Materials (edit)

New types of street coverings are constantly appearing on the building materials market, many of which are used in garden plots.

Concrete

They purchase ready-made tiles or make laying panels on their own using curly shapes. This is an economical and original way of arranging passages.

It should be borne in mind that the strength of self-made concrete structures is low. They are not designed for loaded cars.

Landscaping molds for vibration casting are convenient, they can be made independently from a piece of foam.

Plastic garden paths

Plastic garden paths are made from scrap materials or ready-made panels are purchased. Tracks made of colored bottle corks look unusual. They are placed on a sand and gravel cushion.

You can create drawings, mosaic compositions. Children are involved in the process of arranging paths.

Pebbles, rubble

They are laid on a layer of sand of at least 10 cm, the sharp edges of crushed stone are smoothed out with a surface grinder.

Large stones are chosen for the curbs. In dry weather, they are covered with penoplex or used lubricants to make the stone shine.

Artificial or natural stone

They immediately purchase tiles and borders for garden paths, they are laid at intervals so that the water leaves. Drainage must be done under the stone paths.

Wood

With a variety of antifungal impregnations, this material becomes durable. Paths are laid with round timber - trunk cuts or separate planks.

For low-lying places where groundwater lies close, such material is not suitable.

Decking

When independently arranging garden paths, many factors must be taken into account, then the paths along the site will be durable, comfortable and beautiful.

Question answer

What tree species are best suited for garden paths?

The best option is oak or larch. The wood of these trees has a higher resistance to external influences, and, therefore, paths made of it will be more durable and strong.

How can you make a concrete walkway more visually interesting?

To make a concrete pathway look original and stylish, you can decorate it with various unusual pebbles, river pebbles, glass pieces or even shells even before the concrete solution is completely set.

Can leftover porcelain stoneware tiles be used for garden decking?

Yes. It is not only possible, but also necessary. After laying out the fragments of tiles, you can achieve a truly interesting result, creating a real masterpiece of landscape design. The remains of tiles of different shapes and colors open up a huge space for the flight of imagination. Moreover, it will save a significant amount of money in the family budget.

What are the characteristics of rubber tracks for summer cottages?

Rubber tiles are made from recycled car tires. In terms of its characteristics and appearance, the material is in no way inferior to competitors: the rough surface shows itself perfectly in winter, preventing slipping. The advantage is the possibility of sound insulation, which is why such tiles are often used on basketball and playgrounds.

In addition, the material prevents the formation of puddles and, which is very important, does not emit toxic substances. And the abundance of shades of paths will help create a neat and beautiful path.

What are the features of paths made of plastic plates?

Mobile plastic walkways are very easy to install and do not need to be covered underneath. The material is collected using fasteners, by adjusting which you can create a path of different widths and shapes. The connecting elements in the lower part of the slabs are large enough and firmly connect the elements, in addition, performing the function of a support.

The material has excellent properties: it is non-slip and can withstand high and low temperatures. Since there are many holes on the surface of the tiles, water flows directly into them, preventing the formation of puddles. In addition to simplicity in laying, the stove is easy to assemble in winter and place in any outbuilding. By the way, several tiles can be laid out in front of the front door in winter: the corrugated surface will prevent you from slipping and falling.

DIY concrete laying of a garden path

- Initially, the width and length of the future path are measured. Its depth should be no more than ten centimeters.

- After that, the structure is sprinkled with sand and carefully compacted. After it is spilled with water.

- Next, the frames are mounted. Most often they are made from wooden planks or pieces of plywood. The distances between them should be up to five centimeters. The width should be the same as the width of the future path.

- The frame is filled with concrete mortar.

- When it dries up a little, you can lay out various decorative elements. Many things can be used from tiles to shells.

- The track should dry out for about three days.

- The ground left between the slabs can also be decorated. It can be planted with different plants, for example, a lawn.

Benefits of using track molds

Of course, many people choose the most classic method of tiling or pavers. However, such a formation looks a bit formulaic, and it turns out to be quite costly. For this reason, almost all owners of country houses decide to build garden paths on their own plot using forms. This gives you the opportunity to express your imagination in landscape design.

