DIY technology

Construction tools

Construction tools

If you have data on the properties of the soil, the weight of the building and the skills of working with household tools, you can make a pile foundation with your own hands. The first step is drawing up a diagram of the pile field. On its basis, a calculation of the necessary materials and equipment is drawn up, a construction estimate is prepared.

For work you will need:

- hand or motor drill;

- welding machine, grinder;

- pliers;

- hacksaw, shovel, hammer, ax,

- putty knife;

- level, tape measure;

- brick;

- cement, sand, crushed stone;

- formwork material;

- wire;

- fittings;

- roofing material.

The type of piles is determined by the selected technology. These can be screw-type products, hollow pipes or reinforced concrete pillars.

To pour concrete, you need to build a formwork

To pour concrete, you need to build a formwork

Step-by-step instructions for the construction of a strip-pile foundation:

- Site preparation. The removal of trees and bushes is carried out, the fertile soil layer is removed. Grass is mowed around the working site, a place for storage and disposal of waste is being set up.

- The markup is in progress. The conformity of the horizontal and diagonal lines to the design data is checked.

- Excerpt from the trench. If the installation of the formwork is not planned, it is done along the width of the finished strip. This option is only possible in stable and stable soil, which does not crumble during the excavation process.

- Making holes for bored piles. Reinforced concrete and screw products are submerged to the planned depth, which is controlled by a tape measure and level.

- Backfilling the trench with a shock-absorbing cushion. First, a layer of crushed stone is laid, and then sand. The pillow is wetted, leveled and compacted.

- Formwork manufacturing. With the submerged method, it is brought out over the ground level or slightly above the design level of the basement. Non-immersed formwork is installed on brick supports to avoid sagging under the weight of the mortar.

- Reinforcement. The strapping of the metal structures of the piles and the frame of the tape is being carried out. This is a prerequisite for the structure to be strong, solid and stable.

- Filling the molds with concrete. It is better to pour the foundation under the house on piles all at once, starting from the supports and gradually moving to the tape. The solution should be fed continuously, small gaps are allowed for the preparation of the next batch of concrete. As the piles and formwork are filled, air bubbles are removed from the solution. The surface of the belt is leveled so that the base plate lies flat and without distortion on it.

- After pouring the pile foundation, you need to wait 3-4 hours and cover it on top with dense polyethylene to protect it from precipitation and intensive evaporation of moisture. After that, the structure must be moistened every 6-8 hours for 28 days.

Advantages and disadvantages

If the grillage is made unburied, then heaving and moisture in the soil are not afraid of it. In terms of service life, this option outperforms a buried analogue on piles and a shallow strip foundation. It also wins from them in terms of cost and complexity of work. You will have to dig the earth several times less, the immersion depth is the same, but you only need to remove the soil under the support pillars. Plus, all building materials can be delivered to the site without the involvement of heavy cargo and lifting equipment.

When self-construction of pile-grillage foundations, bored supports made of asbestos pipes are usually used, which are reinforced and poured inside with concrete. It is this option that is discussed in the step-by-step instructions below. In terms of the speed of construction, only a foundation made of FBS or screw piles made of steel can compete with such a foundation for a house.

The strip-pile foundation is great for a small log house

All types of pile foundations have one common problem - drafts in the subfield. In the far north, piles help to avoid heating the permafrost layer. At the same time, in other regions, the wind freely walking under the building is a serious disaster.

Purpose and main types of pile foundations

To build a house, you can use various types of foundations, including piles

To build a house, you can use various types of foundations, including piles

To build a house, you can use various types of foundations, including pile foundations. Through this foundation, not only residential, but also industrial facilities, auxiliary buildings and multi-storey buildings on soft soils are being erected. The technology allows you to speed up the process of arranging basements, basements, or to exclude such construction work from the estimate. The main reasons for erecting a foundation on piles are the following indicators:

- Weakness of the top soil layer. Such mixtures can consist of peat, humus mixtures, sand and clay. At the same time, saturation with water makes the soil floating, unstable, which means that you have to build a pile foundation with your own hands in order to transfer the load of the structure to deeper soil layers.

- Excessive soil density also interferes with the arrangement of another type of base. But pile structures allow you to minimize the amount of land work, as well as reduce preparatory work: digging pits, transporting soil, buying concrete mix, and so on.

