First project

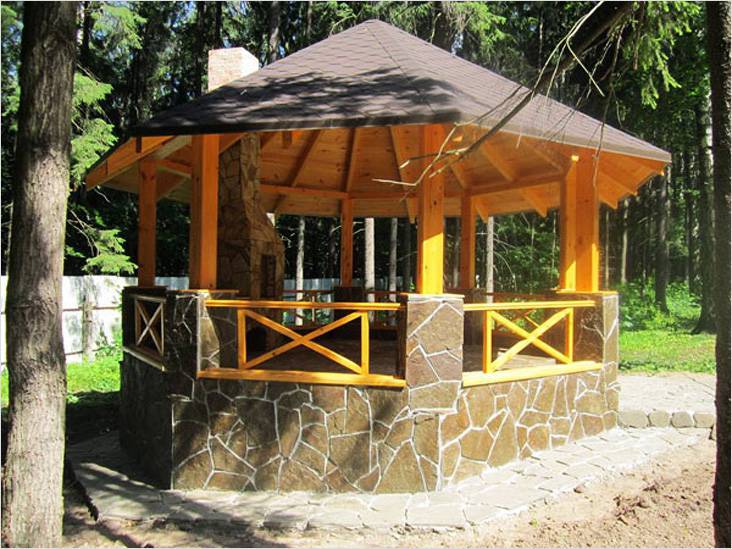

We offer a variant of an octagonal wooden summer cottage.

- On the ground, we mark a regular octagon, a hole in the center, 2 additional holes for installing a floor log.

- We drill a hole 150 mm in diameter to a depth of 1 meter.

- We put asbestos-cement pipes with a diameter of 150 mm into it, reinforce them, then fill them with cement mortar. After the concrete hardens, we cut off the reinforcement, leaving protrusions of 5 cm.

- We collect the lower harness, getting an octagon with parallel bars.

- We insert vertical racks in the corners, fix them with self-tapping screws.

- We make the upper strapping from boards, fasten them with self-tapping screws.

- We make a circle for the center of the structure, attach it to the central pillar. We fasten wooden bars for the rafter system to the racks and the circle.

- We cut the boards at an angle of 22.5 degrees, join them on the rafters. We get a structure resembling a spider web.

- We lay a 40 mm edged board on the floor surface, be sure to impregnate the boards with an anti-corrosion compound in 2-3 layers. We cover the table top and benches with polyurethane varnish.

- We attach the table to the main stand. From the floor we make a table 700 mm high, choose a diameter of 1800 mm. For the manufacture of countertops, a furniture board is suitable. We connect the cut out circle with the legs, attaching them to the tabletop at an angle.

- We make rest benches along the perimeter of the structure. Folding wooden chairs or portable benches can be used.

- We cover the roof of the gazebo with roofing material or flexible tiles.

Attention

! Be sure to cover all wooden parts of the gazebo with an antiseptic solution to avoid damage by insects and reliably protect from decay

Do-it-yourself open gazebo

It shows how to build an open gazebo with your own hands from wood. The design, as you can see, is solid. The main building material will be wooden beams, the volume, and the quantity will depend on the size of the structure, the author does not give figures, so you will have to select it yourself. The second required material is metal rods of two types, T-shaped and L-shaped. And you also need screws, very large screws, twice the thickness of the beams. Do not forget about the ladder, preferably a sturdy one, in this project it is the main tool. Concrete is another essential material for building your gazebo, it will be used as a base and anchor for the entire structure. Once you have drawn the drawing, you will be able to see what dimensions are needed for all the wooden parts. If you have tools, you can cut all the components yourself. This is the cheapest option. If you don't have the skills or tools, you need to find someone to do it ..

The first step is to build the base.

- Prepare the area and fill the slab of the desired size. If you want more strength, add metal reinforcement concrete.

- Next, install the wooden beams and metal supports into the concrete at a 90 degree angle.

- If there are gaps between the metal and wood parts of the supports, use tar and silicone to fill in and create a waterproof seal.

- Repeat this step for all supports. Typically four pillars are installed, but if you choose a different design, more pillars may be required.

- The next step is to place the wooden rungs on the supports, remember to measure all sides and make sure they are equal. Then secure them in place with the screws.

- The next step is to attach the side rails to the ones you installed on the posts.

