Erection of slab and strip base

Gazebos made of brick or stone are no longer a rarity. The advantages of such designs are:

- duration of operation;

- the possibility of equipping a barbecue;

- the possibility of having a rest not only in the summer, but in the winter, due to the glazing of the building.

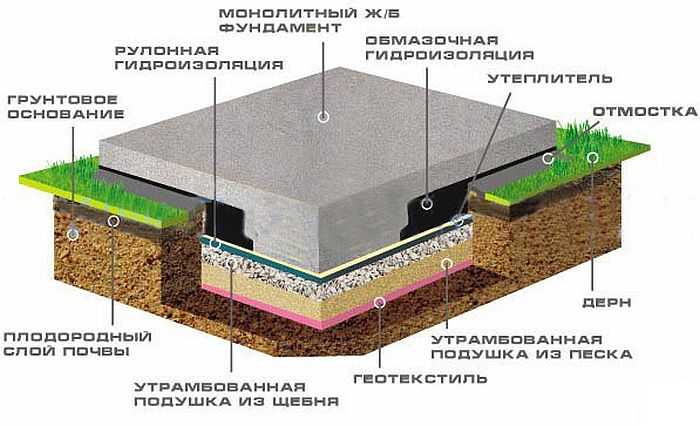

Plate type

Slab base for the gazebo

Slab base for the gazebo

This type of foundation is rarely used in the construction of gazebos due to high financial and labor costs. In addition, along with activities similar to the columnar type for the preparation of the construction site, you will need to perform the following actions:

- dig a pit with a depth of at least 50 cm;

- from the inside of the equipped recess, install the formwork and lay a 15-20 cm layer of sand and gravel mixture on the bottom;

- lay the waterproofing layer on the substrate;

- fill in another 10 cm layer of fine gravel crushed stone (excludes contact of roofing material with reinforcement);

- weld and place a reinforcing grid over the insulation (reinforcement with a diameter of 10 to 12 mm, the sides of each cell are 20-25 cm);

- pour the prepared area with a 30-35 cm layer of concrete so that it protrudes 10-15 cm above the ground surface.

After waiting for the solution to dry completely, you can start placing the remaining structural elements.

Watch a video on how to equip a slab foundation with your own hands.

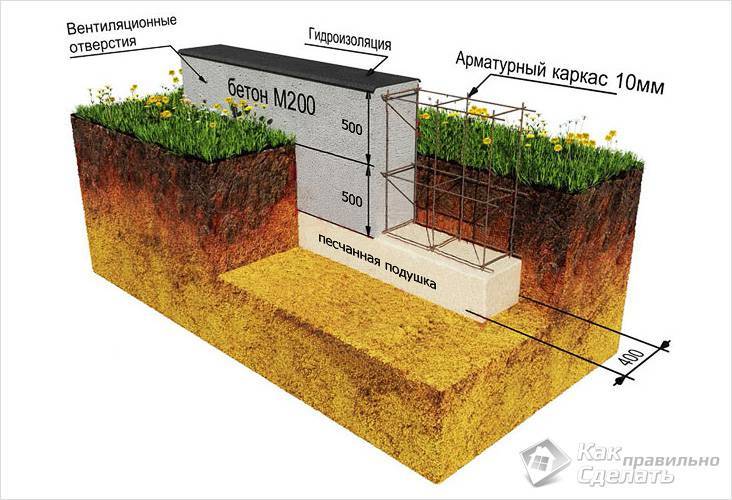

Ribbon view

Arrangement of a tape-type foundation is associated with fewer worries, but the result is no worse than the previous one. Construction features:

- according to the markings, a trench is dug with a width 10-15 cm higher than that of the walls of the gazebo, and a depth of 30-35 cm;

- formwork is installed with a margin;

- reinforcing mesh is laid;

- concrete pouring and final leveling of the composition are carried out.