Pile foundations are of several types: pile-grillage, screw and tape. There are pros and cons for each type, it is worth considering them in more detail.

Pile-grillage base

In the case of choosing this particular type of foundation, it is necessary to increase the accuracy of calculations and adherence to the technological features of construction

In the case of choosing this particular type of foundation, it is necessary to increase the accuracy of calculations and adherence to the technological features of construction

It has its positive and negative qualities. The advantages of a foundation for a house are:

- applies to almost any type of soil;

- has increased stability;

- good load-bearing capacity (holds walls with sufficient specific gravity);

- economy of arrangement - there is no need to buy a solution, you can make everything with your own hands;

- the bond by means of the grillage of the entire structure into a monolith adds strength in the event of soil shrinkage;

- there is no need to additionally clear the construction site;

- possesses the natural ventilating ability of the building plane, which reduces humidity indicators (elimination of condensation);

- provides safety in the event of a flood or if there are increased seasonal floods in the area;

- efficiency of construction.

Cons of the foundation:

- can not be equipped on rocky and stony soils;

- when there is a threat of horizontal soil movements, installation difficulties arise;

- high cost of the foundation in comparison with other types;

- if you need a basement or basement floor, it is better to abandon the pile foundation;

- use is indicated only for light, medium-light, medium-heavy structures;

- the need for extremely accurate calculations, which requires professional research, and this is expensive.

Pile-screw foundation: advantages and disadvantages

This is one of the oldest technologies, so its pros and cons have been studied thoroughly.

This is one of the oldest technologies, so its pros and cons have been studied thoroughly.

This is one of the oldest technologies, so its pros and cons have been studied thoroughly. So, the advantages:

- the cheapness of the arrangement;

- efficiency of construction;

- there is no need to level the ground, dig trenches and generally carry out large-scale excavation work;

- the landscape and soil structure are not disturbed;

- there is no vibration during installation, which means that the house can be installed next to an architectural monument, century-old trees and other objects prohibited from destruction;

- easily erected on marshy, coastal soils;

- built regardless of weather conditions;

- the design can be used repeatedly;

- installation requires minimal physical and financial costs.

Minuses:

- support elements are corroded;

- short service life;

- lack of a basement.

Pile-strip foundation: advantages and disadvantages

The base is quite popular, but has its own specific features

The base is quite popular, but has its own specific features

The base is quite popular, but it has its own specific features. Pros:

- available for arrangement on construction sites with difficult terrain;

- the minimum involvement of technical and human resources allows us to talk about efficiency;

- such a foundation can withstand and hold weak shocks and ground movements;

- piles are made literally from scrap material;

- speed of arrangement.

Minuses:

- the obligation to conduct thorough geodetic surveys of the soil;

- the need for accurate calculation of the parameters of each pile element;

- lack of a basement / basement floor;

- compulsory insulation work on the first floor;

- application for buildings of no more than 3 floors is shown.

Scope of application and design features

These structures are mounted in rather difficult engineering and geological conditions.

These structures are mounted in rather difficult engineering and geological conditions.

These structures are mounted in rather difficult engineering and geological conditions. Such a foundation will cope even with soils saturated with water resources. This foundation structure helps to save money on research and development of the land cover. They are used not only in civil engineering, but also in the construction of industrial facilities.

The variety of structural details depends on the following indicators:

- Pile type;

- Pile driving method;

- Grillage construction;

- Location of the pile element.

Structurally, the device has two main components:

- A tape that is mounted around the entire perimeter;

- Piles, which are responsible for the strength of the building.

The pile looks like a rod, of sufficient length, which is mounted in the soil. There are such types of diving methods:

- With the help of technology, these are parts sharpened at one end, which are manufactured at the factory;

- Self-made types - can be made from different materials and have all kinds of shapes.

Another important detail of the foundation is the grillage. It is a constructional structure that works in a joint system and is designed to redirect pressure to the pile area.

Grillages are:

- Monolithic;

- Prefabricated;

- Monolithic prefabricated.

The pile-strip foundation can be mounted on such soils:

- Loamy;

- Loess-like;

- Sandy-clayey;

- Clown;

- Vegetable.

This type of foundation is used when performing such architectural tasks:

- Construction of a low-rise building;

- Construction of cottage buildings;

- Objects that provide for the presence of a basement or basement floor.

