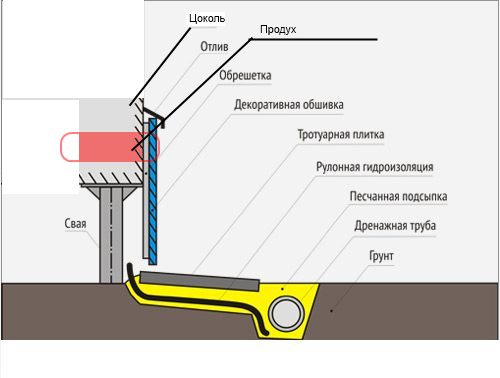

Plinth on a crate

To reduce the cost and speed up the installation of the base, you can make it from sheet materials. Typically, moisture-resistant CBG boards or decorative panels are used for this, corrugated board is also suitable.

The lathing is made of metal or wood. Metal elements can be welded to the foundation piles. The fastening of wooden elements is carried out using bolts in two ways:

- ears for bolts are welded to the piles, bars of wood are attached to them;

- the basis for the horizontal guides are vertically located bars attached to the grillage, while there should be a gap between the ground surface and the bars.

To exclude the penetration of moisture from the soil into the sheathing material and the wooden crate, a shallow trench is dug under the future plinth (along the entire perimeter). A layer of sand (2-3 cm) is poured onto the bottom and compacted, then a layer of expanded clay is poured. A layer of earth is poured over the expanded clay so that there is no gap between the soil surface and the base.

Insulation technology

The pile-screw foundation is used mainly on heaving soils with unstable soil. The peculiarity of the design is that the weight of the whole house is transferred by means of screw piles to the lower layers of the soil, which are more stable than the upper ones.

The classification of the pile-screw foundation depends on the height of the grillage: low, high, intermediate. For all-season living in the house, insulation of the foundation is required, as well as its blind area, to preserve heat.

How to insulate the foundation with decorative panels

This type of foundation can be insulated with sheet or loose insulation. The structure must additionally be insulated by constructing a warm blind area. Insulation of the grillage must begin with marking and preparing a trench, the width of which will slightly exceed the thickness of the selected insulation material.

Next, it is worth cleaning the base from debris and installing a waterproofing layer. Now you can proceed directly to the installation of the insulation. It will require preliminary preparation of special fasteners (dowels), as well as foam.

The technology of insulation with bulk materials and basement panels or thermal panels consists of the following stages:

The technology of insulation with bulk materials and basement panels or thermal panels consists of the following stages:

Dig a trench, the width of which should be within 0.5-1 m, and the depth should be slightly deeper than the pile support cushion is buried.

Make a sand cushion 200 mm thick, which should be well tamped.

Install the frame for fixing the panels. When using a wooden frame, it must be treated with an antiseptic.

Install expanded polystyrene.

Fill the trench with loose insulation, which also needs to be tamped

It is important when filling not to reach the ground level by 50-100 mm.

Install and fix the basement panels, sinking slightly into the bulk insulation. If you use thermal panels, then the installation of insulation is not needed.

Fill the blind area with an angle of inclination of at least 10˚

For this, a conventional cement mortar is used, consisting of cement, water and sand.

The method of insulating the base with a brick

This foundation is the most common. Here, the insulation of the space under the structure is extremely necessary. The technology of the process consists in creating a false plinth. For manufacturing, brickwork is used, or a crate is created from wooden boards, on which the insulation is attached.

In order to make a false plinth based on brickwork, you must follow the following steps:

On all sides of the foundation, it is necessary to prepare a trench 20 cm deep and wide, which should be several centimeters greater than the thickness of the prepared brick.

The resulting trench must be filled with concrete and additionally reinforced with reinforcement with a diameter of 10 and 12 mm.

After the concrete base has hardened, you can start laying bricks.

After the completion of the masonry and its complete drying, you can start warming

When working with expanded polystyrene, it is important to use only special glue for construction that does not contain organic solvents, for example, Ceresit CT83 .. Installation of foundation vents plays an important role in the technology of insulation.

They will allow you to ventilate it, avoiding dampness under the house and as a result of the appearance of fungus on the boards and the rapid decay of the material.

An important point in the technology of insulation is the installation of foundation air vents. They will allow you to ventilate it, avoiding dampness under the house and as a result of the appearance of fungus on the boards and the rapid decay of the material.