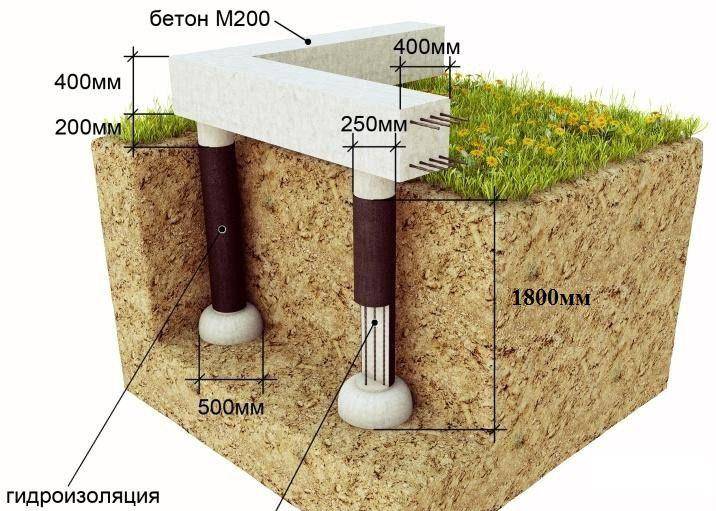

How to make a columnar foundation for a gazebo with your own hands

The key parameter of the columnar structure is the depth of its occurrence. It depends on a number of factors:

- the material used;

- design parameters;

- characteristics of the soil on the site.

An important value of the columnar support for the gazebo is its depth. It depends on the type of material, design parameters and soil properties in the treated area.

In construction practice, the following types of columnar bases are used:

- Shallow, in this design, the columns are installed on the ground surface.

- Shallow, this design implies that to install the posts, it is necessary to prepare pits 350 - 750 mm deep from the ground surface.

- Recessed, that is, the pillars must be installed in pits, the depth of which exceeds the level of freezing.

The pillars should be placed under the load-bearing beams, in the corners and in the center. The pitch of the posts is within 1.5 - 3 meters. The head of the post must rise above ground level by at least 300 mm.

The number of supports is determined by the parameters: the size and weight of the arbor. After installing the posts, their heads must be leveled horizontally and only after that you can proceed to the construction of the grillage.

Builders use several options for the execution of foundation posts. Most often, slag or expanded clay blocks are used. Due to their size and low weight, the posts can be installed quite quickly and there is no need to involve outside craftsmen.

The order of installation of foundation pillars looks like this:

- Cleaning up the territory, leveling it.

- Marking, during its implementation, it is necessary to determine the installation locations of the pillars.

- Digging pits. If the gazebo does not have a large mass, then you can get by with small pits, their depth may be 500 - 700 mm. At the bottom, it is necessary to arrange a sandy - crushed stone pillow. Its height should not be less than 200 mm.

- After the pits are ready, you can start laying the blocks.

In principle, within one or two working days, you can make the foundation for the gazebo with your own hands, without involving outside specialists.

Construction of a strip base

The strip foundation is especially good for gazebos in that its device allows you to erect a building of any design, shape and type. Moreover, it is able to withstand heavy loads and serve for a long time. A shallow foundation can be arranged for brick, wooden and frame gazebos with a large mass. Thanks to its design, the entire load is evenly distributed over the entire surface. If you plan to put an oven for a barbecue or a barbecue inside, you can make a concrete pillow separately under them.

Structure

Structure

Concrete mix, bricks or blocks can serve as a tape. To make such a foundation, you will need:

- rope and pegs for marking;

- shovel for digging a trench;

- scrap for stony ground;

- building level and plumb line;

- sand and gravel;

- boards or plywood for formwork;

- concrete mortar, bricks or blocks, depending on the choice;

- if the tape will be made of blocks or bricks, then make a masonry mortar;

- roofing material to provide waterproofing;

- reinforcement rods Ø12 or 14 mm;

- Master OK;

- facing material;

- roulette;

- hammer.

Reinforcement cage

Reinforcement cage

Let's divide all the work in stages again:

As always, the site needs to be cleaned, markings should be done based on the project. Stakes must be hammered in the corners of the building, observing the dimensions of the gazebo. They are connected with a cord that serves for orientation. Everything needs to be measured with a tape measure, sides and diagonals, and if everything fits together, step back 200-400 mm from all sides and make exactly the same markings.

Now dig a trench around the perimeter, focusing on the markings. Do all work with a shovel, checking the verticality of the walls with a plumb line. The bottom of the trench should also be flat. The depth of the trench depends on the mass, soil and occurrence of water and can vary from 600 mm to 1500 mm.