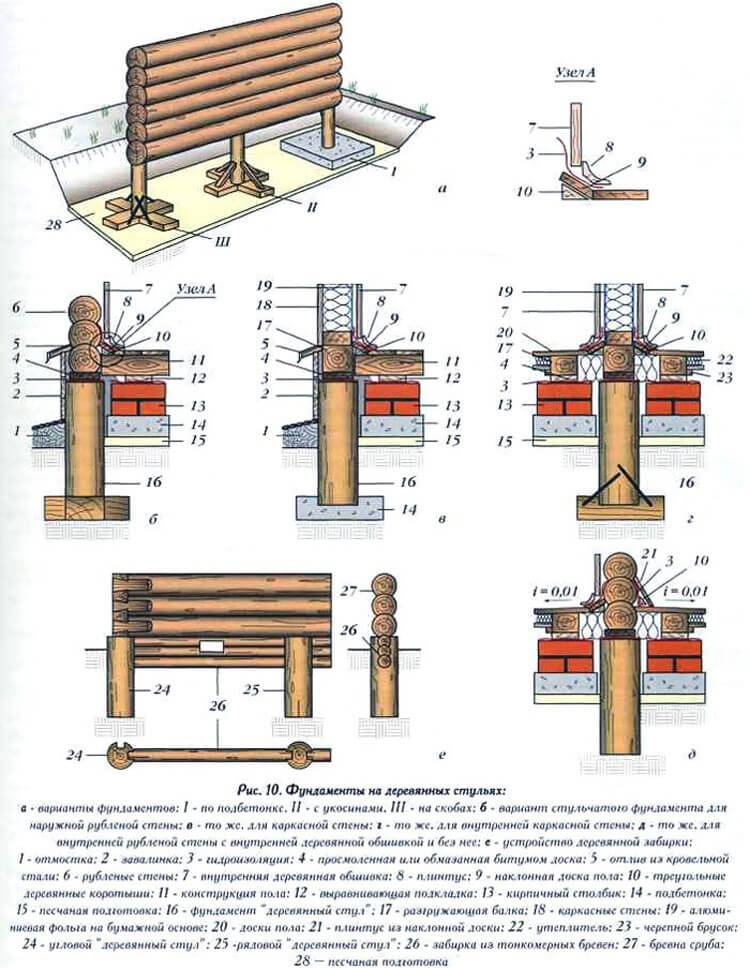

Column foundation

This type of foundation is very popular in the construction of frame buildings or wooden houses, but only on the condition that an underground level is not provided.

The main load-bearing element is the pillars, the installation of which is carried out at all external corners of the structure, as well as on the lines of intersection of the load-bearing walls. In addition, also under the load-bearing walls, if their length exceeds 3 m, additional posts are installed, which contribute to the redistribution of the load and ensure the stability and reliability of both the foundation and the house erected on it.

The size of the cross-section of the pillars, as a rule, is determined by the calculated data, depending on the load, as well as the selected material. An important structural element of a columnar foundation is a randbalk (reinforced concrete, metal or wooden), which serves for the installation of a grillage, which acts as a uniform load distributor from the house to all the pillars.

Columnar foundations, as well as strip foundations, can be of two types:

- monolithic;

- prefabricated.

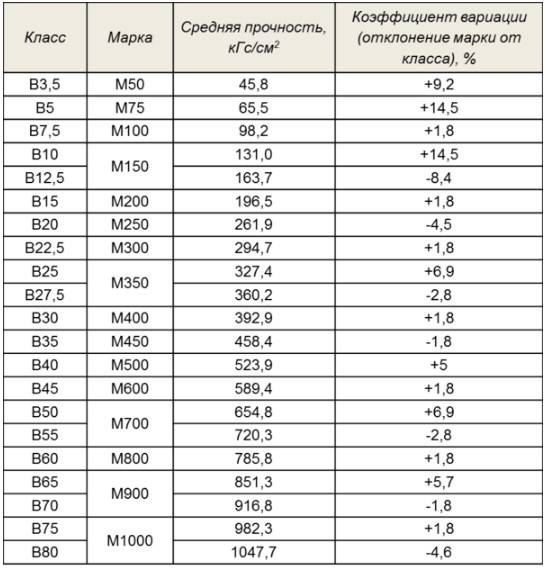

In the case of the construction of a monolithic version, the grade of concrete for the foundation of a private house must correspond to the class B10-B25. In the construction of two-story buildings, reinforcement is necessary, and for one-story buildings, it is decided individually, depending on the weight of the building, the material from which it is being erected, and the state of the soil.