Paths in the garden, laid out in this way, work out, as a rule, very elegant. And, in comparison with conventional technologies, they have important advantages, for example:

- the minimum level of costs for the construction of work;

- the ability to produce tracks of various sizes and configurations;

- simplicity of the work execution process.

Creating a path using forms, they can be filled with various materials, for example: marble chips, pebbles and other materials that will create an originality of the path. However, before you start tinkering the paths, you should perform certain preliminary work on the marking.

Using a special shape, you can build a very beautiful track in appearance. Such coverage is quite popular among summer residents and owners of suburban real estate due to the simplicity of production and the low cost of raw materials.

It is important to know that when constructing a track, you need to take care of drainage. To do this, it is possible to place it on elevated areas or tinker at a certain angle for water drainage.

Otherwise, cracking of the coating may occur during the frost period.

Paving slabs

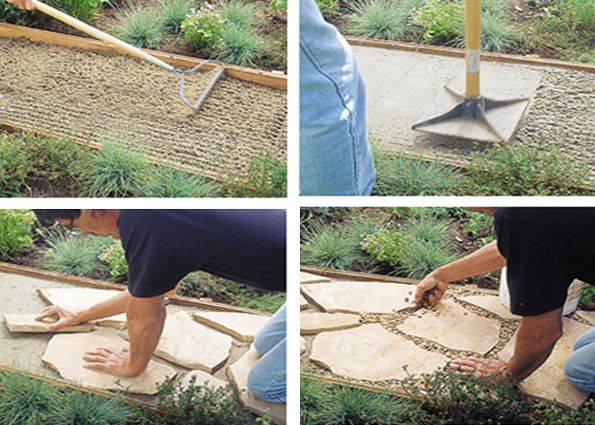

This material is of artificial origin and is often used for decoration on city streets. Today paving slabs are offered in a wide range, where you can find options that differ in their shape, size and color scheme. However, given that it will be used to build a path in the country, it is best to use small-format stones. The very process of creating a walkway from paving slabs will look like this:

- At the first stage, it is necessary to level the sand cushion, for which a trowel or spatula is used;

- Tiles are placed on the prepared layer of sand, and then light blows are applied to them with a rubber hammer in order to firmly fix them in the base;

- To maintain the overall level of the surface, a block of wood should be used. With its help, it is easy to identify tiles that do not correspond to the general structure. To improve its position, they begin to inflict stronger blows on it with a hammer, first placing a bar on the surface of the tile.

Although the prices for paving slabs are quite high, however, deciding to choose this material option for a summer cottage path, you will be able to create a beautiful element of your summer cottage. The laying process itself is usually carried out in the form of a straight geometrically delineated line.

Clinker brick garden paths

A rather solid and aesthetic road emerges from it. For its durability, it is recommended to select high quality clinker bricks.

The base for it, with the rolled upper sandy layer, must be smoothed out using the "rule". It can be constructed from a plank with flawlessly smooth and smooth end faces. The plank must be 200 mm larger than the scale of the roadway. The corners of the lower component of the plank are equal to the thickness of the brick.

After leveling the sandy mass, the installation of the side blocks begins, they are installed on an edge half the width into the ground with a rubber hammer. The sides are fixed: with curbs; solution; or fittings. Then the additional layer of crushed stone is thoroughly compressed.

Having fixed the side parts along the edges, they determine the type of pattern for decorating the middle part. They are laid out in two main versions, it is placed on the end or on its wide side.

For the strength of the masonry, the 1st row must be put in length, and the next one across the path, tamping the bricks into the sandy base. However, for reliability, they are fastened with glue on a cement base.

The solution is placed in such a way that its excess does not protrude over the masonry.

For durability, brick paths are impregnated with a primer

To make the track last a long time, you should choose high-quality materials

After the end of the laying of all blocks, the seams are filled with sand. It is evenly spread with a long-bristled brush.

After the solution has hardened, the formwork is removed

Crushed stone of the middle fraction is poured along the edge and carefully compacted, and on top of it another layer of crushed stone is added

For durability and brightness of the tone, the brick is treated with a penetrating primer, the dried material is painted over with a specialized stone varnish.

Arrangement of concrete paths in the country with your own hands

In the past, the garden was often covered with concrete mixes. Today, these faceless paths have been replaced by other structures - from concrete forms.

Advantages:

- durability;

- practicality;

- spectacular appearance;

- the ability to create coatings "like a stone".