Fill the bottom with a 100–150 mm sand cushion and tamp it down. Then again 50–100 mm of gravel, which is also rammed.

Further work depends on the material of the support. If you will pour everything with concrete, then above the pit along the entire perimeter you need to make a formwork, the height of which is 300-400 mm. It can be knocked out of boards or plywood can be used. A frame made of reinforcement is placed inside and everything is poured with concrete

It must be tamped down by gently tapping the formwork with a mallet and bayonetting the concrete. The surface is leveled and waiting in the wings

As usual, the concrete will take a month to dry. For this period, it must be covered with plastic wrap.

If the foundation tape will be made of blocks or bricks, then the formwork does not need to be done. In this case, mix the masonry mortar, additionally reinforcing the rows.

When everything is ready, you need to cover the structure with waterproofing material. Ideal options in this case would be roofing material, which creep in 2-3 layers.

Now you can install your gazebo on the finished foundation. After the final work on its construction, the outer surface of the plinth can be veneered. The decorative coating is selected based on the material used in the construction. It can be both decorative tiles and wooden planks, then the gazebo will take on a completely different look and will look very noble.

Pile type arrangement

Arbor on a pile foundation

Arbor on a pile foundation

The pile foundation has a great resemblance to the columnar type, however, the piles (or pipes) are installed with smaller intervals from each other, so that the erected structure rests on the supports as much as possible with its area.

The most commonly used type of support for foundation construction is screw piles, the principle of which is based on screwing the cutting part into the ground until the required height of the support element is reached.

A fundamentally important feature of the use of such devices is that if the pile is skewed at the time of its screwing in, in no case should you take actions to pull it back. Having made such a mistake, you will unnecessarily loosen the soil at the installation site, which will subsequently lead to shrinkage of the foundation.

We recommend watching a video on how to make an outbuilding on screw piles.

How to pour concrete into the area under the gazebo

When creating concrete sites, there are a number of nuances that must be taken into account. So, it can be damaged by tree roots or weather conditions.

Also learn how to design a rectangular area.

To prevent this from happening, take into account the following:

- The roots of trees stretch along the diameter of their crown. This means that the foundation should be located further than the roots of the nearest tree. Old trees do not grow in size, so it is better to install a site next to them than near young ones.

- The resistance of the foundation to cracking depends on the quality of the material used. Therefore, the sand and crushed stone must be clean and the cement must be fresh. If it is stored for a long time, then its quality decreases.

- To prevent contact between soil moisture and the floor of the gazebo, it is imperative to use a waterproofing membrane between the layer of rubble and concrete.

- To keep the site level, you need to accurately place the formwork, and then apply height marks to it, which will help level the surface during pouring.

- Concrete is poured at several points so that it can be leveled across the site, and not stretched, otherwise height differences will inevitably result.

- Further work is carried out after the mass has dried.

The use of a particular foundation structure depends on the type of soil, mass and shape of the building. Choosing the right one ensures the gazebo is durable and will last for years.

Pile

At the heart of the pile foundation are small-section supports that go deep into the ground and are well fixed. Metal or asbestos-cement pipes are used as piles. Wooden beams are used extremely rarely, as they need additional preparation. To increase the reliability of the structure, improve adhesion to the soil, you can purchase factory screw piles.

So what are the advantages of a pile foundation? First of all, it is stability even on unreliable soils, small financial investments. The piles have worked well when installing a gazebo on a slope. However, you should be extremely careful when strengthening the piles. They must be very secure.

Unusual versions

It turns out that the foundation can be made even from truck tires. For the first time this method was invented, and after a while and patented by a resident of St. Petersburg Mikhail Semykin. The craftsman suggested laying the tires of buses, trolley buses or tractors in two layers on a flat surface. With proper organization, a solid foundation can be obtained from large boulders and even from underground burrows.

From plastic pipes

The main advantage of such a foundation is the cost of work available to every third Russian citizen. It is possible to prepare the foundation in 7 hours, and thanks to its design features, the autonomous building near the dacha rises about 15 cm above the ground.This is quite enough to protect the structure from flooding.

The presence of free squares contributes to the prompt installation of not only external, but also internal communications. Even if over time there is a desire to make major repairs, you will not have to dig a hole.

