Thatched roof operation and maintenance

I was present at the construction of a house in which the owners - my friends - from the very beginning laid a thatched roof into the project, despite its higher price compared to any other type of roofing material. But they decided to save on the cost of the handlers. First, they themselves covered a large capital gazebo with a thatched roof to try out all the technologies on a simpler object. Then they took up the roof of the house and covered it surprisingly quickly - in about three weeks. I have visited this house many times, and my feelings are the most positive. In summer, under such a roof it is cool without air conditioning, in winter it is warm with noticeable savings on heating. The atmosphere there, especially in the attic, is very pleasant: moderately dry, without the slightest man-made odors.

Thatched roofs are much easier to maintain than other types of roofs.

- It is necessary to regularly inspect the roof in order to notice damage in time - in places where the integrity of the straw begins to rot.

- It is necessary to remove organic and other debris from the roof.

- It is recommended to repeat the treatment with fire retardants every two years.

- Treat the coating with antifungal agents every two years to prevent moss formation.

- It is recommended to change the ridge every ten years.

Now that you have thoroughly studied the subject, you can acquire the necessary tools, harvest straw and start building a thatched roof on your house. If you follow the recommendations outlined in our article, you will succeed and you can be deservedly proud of yourself.

Sewing technique with nails or constrictions

Houses with thatched roofs are often stitched in the area of the roof with nails. This method can only be used on those systems that are equipped with a solid crate. It has to withstand the additional weight of the fastener, so the requirements for it are particularly stringent. For work, three types of nails should be prepared, the first should be 300 millimeters long, it should be used to fix the sheaves from the middle of the roof. The second type of nails has a length of 250 millimeters and is attached to the middle. The third type is the smallest, its length is 200 millimeters, these fasteners should be used for the cornice.

The nails are selected in such a way that the shape is the same for all sizes, one end of the element should be pointed, while the other is made in the form of a hook. As a decorative decoration of the roof, the most often used scheme of stitching by constrictions. It is necessary to carry out these works by means of small pieces of wire, wood or bamboo stalks.

Thatched roof. Three myths

Everywhere and about everything you can hear your legends, myths, stories. After talking with experts, I made a conclusion for myself. A thatched roof of any hut, subject to all the rules and regulations of construction work, will meet the requirements and correspond to a reliable modern covering. And the myths that go about her are just fairy tales. Here are the most common ones:

The roof can catch fire from any spark. If this were true, probably all similar buildings would flare up like matches and put an end to this type of roof. But as you can see, this method still runs and, although not often, you can find it in ordinary suburban construction

Fire retardants are substances that prevent the ignition of any material. This is the secret. The process of processing the straw with these substances occurs immediately before the very laying on the roof. Because of this, simple straw, due to its low flammability, becomes along with ondulin.

- The roof will be a stronghold for mice. The dense packing technique does not allow moisture to penetrate, what can we say about mice?

- Not an aesthetic look, it gives the impression of a poor man. Surely it all came from films, because it is in them that all poor people have a thatched roof.But if you look at reality, then this is far from the case. A peculiar styling technique, uniqueness and style. These are the qualities that will attract people rather than repel.

Features of self-assembly of a straw structure

Do-it-yourself assembly of the roofing structure will save money, but it is quite difficult to do all the work alone.

The assembly of a reed roof is completed in less than a month, if all the recommendations of the experts are taken into account. The optimal slope angle of the structure is from 35 degrees. The thickness of the material and the level of the wear layer is determined by the technological characteristics of the roof (slope angle, slope size) and the length of the reed itself. The absence of a drainage system implies an individual choice of spillway systems.

Thatched roof has a clear structure

Today, a thatched roof is classified as an elite and expensive type of roofing, which is used by wealthy people in European countries. Handwork, environmental friendliness of raw materials and their limitedness are the main factors in the formation of the cost of the coating - from 150 euros per 1 m2. The absence of a hydro and thermal insulation system brings the cost of building a thatched structure closer to a tiled roof.

You need to put straw on the roof in a certain sequence.

DIY reed roof

Only high-quality raw materials can guarantee the durability of a reed roof, however, like a roof made of any other covering material. In Russia, there are about 30 types of reeds, but not all of them are suitable as roofing. The best roofing reeds are obtained from those plants that live on peat-boggy soils, covered with a layer of fresh water year-round.

