Do-it-yourself metal gazebo. Photos, drawings and diagrams of structures

In addition to wood, metal is often used for the construction of gazebos: iron or aluminum. This material is durable and products made of it do not need repair. The elements are connected using welding. Models of metal arbors can have a stationary or collapsible design. In the case of a collapsible version, bolted connections are used as fasteners.

Hexagonal metal gazebo with pointed roof

When planning the location of the gazebo, it must be borne in mind that metal elements get very hot in hot weather. In this regard, it is recommended that such structures be made open and installed in the garden.

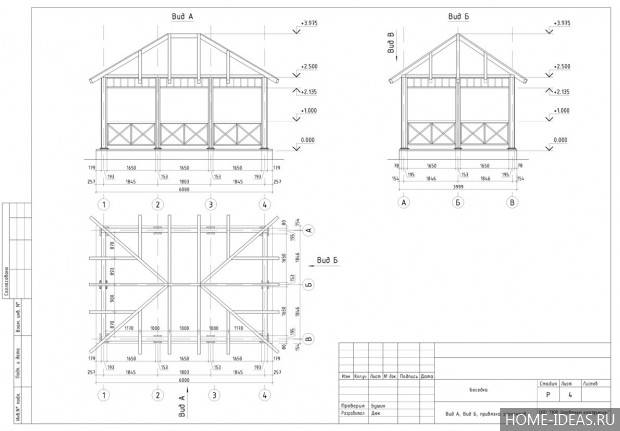

Before starting the project, you need to think over the design of the gazebo, which would match the style of the existing exterior. The dimensions laid down in the drawings of a metal gazebo with your own hands depend on the estimated number of people who can be inside it, as well as furniture and the availability of certain equipment (barbecue, barbecue).

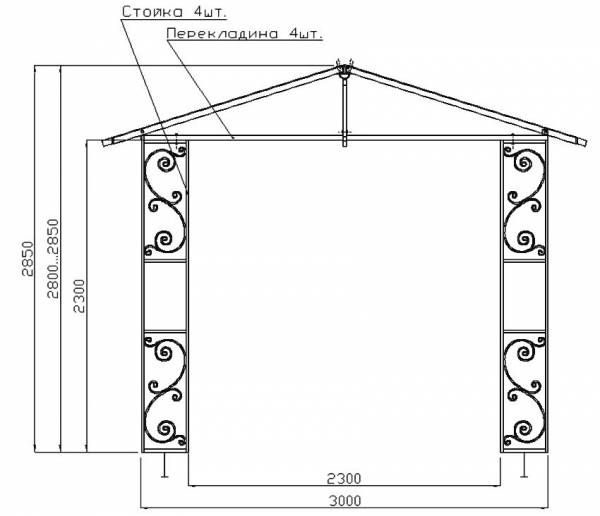

Drawing of a metal gazebo with forged elements

Many people use ready-made schemes for the construction of metal gazebos with their own hands, photos of which can be found on the Internet. Relatively easy to install is a rectangular structure with dimensions of 2.5x3 m. This model will not be bulky and at the same time it is possible to place a table and several seats in it for a comfortable rest.

Do-it-yourself gazebos from a profile pipe. Drawings, photos of finished structures

Due to a number of properties of a shaped metal pipe, many use this material for the construction of a gazebo. Structures from a profile are distinguished by ease of construction, excellent resistance to weathering and durability. In addition, this material is relatively inexpensive, and the structures made from the profile have a decent neat appearance.

A gazebo made of a profile pipe, complemented by a fabric canopy

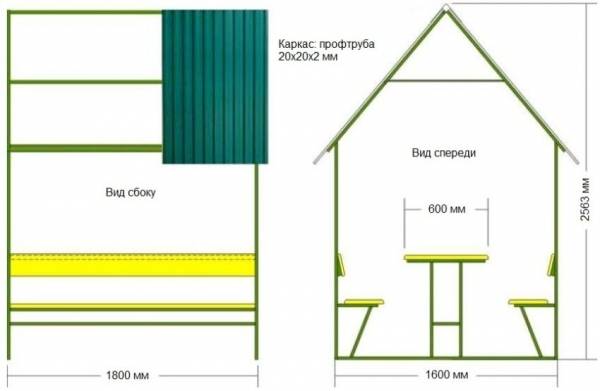

Before proceeding with the manufacture of the gazebo, it is necessary to select the type and shape of the structure, prepare drawings, check the availability of the necessary materials and tools for installation. A do-it-yourself photo of gazebos from a profile pipe demonstrates various configurations of these structures: rectangular, hexagonal, square and other more complex shapes.

