Ways to protect wood for the frame

Before making the roof frame of a house, it is necessary to treat its wooden elements with protective agents against decay and fire.

For this purpose, all the parts that make up the rafters, battens and floors are treated with the following compositions:

- antipyretics, which reduce the degree of flammability of wood and protect the wooden parts of the roof frame from fire;

- antiseptics, which are substances that can destroy bacteria, they prevent the development of putrefactive processes in the material from which the ceilings and rafters are made.

The above formulations are applied with a brush, since when using sprayers it is impossible to impregnate with high quality and deep. This is done in several layers.

Some wood preservatives are toxic and should be applied outdoors or in a well-ventilated area. In this case, you must use the means intended for personal protection.

Design of pitched roofs. What to consider ↑

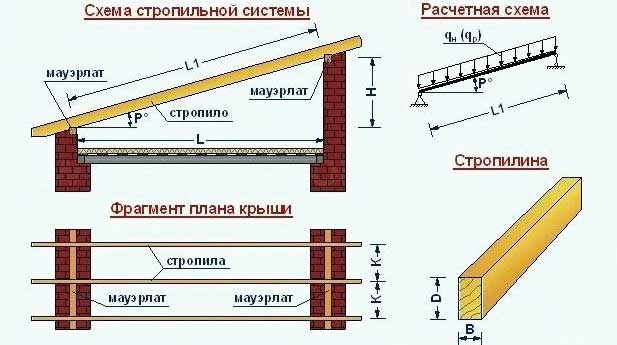

When planning the assembly of a shed roof, you need to take into account and calculate many factors: the scheme of the rafter system, the angle of inclination, loads, and select the appropriate materials. As a result, you should get a drawing with complete information about the future roof.

The classic scheme of a single-pitched rafter system is beams laid across the structure with fastening to the Mauerlat installed along the load-bearing walls. This is the so-called shed roof with simple layered rafters. But this option is possible only for spans with a length of no more than 4500 mm. But, the use of pitched roofs with a greater length is allowed.

- With a span of 5000-6000 mm, the layered rafters need to be reinforced with struts, which rest on the load-bearing wall with an additional Mauerlat. If the width of the spans reaches a value of 6000-7500 mm, you will need to assemble a more complex option - with an emphasis on the truss truss. A headstock is added to the design, supporting an additional beam on which the rafter rests. Naturally, the racks (headstock) are additionally reinforced with struts.

In addition to choosing a scheme for the device of a rafter system, at the project stage, it will be necessary to plan the step between the beams, as well as their section. Such parameters also depend on the width of the span and the length of the rafters used between the load-bearing walls. General recommendations are as follows:

- With a rafter length of up to 3000 mm, its cross-section is selected within 80 × 100 or 90 × 160 mm. The spacing between the individual elements should be from 1100 to 2100 mm (depending on the section!). If the rafter is 6500 mm long, in this case, a section of the timber of 120 × 220 mm is selected with a step between the parts of 1100-1400 mm.

But, in addition to choosing the appropriate cross-section of the rafter beams, and the assembly diagram, a very important factor is the angle of inclination of the future roof.

The choice of the angle of inclination of the ramp ↑

The future functioning of the roof, as well as its strength, depends on the angle of inclination of the slope being assembled. The optimal slope should ensure the removal of precipitation from the plane (especially snow), a low wind load, as well as a stable fastening of the roof deck.

It is also worth considering the type of roofing material used, which is also recommended for use at different angles of incidence of the slopes. For example, you can use the data from the table below.

| Type of roofing material | Recommended angle of inclination in degrees |

| Metal tile | 30 |

| Roll flooring (roofing material) | No more than 5 |

| Corrugated board | 8 and more |

| Slate leaf | 20-30 |

When choosing the slope angles of the slope and the roofing material, it is necessary to take into account that planes with small slopes will have to be cleared of accumulated masses of snow, therefore it is best to choose a flooring that can withstand the weight of a person without subsequent deformations.

Advantages and disadvantages of wooden rafters

However, working with wood and installing wooden rafters does not represent any particular difficulties. In addition, there are other advantages of using wood as a material for rafters:

- low cost of wood;

- widespread availability;

- relatively low weight, simplifying installation;

- there is no need to use heavy construction equipment;

- versatility, the ability to use on buildings made of any material, moreover, regardless of the bearing capacity of the foundation.