Before harvesting, the area of reeds must be mowed, or even better burned, which will create favorable conditions for a high yield in the future. Harvesting begins immediately after the first frost. Reeds are mowed over water at this time of the year. They use agricultural machinery, which greatly simplifies the collection of reeds.

But if you make a workpiece for yourself personally, then you can mow it by hand using a cutting tool - tarpan. This is a rather complicated and time consuming process. One person can mow and impose about 60 sheaves per day. How many such bundles are required depends on the area of \ u200b \ u200bthe roof - residential buildings are covered in 3 layers, gazebos, verandas, and so on in two. About 8-10 bundles (sheaves) are used for each meter of the base.

Roofing reeds should be:

- not older than 1 year;

- have a stem 1.5–2 m long and 5–8 mm thick;

- free of any external defects (spots, damage) and golden color.

The cut reeds are knitted in small bunches and left to dry.

The reeds are knitted in sheaves and left to dry for several months.

When the moisture content of the stems does not exceed 18%, the sheaves are collected in heaps with brushes upward and dried for several months. Then the panicles are cut off, leaves and other debris are removed, treated with special compounds and stacks are formed for subsequent laying.

Pros and cons of a thatched roof

In most cases, reeds are chosen for work of such a plan, since its service life can reach 50 years. Another advantage of this plant is its flexibility. It allows you to make the roof of the most bizarre shape. Nowadays, thatched roof and reed roof is an indicator of wealth and is considered elite among a variety of roofs.

Natural thermoregulation. This advantage of both straw and reed cover allows maintaining a comfortable microclimate in the premises. At the same time, there is no need to install forced ventilation, since the material, like wooden coverings, is able to "breathe".In addition, the straw keeps the inside of the building cool during the hot season and does not allow heat to pass through it during the cold season.

Unique appearance of thatched and reed roofs. Due to the fact that all work is done by hand, the roof becomes truly unique. The straw also gives the roof an original look. Any roofs can be covered with thatch, regardless of their size.

Distinctive features of a thatched roof from the rest

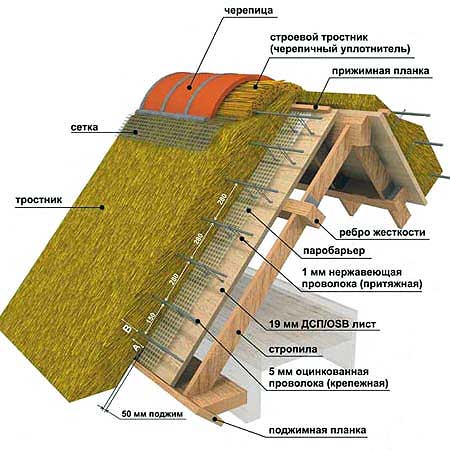

A distinctive feature of this roof is a completely different method of installation when compared with modern roofs that exist today. And if the technological processes are different, does this mean the difference in the structure itself? The answer will be yes, judge for yourself, even the construction "pie" (insulation plates wrapped in waterproofing on both sides) is significantly different from the usual.

Pie ingredients:

- The system of rafters and additional elements made of wood species familiar to us

- OSB sheets, as the main component in the crate

- Special bar as a clamp

- Ribs for stiffening

- Straw sheaves with clamps

- Metal grid

In modern construction, straw roofs are not very popular, but nevertheless, knowledgeable people choose this particular type. She has an alluring uniqueness, in this case you will not have to overpay for it. The device and installation does not have high complexity and does not require high qualifications of workers. Straw is a fairly versatile building material. It can be used to cover any form of roof, whether it is domed or straight.

In conclusion, we can note the fact of tremendous benefits, but such a roof will not suit many, because they will continue to consider it unaccustomed, dangerous and unreliable and, as a result, they will not want to be in such a house. Then you can lay not a residential building, but a gazebo or a shed. Try, experiment and remember that in any business you need to be approached with intelligence and creativity.

DIY thatched roof, garter of sheaves

The quality of a thatched roof will vary in places, which is explained by manual roofing work and sometimes a violation of the requirements for installation and materials.

To obtain a good result, different methods of tying the sheaves are used. Let's take a look at some of them.