In this case, plastic pipes serve as permanent formwork, thanks to which the correct geometry of the structure is possible. The main thing is to adhere to a clear sequence of actions, and then even the smallest gazebo from a terrace board will last at least 30 years.

In order to avoid technical errors, it is better to use the instructions:

- Free the area from the roots of perennial plants and debris.

- Use stakes and cords to mark the pile field.

- Taking into account the characteristics of the soil and possible loads, choose the optimal number of supports.

- Make 2 meter holes for the pipes.

- Install floor slabs in places of additional load.

From tires

This refers to a non-standard type of foundation, acceptable only for light buildings made of lumber or plastic

It is important to remember that the more tires, the stronger the base. It is better to fill the gaps between the tires with a mixture of gravel and finely divided bricks.

Dense linoleum will come off as the top layer.

To make the fill uniform, you need to lay sheets of roofing material on the finished base. Around the tires - build a formwork wrapped in wooden boards. At the end of the work - lay the reinforcement and concrete the covering.

The minimum service life of such a foundation often exceeds 15 years.

From barrels

200-liter drums with a wall thickness of at least 1.5 mm are on the list of the most popular and relatively inexpensive foundation materials. They can be used in the construction of terraces, open verandas and wooden arbors.

Before work, it is important to prepare the material: remove the removable covers, and if necessary, remove the bottom. In the future, such a product can be used as formwork

For gazebos ranging from 8 to 12 m², 4 anchor points are required. When building more spacious buildings - from 10 or more. To isolate the foundation from the outer surfaces, a layer of waterproofing must be placed on the top of the concrete-poured barrels. If desired, the shells can be inserted into the frozen soil, and when installing them directly on the ground, it is advisable to prepare a 12 cm sand compensation support.

To correctly bookmark such a foundation, you must:

- Stretch the cords, along which it will be possible to determine the location of the drums in the future.

- Dig a 60 cm hole under each item.

- Make a sand pillow, on top of which you need to lay several layers of roofing material.

- Fill the gaps between the barrels with a loose mixture.

- Fill the wooden container with concrete.

From roofing material

It is on the quality of the waterproofing of the structure that its resistance to adverse conditions depends. Therefore, up to 40% of specialists prefer a base made of roll materials. Before construction, they are cut into layers and glued to the base using bitumen mastic.

As soon as the material adheres to the base, the foundation can be covered with soil. In this case, the concrete prepared for pouring the pillars is already protected from groundwater. As a result, the shelf life of the future structure increases long before its commissioning.

Sometimes the cost of the foundation exceeds the cost of overhauling the suburban area. But since we are talking about a supporting structure that can withstand heavy loads, there is no place for savings.

Pile-screw foundation for the gazebo. We build with our own hands

Most developers are interested in creating a screw foundation. It is not only lighter, but also prettier than concrete. The gazebos are light buildings, so it would be advisable to use piles for the foundation with the designation SVS-57, 76 and 89. The numbers correspond to the diameter of the pipe with the propeller blades. The latter simplify the immersion of the barrel into the ground; it is advisable to carry out the work together.

Installing screw piles manually

Installing screw piles manually

The creation of a pile-screw foundation is reduced to performing the following tasks:

- Marking the perimeter of the building. It is convenient to mark the places where the piles will be buried with small pegs.

- Removal of the top layer of soil. If this is not done, grass will begin to grow under the gazebo in a year.

- The immersion of screw piles into the ground is carried out using levers. It is necessary to screw in the supports until a high stability is achieved.

- The working area is covered with a 7-cm layer of sand and filled with water, pressed.

- A layer of crushed stone of the same thickness is poured on top. Pebbles are needed to stop the growth of weeds. In addition, they play the role of drainage. Piles placed in the ground will not rust and deteriorate under the influence of moisture.

- Now you need to check if the pile structure is so flat. If the post is too high, it is trimmed. Short piles are built up.

- A sole is made for each pillar. Use sheet metal with a diameter of 0.5 centimeters for this purpose. Holes are made in square blanks for fastening the base and strapping. The soles are welded to the posts and covered with roofing material. The pile-screw foundation for the pergola is ready!

