Features of metal models

The metal structure is the most durable.

The following structures can be distinguished by the type of frame:

- welded or stationary, where the elements are fixed by welding;

- collapsible - such a structure is easy to disassemble and move to any place.

Based on the reference configurations, the following are distinguished:

- A-shaped support. Consists of two logs connected at the top. The crossbeams are connected with a jumper to provide rigidity to the frame.

- U-shaped frame. Support pipes with a crossbar are connected in the form of the letter "P". It is the simplest to construct. To make the structure more stable, it is necessary to bury the pipes and fill with concrete mortar.

A stationary swing is installed on a foundation; strong wooden beams are used for the structure.

A hanging swing is a simple design that consists of a double or single seat suspended by cables, chains or ropes from a bar or tree.

Swing drawings

Currently, on the Internet, you can find a large number of drawings of metal swing structures.

You can make the swing made of metal portable or stationary.

For children's games at the summer cottage, you can equip a special playground.

Portable swing

When mounting and installing a portable swing, 4 pins from the reinforcement are used to fix the legs. The ends of the pins can be easily bent with a vice to keep the swing stable and prevent it from tipping over.

When installing such a swing, the pins are driven into the ground, and if they need to be moved to another place, they are simply pulled out of the ground.

Garden swings are welded for safety, and kerchiefs are welded at the joints. Gussets are metal triangles that are welded at the corners of the crossbeam connection with the supports.

They provide rigidity and reliability of the swing structure. Portable swings are very convenient because they can be removed for the winter so that they do not rust from snow.

Stationary swing

They are convenient to use on a site that has a large area.

According to safety regulations, when operating a swing, the back and front of the structure should be free about two to three meters.

Helpful advice! After you install the swing, they must be painted with any metal paint. This will make your swing more attractive and protect it from rust.

Do-it-yourself swing from a profile pipe

To create a swing for a summer residence made of metal with your own hands, it is necessary to provide for the presence of the following components:

- quadrangular frame (it should become a carrier in the finished swing);

- A-shaped sidewall. It is made by welding several beams;

- one long tube. It will become the basis for attaching the swing bench.

The cover of this design can be plastic, wood or tarpaulin.

Next, you need to act according to a step-by-step algorithm.

How to make a swing with your own hands from metal

The process of installing a swing for a garden with your own hands consists of the following steps.

- Using a grinder, we cut the material into separate fragments. For this, it is necessary to have a preliminary scheme according to which, in accordance with the dimensions, to make blanks.

- We grind the boards using a special machine or manually using emery.

- We connect all the necessary parts to each other using special fasteners, bolts or welds.

- We dig 4 holes in the ground, install a metal swing for a summer residence and fill it with concrete. Next, we paint the structure.

The construction and design of the product can be of any kind.The more complex the frame design, the longer the swing will take.

As a result, you get an individual forged swing for a summer residence. For such a product, it is necessary to have a preliminary diagram showing all dimensions.

Sofa swing for summer cottages

Country swing sofas are in great demand. If it is not possible to buy them, then they try to make them with their own hands. Metal versions are highly durable. And if it is also properly processed, then it will not be afraid of moisture.

Tools and materials for manufacturing

For production, you will need metal profiles, a welding machine and a seating material. Usually a tree is used for such purposes. In addition, you will also need material for the roof. Those who plan to use polycarbonate should know that it is hot enough under it in sunny weather, and it is not practical during hail (the material starts to crack). It is ideal to take a tarp.

How to make a garden swing with your own hands from metal: instructions with a photo

We proceed to follow the instructions for assembling a garden swing.

| Illustration | Description of action |

|---|---|

|

We carry out welding of the frame. You can take your own sizes. It all depends on how much material you have at your disposal. As a result, you should get such a basis as in the photo. |

|

We weld the frame for the swing, to which the sofa will be attached. Next, we bend the arc from the metal profile. They will play the role of armrests |

|

We hang the finished part on the carabiners. Next, we are preparing the tree. |

|

The finished version should look like this. The swing is laid out on the sofa. The upper part of the frame is attached to the frame with strong chains. All metal parts must be primed and then painted |

To keep the bed soft, it can be sheathed with a special fabric or periodically placed on top of a mattress and pillows for rest.