1. The method of piercing with a wire.

Laying thatched roof

Laying thatched roof

If there is access to the roof not only from the outside, but also from the inside, then the flashing is performed by two people together. In this case, one of them is outside, and the other guides the needle with the threaded wire from the inside. The guide helps the upper one return the needle downward, bypassing the encountered beam.

If there is no access to the roof from the inside, then a special rounded needle with rings for fastening the wire is used for stitching. This method requires much more strength and skill, and therefore it is used very rarely.

2. Method of stitching with nails.

This method is notable for its convenience and speed of execution and is performed if the grille is correctly mounted that can withstand the entire load. Its disadvantages include the high consumption of nails, which can significantly increase the cost of the firmware.

3. Method of stitching with constrictions.

Bundles are pieces of wood, wire or bamboo stalks 8 mm long. This method can also be used for attaching bundles of reed stalks to the roof, it is often used when decorating the roof, as well as its individual elements.

4. Method of flashing with screws.

The screws to which the wire is attached serve as a replacement for the wire passed under the roof. Fastening is carried out to the lathing or roof beam.In this case, the wire is attached to the screw in advance, providing the length necessary for flashing the area of the entire roof. This is a very simple and quick method that can be performed even by one person, so we will consider the installation of a thatched roof with screws in more detail.

With this type of installation, the sheaves pressed by the wire are fastened to the covered flooring. Plain or glued fiberboard, as well as multilayer plywood or some other similar materials are used as sheathing panels.

Stacking the straw sheaves is an important step in the insulation of the roof, without making a gap between the sheaves and the lower structure, as it is sufficiently tight. Separating the inside from the outside helps to create a comfortable, fireproof and reliable thatched roof.

The surface of the undercoat must be dry, sufficiently strong, even, clean and free from damage. And its tightness is also an important factor.

Pay close attention to the attic windows and chimneys passing through the thatched roof.

So, the creation of a thatched roof is a rather laborious and painstaking process. However, the result will delight the owners of this environmentally friendly, relatively inexpensive and very reliable roof that will serve you for a long time.

Creating a ventilated roof

When creating a warm roof, it is required to provide ventilation of the under-roof space, between the insulation and the roof. This is primarily due to the need:

- preventing the formation of condensation on the crate from the side of the cold attic space;

- ensuring the natural movement of air masses in the attic, by creating ventilation holes, exhaust shafts, special ventilation windows, etc.;

- removing moisture from the thermal insulation layer and wooden elements of the roof structure;

- reducing the possibility of ice formation on the roof surface.

To ensure the entry of air, gaps are made on the lower surface of the cornice, the total width of which cannot be less than 20 millimeters, if the filing is made of wood. When it is made of plastic siding or aluminum, perforated materials must be used for the hem.

Thatched roof technology

Now we come to the most important question, how to make a thatched roof with your own hands? There are several installation methods. At the same time, regardless of the chosen laying technology, all sheaves are oriented in the same way - with butts down

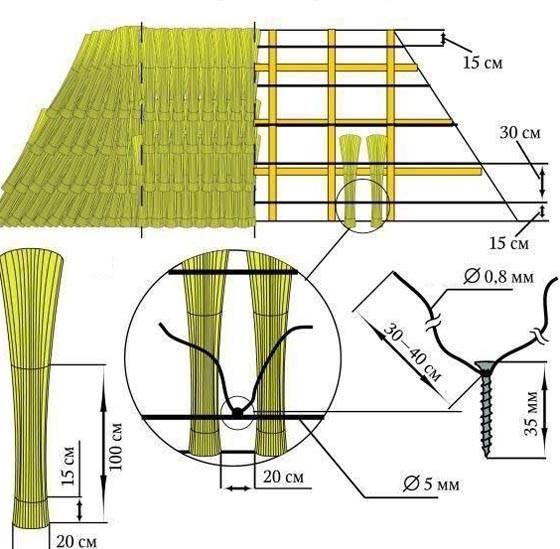

According to the standard, for the arrangement of 1 m2 of a thatched roof with a flooring thickness of 30 cm, on average, 10-12 standard sheaves (20 cm in diameter) are needed, with a vertical pitch of 30 cm. Scheme and main dimensions of the technology of laying a thatched roof

Installation with nails

This is the easiest way to secure the sheaves. It uses long metal pins made of thick galvanized wire. They have one end sharpened, and the other bends in the form of a loop.