For prefabricated columnar foundations, the following can be used:

- ceramic brick;

- natural stone, including rubble;

- reinforced concrete or asbestos pipes;

- concrete for pouring into prepared and reinforced wells.

In the event that the question of which foundation is better for a bath is being considered, then you can opt for using wood - processed oak, larch or pine trunks.

Despite the fact that the cost of such a foundation, in comparison with a strip foundation, is 30-50% lower, due to the need to attract special equipment, it is not popular for capital structures of 2-3 floors, although for the construction of light buildings that do not require great depth laying, and all the work can be done by hand, is a completely rational choice.

In addition, it is necessary to accurately observe the proportions of cement and sand for the foundation, since the savings due to the use of cheaper materials in this case are inappropriate.

It should be borne in mind that all types of columnar foundations are subject to strong heaving forces, therefore they can only be used on stable, stationary soils.

In addition, it is important not to leave them unloaded for a long time, especially in winter, since under the influence of destructive ground forces, they can simply be squeezed out.

Column foundation with your own hands, video:

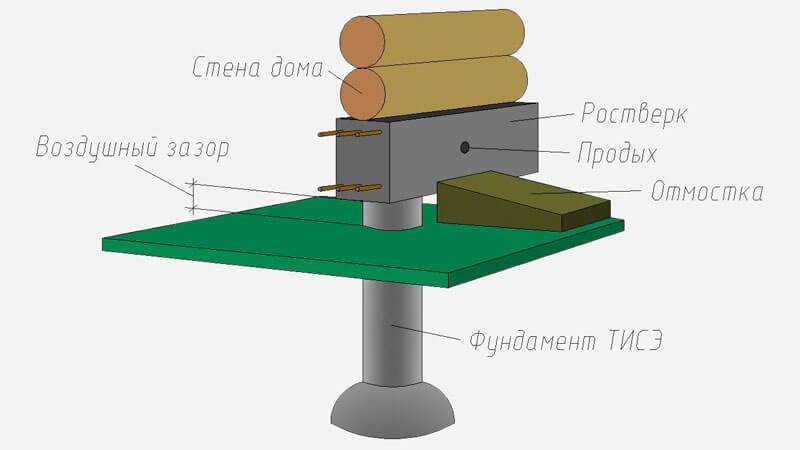

The ideal foundation for building a house in difficult conditions

The combined foundation of TISE, by its type, is columnar-strip. It is indispensable on difficult soils when erecting heavy buildings from two floors. For example, in conditions where the depth of soil freezing is so great that the construction of a strip base is unprofitable, and the columnar base simply cannot cope with its task.

A distinctive feature in the construction of pillars is the presence of the so-called heel, a special expansion, due to which greater strength and stability is achieved. Most often, in this case, monolithic pillars are made, and reinforcement for the foundation is also used, but the construction of a structure using asbestos-cement or metal pipes is allowed.

As a grillage for this foundation, formwork is made at ground level for the manufacture of a strip monolith.

But it is important to consider that it is required to adhere to the principle of simultaneous, but phased concrete pouring: first the pillars, then the tape.

To make wells for pillars, a TISE drill is used, which is a device consisting of two rods and a cutting bowl. Moving due to rotation into the depth of the soil, it gradually unfolds and forms a dome-shaped widening in the lower part of the well.

It is thanks to this design feature that additional strengthening of the foundation structure is achieved, which, of course, affects the strength of the entire house. Depending on the design loads, drills of several sizes can be used, differing from each other in the long rod, the diameter of the plow, and the volume of the accumulator for soil.

The scheme of creating a bored base

The construction of a bored foundation also takes place in a strict sequence, but it is a more laborious process.

Site marking

Here we clean the site of unnecessary objects and vegetation, if necessary, remove the top layer of soil.Using the pegs, mark the points for creating the bored piles. We carefully mark all distances according to the design data. If any inconsistencies are found, we immediately correct the errors.

Drilling site marking

Drilling site marking

Drilling of the wells

The next step after the marking is the drilling of wells. The drilling depth is done according to the data in the project. You can use both a hand drill and use special equipment.