Molds are made of wood or buy polypropylene stencils. They are designed for about a thousand fillings, differ in size and configuration of jumpers.

Stages of work:

- coverage marking;

- drawing up a diagram;

- trench preparation;

- compaction of the bottom, backfilling of crushed stone or fine gravel;

- laying a layer of geotextile;

- backfilling of the sand layer.

It is not recommended to use polyethylene for the bases, since then moisture will accumulate in the trench.

Mix the mortar for pouring forms: cement - 1 part, sand - 3 parts. It is advisable to lubricate the form with machine oil, so it will be easier to work with the solution.

Install the form on the base, carefully pour the solution, leveling the surface. Remove the excess with a trowel, then wait 20-30 minutes. The solution “grasps”, the mold is taken out and placed in another place for pouring the next portion.

On a note!

To increase the speed, it is recommended to use 2-3 stencils.

After the installation is completed, the gaps are filled with a mixture of cement and sand so that the coating is even. Complete solidification occurs in 4-5 days. For the best result, the surface is constantly moistened and covered with a tarp.

Instead of a cement mixture, soil is sometimes poured into the gaps and a lawn is sown. Get an original concrete track interspersed with green seams.

If desired, dyes-pigments are added to the cement mixture. The coatings into which decorative elements are pressed in look original:

- seashells;

- pebbles;

- shards of glass;

- shards of tiles.

Using purchased or homemade forms, straight, winding paths are made.

Pros and cons of different materials

Today there is a huge selection of materials, the origin of which can be both natural and artificial. Each of them has its own advantages and disadvantages, which should be familiarized with before making the final choice.

Did you know? According to the teachings of Feng Shui, garden paths carry the main vital energy of Qi, which means that their route should be winding and smooth, which will allow it to be evenly distributed throughout the entire site.

Natural stones

Among the wide range of natural stone, which can even confuse an inexperienced builder, the most popular are:

- shale - rocks of a rock, which include parallel mineral intergrowths;

- granite - is an igneous rock consisting of quartz, plagioclase, mica and potassium spar;

- shungite (also called "slate stone") - a rock that can be found in black, brown or dark gray;

- sandstone - a stone consisting of detrital sedimentary grains, ranging in size from 0.5 to 2 mm, interconnected by mineral substances;

- quartzite is a hard rock, consisting mainly of quartz and known to be difficult to work;

- cobblestone - a natural stone of small size and round shape;

- pebbles - fragments of natural stones that have passed different degrees of rolling.

- Despite the different characteristics, natural stone has general advantages over artificial:

- high decorative qualities;

- wide choose;

- ease of installation, which makes it easy to manage on your own when paving paths;

- long period of operation (more than 300 years);

- high rates of heat resistance and frost resistance.

- The use of natural stone also has some disadvantages:

- high material cost;

- the need to use special vehicles to transport the stone (due to its massiveness);

- compulsory drawing up of at least a small project with sketches and calculations.

Artificial materials

The building materials market also offers a huge selection of various artificial materials, among which they are usually used:

- paving slabs;

- concrete;

- paving stones;

- porcelain stoneware and others.

Among the advantages of using such materials, they note their low, in comparison with natural, cost, simplicity and speed of installation, a wide range, as well as the possibility of creating an exclusive decoration. The main disadvantages are the need to install a drainage system in regions with unstable climatic conditions (for example, frequent heavy rains), as well as a short service life.

Path of tiles and ceramic tiles

Remains of tiles after construction or renovation may well be used for laying paths in the garden. Moreover, not only whole tiles will be used, but also individual pieces.

Whole paths can be arranged both as an independent material, and in combination with facing brick or natural stone.

Pieces of ceramics and tiles can be laid out in a beautiful mosaic or in the form of a thematic picture. However, this will take a lot of perseverance and a lot of time. But the result will please.

To decorate the tracks from this material, proceed as follows:

- By established standards, they dig a trench 10 centimeters deep for the track.Crushed stone is poured onto the bottom in a thin even layer and carefully tamped.

- To strengthen the base and give it strength, reinforcement is made from a thick metal mesh.