- Then you need to make a triangular structure that will support the roof. The triangular shape of this part of the structure is designed to distribute weight down to the supports, which will be especially useful if you live in an area with high rainfall, especially snow.

- Use metal rods to hold the diagonal pieces securely in place.Pass the metal bar through the two pieces of wood to make sure they hold firmly in place.

- Now install the top bar where the roof will be attached. This may require the use of a rope or extra help to keep the pieces together.

- Now it's time to put in the roof supports to help support the weight. Place the support approximately every 55 cm. Fasten the supports securely with screws.

- Cover the roof with sheets of plywood, this layer must withstand a lot of weight, it must be fixed very securely.

- Then attach the waterproof layer. There are different types of roofs, you can choose whichever you prefer, but laminated tiles are a popular and effective choice.

Varieties

The main advantage of the octahedral design is considered to be a large square. Compared to conventional rectangular buildings, there is always room for a company of 12-15 people.

Provide a cozy ambience in your gazebo

Provide a cozy ambience in your gazebo

Octagonal arbors made of natural wood are held in high esteem (38% of consumers). And although under the influence of time this material loses its primary operational properties, it has more advantages than disadvantages. Among them:

- easily renewable raw material base;

- high specific strength (for example, if we compare the strength of beech and steel, the indicators will be approximately the same);

- resistance to chemically aggressive environment;

- low thermal conductivity;

- a wide range of products - from natural materials to fibreboards, which are more affordable in monetary terms.

Pergolas covered with climbing plants are a relatively inexpensive option. True, in bad weather, such structures are unlikely to protect from rain and cold. In this case, an octagon made of decorative stone, ceramic bricks, polycarbonate, and even better metal, may become a more advantageous offer. The latter has an almost unlimited life.

The finished steel frames are assembled in just a few hours. They look good on hills, and under the influence of sharp temperature changes they retain their original appearance for a long time.

Varieties of materials for the building

An octagonal gazebo can be made from a variety of materials. Some options take a long time to build, while others take days to build.

The most commonly used materials are:

- wood;

- metal;

- professional pipe;

- brick.

Important! It is worth noting that the wooden parts of the structure do not deteriorate, it is necessary to make and periodically renew the protective coating against decay and fire.

Wood

Often such structures are made of wood. This eco-friendly material is in good harmony with any building and landscape. The wooden structure is quite comfortable and aesthetic. It can be made stationary and mobile. Portable gazebos are suitable for use in warm weather. In winter, it is removed. This allows you to save wood from the negative effects of weather events - frost, rainstorms.

Metal

Metal arbors are strong enough. The metal is resistant to negative weather conditions and fireproof. If you wish, you can use decorative forged elements that will decorate the structure well.

We recommend that you learn how to make concrete products for landscaping.

In order to make and install this structure, you need to be able to use a welding machine. The very process of creating such a metal structure is quite time consuming and costly. Instead of welding, parts can be connected with screws and bolts, but they will also need to be drilled with a special tool. Such a building will last for many years. It is not recommended to place it in sunny areas, as the metal heats up well.In winter, this material cools down and becomes cold. So that the metal structure does not undergo corrosive processes, all its parts should be treated with a special coating.

Proftruba

You can use a metal professional pipe to equip a gazebo. In this case, you will need additional details in the form of wooden bars, material for the floor, roof and walls. The structure can be made closed and double-glazed windows or polycarbonate can be used. The durability of this structure will depend on the quality of the materials used. Polycarbonate has different colors, and you can choose the right option.

Did you know? In Pyatigorsk, near Mount Mashuk, in 1831, a singing pavilion Eola was built in the Greek style with white columns. There used to be two harps in it, and when the wind blew, you could hear the music.

Gazebos made of this material are more fire resistant than wood. You can install a brazier in them without fear of fire. The lack of thermal insulation can be attributed to a design flaw. The surface of the parts will need to be monitored so that corrosive processes do not appear.

Gazebos made of this material are more fire resistant than wood. You can install a brazier in them without fear of fire. The lack of thermal insulation can be attributed to a design flaw. The surface of the parts will need to be monitored so that corrosive processes do not appear.

Brick

Brick gazebos are considered more capital. This is a fairly refractory and durable material. It resists environmental influences well. The construction of such a gazebo takes more time and costs for building materials, but it will last a long time and will be quite comfortable. It can be safely equipped with a barbecue or barbecue.