Operational features of modern heaters

The modern market of insulation materials offers a wide range of required products. However, despite the large assortment of goods, among consumers, foam plastic, expanded clay, polystyrene and polyurethane foam are most often in demand. Often, foam glass is also used for insulation outside.

| Insulation | Operational Features |

| Polyurethane foam | An expensive material, for the installation of which it is necessary to use special equipment. It is applied to the surface of the foundation by spraying. Differs in high thermal insulation capabilities. |

| Styrofoam | More affordable products in terms of price. The special structure of such a material contributes to the emergence of difficulties during installation - during cutting, the foam crumbles very strongly. During the work, additional waterproofing may be required. |

| Expanded clay | The expanded clay layer is capable of absorbing moisture very well, due to which this material is positioned as a very good heat insulator. It creates a kind of pillow around the base of the house and prevents the penetration of cold air. |

| Foam glass | Used relatively recently. It is easy to process and prevents moisture penetration. |

| Polystyrene | Given the flammability of such a material, it is strongly recommended to refrain from using it as a facade insulation. But for underground insulation, polystyrene is ideal. Its resistance to increased moisture deserves special attention. |

Earth as insulation

The simplest way to insulate the foundation of a wooden house with your own hands is to backfill with earth. However, there are many questions to this method. It is advisable to use this method only before the start of the construction of the walls.

The difficulty of this method of warming lies in the need to use a large volume of soil. Otherwise, it will be very difficult to achieve a positive final result. Moreover, even if you insulate the foundation from outside with earth, you may not get the expected effect. This is due to the low thermal insulation potential of the material.

It should also be added here that warming the foundation with earth with your own hands will be associated with great difficulties. In this case, it becomes necessary to use specialized equipment, the rental of which is not cheap.

Warming options

The plinth cladding can be of several types. The decision which one to use is made based on aesthetic considerations, financial capabilities, and the qualifications of the workers who will carry out the finishing.

Warming of the basement can be carried out in two ways:

- on a separate tape structure;

- along the crate, which is attached to the piles.

Belt design

The first option is more complicated and also has a number of limitations. A shallow-type belt structure can be made of concrete or brick.Most often, it rests on the ground or its small monolithic foundation (more about the device of a shallow strip foundation). But when building on heaving soils, it is strongly discouraged to use this option. Especially when it comes to a brick plinth. In this case, the earth rises (swells) in winter. Moreover, the process is uneven. Having dug out the construction of the basement from the snow, at some point you will have to see inclined cracks, which indicate damage by frost heaving.

This phenomenon can be prevented by excluding one of the heaving factors:

It is impossible to fulfill the first condition in the manufacture of a non-buried tape. The soil under the plinth of the house will still freeze and deform. Moisture wicking can also be ineffective.

It is reasonable to use tape sheathing only on those soils that are not prone to heaving. Such bases include coarse-grained soils, medium or coarse sand. Also, the option is suitable for regions with a warm climate, where freezing temperatures are rare.

The insulation is fastened to the brick according to the standard scheme. Penoplex is best suited

The insulation is fastened to the brick according to the standard scheme. Penoplex is best suited

Fastening of the insulation is carried out on a concrete or brick wall according to the type of thermal insulation of the external enclosing elements of the building. It can be performed both without an additional frame, and with its use. The method depends on the type of finish chosen.

Insulation of the basement on the frame

This option for the home will become less costly and easier. In this case, the insulation of the foundation on piles can be performed using a variety of materials. Examples include:

- basement siding;

- clinker panels;

- metal profiled sheet.

The choice among the options is based on financial possibilities and aesthetic considerations. All options are attached in about the same way. Read a detailed article on finishing the base of the pile-screw foundation. To provide a base for facing the basement of the house, it is necessary to provide a frame.

The frame can be made of wood or rolled metal. When cladding with metal materials, it is wiser to use steel as a lathing. The frame is usually made of two longitudinal straps. More longitudinal elements can be provided if necessary. It all depends on the height of the base. It is also possible to provide vertical frame elements. The need for them depends on the chosen material for facing the basement of the house.

Before insulating the foundation on screw piles, it is required to provide for fastening the frame to them. The method depends on the material:

- When attaching the cladding to wooden slats and bars, it is necessary to provide metal embedded parts in the upper part of the piles in advance. They can be made from a corner or other similar types of rolled products. Fastening to piles is carried out for welding.

- When using steel frame elements, there is no need for preliminary preparation. The metal profile is welded directly to the foundation elements.

To prevent soil moisture and frost heaving from destroying the finish and thermal insulation, it is worth raising the basement above the ground. The damping gap can be from 5 to 15 cm. At the final stage, this distance can be closed with some kind of bar.

Air vents can be provided in the place indicated on the diagram or in the gap between the cladding and the blind area

Air vents can be provided in the place indicated on the diagram or in the gap between the cladding and the blind area

Insulation for the basement of the house is attached to the same frame as the finish. Depending on the type chosen, a number of additional activities will have to be carried out.

When insulating, it is important not to forget about underground ventilation. For this, special holes or vents are provided in the finishing design.