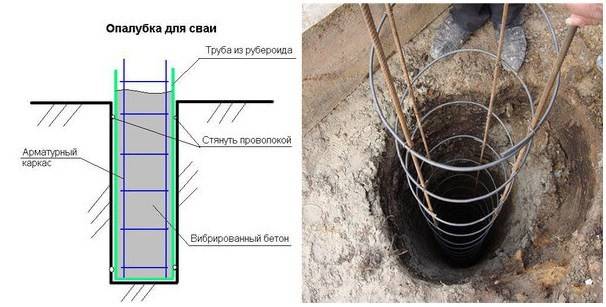

Reinforcement

The formwork is lowered into the drilled well using a piece of plastic pipe or a pipe rolled from roofing material, suitable in length and diameter. It will remain in the well, performing the function of waterproofing.

Now we collect the reinforcement cage. You can use a lattice of 4 vertical bars connected by transverse sections of smooth reinforcement.

The dimensions of the frame should allow it to be easily lowered into the well, but not allow it to hang freely there. The optimal distance of the rods to the borehole walls is 3-5 cm.

Reinforcement process

Reinforcement process

Pouring concrete

We use concrete grades from M200 and above. We can use both ready-made material and prepare it on site.

We fill the entire well with concrete and do the bayonet (we pierce the concrete with a long rod, removing air bubbles).

Now we are waiting for the concrete to gain structural strength, usually from 20 to 30 days.

Concrete types

Concrete types

Strapping

The piping of such wells is a grillage - reinforced concrete tape. The method of making a concrete grillage is similar to the technology of casting a tape.

The only difference will be in the absence of support on the ground, so we build the formwork in the form of a gutter with a solid bottom.

As a result, a solid concrete belt is obtained, which is located under all load-bearing walls and connects the bored piles into a single support system.

Strapping example

Strapping example

Installation of the pile-screw foundation.

The type of foundation is selected depending on the weight of the future structure, the type of soil, the depth of freezing. It is necessary to start the construction of the foundation with a geodetic survey of the soil. This procedure is necessary to determine the level of groundwater, as well as stable layers. At the end of the survey and preparation of the site, they proceed to the installation of the foundation.

Manual screwing in of the supports requires the efforts of three workers. One of them must constantly monitor the level of the pile, and two must screw it to the desired mark. Leader holes cannot be used. After screwing in the support below the level of soil freezing, it is cut off at a single level and poured with concrete. The cement mortar must also get inside the pile pipe, since this will only strengthen the support and relieve the metal from corrosion. After the concrete has set, a metal head is welded to each pile.

What is the best foundation for a foam block house? - here is more useful information.

To evenly distribute the load of the structure, pile strapping is carried out. To give additional strength to the foundation when using heavier structures, the strapping is made from a channel. The grillage is called the upper part of the foundation. It evenly redistributes the load of the structural elements of the structure. On an uneven area, the supports will have different lengths, but their tops should be at the same level. It takes 30–45 minutes to install one pile.

How to make a screw pile with your own hands? Video:

Many people wonder how to insulate a pile-screw foundation? In fact, its insulation is not required, since this type of foundation is referred to as ventilated. Sufficiently high supports reliably protect the house from the cold coming from the ground. Insulation can be done with a grillage. At the same time, you should be aware that improper insulation leads to the appearance of moisture.This can affect the entire building.

You will be interested in this article - DIY Foundation. Types of foundations for private houses.

For maximum heat saving, it is necessary to do high-quality insulation of the floor, and not the foundation.

The base of the pile-screw foundation is made hinged. For its device, sheet slate, asbestos-cement slabs, combined facade slabs with insulation and other building and finishing materials are used. Sheathing the plinth, leave a small gap (5–7 cm) between the ground and the building material of the sheathing. Such an installation prevents damage to the finish when the soil heaves on frosty days. The ground ends of the supports are protected with a metal mesh, which will prevent animals from entering the house. Finishing the base of the pile-screw foundation provides for the creation of favorable conditions for ventilation of the subfloor. To do this, equip small holes called vents. They are left open even on frosty days.

If the construction of a house on screw piles ended with a slight subsidence of the foundation, it is quite possible to quickly repair it by replacing the sagging supports with new ones. The possibility of such repair is considered one of the main advantages of the pile-screw foundation.