- A concrete solution is prepared, the track is poured and leveled. The pattern or pattern of tile pieces is started to be laid when the cement composition starts to set slightly. To make the work go faster, the drawing is laid out in advance next to the track. Then it is only transferred to solidified concrete.

- After laying the tiles, the seams are rubbed.

If whole tiles and pieces are laid out, then large elements should be placed along the edge and in the center, and the space between them should be filled with smaller ones.

As borders, you can use glass bottles with sand, turned upside down, as in the photo.

Construction of a walkway using curly shapes (master class)

Today, shops and manufacturing companies offer many forms for self-made garden alleys. One or two is enough to quickly and beautifully lay out the original track in the country with your own hands. The molds are made of durable material and are reusable.

Execution of works:

First, mark the path, taking into account the size of the forms. As a rule, they have a standard size of 60x60 cm.

That is, the track can be made 60 cm or 1.2 m wide. The shapes have such contours that they closely adjoin one another, like children's puzzles. When building a wider track, two forms are laid at once across the trench. If the path is not so wide, then two forms are installed along the trench.

A bed for the path is dug out according to the markings, immediately leveling the bottom. The earthen base is thoroughly rammed using a special device - an electric vibrator. If this process is done manually, it takes a lot of effort and time.

At the bottom of the tamped trench, pebbles or gravel are poured into an even layer, then sand. Prepared forms are poured abundantly and installed - they are pre-coated with machine or ordinary vegetable oil.

Prepare a solution for pouring, observing the following proportions: for 1 part of cement, take 3 parts of sand and 4 parts of water. A plasticizer is added to the mixture, it serves for better bonding and gives the solution strength and elasticity. Water is added to the mixed dry components in small portions. The consistency of the finished solution should be similar to thick sour cream. When the solution is ready, paint can be added to it to make the track colorful and bright.

The finished solution is carefully poured into all the cells of the mold, trying to avoid air bubbles. Excess mortar is removed using a wooden or plastic strip.

Within an hour, the solution sticks, and the mold can be carefully removed. It is shifted next to the flooded area and the path is continued to fill.

You can additionally decorate the track by pressing decorative elements into the semi-baked solution. The composition dries completely after 3-4 days, so it should be protected from children and animals by placing fences or covering it with protective material.

As you can see, even from improvised materials, you can make a beautiful and original garden path in the country with your own hands. Photos of the options presented will help you understand the manufacturing process and inspire original ideas.

Step-by-step instructions for creating a track

The preparation of a drainage concrete solution and the production of a garden path from the resulting material is, in fact, a single and continuous process.

Important! Do not mix water-permeable concrete at temperatures below + 5 ° C.

After the foundation for future passages has been laid, and all the necessary materials have been prepared, the work should proceed quickly and quickly according to the following scheme:

- Mix the required amount of solution.

- Lay out the finished layer in the prepared trench so as to immediately fill the specified volume along the entire length of the passage. The thickness of the coating should be approximately 10 cm.Overlaps and joints should not be allowed, since in this case the formation of irregularities or sagging will inevitably entail loss of strength and rapid destruction of the finished structure.

- Align the preparation track with a roller (you can use a special roller, a lawn roller or make a device with your own hands, for example, from a metal pipe, a used gas cylinder or, in extreme cases, a plastic bottle filled with any heavy material - liquid or loose).

- Cover the track with a tarpaulin, plastic wrap or other waterproof material until it solidifies completely. Leave it on for a few days.

- If desired, lay paving slabs on top. The joints between the tiles can be sealed with the same porous concrete, but when preparing it, use crushed stone of the minimum fraction.

Wooden paths: practical and functional

In regions where there is no shortage of wood, wooden boards and saw cuts of logs are used to arrange sites. The cost is determined by the type of wood, the selected processing methods. Wood is exposed to moisture, temperature changes, so it is necessary to use additional processing of the material and impregnation to increase the service life.

Wooden flooring is versatile and practical, it goes well with lawns, flower beds and flower beds. In rustic areas, these materials look best. Economical options:

- boards, bars left over from construction work;

- cuts of trunks and thick branches of old trees from their site.

Decking coverings, which are based on thermowood or polymer materials, will cost more. For such sidewalks, you will have to prepare the base, equip the logs.

The best wood is larch or oak, which is less prone to rotting and decay. They also use the wood of conifers (pine, spruce), aspen.