The installation process is as follows. The nail is driven into the crate, after which the hook is pressed against the fastening wire located on top of the sheaves and fixing them. The advantage of this method is the ability to do without pulling wire, self-tapping screws and a screwdriver. Installation can be carried out alone, without an assistant. The fixing strength is also quite high. This method can be used on both solid and open battens. Above the surface of the thatched roof, "nails" with a loop at the end are visible

Above the surface of the thatched roof, "nails" with a loop at the end are visible

Installation with self-tapping screws

The fastening wire located on top of the sheaves is wrapped with a pull wire, which in turn is fixed with a loop on a self-tapping screw.

The sequence of installation can be different. In the first version, a screw with a pulling wire is pre-screwed into the flooring, after which sheaves are placed on top. In the second option, the sheaves are first laid. After that, a screw is pushed between them with a thrown loop of the pressure wire and, using a long magnetic bit, is screwed into the flooring.

The use of the second option is preferable, since, by pulling the screw, you can more tightly press the straw sheaves to the base. The advantage of this method is the high strength of the fastening and the efficiency of assembling the thatched roof with your own hands.

Installation with a needle and a loop

This method can only be used for a roof without a continuous protective deck. The installation sequence is as follows:

- The needle, with a wire attached to it, is pulled through the bundles of straw on one side of the sheathing bar.

- On the other side of the timber, a loop is pushed through at a slight angle.

- The wire is threaded with a needle into the loop, then pulled out to the outside of the roof and fixed there on the fastening wire. The loop is inserted at an angle to the needle, after which the wire is pulled to the surface

You can make such tools yourself, and after a little practice, laying a thatched roof can be done alone. With an assistant, the same principle of securing the sheaves can be practiced even without tools. The master, located on the outside of the roof, pushes the wire inside, after which the assistant bends it through the beam and pushes it back.

Special moments of installation

There are two thatched roof elements that require special skills to set up. This is an eavesdropping and a hobbyhorse. Traditionally, double sheaves were used to arrange the eaves in an old Russian hut with a thatched roof. They were put on in the snow on both sides, after which they were pressed with special strips - tied. The swells were fastened to each other with ropes woven from straw - twigs. Today everything is done much more technologically. The sheaves that form the eaves are simply pressed against the wind board and fixed in the usual way - using nails or screws through the fastening wire.

It is recommended to protect the ridge with a special wide semicircular tile, having previously reinforced the sheaves with a metal mesh. However, to make the structure more authentic, many craftsmen cover the ridge with straw mats, fixing them horizontally. Bundles of reeds should be placed under these mats to create a ventilated space. The interweaving of bundles of straw from extreme sheaves is considered to be a special chic. The ridge formed in this way looks very nice. Modern thatched roof house

Modern thatched roof house

Imitation of a straw roof

In our technogenic age, everything natural is copied. Straw is no exception. Roofs are also covered with synthetic imitation of straw ("ersatz-straw", "polymer-straw"). There are already many manufacturing companies both here and abroad.

It is very easy to cover the roof with artificial straw produced by the Dutch company Riethandel E. Prosman b.v

You can even set the color of this material - fresh straw, biennial straw, gray, dark, possible color mixes. “Straws” of the same shape, the most optimized for water drainage, are arranged in small dies, which are easily sewn onto the lathing and form the edge of the roof.

Faux straw strips can be easily sewn onto the battens and form the edge of the roof

Artificial Thatch Roof

The artificial straw roof has the following advantages:

- the possibility of laying on roofs with a small (up to 30 °) slope angle and any, the most bizarre, shape;

- absolute fire resistance without additional processing;

- resistance to decay and discoloration;

- high strength - you can safely walk on such a roof throughout its service life;

- resistance to any precipitation, wind, temperature extremes;

- noise and heat insulation qualities are slightly inferior to natural straw;

- complete unsuitability for the settlement of rodents, insects, parasites, birds;

- durability - lasts much longer than fifty years;

- ease of repair and maintenance;

- lower cost than natural straw.

I did a little marketing research and I was amazed at the results. For any region, the price per square meter of natural straw is about twice as high as that of artificial straw. For example, in the Moscow region, the average price of material for a thatched roof per square meter was about 1,700 rubles, for an artificial one - about 800. four thousand. Despite this, the number of companies operating on the market that supply and install natural material - straw, reeds, reeds - is several times greater than the number of companies dealing with artificial analogs. This directly shows the increased interest of people in natural materials, their desire to live in houses, from the foundation to the roof, which are impeccable from the point of view of ecology. And such statistics are also valid for all regions of our country.