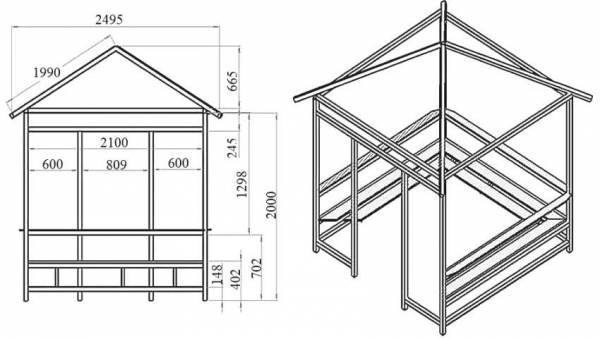

The project of arranging a rectangular gazebo from a metal profile

Sketches and drawings of the gazebo can be done independently or you can use ready-made schemes, proportionally changing the dimensions to suit your option. In the drawings, it is necessary to indicate all dimensions, perform all calculations as accurately as possible, since the appearance of the structure and the selection of the necessary materials will depend on this.

For the construction of the structure, the following materials will be needed: concrete, a profile pipe, a primer for processing metal surfaces, accessories, roofing material. Of the tools you will need: a building level, a drill with a set of drills, a grinder, a welding machine, a shovel, fasteners.

Project of a square gazebo made of a metal pipe with wooden benches

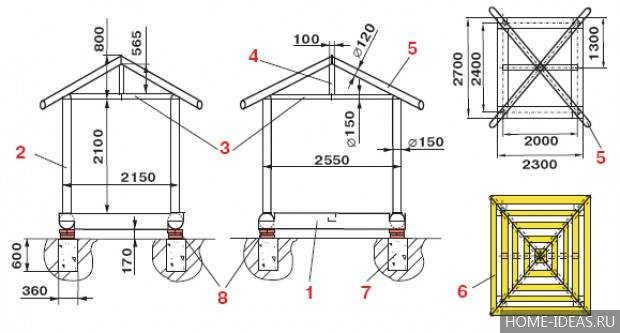

Having chosen and marked out the place for the structure, they proceed to the construction of the pits. Their number is determined by the number of supports, according to the drawings. The pits are made about 60 cm deep. The height of the support posts is taken taking into account this value. For the supports, a profile with a section of 80x80 mm and a wall thickness of 3 mm is used, to which the supporting metal heels are welded. This will give the structure additional stability.

The bottom of the prepared pits is covered with crushed stone, carefully tamped, support posts are inserted and concreted

At this stage, it is important to maintain the maximum verticality of the installed racks. To do this, as soon as the concrete hardens a little, the position of each support is checked and leveled.

Drawing of a gazebo from a profile with a square section

After installing the supports, it is necessary to withstand about 2 days until the concrete has completely set, and then proceed to the lower horizontal strapping. For it, a profile of a smaller section is used, which is welded to the supports at a certain height above the ground. The distance from the ground to the horizontal harness is taken so that it is as comfortable as possible to enter the gazebo.

Next, proceed to the manufacture of the roof. A rafter system is formed from the profile according to the diagrams. For a gable form, a profile is welded at an inclination of 15 degrees. For the convenience of fastening the roofing material, a profile pipe is welded to the roof frame as a batten with a pitch of 45 cm. On this, the arbor frame is considered assembled.

Diagram of a collapsible arbor from a professional pipe measuring 20x20x2 mm

Peculiarities

Gazebos can be classified according to different criteria. So, depending on the shape, they can be round, polyhedral, square or rectangular. Each of the types differs in design and design features, as well as in purpose.