Dear readers, if you do not understand enough about the question of how to make a garden swing with your own hands, do not hesitate to ask questions and share your opinion. Our team will definitely contact you as soon as possible.

Garden swing with supports

What do you need

- Bar 100 × 100 mm;

- timber 50 × 50 mm;

- galvanized chain;

- board 25 × 100 mm;

- bolts;

- mounting plates;

- screws;

- sanding paper;

- hacksaw;

- jigsaw;

- roulette;

- pencil.

How to do

1. Cut four racks 195 cm high from a 100 × 100 mm bar.

2. Assemble two supports in the form of the letter "A" with upper and lower jibs from a bar of 50 × 50 mm. Drill through the parts and bolt.

3. Cut a cross-piece 1.8 m long from a 100 × 100 mm bar and fasten it to the upper supports of the uprights by tightening them with bolts.

4. Saw six boards 120 cm long: three for the backrest and three more for the seat.

5. On the top board of the back, if desired, cut a pattern with a jigsaw. Sand everything well with sandpaper.

6. Attach three boards with screws to pieces of timber 50 × 50 mm - this will be a seat.

Do the same for the backrest and join the two pieces together at the desired angle.

7. Saw the armrests out of two planks and attach them with screws through the timber to the seat and backrest.

8. Drill bolt holes in the beam and install them through the chain link. Fix it with a nut on top, and so that it does not fall into the tree, place a metal plate or a large-diameter washer.

9. Make holes in the seat beams, insert bolts into them and secure the ends of the chains.

10. Adjust the length of the hangers to the desired position.

What can be changed

- For added strength, you can add another cross-piece along the bottom of the rear of the legs.

- If desired, build a polycarbonate or tarp canopy to protect from the sun and precipitation.

We mount a garden swing with our own hands

It will not be difficult to make a do-it-yourself garden swing device on your site when the preparatory stage is done in good faith.Wooden models that are offered for installation require a flat surface. It is advisable to carry out the work with a partner so that it is convenient. We begin to mount the elements of the garden rocking chair from the prepared material:

- We make a base in the shape of the letter "A", for this we take prepared logs with parameters: 2.5 meters by 120 millimeters thick - 2 pieces, and 2.1 meters long by 90 millimeters thick - 1 piece. The transverse log is superimposed on the main one, taking into account the indentation.

- At the intersection of the logs, it is necessary to drill holes, then we tighten the entire structure with prepared bolts. With a grinder or a hacksaw for metal, it is necessary to cut the remaining length of the bolts, for aesthetics and safety. We also assemble the second part of the rocking device.

Bench making

From how this node of garden swing devices will be made, comfort and convenience will depend. It is necessary to choose such an angle of inclination of the seat so that it is convenient for all family members, it is necessary to conduct a survey, especially in children. What is the angle of the bench? If you do it at a right angle, then the ratio of the back to the seat will not give comfort and relaxation.

If a little, just 10 degrees to make the angle more up to 100 degrees, you will immediately feel that you can lean on the back of the bench. It is necessary to take the prepared bars of 60x60 millimeters, and applying them, we dilute them to the required angle, it may not be quite accurate, an obtuse angle of 95-100 degrees will turn out. Using a pencil, we make marks on the bars, we get our size, and places for sampling with a chisel. Sampling is necessary for a better connection and a nice looking bench.

It is necessary to carry out work in the sequence:

- We take a chisel, a hacksaw and do the following: washed it down with a hacksaw along the pencil marks, select wood with a chisel inside the saws. We try on the bars, to each other and earn extra money with a chisel.

- When we have achieved the perfect connection, in the center we drill a hole for a bolted connection, in two bars at once, then it is advisable to cover the samples with PVA and connect everything with a bolt. Cut off the excess length of the bolt with a grinder.