The disadvantages of artificial straw are obvious: it is just a plastic imitation of natural material, and the roof from it looks thin, flat and "combed".

Features of a thatched roof

In terms of the method of laying, straw roofing is significantly different from other coatings popular today. If we talk in detail about what includes a roofing straw pie, then these are:

- flat crate based on OSB sheet;

- clamping bar in the area of the ridge; stiffening ribs located under the OSB plates;

- sheaves of straw, reinforced with special presses;

- metal mesh overlapping the ridge;

- either shingles or sheaves of straw on the roof ridge.

The device does not carry any complexity, it is only necessary to correctly collect and strengthen the bundles of straw on the roof. Moreover, the material can be used on roofs of absolutely any type with any shape. The roof can be gable, semicircular and in the form of a dome. Today, thanks to the work of professional designers, it is possible to create a truly unique, fashionable and inimitable structure that can distinguish a building among the mass of similar buildings and amaze any, even the most demanding critic.

It is not difficult to lay a thatched roof with your own hands; you do not need any special tools, knowledge or skills. It is only necessary to correctly assemble the rafter system, lay on it the crate and support rails, which carry the bulk of the weight. Further, the pre-prepared straw must be collected in sheaves

With the help of a special paddle-cue ball, the coating layer is formed, due to which the coating will lie flat and, as a result, give the roof a harmonious look.

Factors to keep in mind when placing straw on the roof:

- the material must be solid and have an even color, without rot and any signs of burning;

- the clamping wire is best used galvanized. The distance of the first clamp from the bar should be 200 millimeters, the second - 120 millimeters after the first, after that - every 260 - 300 millimeters;

- the fixing wire must have a cross section of 1 millimeter;

- the thickness on which the coating layer is laid depends on the parameters of the slope - its length and slope. If the slope does not exceed 40 degrees, and the length is 7 meters, then the layer thickness can be 22 centimeters at the ridge and 25 centimeters at the base.

There are different ways to tie up the bundles of straw, but professionals recommend doing this with wire and screws.

Thatched roof technology

Roofs made of straw and reed were installed differently in different places. So, in the Russian tradition of roofing, it relied not on the rafter system or crate, but on the slabs - longitudinal guide poles passing through the sheaf. And already these structural elements were attracted to the rafter logs.

Operationally, such a technology may look like this:

The installation of the rafter system from logs is carried out at an angle of 37-45o, the rafters and transfers are attached to the upper crown of the frame, which in this case plays the role of a mauerlat. The upper parts are mounted to the ridge log. In modern conditions, of course, timber is used. For rafter legs, you can use material with a cross section of 40-50x100 mm, for transfers - 50x150 mm. Additionally, you need to install crossbars and wind stops. Other elements inherent in modern rafter systems can be omitted. The load from the roof is low and amounts to 25 kg per square meter of the roof.

The roofing material is placed on the ground in bulk, the sheaves are formed before being fed to the roof.

If the material is overdried, it is sprinkled abundantly with water to soften it before tying. The stems for the production of matings must be soaked in any container for 1–1.5 hours to give them plasticity when twisting.

The lower ends of the sheaves are carefully leveled, if necessary using a cutting tool

This is especially important for the sheaves of the lower row, forming an eaves or overhang in modern terminology. It is better to lay out the first row along a stretched cord.

The sheaves of the first row should be the same in size, forming the thickness of the roof and the eaves even along the length.

Before laying the first row, you need to prepare two even poles with a diameter of 3-4 centimeters

The best material for this is willow, but alder or aspen can also be used. The sheaves of the lower row are pierced with such a pole, called a prituga, through and through along the entire length. It is fastened with knots from an unrooted willow twig to the slugs. For additional stabilization of the preload, holes are made in the rafter legs and stops in the form of wooden stakes are installed.

Roofing is done by two people. One person places and compacts the sheaves from above, and then inserts the knitting material (vine or wire). The second for knitting attracts the coating to the slabs and fixes it.