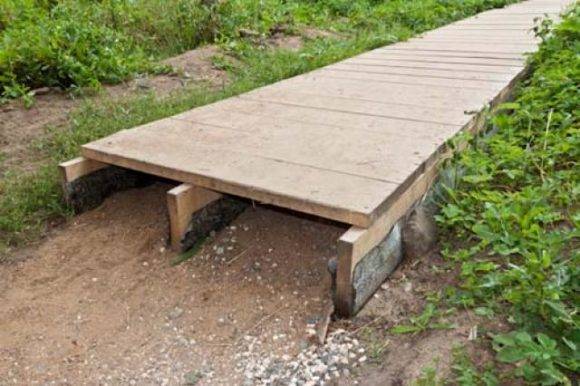

Wooden flooring

Sidewalks are built above the ground to form walkways. The gasket is made using lags that provide ventilation and a longer service life of the structures. The main stages of work:

- schema planning;

- preparation of logs - bars and boards for flooring;

- removal of sod and the upper part of the soil (approximately 25-30 cm);

- careful compaction of the base;

- dusting with sand (thin layer) and crushed stone;

- treatment of bars with waterproofing compounds, mastic to protect against moisture;

- antiseptic treatment of boards;

- laying bars on crushed stone;

- installation of boards, fastening with screws or nails.

On a note!

The width of the covering is 80-100 cm. With such dimensions it is convenient to move along the flooring.

The nails should be completely “sunk” in the wood to the “heads”, not sticking out. Sometimes the flooring is done immediately on the ground, without lags. Wooden paths in the country look natural, beautiful, but the boards quickly deteriorate. Floorings on logs are more durable, reliable and practical.

Dug-in paths for the site

With this method, boards or log cuts are used. The material is dug into the ground, while it protrudes slightly or lies flush with the surface. Untreated wood will quickly rot, so the dies are treated with an antiseptic composition. The upper part is covered with varnish.

The height of the cuts is 15-18 cm. The diameters should be approximately the same, and small cuts are placed between large logs. Stages of work:

- marking on the site;

- removal of the top layer of the earth;

- digging a small trench (calculated by the height of the dice, adding 10-12 cm);

- laying waterproofing materials;

- backfill of crushed stone, gravel (10 cm);

- laying sand (5-8 cm);

- thorough tamping of the base (sand is slightly moistened with water several times);

- installation of dies (arbitrary or by ornament);

- tamping.

Align the cuts in level, achieving an even continuous coverage. The voids are covered with crushed stone, sand, gravel, pebbles, sawdust. The cuts of the logs can be dug in completely, they can rise slightly above the ground.

It is not difficult to make wooden dug-in paths in the country from log cuts, from crushed stone, gravel. Combined coatings are more economical, but they look no worse than completely wooden ones.

Stages of work:

- preparation of log cuts (sanding, impregnation with antiseptics);

- arrangement of the base (digging a shallow trench, backfilling of gravel, laying a layer of sand, tamping);

- installation along the edges of the trench in a row of cuts;

- laying on top of a sandy "cushion" of geotextiles;

- backfilling with gravel, leveling.

The hemp is left in its natural form or dyed in different shades. If the farm has boards, then instead of log cuts along the contour, they are used. Crushed stone or gravel is poured onto the prepared base, short planks are laid on top.

Place them across the base at the same distance from each other. The boards are lightly pressed into the gravel. These coverings are great for rustic areas.

On a note!

When preparing any paths, it is advisable to equip drainage systems near them. Drainage grooves will allow excess water to drain.

Instead of rubble or gravel, small pebbles are poured. The shade of the pebbles is one-color or different, which will give the trail a special flavor.

Garden paths from tiles

Although the tile cannot be called a very cheap material, it is still used very often for the manufacture of garden paths. There are several reasons for this: aesthetic appearance, good performance and ease of working with the material. In the latter, you will be convinced by the technology of laying a track from a tile:

- Outline the boundaries of the future path using pegs and cords.

- Prepare the base: remove the top of the soil - no more than 35 cm deep with a slight slope for drainage.

- Lay geotextiles on the base - thanks to it, the tile joints will not be overgrown with weeds.

Garden path from tiles

- Pour a layer of sand up to 10 cm on the geotextile, moisten it with water and tamp it.