Check out also the application of a dry stream in landscaping.

Equip such a building with a table, seats, and other furniture elements. It can be made open or closed. In the second option, it will be convenient to make a barbecue in it in the winter or enjoy the natural landscapes.

Finishing

On an elevated base

On an elevated base

The first step is to ensure that the material from which the project was made is protected from the effects of various weather conditions. In this case, the metal is cleaned from rust or treated with a special compound that removes it. The next layer is primer and topcoat. For wood, the process will be a little more troublesome. The entire structure will need to be sanded with a tape or eccentric machine. If it is necessary to change the shade, it is opened with a stain. The raised fibers are sanded again. Three layers of varnish are applied. After the first two, you also need to walk with fine sandpaper to improve adhesion.

To make it convenient to be inside, you need to take care of the benches. Preparation for them must be done even at the stage of erecting the frame. Special supports can be provided, for example as described for the metal version. The edged board for the flooring is carefully sanded, the ends are trimmed at an angle of 22.5 °. Their size should be such that they fit half of the support. They are processed in the same way as the wireframe. The backrests made of wood are installed at a suitable height.

It is good if the table also has 8 sides in shape. This will allow it to fit perfectly into the interior. The optimal width will be 1.5 m. In this case, it will be convenient to reach the middle without additional effort. To strengthen it in the metal version, you will need to weld the frame, and lower the racks to the jumpers that go along the base. For a wooden structure, you can order a table that will not be fixed inside, but will be a separate element.

Wooden octagonal gazebo pergola

Wooden octagonal gazebo pergola

The side walls are decorated in any interesting way. It can be a wooden lattice, which is made of boards of small thickness, they are located one in relation to another at an angle of 45 °. If desired, the bottom can be closed completely to the middle, and double-glazed windows can be mounted in the remaining openings.This will allow you to use the building in any weather, even with strong winds. To protect yourself from little bloodsuckers, you can cover the entire area with a mosquito net. Fresh air will calmly enter the middle, but insects will not be able to get inside.

Octagonal glazed gazebo

Octagonal glazed gazebo

In some designs, the brazier can be placed inside, but more often this brings certain inconveniences, because smoke can be very disturbing to those nearby. To make it much more comfortable, you need to think over an additional area near the building or bring out a separate chimney.

For an evening pastime, you need to think about what kind of lighting will be in the gazebo. The most economical option is LEDs. In principle, if the roof is made of high quality and does not leak, then an ordinary lamp or chandelier will do. But due to the high humidity, the internal contacts oxidize very quickly. To prevent this, sealed products have been developed with an IP67 or IP68 rating. They are not afraid of any drops of water or dust. The main wiring can be done with a double-braided cable. This, for example, can be VVG. It contains a monolithic copper core. To prevent it from sagging, it is tied to a rope. There is a kind of wire in which the metal cord is already soldered into the outer braid. The dashboard should have a separate machine, with which, if necessary, it will be possible to de-energize the gazebo. Switches and sockets are matched to make them stand out. They will be outdoor installation. It is desirable that both switches and sockets are also sealed.

With a two-level roof

With a two-level roof

Diy rectangular gazebo

Building a rectangular gazebo with your own hands is not so difficult, and it will undoubtedly decorate your site, but it is a little more complicated than a square-shaped design. Always plan to shape everything at the very beginning if you want to get a good result. Plus, proper planning can prevent many costly mistakes.

Choose materials with great care, making sure all parts are straight and in good condition. Building a rectangular gazebo is a little different from building a square one, but anyone with average carpentry skills can handle this task easily.

We will not describe the process in detail, all steps are shown in the diagrams, more detailed information can be obtained on the website, link under the photo with drawings.

The second part shows how to make a roof for a rectangular gazebo. Building a roof for a rectangular gazebo is a daunting task as it involves many cuts and measurements. Besides, you will definitely need an assistant. To make everything work out beautifully and reliably, observe building codes and select quality materials. It is also necessary to use good quality weatherproof lumber without defects. The sequence of works is shown in the pictures in the gallery; details of the construction stages can be found on the source's website.

Another option is how to make a rectangular gazebo with your own hands. If you have the financial resources, then of course it is better to buy quality wood, such as cedar, pine or mahogany. Also make sure that the material used is suitable for the climatic conditions. According to this project, if all the materials are available, the gazebo can be built in one day.