According to the standards, their total area should be equal to 1/400 of the area of the underground. Also, a gap between the ground and the casing can serve for ventilation. To do this, it is covered with a special mesh that prevents the entry of rodents and insects, but does not impede the movement of air.

Strip foundation

First, dig a trench to the very bottom of the foundation. Its width is 80-100 cm, since the insulation of the blind area is also carried out at the same time. If the foundation is of a buried type, then the first 40 cm in depth the trench is dug to the width of the blind area, and then, to save energy, you can make it 50 cm wide.

If the house was built some time ago, then cracks may appear on the concrete. They are covered with a mixture of cement with construction glue, if the cracks are small. Larger damage is repaired with cement mortar.

The next step is waterproofing. For this, the surface of the foundation tape is covered with bitumen mastic, on which roofing material is glued. The sheets are glued with an overlap, the seams are additionally coated with mastic. More modern roll materials are also used, such as self-adhesive roll waterproofing.

After that, the insulation is glued. Although penoplex is often attached to dowels, it is still better to give preference to glue or liquid nails - they do not violate the integrity of the sheets. How to insulate a strip foundation with expanded polystyrene, see the video:

The joints between the sheets are foamed with liquid foam.

After installing the insulation, geotextiles are glued to it. It will reduce the effect of soil heaving on the heat-insulating layer.

Next, the trench is filled up to the level of the blind area. Sand and fine gravel are poured under the blind area with a layer of 0.15-0.2 m, the pillow is carefully tamped. This layer will protect the blind area from the loads arising from the movement of the soil. A layer of dense insulation is placed on top. The same penoplex is suitable due to its resistance to compressive loads. Concrete is poured from above, in addition it can be reinforced with a mesh.

Attention! To reduce the effect of frost heaving, a layer of insulation is placed at the level of the basement sole. The most effective combination of foam insulation to the level of the walls in combination with insulation of the blind area at the level of the sole

Work technology: execution of the blind area

If you are faced with the question of how to insulate the pile foundation of a wooden house, then you should familiarize yourself with the technology. It provides for work on the blind area. Many perform it after carrying out insulation work, but experts recommend starting manipulations from the blind area. In this case, you can lay insulation that will adhere to the insulation of the blind area, and not to the ground.

The blind area is performed using the following technology. You will have to dig a trench around the perimeter of the house, which is a meter wide. It is necessary to deepen by 40 cm. Sand is poured at the bottom of the trench, the layer thickness should be 20 cm. The sand is well compacted. After that, a 5-centimeter layer of crushed stone is poured, which is well leveled and compacted. Next, you need to lay a waterproofing film, the canvases of which are laid with an overlap.

The next layer will be thermal insulation material. Extruded polystyrene foam is excellent for these purposes. A drainage pipe must be laid along the edge of the blind area. This completes the work of the blind area. If the foundation is insulated from the outside, and on the territory there is heaving soil, then at the junction of the basement and the blind area, the trench must be covered with expanded clay. So you can exclude the breakage of the base when the soil heaves.

Warming options

Insulation of the foundation made of screw piles with brickwork

Insulation of the foundation made of screw piles with brickwork

Before carrying out work on the insulation of the foundation of the pile-screw type, a number of essential points should be assessed: the features of the building, its location, the height and material of the piles. Based on these factors, the base can be insulated using the following methods:

- External cladding. The whole point lies in the construction of the frame of the basement floor from the surface of the earth to the beginning of the floor slabs. Upon completion, depending on the climatic characteristics and the financial well-being of the owner, the insulation is installed along the perimeter of the frame and decorative finishing is performed. The relevance of the presented method especially increases with a small distance of the floor from the ground.

- Outdoor floor insulation work at home. There are often times when, due to the peculiarities of the structure, the characteristics of the soil, the excessive difference between the levels of the floor and the ground, it is not possible to insulate the base in the first way. In this case, it is more advisable to carry out floor insulation from the outside.

- Complete finishing. It includes both internal and external work to insulate the foundation and floor slabs.

The presented method in the course of its implementation is divided into the following stages:

The presented method in the course of its implementation is divided into the following stages:

- waterproofing measures;

- construction of a frame for the basement;

- installation of heat-insulating material;

- internal insulation of the basement;

- floor insulation.

Pile foundation

How to insulate the foundation of a wooden house on piles? For a pile foundation, as well as for a columnar foundation, they construct a pick-up - an imitation of a basement, closing the space between the piles. This alone will reduce heat loss to some extent. For effective thermal insulation of the pile foundation, you need:

- arrange a plinth,

- insulate it from the inside and outside,

- insulate the floor.