- We attach armrests to the bases made (logs: length 100 centimeters, diameter 80 millimeters). Using the hole made by the drill, we connect them with bolts, after putting on the chains.

- The resulting triangular structures must be connected with boards 1.8x 0.14x0.04 meters. Difficulties cannot arise here. With the help of self-tapping screws, the boards are attached to the foundations of the future bench. After the work done, we will see the finished element of a garden swing, a bench.

Making the roof

We prepare the beams for the rafters, take the prepared timber 60x60 900 mm long and 60x60 500 mm long, collect 3 triangles with the parameters: 560x560x960. The kanevka of a swing from a log 2.8 meters long and 140 millimeters thick must be placed inside these triangles.

How to equip a tree swing?

The simplest type of garden swing is to mount it on a tree branch. If there is a sufficiently old tree in the garden at the summer cottage, a branch of which can be used to fasten the rope, the question of their arrangement is solved simply:

Classic version with a plank and a pair of nylon cables for fastening

For this purpose, we pay attention to the fastening of the cables, using the safest knot. We drill holes in the plank and pass a cable through them, which is attached to a tree branch.

It is better to use oak for these purposes, if there is one.

If not, it is necessary to carry out activities: inspect the branch on which they will be attached, it should not have cracks and be sick.

If chains are used for reliability, they must be put in a plastic tube so that fingers do not get caught in the chain links.

It is necessary to check the condition of the branch on which the gurney is mounted on a weekly basis for safety. When kids want to ride them, check them out for yourself.

Basic Requirements

Before starting work, you need to familiarize yourself with a number of requirements, the observance of which will allow you to create a quality product. Since garden swings are considered quite traumatic, it is necessary to take good care that no curious situations overshadow the rest. All elements must be reliable. And during operation, it is impossible that there are objects nearby that can become an obstacle to the maximum swing of the swing.

As a rule, children love to swing. But sometimes adults do not mind taking a break after hard work days. When deciding how to make a swing, it is imperative to provide for a high carrying capacity and maximum dynamic load. A strong swing frame is essential for safety.

Depending on where the swing will be installed, it is chosen from what to make them. Most often they are used in the garden, outdoors. Building materials, accordingly, must have characteristics that are resistant to atmospheric phenomena. Then they will last a long time. We should not forget about the appearance. In order to give your hand-made garden swing a neat look, you need to choose materials that are easy to care for.

Having analyzed all the requirements and decided on the parameters, you can choose the type of product. By the method of installation, they are distinguished:

- Mobile. If the exact place for their installation does not exist, then it is better to opt for a portable model to the country. Then the swing can be rearranged to any convenient place.

- Stationary. When creating a swing with your own hands, the installation site is determined once, it remains unchanged throughout the entire period of operation.

According to the principle of the device, they are distinguished:

- Suspended. The seat is attached to the frame by means of hangers.

- Wireframe. They are characterized by a one-piece frame, welded from pipes or made from wooden beams.

As for building materials, the most popular are do-it-yourself garden swings made of metal, wood, or a combination of them. All of the above designs meet the requirements to one degree or another. However, if you put safety in the first place, then the stationary frame swing made of metal will be the best option. Compared to other options, they have greater stability and carrying capacity.

Assembling the swing

Putting the frame together. Better to start with the sides of the swing. Measure and cut the pipes according to the drawings, using a grinder. Check the identical dimensions of all four elements from which the sidewalls will be assembled. Using a welding machine, connect the prepared pipes in pairs, making two identical structures in the form of the letter L.

Then the sharp upper end of each structure should be sawed off at the same level, having prepared the platforms on which the horizontal beam of the swing will rest. It is better to carry out work according to a previously prepared template.

The short sides of the base frame should be sized to match the distance between the bottom ends of the resulting sidewalls. They are connected by welding to long base elements, the size of which corresponds to the drawing. The sidewalls and the upper horizontal tube are welded to the base frame. Assembling a metal swing requires checking the geometry of the structure at each stage: the side planes should be located strictly vertically, and the beam for hanging the bench should be parallel to the base. Use a building level to check.