The disadvantages of choosing wooden rafters are insignificant, but they also need to be known "by sight" before starting construction:

- the need for treatment with protective agents that prevent fire and decay of the tree, as well as reduce its "attractiveness" for various insect pests;

- the use of wooden rafters is possible only on spans up to 14-17 m, for wider spans it is recommended to use metal or reinforced concrete;

- slightly reduced service life, compared to metal or reinforced concrete trusses.

Thus, all the disadvantages are rather features than real negative aspects. This explains such a widespread use of wooden rafters in private housing construction.

Roof parameters

Immediately before the start of construction work, at the design stage, the optimal parameters of the roof are calculated: the angle of inclination of the slopes, the dimensions of the section, the frequency of the installation step and the layout of the rafters.

Wind and snow loads are uneven in different regions of our country. SNiP 2.01.07-85 will help to calculate them for a specific area. At the same time, experts recommend making a certain margin of safety for the roof frame, taking into account possible peak loads.

In addition, there is still a constant force of impact on the rafter system - the pressure of the roofing material. The table shows the weight of popular coatings per 1 m2 of surface.

Different types of materials also have different requirements for the optimal slope angle of the slopes. This aspect must also be taken into account when designing a roof.

Roof inclination angle depending on material

Equally important is the calculation of the step of installing and attaching the rafters to the Mauerlat, that is, the distance between adjacent trusses. Usually this value is 0.6-1 m. A change in this indicator upwards leads to an increase in the load on the rafters and, as a result, to an increase in their cross-sectional area. It is necessary to place the supports so that the fastening step is the same for all pairs.

The cross-section of the rafters directly depends on the above indicators. By the way, the strength characteristics of wood of different species differ (glued laminated timber has the greatest strength). Here is a table for calculating the cross-sectional dimensions for rafters made of coniferous varieties, depending on the installation step and the length of the support.

Required materials and tools

When starting the installation of rafters, you must first take care of the availability of the necessary materials and tools. These include:

- timber and boards in the right amount;

- protective materials: membrane or plastic film, roofing material, moisture-proof wood impregnation agent;

- hacksaw or power saw;

- screwdriver;

- plane;

- anchor bolts, staples, screws and nails for fastening frame elements;

- a cord or thick rope for tension between the posts.

How to choose the right self-tapping screws, read the article Self-tapping screws: types and applications.

The lumber should be dried, it is better to use a beam and boards of coniferous trees. They should not have distortions from sharp drying, cracks and a large number of knots.

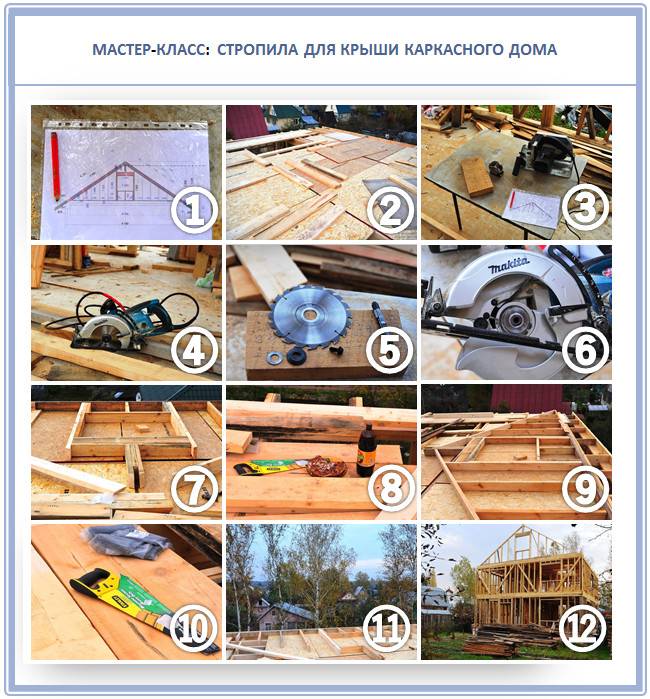

Nowadays, many modern tools are used, with which you can speed up and facilitate the installation process.The capabilities of modern tools are clearly shown in the video, which describes the entire process of installing the frame.

Work process

After the rafters are prepared, we proceed to the installation process itself. All work should be done in a team, it is better that it consists of at least three people. In this case, there is less risk of injury and the process itself will occur faster.

- To facilitate and speed up the work, a template is first made. Two pairs of rafters are raised to the roof. Further, their upper end is placed on the ridge girder, and the lower end on the Mauerlat. In this case, the angle of inclination of the slope and the vertical position are verified. The top of the rafters is connected with a transverse link. The junction with the Mauerlat is marked and cut out from below. This work must be done correctly and accurately, all further actions depend on it. Instead of rafters, two boards can be used to make the task easier.