Speaking of dimensions, they can be large, medium or small. Especially popular are structures with dimensions of 3 by 4 meters - they allow you to accommodate a large number of people, while not occupying a significant piece of the site.

There are also many materials from which you can create a gazebo.

The gazebo can be made of various materials

The wooden structure is distinguished by a long service life and presentability. But they require careful care and treatment with special agents.

Metal structures will be durable and reliable, and the addition of artistic forging elements will add originality and attractiveness. However, in the heat, the metal heats up, and inside it becomes stuffy and uncomfortable.

Another popular material is polycarbonate. It has a high light transmittance, transparent and easy to install. It is also resistant to negative mechanical and weather influences. In addition, this material is notable for its democratic cost and there is a wide color palette. So, by choosing an orange polymer, you will have pleasant warm lighting even in cloudy weather.

Brick buildings are durable and reliable. They will stand for more than a dozen years. If you add a polycarbonate roof with good glazing to such a gazebo, it will become a truly design and architectural decoration for your site.

In this video, you will learn in more detail how to make a 3 by 4 meter gazebo:

Let's note the fact that today there are tendencies towards combining several types of materials: wood with polymer or clapboard, glass and brick, metal brazier. The combination of different materials provides additional functional and aesthetic benefits.

We should also pay special attention to the roof. You can apply different stylistic solutions - make it flat, gable or rounded.

The roof can also be tiled or slate.

You need to choose the shape of the roof based on the type of the gazebo itself. If the structure is hexagonal, then it is better to make the coating six-sided, which will give organicity and attractiveness.

See the same: how to choose the right roof for the gazebo.

Recommendations for the arrangement

If it is difficult to figure out what the geometric shape of the gazebo should be, you should give preference to the hexagonal classics. The octagonal scheme is often chosen because of the originality of such a solution. Who wants to simplify his work as much as possible, chooses a rectangular design, such buildings can be made even by a beginner in construction.

A five-corner gazebo looks best under a pyramidal roof covered with traditional tiles.

When glazed solutions seem unnecessarily expensive or complicated, you can look for alternatives:

- removable glass blocks;

- tarpaulins based on transparent film;

- partially closed walls.

It is very important to immediately clarify whether the floor will be equipped or not. When it is not done, installation on a site of paving slabs, concrete, asphalt, paving stones and similar materials is allowed.

The frame in a gazebo that does not have a floor will have to be thoroughly protected from excess moisture.

The organization of a real floor is unthinkable without creating a foundation. In the presence of large boulders with a flat edge, you can lean a light structure on them. Brick gazebos should be placed on strip foundations with a slight deepening. It is enough to bring them 0.2–0.3 m under the border of fertile soil.

Wood structures with a floor on the same basis will have to be lifted on supports. The non-standard finishing of the upper lobe of the building is achieved by specially placed thin planks.

For your information: such a slab should be 0.5 m wider than the structure itself. Moreover, the additional section is formed with a certain slope, providing a drain of moisture. Such an impromptu blind area avoids freezing of the soil under the gazebo. As a result, the tiles will not be turned out and cracked. More detailed information can be obtained in individual consultation with architects.

Polymers (PVC) are attractive because structures based on them are not destroyed by microscopic fungi and do not need special protection. Certain types of such material calmly survive freezing and thawing without harming themselves. But the disadvantage of the plastic construction of the gazebo is its low strength. You will have to avoid pressure on the frame at all times. You can't even just lean, lean on it; all the more inconceivable heavy furniture or barbecue.

The primer on the metal of the gazebo should be applied twice. First, this is done before construction, and then after welding. If rust is found, it must be cleaned off or covered with a converting agent. Only then is it allowed to apply a primer. Exterior metal paint is used on top of it, and no more decorative processing is required.

As a cladding, you can use:

- durable fabric;

- profiled metal sheets;

- planed boards;

- lining;

- round sawn timber of small section;

- block house;

- polycarbonate;

- tempered glass grades.

Brickwork, if it looks attractive, need not be finished at all.