When starting the construction of a house, bathhouse or other small buildings, you should pay attention to the screw piles, because thanks to them it became real to quickly build everything you want and at the same time significantly save on materials

Installation techniques for this foundation

Piles organize protection from unfavorable soils, so their choice must be taken seriously and not saved

Piles organize protection from unfavorable soils, so their choice must be taken seriously and not saved

Piles organize protection from unfavorable soils, so their choice must be taken seriously and not economized. The best for these jobs are parts with a circular cross-section, which can be in the form of pipes.

Below we describe the most elementary way to build a foundation, which we have compiled based on numerous sources of literature, videos and expert advice.

Making a trench

The first process is trench preparation

The first process is trench preparation

The first process is trench preparation. This is a very important stage, because it is the piles that are responsible for the stability of the building. The marking of trenches is carried out, as in any other construction, namely: stakes are installed in the corners, which are then covered with a wire along the outer and inner space. The width of the channel should correspond to the size of the building wall with a small margin for formwork.

Stage - well

After the trench is ready, you can start drilling a pile well.

After the trench is ready, you can start drilling a pile well.

After the trench is ready, you can start drilling a pile well. The depth of the well should reach the fixed layers of the soil, that is, below the level of soil freezing. The distance between them is measured depending on the mass of the building and the characteristics of the soil of the site. Next, the wells are filled with sand, about a 20 cm pillow.

We perform well waterproofing

The next step is to install waterproofing

The next step is to install waterproofing

The next step is waterproofing. For this action, we need a hole-sized pipe that we make from roofing material. When the roofing material straightens, it will stretch along the walls of the well space and protect the pile from moisture. After the work done, we can proceed with the installation of the pile.

Installing piles

This process requires increased attention, as it plays a large role in our architectural project.

This process requires increased attention, as it plays a large role in our architectural project.

This process requires a lot of care as it plays a big role in our architectural project. Concrete dries quickly enough, so you need to be on time and properly mount the pile.

It is necessary to create a pile base. How to do it? We lower it into the well, where sand has already been poured, then we pour part of the solution, which flows into all the existing cracks. This element makes the installation more robust and reliable. You need to take care of the reinforcement. We lower the frame from the metal rods, put the formwork and completely fill it with cement.

And finally, we carry out waterproofing and insulate the base. That's it, the pile-strip foundation is ready.

Types of strip foundations.

Let's first look at what types of strip foundations exist. Knowing this information will help in choosing your future home foundation. Not only the final cost of the building depends on the correct choice of the strip foundation for the house, but sometimes the safety of the residents. After all, the wrong choice of the type of foundation can have dire consequences. Up to the destruction of the entire structure of the house. So let's get started.

Shallow strip foundation.

As the name implies, a shallow strip foundation for a house differs from a deep one. You may have a question, exactly what depth of the strip foundation should be in order for it to be considered shallow? We answer: this value should be less than the depth of soil freezing in your area. Hence, the features associated with this type of foundation follow.

Since the soil under such a foundation can freeze, then this circumstance must be taken into account when designing. The freezing soil expands, which means it will push the foundation and everything that is built up on it. And not always evenly. From this, various distortions of the building are possible, an uneven load on the base can break the foundation. To prevent this from happening, the shallow foundation must have sufficient reinforcement, calculated by the construction calculators on our website. You can find them in the top menu.

In what cases do they most often choose a shallow foundation for a house?

- When there is no heaving soil under the house (stone, sand, etc.).

- When the water table is low enough.

- When drainage is done around the house.

- When an insulated blind area is made around the building.

- When the structure to be erected is sufficiently light and mobile (for example, a frame house, a sauna from a bar, a greenhouse).

If you decide to choose this type of foundation for your building, try to avoid mistakes in planning it, taking into account all of the above circumstances. After all, a shallow strip foundation has an undoubted advantage: it is strong enough and relatively cheap.

Pile strip foundation.

In fact, this type of foundation is not a strip foundation. The correct name for the pile-strip foundation is the pile-grillage foundation. And it is in this form: piles plus grillage, and it should be done. But some of our craftsmen make it easier for them. The piles and the foundation strip are poured directly along the ground or shallowly buried it. As a result, in winter, this tape and piles stick out from the ground. Soil gets into the voids under the piles and in the spring, when the earth returns the foundation to its place, it will be skewed or cracked. We do not recommend that you make a pile-grillage foundation in this way. Between the grillage and the ground, there must be a sufficient gap for the expansion of the earth from frost heaving.

Recessed strip foundation.