- Next, the template is lowered down and with its help two pairs of rafters are fitted. First, you should put the end elements of the system. It is not necessary to fix them "firmly" at once, just make money. The best way to do this is with struts that are installed on both sides of the rafters.

- After that, the evenness of the installation of the rafter pairs from the ends of the house is verified and a rope is pulled between them, which will serve as a guide for other components of the system.

- Next, the rest of the rafter legs are assembled and put in their place. Where to do it? Many "home" masters face this question. The easiest way is to collect the rafter pairs on the ground and then lift them up to the roof. But in this case, you cannot do without special equipment. This design can weigh two hundred or more kilograms. Therefore, if there is no crane, it is better to lift everything in parts, and carry out the assembly on the roof.

- After everything has been level, the rafters should be secured with nails or other devices. It is better to leverage this in several ways. In this case, the structure can last longer. Most often, nails are supplemented with staples or metal strips. Some experts recommend that you additionally reinforce the joints with thick steel wire.

Related videos:

Next, proceed to the installation of struts, struts and other additional components of the roof frame. In conclusion, the crate is made and the installation of waterproofing, insulation and roofing material is carried out.

How to protect the rafters?

To create rafters, natural wood is used, which is exposed to the negative effects of rodents, moisture, fire and mold. In order for the elements to serve for a long time, it is imperative to protect them with different solutions.

Therefore, before using any board, it is important to make sure that it has been covered with fire retardants, antiseptics and special insect and rodent repellent agents. If this has not been done in the factory, the buyers themselves are obliged to take care of such protection of the main parts of the roof.

Thus, the rafters are the basic elements for creating any roof. To create them, timber or boards can be used. It is required to choose for this only high-quality wood that does not have any significant drawbacks and defects. With the right choice of material, a durable and reliable roof structure is guaranteed.

Stages of installing the rafter system

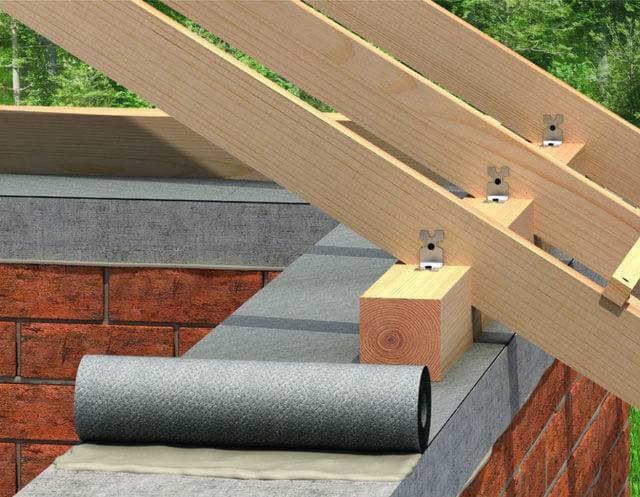

The construction of the frame begins with the installation of the Mauerlat. Before installation on the walls, the timber is wrapped with roofing material for waterproofing. The base is attached to the studs laid down during the laying or with the help of anchor bolts.

Installation of rafters is carried out on a fixed Mauerlat. For a firm fixation, it is necessary to make cuts on the boards. To ensure that all inserts have the same size, they are made according to a template.The upper part is cut with a bevel, which provides the possibility of deflection of the rafters. The bottom notch serves as a solid support for the Mauerlat.

The roof rafters are fastened with nails and corners screwed in with self-tapping screws. It is possible to simplify the installation of the frame by installing the extreme rafters and stretching a rope between them that defines the plane.

The end of the installation will be the stuffing of the crate. Its bars are located perpendicular to the frame, the attachment pitch depends on the finish coating. A continuous crate is made for rolled material. For covering, moisture-resistant plywood or OSB boards are used. After installing the rafter system, a waterproofing sheet is laid and the roof is insulated. The final stage of work is the installation of the roof covering.

We select the material for the rafters

So, if you have decided on the future loads, it's time to choose the right material. As it for the manufacture of rafters, they are usually used:

- Wood. Solid wood, boards or glued beams.

- Lightweight metal profile. These are galvanized steel profiles.

- Black metal. These are I-beams and steel channels.

- Heavy reinforced concrete structures for industrial construction.