Bench. For the manufacture of the frame, it is most convenient to use a steel corner. For the bench to be comfortable, the back should be approximately 120 degrees to the seat. A triangular cutout (60 degrees) on one of the shelves will help to bend the corner correctly. The frame can also be made by welding from a rectangular pipe of a suitable section. The sides are connected by horizontal bridges at the edges and at the bend of the structure.If desired, armrests of a suitable shape can be made.

The seat and back of the bench are made of sanded planks or cut-to-size blocks. For fastening wooden elements, holes for bolts are drilled in them and in the frame. It is advisable to completely drown their heads in the wood, making the appropriate indentations. Before assembling the bench, wooden elements are impregnated with an antiseptic and varnished, metal elements are primed and painted.

At the corners of the bench frame, install the eyebolts - bolts - chains will be attached to their ears for hanging with carabiners with a latch or a threaded coupling.

The same eye bolts are mounted on the upper beam of the swing - above the edges of the bench or at the corners of the structure, at the junction of the sidewalls and the horizontal element. In the second case, the bench will practically not dangle from side to side.

Instead of eyebolts on the horizontal beam, you can attach special blocks for hanging the swing, equipped with bearings - this system is more comfortable to use. The blocks are bolted through through holes in the horizontal beam. The chains are adjustable in length so that the bench is parallel to the base with a slight slope towards the back.

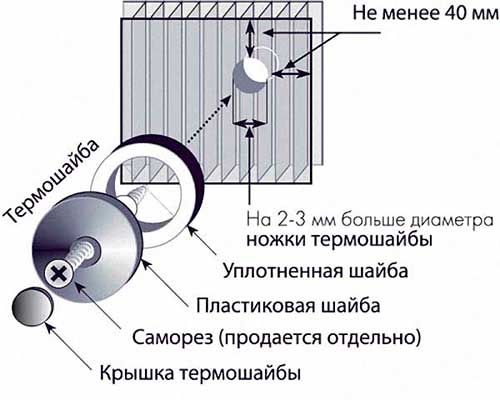

We make a visor. It will protect people sitting on swings from precipitation and the scorching sun. The rectangular structure of a metal frame with bridges and a sheet of cellular polycarbonate is mounted at a slight angle so that precipitation can flow freely to the ground. The frame of the visor is welded from rectangular tubes of small cross-section. Then the visor is welded at an angle to the top of the swing frame. After the completion of all work, the entire structure is primed and painted.

The honeycomb polycarbonate cover is attached to the frame with special self-tapping screws with sealing washers. The ends of the sheet material should be covered with a polymer profile to protect against dust and insects.

It is advisable to securely attach the finished swing to the platform. If the structure is installed on solid ground, the frame can be secured with several reinforcing bar clamps. The ends of the clamps should be sharpened and go into the ground for about half a meter. The swing is attached to the concrete platform using anchor bolts pre-installed in the right places. After tightening the nuts, the protruding threaded part is cut off with a grinder.

Video on the topic "do-it-yourself garden swing made of metal":

Decorating process

After the swing is mounted, you need to take care of their appearance. It is easiest to paint them with oil paint. This method is suitable for both wooden and metal structures. You can dream up and make the swing especially attractive for children.

The easiest way to decorate is painting with paint

Do not neglect the rules of using a children's swing, which will help to avoid injury. It is forbidden:

- Get too close to them when using them by other children.

- Sway while standing, resting your feet on the seat.

- Twist ropes, chains or other hanging elements.

- Get off the swing before it comes to a complete stop.

- Sit on one seat for several children at once.

Before operating the swing, it is necessary to carefully inspect all nodes and connections for their integrity and functionality. Lubricate the swing regularly to prevent rust and squeak. Make sure there are no sharp objects, protruding bolts, or unpolished wood in the structure.

It's easy to make a swing with your own hands. The main thing is to adhere to the manufacturing technology of the product and the recommendations of specialists.