And finally, the most frequently poured type of foundation is recessed. Its depth should be greater than the freezing point of the soil. It is carried out either in the form of a monolithic reinforced concrete tape, or it is made of FBS concrete blocks, which are placed on a reinforced concrete cushion. An armored belt is made from such blocks on top of the masonry, to fasten the foundation into a single whole.

Foundation markings

Work begins with marking. You should initially decide on the width of the tape that will be used - as a rule, the value is 40 cm, with a depth of 60 cm or more.Next, mark the location of the trench, marking the boundaries with a nylon rope or fishing line. Based on this, the place of installation of the piles is determined, the step is 2 m.

The first piles are placed at the corners of the structure and in the center, the rest are distributed along the perimeter of the structure. To obtain an even distribution of components, the gap between the piles at the corners is divided equally. In accordance with the obtained value, and take a reference point for the subsequent installation.

Features of the design of the pile foundation

When choosing a pile foundation, it is very important to pay attention to its design in order to build a durable and solid foundation on which any structure will stand. To do this, you need to draw up a detailed project of the pile foundation, which will take into account the following points:

- Ground structure.

- Pile foundation type.

- Site plan showing all buildings.

- The plan of the structure of the above-ground structure, that is, the number of floors, the use of materials and other features.

- Characteristics of structures that are located near the construction site to determine possible shrinkage.

- Drawing of the underground part of the construction site, that is, the depth of the piles, underground communications.

- Calculation of the load on the floor surface in different situations.

All these data must be taken into account when designing a pile foundation, otherwise the erected structure will not stand for long.

In conclusion, I would like to note that the pile foundation is a multifunctional and durable foundation for any structure, even in spite of all its advantages and disadvantages. However, in order to obtain high strength and durability, the construction of the foundation must be performed according to all technologies and preferably with the help of experienced specialists.

Strip-pile foundation

This structure makes it possible to reduce the cost of construction work and increase the strength of the building.

This structure makes it possible to reduce the cost of construction work and increase the strength of the building.

The strip pile foundation is a type of monolith that is ideal for soils such as heaving and weak. A distinctive feature is manifested in the fact that the walls press on a solid strip base, and the strength of contact with solid rocks of the earth is created by piles, which are mounted at a depth.

This structure makes it possible to reduce construction costs and increase the strength of the building.

Technical description

In this design, the tape is responsible for the distribution of the load evenly, which protects the building from deformation.

In this design, the tape is responsible for the distribution of the load evenly, which protects the building from deformation.

In this design, the tape is responsible for dividing the load evenly, thereby protecting the building from deformation. Piles, on the other hand, stabilize the tenacity of the building to hard soils, which protects the building from subsidence and distortions during seasonal ground shifts.

Such a combination of elements at the base makes it possible, even on a moving land plot, to erect a stable and durable building, which is not afraid of the climatic features of the soil. The most frequent use of such a foundation is observed in places of swampy soils, which are characterized by a humid climate and high groundwater.

Variety

It is the features of this combination that contribute to the high strength and protection against soil shifts.

It is the features of this combination that contribute to the high strength and protection against soil shifts.

There are three types of such a foundation:

- With a pile screw. In this case, metal piles are used, which have blades of certain sizes. They are mounted in the ground with their own hands or with specialized equipment. To extend the operational period of their life, it is recommended to treat them with a primer or special paint for protection.

- Bored piles. They are mounted on the construction site, so their price is much lower.The first thing that these parts require is a well of a certain size, not lower than the level of soil freezing. The principle of construction consists in a reinforced water intake, which is poured with a concrete solution.

- Pile foundation made of rammed elements. Differs in its design. Its scheme consists of a monolithic reinforced concrete tape on which all the piles are installed.

Pros of founding such a combination

The pile-strip foundation has the following advantages in its functionality:

Construction speed. This foundation is being built in a matter of time. This is due to the shallow penetration of the tape and the ease of piling.

- Low cost. This base does not require special costs, for example, as a deep belt. It is worth noting that the result of the work is practically the same.

- Lack of need for correction with correct calculation. And repairs in this case will not be useful for ten years, because the device does not lend itself to the influence of water, flowability and antinodes of the soil.

Cons of the pile strip foundation

Buildings that are based on such foundations have several disadvantages. So, the cons of the designs:

- The impossibility of building a basement or basement room. For such purposes, the tape part must sink lower into the ground.

- There is an additional need to insulate the floor covering, as the soil can freeze.