If heavy loads are not expected on the rafter system, then make the rafters from dry planed boards with a small section. But if in your area it is not uncommon for knee-deep snow and the roofing material is not easy, then you will have to make glued some of the constituent elements. That's the whole difference.

It is most convenient to make elongated side rafters and diagonal rafter legs from the board. So, a 40 mm thick board, which is often used for outbuildings, is not suitable for a roof. Not less than 50 mm! Moreover, the longer the rafter leg is planned, the wider the board itself should be. So, rafters with a length of 6 meters will have to be made from a board with a width of 150 mm, and even longer - from a board of 180 mm.

For the roof of a frame house, this is really one of the best options!

And also rafters from a board are the most economical, and at the same time they are almost not inferior in strength to timber

It is only important to choose the right cross-section and use high-quality material. Therefore, when buying material, be sure to bring a special device for measuring wood moisture content and use it.

There is nothing worse than raw rafters. And it's not just about the future mold: such a roof will lead and warp, because this material changes its shape when it dries. Fasteners will fly off at the rafters and even the covering of your gable roof will bounce off in places. In a word, you will not end up with problems!

But from an ordinary board, it is most convenient to splicate the rafters along the length:

And, you will be interested to know that rafters can be made not only from wood! So, iron truss systems, which were once used exclusively for industrial construction, are returning their former popularity today. And, note, this material for the roof has many advantages, the most valuable of which is the complete absence of fungus from dampness. The under-roof space, after all, most often "pleases" with accidental leaks.

And the work itself with such rafters during installation is no more difficult than with wooden ones - see for yourself:

The beam is more durable, but it is bad because it has a lot of weight and you have to make cuts in the attachment points. For a log, this is not only a problem, but also some loss of the bearing capacity of such a rafter leg. But so far, this material is the most popular for the manufacture of rafters.

Most of all, lumber is suitable for the manufacture of rafters, which meets the requirements of GOST 8486-86 or 2695-83. And this:

- Humidity not more than 18%, measured with a moisture meter.

- Cracks that are not through and do not exceed half the length of the board.

- For each running meter - no more than three knots, and each of them - no more than 30 mm in diameter.

Therefore, when buying wood for rafters, be sure to check the documents with the seller, which speak about the quality of the products.

The type of wood is also important. The fewer knots and cracks on the bars, the better.Some varieties also delight in good moisture resistance and resistance to decay and pests. For the roof, this is what you need. Therefore, we recommend making rafters from coniferous wood, which is rich in resin, and resin is a natural barrier against decay. But special processing is still needed.

And take into account this fact: when making a rafter system, you need to purchase 5-7% more material than necessary, because it will not always be possible to make a perfect rafter cut or a cut of the required depth. There will still be an overrun, and therefore stock up on it in advance so that you have a tree of the same moisture content and properties for the entire rafter system.

Otherwise, if you had to purchase some individual roof elements separately, they may take longer to dry (wood always dries), or vice versa. Distortions can turn out to be considerable, i.e. the entire roof frame will be constantly subjected to different physical tensile and pressure forces. Any experienced roofer will tell you how bad it is and what it entails. Therefore, take more material for the manufacture of rafters than you plan. If everything goes smoothly, there will be something to make the first bench in front of the new house.

Do-it-yourself installation of rafters for a gable roof

Laying Mauerlat on the walls

This element is attached to the load-bearing wall along its entire length. If we are talking about a log house, then the upper crown can serve as a mauerlat. For buildings made of aerated concrete or brick, a Mauerlat equal to the length of the wall will be required. Sometimes this part can be laid between the rafters.

If there is not enough length of material for the Mauerlat, several pieces can be spliced. At the same time, the edges are sawn down at 90º and are joined using bolts - wire, pins or nails are not suitable.

There are two ways to lay the Mauerlat on top of the load-bearing wall:

- symmetrical in the center;

- with an offset in the desired direction.

Installation of Mauerlat is carried out on a pre-laid waterproofing layer of roofing material. This will protect the wood from rotting.

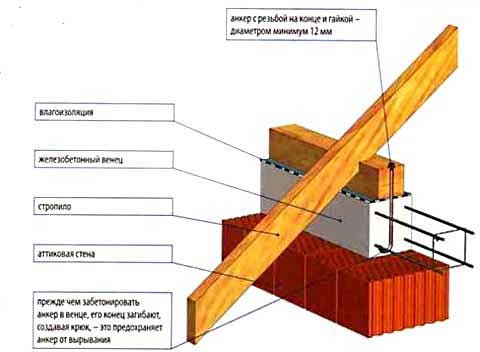

It is worth taking a responsible attitude to the process of attaching the Mauerlat, since in a strong wind it must withstand a particularly heavy load.