You can build a thin brick wall around the perimeter, or you can use slab materials that are attached to the crate. If the option with a brick wall is chosen, you need to fill in a shallow concrete tape 20 cm thick, on which the wall will be built. It is not necessary to use ceramic bricks, you can take foam blocks or foam glass.

Important! Do not make the space under the floor airtight. After the device of the pick-up, it is necessary to make air vents in it - ventilation holes measuring 10-15 cm

They are placed evenly on all sides of the house so that they are opposite each other.

For fastening panels or slabs, a crate is made of a metal profile or wooden bars. As an external cladding, you can use, for example, DSP. There are already insulated facade panels that perform a decorative and heat-insulating function.

A shallow trench is dug under the cladding, where a layer of sand (2-3 cm) is poured, expanded clay is placed on it, and the trench is covered with earth on top, so that there is no gap between the soil and the cladding.

The video shows the device and insulation of the false base:

To insulate the pile foundation, use

- expanded polystyrene,

- Styrofoam,

- foamed glass in blocks,

- liquid penoizol (urea foam).

The first two options are most often used. Foamed glass is too expensive for a private house, and liquid penoizol requires special equipment or the work of specialists, which is also expensive. It is easier to insulate the foundation in a wooden house with your own hands with polystyrene or expanded polystyrene outside. The main thing is that the material does not absorb water, so mineral wool will not work here. They glue the foam on glue-foam, for reliability, you can use additional wooden strips, which are attached with self-tapping screws to the crate through the foam.

Important! It is advisable to fix the expanded polystyrene or polystyrene on the guides, and not between them.In this case, there will be no gaps and cold bridges, since the thermal conductivity of wood, and even more so of metal, is greater than that of foam

It is possible to insulate the pile foundation with foam or EPSP from the outside or from the inside. If this is done outside, then the insulation is attached before finishing. If the finish is already attached to the plinth, for example, if these are facade panels or DSP slabs, then the insulation is mounted from the inside.

Floor insulation

To insulate the floor in a wooden house on a pile foundation, I usually use mineral wool, basalt wool, expanded polystyrene, polystyrene, liquid insulation.

Thermal insulation is done during construction and flooring as follows:

- They make a rough floor on which the insulation will lie.

- A vapor barrier and windproof layer is first placed on the crate.

- Then they put insulation.

- Vapor barrier and waterproofing are placed on top.

- After that, a finishing floor is built.

The layer of mineral wool should be at least 10 cm. If it is necessary to put cotton wool in two or more layers, this is done in a checkerboard pattern (so that the seams do not coincide). The video shows floor insulation in a house on a pile foundation.

For waterproofing, you can use glassine, polyethylene, isospan, wind-moisture protective film. Polyethylene is the cheapest option, but not the best.

Important! In a house made of wood on a pile foundation, it is imperative to treat all wooden floor elements with an antiseptic. Insulation of a pillar foundation differs little from insulation of a pile foundation, the same materials and techniques are used

Insulation of a columnar foundation differs little from insulation of a pile foundation, the same materials and techniques are used.

Materials for insulation of the screw foundation

It is quite possible to carry out thermal insulation of the foundation on screw piles with your own hands, the main thing is to choose the right material. Due to the large assortment of products for thermal insulation, problems with the choice of insulation for the basement should not arise.

It is recommended to choose the following options from the whole variety of thermal insulation materials for the protection of the screw foundation:

- Liquid polyurethane foam. To use this material, it is necessary to create a crate, placing the boards very close so that there are no gaps. Thermal insulation is applied by spray from cylinders using special equipment. When the foam solidifies, a continuous coating forms on the surface, which does not form cold bridges.

- Extruded polystyrene foam. The material is characterized by high thermal insulation properties, good moisture resistance and reasonable cost. The combination of these characteristics gives EPPS a great advantage over other options for thermal insulation materials. Fastening of the insulation can be carried out on a sparse crate or on a solid base.

- Facade thermal panels. This option can be called the most profitable of all modern materials that can be used to insulate the screw foundation of a wooden house. The advantage of thermal panels lies in the combination of heat-insulating and finishing materials, however, in this regard, the cost of this type of insulation increases.

- Foam glass blocks.

- Brickwork is one of the most effective and at the same time expensive options (read more about the brick foundation). If you carry out masonry from ordinary bricks, then additional plinth cladding will be required. The use of facing bricks avoids the finishing step and slightly reduces costs. However, it should be understood that the pile foundation is most often erected on weak unstable soils, which can cause the destruction of brickwork.

Materials for insulation of the foundation

It is not recommended to use polystyrene foam for thermal insulation of the screw foundation of a wooden house. The structure of the material promotes the accumulation of moisture between the styrene balls, which, when frozen, exerts high pressure on the particles of the material. This causes the destruction of the foam at low air temperatures.