The sheaves of the roof are fixed by tying from willow rods (wire) to the slabs. Considering the way they are installed, it is obvious that the gap between the roofing and the upper crown of the log house is also overlapped. For greater reliability, the place of conjugation of the roof with the frame is laid with rolls - a mixture of clay and straw in the form of balls with a diameter of 10-12 centimeters.

The second row of the coating is laid on top of the first in such a way that the places where the sheaves are knitted overlap, that is, by approximately 2/3 of their length. As a result, a protrusion is formed. It is pierced with spatulas and nails. At the same time, the covering is compacted due to the penetration of straws of the upper row between the lower ones, and the roofing becomes even. The sheaves are also fastened with wicker knots, which are currently being replaced by pieces of stainless or galvanized wire. The next rows of sheaves are installed in the same order.

The ends of the upper row on the ridge transition are bent to the opposite slope.

The opposite slope is formed in the same way. As a result, a double layer of covering stems is formed on the ridge. They are attached to the slabs by knitting.

The slopes along the ridge are most susceptible to wind loads. Therefore, they are additionally strengthened with the so-called goats. Two poles with a diameter of 3-4 centimeters are tied crosswise with thick ends and are located on both sides of the ridge parallel to the direction of laying the sheaves. The distance between them should be 30-40 centimeters. The goats are fastened by knitting to the slabs.

At the end of the installation of the roof, at its ends, moorings from a board up to 20 centimeters wide are installed, protecting the roof from the wind.

Depending on the size of the roof, the thickness of the roof can be up to 50 centimeters. Over time, under the influence of precipitation and wind, it decreases to 35–40 centimeters. Therefore, the knits need to be tightened from time to time.

The technology for using simulants of straw or reeds is exactly the same as described for natural materials.

Elements of the rafter system

The main part of the rafter system is the rafter. In addition, the design contains the following main elements:

- mauerlat - a timber made from coniferous trees is used for it. It is necessary to connect brick, concrete, as well as metal parts of the building and the rafter system. Transfers the load from the weight of the roof to the walls of the building. The most commonly used dimensions of the Mauerlat are 150x100 millimeters, or 150x150 millimeters, much less often you can find a bar with a section of 100x100 or 200x200 millimeters;

- beds - are necessary to remove the weight load from the floor, which is transmitted from the roof structure through the racks. In this way, the influence of the weight of the roof is redirected over a larger area. The size of the bed depends on the parameter of the racks. The main thing is that the rack is fully supported on the bed;

- racks - perform the function of columns that support the run and rest on the beds;

- girder - is a bar made of natural wood, it does not allow the rafters to bend. This element of the roof of the house is used in the truss structure when heavy roofing materials are used on long slopes;

- the rafter is the main part of the frame system; with its help, the skeleton of the roof is built. It is impossible to calculate the roof structure and draw up a project without calculating the dimensions of the rafters.

Preliminary preparation of supporting structures

When preparing the rafter system, special attention should be paid to the places where the sheaves of straw adhere to the chimney. They must be separated by a non-combustible material with good thermal insulation.

The chimney itself must exceed the height of the roof ridge by at least 1 m. Inside the chimney, a metal mesh deflector must be installed to catch sparks. Air vents, ventilation openings, dormers and ordinary windows are prepared before the start of the main stage of installation of the roof covering. They are sheathed with the same layers of roofing cake as the main roof plane.

Sheaves should be prepared in sufficient quantities. The straw should be dry, not wrinkled or rotten. The ends of the sheaves are aligned. All lumber used in the construction of truss structures is treated with fire retardants and antiseptics. For processing with fire retardants, both external and internal, it is also recommended to tuck the roofing material itself.

Harvesting of reeds, straw

The time for the procurement of this roofing material is - frosty autumn or the beginning of winter. Of course, the time of the year does not greatly affect, but the main thing is frost. It is thanks to him that all plants "freeze" and the harvesting season begins, during which all cut reeds are collected under a canopy and thoroughly dried.

After drying, it is time to sort by quality, diameter and length. This is a rather painstaking work, but very necessary, because stems with mechanical damage, porous core or rot will no longer be used. It is also worthwhile to weed out accidentally caught herbs, leaves and plants.

The diameter of the reed should generally be 5mm. This value is most suitable as a roof covering, and if you have to deal with large numbers, then such material will go to the lower base.

The length of the reeds should be in the range of 1.5-2m. If their length is less than these values, then they are set aside for processing styles.