The following consumables can be used as mounts for the Mauerlat:

- Anchors that are indispensable for monolithic materials.

- Wooden dowels. These parts are used in houses made of timber and logs, although additional fasteners are required for them.

- Staples.

- Fittings or special studs. This option is preferable for buildings made of foam or aerated concrete.

- Knitting or steel wire is an auxiliary fastener that is almost always used.

Assembling trusses or truss pairs

Assembling trusses can be done using one of the following methods:

- The rafters are assembled and attached directly to the roof of the building. This process is quite laborious, since all measurements, trimming and hitching of the beams will have to be done at a height. However, you can do it yourself, without involving technology.

- Trusses or trusses can be fixed to the ground, and then the finished elements can be lifted to the roof of the building. On the one hand, this simplifies the process of installing the rafters, and on the other hand, due to the large weight of the structure, lifting it up will require special equipment.

Please note that it is worth starting the assembly of rafter pairs only after applying the markings. And if you make a template in advance, for which you take two boards equal to the length of the rafters and connect them together, then all pairs will turn out to be absolutely the same.

Installation of rafters

After assembly and lifting to a height, the rafters of the gable roof of a wooden house are installed. To fix them on the Mauerlat, cuts are made at the bottom of the rafters. The first to install two trusses from opposite ends of the roof.

After that, a rope is pulled between the starting pairs, along which all other rafter trusses will be aligned and the skate will be installed.

Now you can mount the remaining pairs, observing the calculated step between them. In cases where the pairs are assembled directly on the roof, a ridge girder is attached between the two end trusses. Subsequently, the rafters are installed on it.

The order of installing the halves of the rafters, according to the opinions of professionals, may differ. Some people prefer to lay the beams in a checkerboard pattern so as not to overload the foundation and walls in the process. Others are inclined to consistently install pairs of rafters. Be that as it may, rafter legs may need supports and uprights - it all depends on the size of the roof and the shape of the trusses.

Ridge attachment

The ridge is an element that is formed by attaching the rafters at the top point. As soon as all the details of the rafter system for a gable roof are installed, capital fastening of all structural elements should be performed.

Installation of the lathing

The presence of lathing is a must for the construction of any roof. It not only supports the roofing material and allows it to be securely fastened, but also makes it possible to move along the roof during operation.

The distance between the individual boards is chosen based on the type of roofing material:

- the soft roof is laid on a solid crate without gaps;

- for metal tiles, a crate is needed with a step of 35 cm (between the two lower rows - 30 cm);

- slate and corrugated board can be laid on the crate in 44 cm increments.

Outcomes

Thus, in order to assemble a rafter system for a roof with two slopes, many nuances should be taken into account and any possible complications should be foreseen. We hope that our tips will help you cope with this difficult task and create a high-quality and durable roof for your home.

Installation of the rafter system ↑

Mounting methods for Mauerlat ↑

In houses that are built of logs or beams, the upper crown serves as the support for the lower part of the rafters, and in brick or stone houses, a special support beam, the Mauerlat. It is laid on a waterproofing pad from the inside of the wall in the attic.  Mauerlat is fixed to the wall:

Mauerlat is fixed to the wall:

- by means of a reinforcing belt (on concrete with pins), on pins embedded in the masonry of the walls, using a wire rod.

The hairpin is a threaded metal rod. Its length is chosen on the basis that one half of the stud will be embedded in the wall, and the protruding part should be 3-4 cm long enough to tighten the nut on top of the Mauerlat.

Ridge run ↑

The structure of the gable roof with its upper part rests on the so-called ridge girder. It is a log or timber to which the upper ends of the rafter legs are attached. It is this girder that will further serve as the ridge of the roof.

- With a house length up to 6 m, it is allowed to prepare a ridge run from a single bar or log. At the same time, it can be supported on two pediments without additional supports. With a house length of more than 6, building trusses are used for the installation of a composite ridge girder.

Additional elements ↑

- The side girders provide additional support for the system itself. They are supported either by construction trusses or by the gables of the house. If the structure is heavy, the girders are made in the form of a "building lift" or a rocker arm. The struts help relieve the rafters in the center. They are installed under all "legs" at an angle of 45 ° and more. Thus, it is possible to arrange a gable roof up to 14 m. Braces (diagonal beams) strengthen the rafters and help the gables withstand strong wind loads.The support of their upper part is the corner of the pediment, the lower one is the central floor beam.