Decorating gazebos made of foam concrete blocks is similar to decorating houses from the same material. When the walls are leveled using steel mesh and plaster, both decorative plaster and natural stone can be used.

Above a rectangular gazebo, it is allowed to place a roof with one, two or four slopes. Single-slope options are the simplest in execution, but the gable ones are more resistant to bad weather and to the accumulation of snow and ice.

For information on how to build a 3 by 4 gazebo with your own hands, see the next video.

Style selection

An important nuance is taking into account the style of construction in accordance with the landscape design. The most common gazebo styles include classic, Victorian, rustic, oriental, and custom.

The classic style of construction is characterized by clear lines. The design is based on hexagonal and quadrangular bases.

Ornamental and ordinary plants are inherent in the Victorian style, therefore, when building with this nuance in mind, the base of the gazebo is built along with a special lattice.

The oriental style differs from others in the shape of the roof and extraordinary ornaments.

Features of wooden arbors

Features of wooden arbors

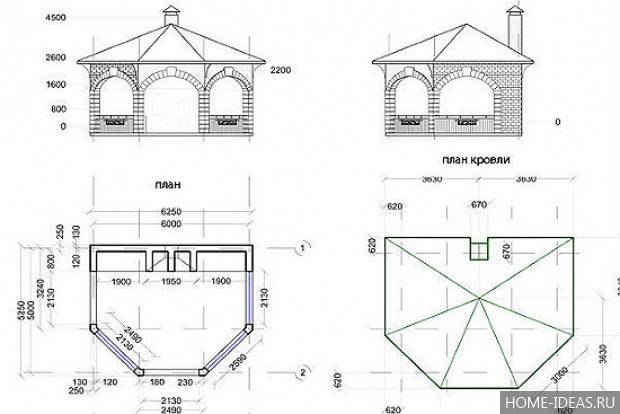

Pavilion 4x3 with barbecue

Many people cannot imagine their summer cottage rest without deliciously cooked meat. And a logical purchase for kebab lovers is a brazier or barbecue. These devices for frying can be both portable and stationary.

If rest is impossible without meat on coals, then you can place a country fireplace in a gazebo. The 4 by 3 pavilion has just a place for the installation of such equipment. Then the main area will be about 3x3. There is enough space to accommodate an average family and 2-4 guests.

When erecting a gazebo with a barbecue, it is worth considering several nuances:

- even at the design stage, the place of the future brazier, work surfaces for the cook (if any are planned) should be indicated on the drawing;

- when creating a drawing, it is worth considering that an open fire requires protection from wind and rain;

- highly desirable processing of wood with compounds that increase resistance to fire;

- it is also possible to use other materials for the construction of walls, for example, brick or polycarbonate.

Types of summer cottages

The architectural ensemble, as well as landscape design, play an important role in the selection of material for the construction of a summer cottage. Therefore, the style solution of the building should be a harmonious continuation, and not a foreign body, of the main structures of the site. Also, an important criterion when choosing a design is its functionality, it must provide maximum comfort for the owner.

Consider the main types of summer cottages:

- Closed.

- Semi-open.

- Open.

Closed. Closed gazebos are becoming popular among residents of the northern regions. As a rule, the design features of such structures are doors and large windows. They are made mainly of wood and can be insulated if desired, so they are ideal for outdoor activities in the winter. A fireplace, a brazier in the center or a refractory brick stove will allow you to equip a kitchen area for a comfortable rest with the whole family.

Another type of gazebos of a closed type are small houses made of polycarbonate, brick, metal and wood. They help protect owners from the vagaries of nature in the summer.

Semi-open. Semi-open gazebos have one solid wall and a light canopy. Its main purpose is to protect the barbecue or fireplace from natural precipitation. For the construction of this type of structure, rounded or decoratively processed timber is used. It is allowed to use fire-resistant bricks where the frying element touches wood.

Open. Open-type gazebos are considered the most common. They are distinguished by a relatively simple design that allows you to create a cozy corner for outdoor recreation. They are made mainly from larch, spruce or pine. These materials are able to give the gazebo lightness, while maintaining the maximum reliability of the structure. If a brazier is planned to be installed in the structure, you can use refractory bricks or decorative stone to assemble the base for the brazier.