- Prepare the cement mixture on which the tiles will be laid: mix 1 part dry cement, 3 parts sand and 1 part water.

- Begin to lay the tiles "away from you" clearly along the contour cord. You can use special crosses to make the tile joints the same width.

- When the last tiles are laid, remove the crosses and grout the joints. After the walkway has dried, rub the surface and clean it from the remnants of the building compound.

Now you know many interesting ways to make a garden path with your own hands at low cost. Following simple instructions, you can implement any of the above options on your site, so feel free to get to work and discover new possibilities for improving your garden area.

Preparation for a garden path

Before preparing the soil itself, you will first need to draw up a drawing on which the shortest paths from the house to the outbuildings and beds are indicated. On the diagram, indicate the configuration of the lines, the width of the path. More often, the width is determined by the parameters of the material used, but the average value of 60-80 cm can be taken as a basis.

According to the plan, marking is carried out on the site. At this stage, small changes can be made to the scheme, since the binding to the terrain is always somewhat different from the idea itself. Pegs and a cord will help determine the area of the tracks.

On the side of the greater slope, a drainage system is being arranged, which will make it possible for the liquid to quickly be absorbed into the soil during heavy precipitation. You can also run a pipeline to collect water in a storage tank for further economic use.

• brick;

• wooden beam;

• tile;

• bottles filled with sand;

• large stones, etc.

It is recommended to treat the bottom of the pit with herbicides to destroy the weed root system. Laying geotextiles on compacted soil will also help prevent the germination of weeds. The flooring surfaces should be covered with a 5 cm layer of sand. Then the pit is filled with a 15-30 cm layer of crushed stone or gravel mixed with sand. To make the track stiff, the pillow is carefully compacted with a tamper with moderate moisture. The thickness of the pad depends to a large extent on the type of soil. If it has a dense structure, 20 cm of bedding is sufficient. On loose and clayey soils, more reliable bases are used for stability in the rainy weather. The type of cover you plan to use for the flooring can also affect the thickness of the pad.

Progress

It is necessary to take into account the climatic features. Natural materials are not afraid of cold weather and moisture, but water must drain from concrete so that the base does not crack.

Take into account the seasonality of living in a country house. If the inhabitants live all year round, the paths will need to be cleared of fallen leaves, snow

In this case, the coating should not be damaged.

If in private houses they equip a road for cars - they make an entrance to the house, garage, then when styling the rest of the site it is not at all necessary to use the same laying material.

Natural stone or concrete is appropriate to combine with other materials.

Paving slabs are laid on a sand cushion. On soft soil, reinforcement mesh is additionally laid, it restrains the movement of the soil during the melting of the snow.

Those plots where further development is planned are equipped last. The paths are designed for pedestrians. Under heavy load, for example, when transporting a laden wheelbarrow, the base can collapse.

Concrete often crumbles, cracks appear on the plastic tiles. The aesthetic component of the site will suffer. The track will have to be redone.

How to prepare a solution for a garden path: making a concrete base

Often, the site owner decides to make a concrete base for his path, and this is perhaps the best choice, because concrete will last much longer, and maintenance with such a base will be several times less.

In this case, it is important to properly prepare the solution, to correctly observe all proportions and consistency. So, what are the secrets of making a concrete solution for a garden path?

It is better to choose a cement for the base of 300 or 400 brands. If you notice small lumps in it, it is better to sift the cement to avoid crushing during mixing. But the sand must be sifted, because most often not very high-quality quarry sand is used for construction work. And the third component of the solution is water. It should be at room temperature, too hot or cold can ruin the entire solution.

Next, knead the solution in this proportion of 1: 3 (1 part of cement and 3 parts of sand) until the consistency of thick sour cream. do not make a too liquid solution, later it may crack.

Skillful builders advise adding modern components to the solution, for example, to give the desired consistency a plasticizer, and to obtain the desired color - colored granules or dye.

Another secret of a good concrete solution: sand and cement are best laid in layers, 1 thin layer of sand, 1 thin layer of cement. This will make it easier to stir the solution. Water should be added only after thoroughly mixing all the ingredients dry.

With the help of these simple secrets, you will be able to make the right mortar for the base of your garden path!

