrails to be given a wide variety of shapes.

- Low cost. Perhaps, in terms of price, these products are out of competition compared to analogues.

- Like wood, the material is warm. That is, even in severe frost, you will not feel the discomfort, as in the case of touching the aluminum railing.

- High impact resistance.

- UV resistant.

- Electric current non-conductivity.

- Acrylic. Such products are characterized by excellent appearance. If we talk about a transparent material, then it is an excellent alternative to glass, but at the same time, acrylic is stronger and safer than glass.

The most interesting option is the illuminated railings. The backlight runs along the end of the handrail, shining through it along its entire length. This is especially useful in poor lighting conditions, because leaning on the luminous handrail, you can not be afraid to stumble.

How to make curved handrails

Marching staircase structure is the most common today. However, spiral staircases are not uncommon for which standard straight railings are not suitable. Such designs require special semicircular handrails.

In this regard, many home craftsmen have a question: "how to bend the handrail for a spiral staircase?" In reality, everything is much simpler than it seems at first glance. Bending instructions directly depend on the material:

- Wood.

There are two technologies for giving wood a curved shape:

- The wooden workpiece should be soaked in boiling water until it is completely softened, after which it bends in the right places. Further, it is fixed in a bent position and left so until it dries completely.

- A more modern method involves gluing thin lamellas, giving the workpiece the required shape. This method allows you to make blanks of any, even bizarre shapes.

- Plastic. As mentioned above, for this procedure, a building hair dryer is used, the hot air flow of which is directed to the workpiece, which begins to bend in direct proportion to the air stream. The workpiece should be heated gradually and carefully so that the fold does not come out excessive.

- Metal.

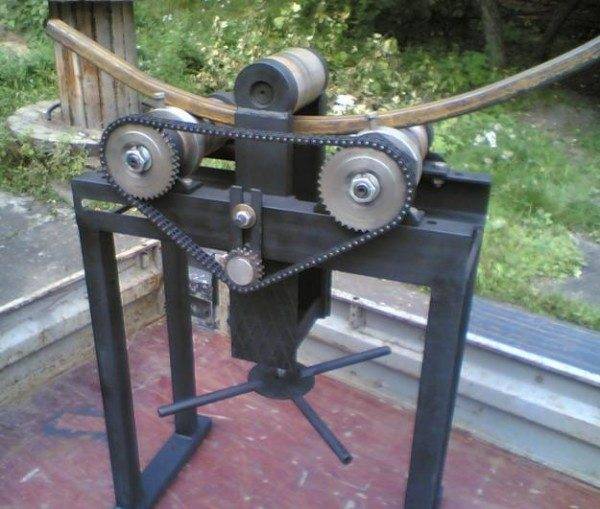

There are two types of bending of metal products: hot and cold.

- In the hot method, the metal is heated in a special forging furnace, after which it is given the required shape with a hammer.

- The cold method is more laborious, but more suitable for domestic conditions. A strip of metal is clamped in a vice and a hammer is given the required shape.

There is also a special machine for bending metal.