How to make a drawing

Before starting construction work, you need to draw up a detailed construction project. You can either take a ready-made layout or create a new one. Without a drawing, difficulties and technical errors may arise that will significantly harm the quality of the structure.

If you have experience in these works, you can draw up a layout yourself, otherwise it is better to order from a professional.

A project can be made unique by executing it in a specific style:

- Russian. The use of wood, mostly log elements, is characteristic. The style looks natural and fits aesthetically into the site.

- Alpine / chalet.A combination of stone and wood, the color scheme tends to gray-brown shades. Gives the building strength and external solidity.

- Canadian. A distinctive feature is the simplicity and clarity of lines, a certain cubism. They use stone, glass, wood.

- Oriental. Soft lines are most often made by boat roofs. The design in this style creates an atmosphere of serenity.

- Modern. Modern materials such as plastic or polymers are used, metal is also well suited. The style is suitable for various design experiments.

First you need to make a drawing

Ready-made drawings of gazebos with dimensions

If you do not know how to make a drawing of a gazebo yourself, you can use special thematic sites on which ready-made drawings of gazebos with photographs are presented. It can be any building, small in area and huge, accommodating a large number of guests. Before choosing, it is advisable to decide on the shape of the gazebo, today you can find:

- hex or octagonal;

- square;

- round;

- rectangular.

After you decide on the constructive form of the gazebo, you can start building the foundation for the base of the structure.

Floor

Next, proceed to the floor. To do this, you need lags, and, as you know, you can also do them yourself. Use 7x3 cm boards or 10x5 cm bars to create lags. Using nails or self-tapping screws, fix them to all posts. Then install the waterproofing - it can be any suitable material, for example, roofing material, covered with plastic wrap.

The floor can be laid directly on top of the insulation. Use boards or composite materials for this. Do not forget about the mandatory treatment with antiseptic and other protective agents! Having prepared the floor, proceed with the partitions. It is worth noting that a hexagonal gazebo can have both solid partitions in the form of solid walls, and a railings of a meter height.

Stages of work

After the preparatory stage, the construction work process follows, which includes the sequential execution of the steps:

Clearing and leveling the construction site. At this stage, you need to clear the area of debris, cut trees and bushes if necessary, level the area.

The choice of the foundation. A well-laid foundation is the basis for the success and longevity of a building. There are such base options - tape, slab and columnar. The simplest and not requiring large financial investments is columnar. To do this, it is necessary to mark the territory of the future gazebo with wooden posts and ropes stretched between them. Then, remove the top soil layer at the allocated area with a depth of at least 0.5 m. After that, lay sand (10 cm), crushed stone (10 cm), concrete mortar (30 cm) in succession. Such a solution is made from sand, gravel and cement. Next, lay a layer of roofing material on the concrete layer. Then you need to make posts of brick in three or four rows in order to create space between the ground and the gazebo in order to avoid rotting wood. At the final stage of creating the foundation, you need to re-lay the layer of roofing material.

Floor installation. To accomplish this task, it is necessary to choose the option of installing the floor: on the basis of the structure or taking into account the emphasis on the floor of the walls. The second option is quite simple

For the arrangement of the floor, wooden beams are used, treated with layers of copper sulfate in order to prevent them from rotting and eating by insects.

Building the frame and roof

When performing such work, it is important to focus on the supporting beams, because they are responsible for the stability of the gazebo. When assembling the frame, wooden boards and beams are used

Bearing supports are mounted from wooden blocks

The basis of the frame is made up of special beams that are placed on concrete blocks. Floor joists and vertical posts are attached to the base of the structure. To the frame - vertical posts using metal corners and self-tapping screws. For the vertical arrangement of the base, it is necessary to use special props. When building the frame, the so-called upper straps (special horizontal beams) are used. The easiest way to build a roof is to use timber logs to create geometric outlines for the building.