Overview

A gazebo is a small architectural form, the dimensions of which directly depend on the area of the site, the functionality and household needs of the owners. It can be a mini-structure, and sometimes it is a grandiose combined building of 2 floors.

Types, shapes and sizes

And besides, there are open gazebos - awnings, rotundas, classic-looking or closed - pavilions, grill houses according to Finnish standards or summer kitchens. Any shape of the building can also be chosen: round, rectangular, multifaceted, curvilinear, combining several rooms of different geometry at once.

Materials (edit)

The main materials for construction are: wood of various breeds, metal, including forging and welded structures, stone - marble, granite, quarrystone and artificial, brick, concrete with tiles or sculptural, natural materials - bamboo, reeds, willow twig, straw ... And recently, there has been a tendency to build from improvised household materials, such as plastic or glass bottles.

Optimal solution

When building gazebos with barbecue, preference is still given to concrete, stone and brick - these are non-combustible materials, therefore they are practical for setting up a hearth. Often these materials are combined with forging, wood or polycarbonate.

We have identified the main trends, but in some cases the owners decide to abandon stone or brick buildings in favor of wooden

It is important to understand that such gazebos will require additional processing of wooden elements with fire-resistant impregnations.

Important: At the request of fire safety, outbuildings should be 5 m away from the main building, and no closer than 8 meters from the neighbor's house. SNiP also regulates that a fire entrance must be provided for such a building. ... Slab foundation for a gazebo made of wood with barbecue

Slab foundation for a gazebo made of wood with barbecue

Do I need a foundation for a gazebo

The foundation's job is to provide support from wind and erosion and help distribute the weight of the structure. It also separates the wall or supporting pillars from contact with the ground in order to minimize the risk of collapse due to moisture, so where a timber structure is on the ground, its durability is always extended by laying a foundation.

If the gazebo is made of polycarbonate or is installed on a site covered with bricks, tiles or concrete, then this element is not required for it. Summer structures can also do without a foundation, which are sheltered for the winter and have minimal contact with moisture.

Important! The gazebo should be installed where there is good natural air flow. It provides quick drying of the building after rain, thereby protecting it from dampness and mold.

Criteria for choosing a foundation for a gazebo

The foundation is the fundamental part of any, even the smallest, structure. Any foundation is bad and does not fulfill its functions if it is built incorrectly.

Basically, there are very few types of foundations. They all have a certain depth; lie on a cushion of draining rubble, pebbles, sand. There is always waterproofing between the foundation itself and the structure erected on it. As exceptions, pile foundations can be noted, which do without a pillow (although sometimes there is a buried grillage of the pile foundation on the pillow), and not buried, simply lying on the pillow, foundations used for the lightest structures.

Types of foundations

By the depth of location, all foundation foundations are subdivided into buried, shallow and not buried.

By engineering design, they are divided into four main types: slab, tape, pile and columnar.

Platen

It is used in cases of quicksand, close occurrence of waters, subsiding soil. Advantages: solidity, reliability; in our case, a thin monolithic foundation can be much more convenient than a strip foundation, since a platform is immediately created - the floor of the gazebo. Disadvantages: requires more labor and more materials than other types, respectively, it is more expensive.

The heavy slab foundation shown in the diagram is, of course, redundant for the gazebo

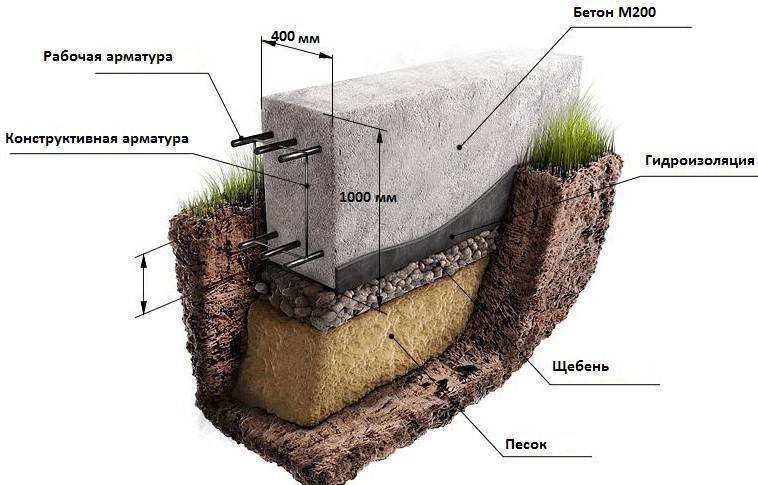

Tape

Usually, strip foundations are the most popular option, but not for gazebos. Advantages: solidity, reliability. Disadvantages: completely redundant for a gazebo. Although if it is very heavy, then a strip foundation is preferable to a monolithic one - it is cheaper and better copes with soil deformations.

