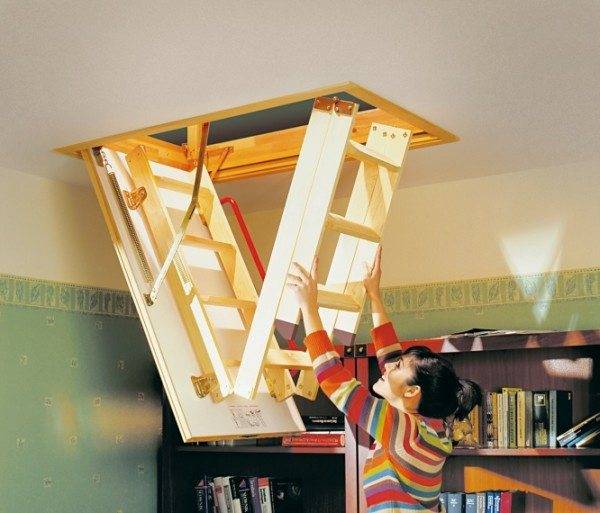

Folding wooden loft ladders are a special type of lifting structure. Provided they are properly installed, they provide a fairly comfortable move to the attic or attic, while taking up almost no free space in the room.

The device of such stairs, as well as the algorithm for their self-production, are described in our article.

General information

Device diagram

In most old-style private houses, the attic is a "dead zone": this room is used mainly as a warehouse for unnecessary things, and it is good to go up there if a couple of times a month. In such a situation, folding steps are useless - an attached structure is enough, and the entrance can be done from the outside.

If you decide to use the attic more actively, then it is better to equip the most comfortable rise.

For this:

- The entrance to the room under the roof is done from inside the house.

- For climbing we use a stationary or folding ladder.

Stationary steps are convenient in that they are available for use at any time. However, in a house with a high ceiling, such a staircase will take up a lot of space, and that is why many people prefer to use folding structures.

What is a folding attic staircase?

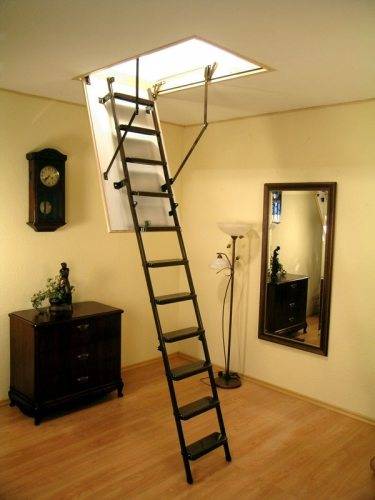

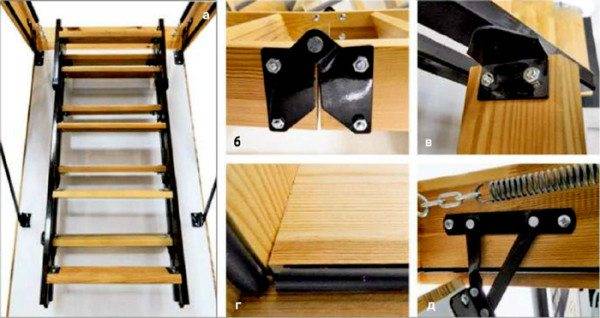

- The basis of the device is several segments, which are two parallel wooden or metal bowstrings. There are steps between the bowstrings.

- The segments are connected by metal hinges.

- At the top, the staircase is attached to the attic hatch. In the most advanced models, such as the Fakro folding loft ladders, the hatch is an integral part of the device.

- A special lock is responsible for fixing the stairs in the unfolded or folded position.

In the folded position, the segments are either in the attic, closed by a hatch, or against the wall. If necessary, it is enough to pull the lever connected to the mechanism, and the ladder will lower on the hinges, resting on the floor. In the same way, it simply stays in place.

Advantages and disadvantages

The advantages of this type of ladder are quite obvious:

- First of all, this is, of course, saving free space.... When the ladder to the attic is not needed, it is simply outside the room or hanging along the wall.

- Also, the advantages include ease of use.: Modern models are easy to fold and unfold so that even a child can handle them.

- Devices combined with an attic hatch ensure efficient heat retention in the room... Ideally, the hatch should be equipped with a sealing loop, but even without it, the reduction in heat loss will be significant.

- Relatively light weight (and even folding metal attic stairs are made quite light) is also a plus: in any case, the load on the load-bearing elements of the building is much lower than when installing a stationary staircase.

The disadvantages of such devices include:

- Fairly high complexity. Indeed, a large number of hinge joints require maintenance, since otherwise problems arise over time when bringing the ladder from the folded position to the working position and vice versa.