Requirements for garden paths

The path serves primarily to connect household facilities, and also makes a convenient way to remote parts of the dacha complex. A properly planned path should provide the shortest distance from the building to the garden, garden, flower bed. However, such an arrangement may contradict the aesthetics of the entire landscape, in this case, winding paths are used.

Like any object of the general system, the paths in the country must meet certain requirements:

- The relief of the dacha space determines the configuration of the paths;

- Aesthetic properties must match the uniform look of the entire economy. This circumstance is taken into account when choosing a coating, i.e. if the facade, patio, playground are made of a savage, then the path must also have elements of this raw material;

- All paths are divided into main and auxiliary paths. The width of the first should be at least a meter, the second - from 50 centimeters;

- Wide passages are made convex or at an angle so that water does not accumulate on them. Narrow ones can do without slope;

- When planning, it is necessary to prevent the appearance of forks;

- The paths should unite all landscape structures: a greenhouse, a decorative pond, a gazebo, and other elements;

- During the journey, all significant parts of the decor must be clearly visible;

- Distribution into areas must be done so that the lines divide the entire area into characteristic parts, produce zoning of the space.

What are garden paths in general?

There are no so many classifications - both by material for manufacture, and by location, and by size. We will take a division into views based on the way of the device.

Garden trails

This is a natural view as the paths appear on their own without any special planning. Usually they are trampled by the feet of people or rammed by the wheels of garden equipment and serve to connect the most important points of the site - a house, a bathhouse, a vegetable garden, a garden, a gate. An ordinary unpaved path has disadvantages (mud after rain, puddles, overgrown with grass), so it is possible only as a temporary option. By the way, the trail can also be refined: it is enough to lay out a curb of cobblestones or paving slabs along the edges.

Garden trails are ideal for areas located in dry areas

Backfill paths

They are easy to arrange: a ditch should be dug, about 100 mm deep, geotextiles should be laid along the bottom and edges (density not less than 150 g / m²), and the sides should be reinforced with curb tape. It will remain on the finished base to fill in pebbles, crushed stone, marble chips or screenings. If this option seems simple, you can additionally lay stone or concrete slabs on the surface - in an orderly or chaotic manner. For ease of movement, the slabs should be drowned in the backfill so that they are flush with the surface.

Having picked up gravel or crushed stone of different colors, you can decorate the paths or divide them into zones

Solid fill tracks

The durable cover is ideal for heavy loads. Paving of garden paths takes place on a concrete base with further laying of decorative elements on it: tiles, paving stones, natural stone. The use of materials of different colors gives the decor a natural look. It is better if the finished object will rise 50-70 mm above the ground - this will save it from erosion by water and soil sediments.

Slab or stone paths laid on a concrete base are reliable and durable

Construction of a walkway without cement

The difference between this option is that cement is not used when laying out a paved road.

The base is also crushed stone, raw sand is poured on it, compacted and smoothed by the "rule". The level of the sand layer is always 30 mm less than the level of the curb or formwork. It is with such values that the stones will begin to stay flat. It is necessary to align the filled mosaic along the border.

It is easier to cover the stones not in 1, but at the same time to lay them in rows, tapping on top with a hammer. The sand will need to be additionally moistened.

The rise of pebbles must be regularly checked with a special building level.

Having laid out a specific segment of the mosaic, before the sandy base dries, it is necessary to tap the plane one more time with a hammer, and then add more sand on top. The excess of such filling is then immediately swept away with a brush.

Further, the finished mosaic is poured with water through a spray bottle.

After the filled surface has completely dried, it is possible to walk one more time on the plane with a brush.

When the sand level drops in a couple of hours, it is necessary to duplicate the filling and watering again.

After another drying of the mosaic, all stones are wiped with a damp sponge.

The completed structure is moistened with a small amount of water every day, for a week, so the path “accumulates hardness”.

If the installation process is carried out in an open space, in this case, so that the canvas does not wash out with a downpour, it is preferable to cover it with non-thick foam rubber. It has a porous structure that allows some moisture to pass through, but will not allow the flow of water to wash away the sand.

If the paved road was erected using plank formwork, then at the end of the masonry, it is necessary to strengthen the canvas with stone or brick curbs.

You can lay out the track without cement

Sealing sand is used for laying tiles without cement.