2 interesting photos: Gazebos from birches

How to build a gable roof for a rectangular gazebo.

The first stage is the manufacture and installation of the upper ridge and rafters. As you can see in the picture, it is necessary to cut off the ends of the rafters of the required size and fasten them to the upper rails with screws. Make sure the top ridge is horizontal, otherwise the roof will not be symmetrical. The next step is to install the rafters on both sides of the roof. You have to place the beams in the center.Cut the rafters to the required size (45 °) and shape and install them in place. Drill the holes and secure them with galvanized screws. Attach the rafters to the front and back edges of the rectangular arbor. Install the side rafters. Secure the roofing sheets. In order to protect the gazebo from precipitation, it is recommended to cover the roofing sheets with tar paper.

Attach the planks to the rafters, but it is very important to cut the ends of the planks at a 45 ° angle if you want a nice looking roof

Guided Installation Guidelines

Having received the finished drawing, you can start building the gazebo

At the initial stage, it is important to clear the area of debris and plant roots, then draw an octagon of the required size on the site. A hole in the ground can be made with a garden drill

The optimum depth for metal structures is 1 m. In this case, the pipe in the center should be higher than the others, on average by 100–110 mm. The average life of a metal gazebo is 25 years. But if, during the installation process, each foundation pipe is treated with bituminous mastic, and several layers of roofing material are laid on top, this indicator can actually be increased by 1.5 times.

Before starting the main work, do not forget about basic safety precautions. It will be useful to stock up on welding goggles and overalls. It is advisable to use properly sharpened tools. If the saw teeth are not set, there is a 48% chance of injury. And if the instrument is dull, it’s better not to use it at all.

Foundation and bottom base

For polygonal structures made of metal and brick, a strip foundation is more suitable. Since it is a solid concrete monolith, it is able to withstand any tricks of the weather. The installation of the supporting structure is possible without special equipment, and the bundle of fittings is possible without welding equipment. In this case, you can get by with wire.

Do not skimp on the quality of the material for the gazebo

Do not skimp on the quality of the material for the gazebo

The base is waterproofed along its entire perimeter. Around the building you will need to make a blind area

When choosing a columnar foundation that can be built even on fairly frozen ground, it is important to consider:

- the optimal pit depth is 55–60 cm;

- the level of the pipes is determined using a hydro level, which can be made from improvised means (for this you will need a piece of an elastic tube, a knife, a plastic bottle, 2-3 syringes and liquid soap);

- concrete is poured into metal products, and a reinforcing bar is installed on top of them;

- before further work, the structure is not touched for at least 7-10 days.

Base and flooring

In the case of a wooden base, the materials are divided into equal 8 segments with a margin of several centimeters in length. It is better to wash down to connect them at an angle of 135 °. All elements of the lower strapping must be of the correct dimensions. Otherwise, the base cannot be installed on the foundation, and its component parts cannot be fastened with self-tapping screws.

For closed structures, a wooden floor is well suited. The optimum thickness of the boards is 45 mm. In seasonal buildings, it is acceptable to use decking or garden parquet. If a long term of use of coatings is important, it is better to purchase paving slabs.

Racks and rafter system

The vertical posts should be inserted into the ground in such a way that the strapping resembles a regular geometric figure in shape. Structural elements supporting the top rail and roof are best positioned symmetrically.

The most difficult of them is the rafter system. It can be made from a wooden beam or its octagonal cut. It is supposed to be cut from the end at an angle of 23 °. This is necessary for the convenience of attaching the rafters. The materials are attached to the central bar with self-tapping screws.

Roof

Many experts recommend natural shingles. This material is not afraid of moisture, ultraviolet radiation and frost. It also absorbs noise well and is divided into parts.Therefore, if installation work is carried out on difficult surfaces, this is the best that can be offered to amateur builders.

Before installation, wooden roofs should be treated with protective impregnations. This will avoid premature destruction of materials. Ridge templates should be installed at the joints of the products - this is the best protection of the roof from high humidity.

See also: tips for choosing a roof for a gazebo.

Octagonal gazebos with built-in barbecues are especially popular among the population. First of all, we mean brick and metal structures. Unlike wooden ones, they are non-flammable and withstand abnormally high temperatures well.