- Low level of comfort. If children or the elderly often have to climb into the attic, then it is better to choose a stationary model.

- The price of such an engineering solution can be different: there are both quite budget models and quite expensive devices on sale.However, if you do not want to spend money and buy folding attic stairs in Leroy Merlin or other similar stores, then in the next section we will tell you how you can make such a structure yourself.

Do-it-yourself stairs

Materials and fixtures

If you have the skills of welding, then metal shaped pipes can be used to make the main segments. We will tell you how to make a folding attic staircase with your own hands from a wooden bar.

For manufacturing we need:

- Bars with a cross section of at least 40x80 mm for making a bowstring. The total length of the beams should be about a meter longer than the height of the room - this way we can descend or ascend at an angle.

- The optimal step width is 700 mm. For their manufacture, it is advisable to use beams 40x40 or 40x50 mm.

Note!

The wood for making the segments must be strong and dry, without cracks, knots and chips.

Before starting work, all blanks must be treated with an antiseptic.

Fireproof impregnation will not be superfluous either.

- The hatch is made of pine or birch board. The hatch thickness must be at least 20-30 mm.

- To connect the elements, we need hinges and hinges. Their number is determined by the design of the staircase itself.

To make your life easier, you can purchase a ready-made set of mechanical elements for a folding ladder (see also the article Accessories for stairs: types and purpose). Of course, this will be more expensive than just buying a few loops, but on the other hand, you will be sure that at the most inopportune moment the whole system will not fall apart.

The tool used is the simplest:

- Saw for wood (it is better to use a saber or disc, but a hacksaw will also work).

- Hammer.

- Screwdriver.

- Perforator (if it is meant to be mounted in concrete partitions).

- Measuring tool set.

Sequence of work

The instructions for making a folding mechanism provide for the following actions:

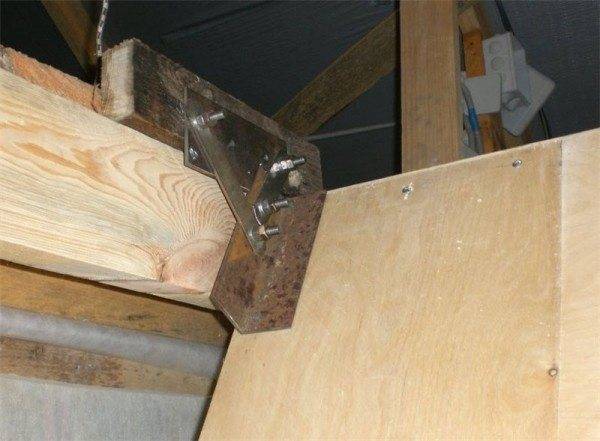

- First, we make a hatch in the ceiling. The dimensions of the hatch should allow the folded ladder to fit freely inside, therefore the width and length should be 5-8 mm larger than the largest segment of the ladder.

- We reinforce the hatch cover with wooden beams and fasten it to the ceiling using special hinges. The hinges must be reliable enough, because the load on them will be serious.

Advice!

The hatch is secured by a door latch.

It is better to use the reinforced version: this way we guarantee that the hatch will not open at the wrong moment.

- We collect segments of our future stairs from the prepared wood. As a rule, a three-segment folding structure is installed in private houses.

- We connect the bowstrings and steps "on a thorn" with glue. For additional reliability, we fix the steps on the sides with self-tapping screws.

- The hinge elements are either cut out of sheet metal and corners, or purchased separately. The main thing is that the hinges ensure the installation of an open staircase at the desired angle.

- We connect the segments of the stairs with hinges, fixing them with self-tapping screws.

- In the upper part, we fix the bowstrings on the hatch cover.

- To ensure that the hatch is closed, we install special brackets on it. If finances allow, you can replace them with factory-made closers.

Thus, we get a folding structure of three ladder segments, fixed on the hatch cover. If necessary, we open the hatch to the attic, and unfold the stairs, and then we simply fold it back.

Naturally, factory-made Fakro or Oman folding loft ladders will surpass our homemade ones in terms of reliability and ease of use, but the price gain will be quite impressive.

Output

If necessary, folding attic stairs can be installed in almost any room - if only there is free space.At the same time, significant savings in area and the possibility of self-production (albeit with a fair amount of effort) make structures of this type very popular among the owners of private houses. In the video presented in this article, you will find additional information on this topic.

In my opinion, such a staircase is the best solution for a home. It is quite easy to make such a staircase yourself. the materials are quite accessible, but I think it's not even worth talking about functionality. compact and does not take up much space.