A strip monolithic foundation is not the best solution for a gazebo

Pile

These are supports of a small cross-section, deeply embedded in the soil and well-fixed in it - asbestos-cement or metal pipes. Rarely, but still sometimes such a foundation is made of a wooden beam, but its special preparation is necessary. In some cases, factory-made metal screw piles are used, which increases the reliability of the structure and adhesion to the soil. Advantages: ideal for unstable soil, when building on a slope; a pile foundation made of asbestos-cement pipes does not require large financial investments. Disadvantages: requires labor and great care when strengthening the piles and is often unnecessary in the case of building a gazebo.

Pile foundation with screw piles and concrete grillage used on slopes

Columnar

The lightest in execution and most often used for gazebos is the foundation. Sometimes it is buried, shallow and not buried. For gazebos, the last two types are used. The blocks are placed on a crushed stone or gravel bed either directly on the cleared area or in the pits. Advantages: extreme ease of execution, very cheap, suitable for any soil. There are no downsides.

Column foundation made of blocks with a wooden grillage - the best solution for a gazebo

Video: construction of a slab foundation for a gazebo

Since your main house has already been built, you already have on hand the expert opinion on your grounds, made before designing it. Moreover, you already know how your buildings behave: what are subsidence, soil shifts, flooding. The choice of a type of foundation for a gazebo or veranda will be based on the opinion of professionals and your own personal experience. Of course, you have to consider the indicators of the site survey. But in the case of a gazebo, everything is much simpler: the requirements are not so stringent; deepening is either insignificant or absent; the grillage is the simplest.

The foundation for the gazebo - step by step

So, in order to build a foundation for a gazebo with our own hands, we need to do several operations first and prepare the necessary tool:

- screwdriver or drill;

- welding;

- grinder or jigsaw;

- a set of screws and nails;

- wooden material (boards, blocks, stakes, spacers);

- iron material (fittings, wires, rods);

- hammer;

- threads;

- roulette.

With the tool sorted out, let's get to work.

Markup

First of all, it is worth marking the outer side with pegs, where we will dig the trench. To measure the length and determine the angles, we use threads and a tape measure. Everyone builds their own gazebo, so there is no point in telling about the exact dimensions.

Helpful hint: you can check the rectangularity of the marking by pulling the threads diagonally.

Further, it is necessary to mark on the stakes using the hydro level, the points of the horizontal plane. We will pull the cord over them. This will help us define the boundaries of the trench.

We install stakes from the inside, taking into account the dimensions of the foundation and trench. By analogy, we pull the threads along the perimeter. It is recommended to use a prepared drawing.

Trench

After we have made the markings, we begin to dig a trench, its minimum depth should be half a meter, or a little more. It is better to lay roofing material or plastic wrap at the bottom of the pit. Then cover the whole thing with sand and gravel in layers of 15 - 20 centimeters. You should have three identical layers.

Moreover, each embankment must be well spilled with water and tamped. Level the top of the pillow exactly horizontally. In some areas, add sand as necessary.

Formwork

Now we turn to the formwork blank. Its dimensions must correspond to the foundation. Both in length and width. You can fasten individual elements of the board with the help of bars.

We start assembling, starting from the inside.

- We lay the boards, trying to keep an even angle of the edge of the formwork. Then we connect them with screws, so that it would be easier to disassemble the structure.

- Now, once again we check the level of the edge of the formwork, if necessary, adjust it.

- For rigidity of fixation, we beat the shields from the outside and inside. Three pegs on each board and fix them with screws or nails.