Installation procedure ↑

The rafters can be installed in two ways:

- collect a farm on the ground and raise it up; assemble the trusses right at the installation site.

The choice of the installation method, of course, is up to the performer, however, in any case, when creating the same type of trusses, it is more convenient to use a template according to which the rafters will be cut and connected.

Making a template like this is not difficult at all.

- To do this, take two boards, slightly longer than the rafters, raise them up and set them up like a future structure. Align them vertically so that the top of the ridge is installed in accordance with the drawing, the boards are connected with one nail. Lowering or raising the ends of the boards, achieve the required angle of inclination and connect the boards using a transverse bar and thus fix them in the desired position. The finishing option is fitted to this template and connected.

Mauerlat fastening technology ↑

Fastening is one of the important points when installing a roof. The rafters are attached to the Mauerlat in two ways.

Rigid fastening. The main principle of this technology is the exclusion of any effects on the connection - bends, turns, shifts. Such staticity can be achieved by fastening the rafters with corners or support beams. You can also make saws on rafters, use staples, hammer in nails. Additionally, they are attached to the wall with wire or anchors.

Sliding (articulated). This type of fixing, which has 2 degrees of freedom, is especially recommended for wooden houses. The moving part in this structure is the rafters. It is performed with the help of a special gash, securing the adhesion point with two nails driven at an angle, or a metal plate equipped with holes for nails and others.

The trusses are first mounted at the beginning and at the end of the structure, after which a cord is pulled between them. The horizon should be perfectly flat. If a distortion is found, one of the trusses can be lowered slightly. All other rafters are installed under this cord with the step specified in the project. After that, additional elements are mounted: retaining beams, braces, frames and crossbars.

As an example, watch the video: "Gable Roofs: Installing the Truss System".

Calculation of the step depending on the roofing material

For each coating, its own standards and dimensions are developed for the rafter system. The main factors are the strength of the material, its weight and resistance to external loads. Let's consider the main types of coatings.

Corrugated board

The step of the rafters under the corrugated board can vary from 0.6 to 0.9 m.The end result depends on additional conditions, which we will talk about below. If, for some reason, the step should be larger, add a transverse board with a large section. In this case, usually the rafters themselves are chosen with dimensions of 50x100 or 50x150 mm.

In addition to the rafters, a crate of 30x100 millimeters is used. The gap between the boards should be about 0.5 meters. It can be more, it all depends on the type of corrugated board and the height of the wave. Sheathing boards protruding beyond the borders of the eaves should be 1.5 cm thicker than usual. This is done on the basis of the need to fix ventilation, chimney or drain.

Ceramic roof tiles

The main difficulty in designing a rafter frame for ceramic tiles is the large weight of the material for the roof. It is 10 times heavier than corrugated board and accounts for 40 to 60 kg per square meter.

For such a coating, dry beams are used, with a moisture content of only 15%. Their section should be either 50x150 or 60x180 mm. With such indicators, the maximum permissible distance between the rafters can be 1.3 meters.The minimum allowable step through which the rafters can be placed is 0.8 m.The final decision is influenced by the slope of the roof: at 15 °, a step is made 0.8 m, at 75 ° - 1.3 m.

The distance between the lathing boards is selected so that each tile intersection has its own base. The standard length of the material is 400 mm, and the overlap during installation ranges between 55 and 90 mm. It turns out that the distance between the central axes of the crate can be either 310 or 345 millimeters.

Metal tile

In recent years, the question has been particularly acute: how to determine the distance between the rafters under the metal tile?. It imitates the more expensive ceramic material, but at the same time has the positive properties of corrugated board. Installation of such a coating is simple and does not require large financial costs. All this makes the material attractive for the roofs of private houses.

The mass of the metal tile is less than the ceramic one, therefore, a simpler frame is required. The cross-section of the beams is reduced to 50x150 mm and the step between the battens is increased. The step of the rafters under the metal tile ranges between 0.6 and 0.95 m.

Ondulin

The permissible pitch for the ondulin coating is 0.6-0.9 meters. The standard section of the rafters is 50x200 millimeters. These dimensions will allow you to withstand the generated load of the roofing cake on the gable roof.

On top of the counter-lattice, a crate of bars with dimensions of 40x50 millimeters is attached. The pitch between the center axis is 600 mm.