Wall cladding. At this construction stage, the choice of material is important: sheet metal, boards, slate and others. The main disadvantage when choosing sheet material is the lack of sound insulation, especially in rainy weather. The simplest option is to use wall cladding with wooden planks. Depending on the style and design of the planned structure, solid or lattice walls can be made.

Improvement of the gazebo. The final stage is filling in and creating the necessary interior of the resulting structure.

How to make a wooden gazebo

It shows how to build a do-it-yourself octagonal wooden gazebo with a hipped roof. This is not an exhaustive treatise of the whole process, although the author tried to display all the stages in some detail in the step-by-step photos. Note: Unavoidable changes during construction will require changes in some details. All dimensions are for this particular gazebo, but you can change them at your discretion. All lumber is rated for outdoor use and fasteners are galvanized. The roof is made from CDX plywood, which is rated as inferior quality, but is by far the strongest type of plywood in the construction industry. Now for the planning, the diagram is pretty simple. An octagon is just a square with the corners cut off. Start by creating a square. To do this, using a tape measure, pegs and a cord, a square is marked, divided into 8 parts, and the corners are cut using a building level and a cord. As a result, we get a regular octagon. Further on the order of work, look at the step-by-step photos, if something is not clear, you will find very detailed instructions on the website, the link is under the gallery.

Select the type and material of the roof

The roof configuration depends on the shape of the building itself.

- Single-slope - the easiest to manufacture and in appearance, it is convenient for a square and rectangular gazebo.

- Gable - suitable for rectangular buildings.

- Four-slope hip and hip and multi-slope - the most complex and beautiful, suitable for a square and polygonal gazebo.

For roofing, use any material based on your budget and personal preference. Ondulin, bituminous shingles and polycarbonate are easier and more convenient to use for beginners. Profiled sheet and metal tiles will be more troublesome, especially on a roof of complex shape.

If there are already other buildings on the site, then the roof should be in harmony with them. However, this is true only for cases when the gazebo is located next to the house. If it is located separately or in the back of the garden, the roof can be of any kind.

Rectangular gazebo 4 x 5 m with a tiled roof

This garden gazebo is quite spacious, its size is 4 by 5 m and you can do it yourself using the step-by-step instructions that are presented below.

To build a gazebo, you will need the following material:

- boards 40 by 150 cm and timber;

- OSB board;

- flexible shingles;

- lining.

Self-tapping screws are used to fix the boards, and a furniture stapler is used to fix soft tiles. The point foundation is made of bricks and concrete.

Operating procedure:

Mark and fill the point foundation. Lay waterproofing.

Lay out the base of the floor with a bar. Collect the bottom and top frame. Align the uprights with a spirit level and spacers.

Screw the horizontal boards with self-tapping screws.

Lay the floor, saw off the edges.

Assemble the roof structure, set it up. Cover the OSB with a plate, reinforce with self-tapping screws.

Set the corners at the corner.Cover the roof with shingles with a construction stapler.

Pull the walls with a rail, process the surface of the boards.

Make a ladder with 1 step from a 40 x 180 mm board.

It remains only to paint the gazebo with special wood paint. The whole process of building this gazebo can be seen in detail in the video.

Iron frames, forms and sheathing

Buildings of this kind are assembled using sections from profiles of various shapes or a special corner. It should be borne in mind that the metal itself can be either galvanized or painted. There are times when welded sheds without parapets are installed on the territory.

An excellent solution would be a forged gazebo, but their cost is quite rather big, but it is fully justified due to its strength and beauty.

Consider the options for the forms of such structures. Usually they have polygonal shapes, and each of them is original in its own way.

By design, they are distinguished:

1. Open version - they are able to provide maximum visibility and are much cheaper.

2. Closed version - the walls are sheathed completely, in this case the vacationers are maximally protected from weather manifestations in the form of wind or rain.

Regardless of the purchased option or made independently, the designs are divided into:

- stationary - in this case, the support pillars are dug in and poured with concrete;

- portable - the supports are fixed using the lower frame, which has a horizontal position, the dimensions are much smaller.

Summarizing all of the above, we can conclude that this kind of design can be either a simple option or an exclusive one.