- Further, if necessary, align the side of the formwork board. To do this, we drive in a stake opposite the board and insert a stick between them, thereby adjusting the slope. It can be measured with a taut thread.

- The resulting wooden spacers must be secured with screws.

Upon completion of the actions, we proceed to the next stage of work.

Reinforcement

To give a more reliable look to the foundation for the gazebo, you can reinforce it with your own hands. For a bundle of iron reinforcement, welding or steel wire with a diameter of 1 - 1.5 mm can be used. You do not need special knitting tools; you can use a regular bent screwdriver.

The construction of reinforcing rods must fully comply with the dimensions of the foundation. You need to make a grid according to the following scheme.

- We connect the resulting boxes into one structure. Additionally, it is possible to strengthen the corners of the base using bent rods with a diameter of 5-6 mm.

- Next, we assemble the outer formwork in the same way as the inner one. We do the same and fix it.

- The last step is to pour the resulting structure with concrete.

This process is irreversible, so it should be carefully considered. It is recommended to make a test batch and see how it will set. High-quality concrete will harden in a day.

Concrete filling

We proceed to filling the concrete. It must be tamped well, and the excess layer must be removed with a direct tool.

Helpful Hint: For a better reaction, the foundation must be rinsed and kept moist for several days. After a few days, we remove the formwork and get a fresh base.

Making a pillow

An integral part of the formation of the base is the creation of a foundation cushion between the ground and the base. To create such pillows, the following materials are used:

- crushed stone;

- concrete;

- sand.

Sand is used as the most budgetary option to create a foundation cushion.

To create such a pillow, only coarse sand is used. The use of fine-grained material is strictly prohibited.

To create such a pillow, only coarse sand is used. The use of fine-grained material is strictly prohibited.

Sand pad application conditions:

- low building height, ideally a one-story building;

- the depth of the groundwater is deep;

- the building is not built from massive materials.

We suggest that you familiarize yourself with the information on how to make a gazebo out of boards with your own hands.

The basic rules for its formation for the arbor base:

- The pillow is made up to 20 cm high.

- Level its surface.

- Pour water over it.

- Thoroughly ram the layer of sand.

To create a stable structure, the crushed stone pillow is made 30 cm wider than the foundation itself.

To create a stable structure, the crushed stone pillow is made 30 cm wider than the foundation itself.

When creating a massive and heavy gazebo, a sand foundation cushion will not work. Then a layer of crushed stone is used. With its help, the base can withstand significant loads. The size of the crushed stone is different. The best strength material for such purposes is considered to be medium-fraction crushed stone from granite.

Important! For the construction of heavy stone buildings, ready-made reinforced concrete cushions are used for the foundation. They are made in special factories and are quite expensive.

When creating a pillow, follow these rules:

- A small layer of sand is poured onto the bottom of the base, for better adhesion to the soil, which is leveled and rammed.

- Having decided on the fraction of the stone, a layer of crushed stone is poured up to 20 cm.

- The layer is moistened with water.

- With the help of special equipment, it is tamped.

They are installed after leveling the ground and applying a sand layer. For a garden gazebo, a sand-crushed stone pillow is mainly used, which is covered with roofing material on top to protect it from water.

Find out also the rules for decorating a high-tech gazebo.

Do I need to make a foundation for a gazebo?

Among novice builders, the question is common: is it necessary to pour the foundation under the gazebo? After all, the design is light in weight and will do without such a foundation. Can it be enough to clear the site, and then put the necessary supports or immediately lay the walls?

Not so simple. A tree, for example, does not like contact with a damp and damp surface, from this it begins to deteriorate. The foundation will act as an intermediate element. By making a concrete platform for the gazebo, you will exclude the possibility of flooding: the structure will be more stable and stronger.

How to make a foundation for a gazebo will be properly discussed below.

Conclusion

The essence of columnar foundations, which are a variety of supports for most buildings, are racks extending vertically downward, connected to each other by an overhead grillage. The materials for the manufacture of this base are: wood (usually oak), stones (natural and artificial), brickwork and pipe sections (asbestos-cement and metal).

Columnar foundation is cheaper than others. Its price is mainly determined by the material of manufacture, the technology used and the dimensions. It is necessary to calculate and build columnar foundations on the basis of the relevant GOSTs and SNiPs.