We build a gazebo with our own hands

You have already decided on the design of the future gazebo, prepared the site, chose the material, made a layout and even sketched the assembly drawing. Now it's time to figure out how to build it correctly. So, we are building a gazebo with our own hands.

First stage: preparing the foundation

Any construction begins with pouring the foundation. When laying the foundation, it is practical to use reinforced concrete slabs. When preparing and pouring concrete, there is no reason to worry about how to make the floor in the gazebo in the future. In the following, we will describe how this problem can be solved very simply and easily.

We prepare a ditch in the selected area, install iron reinforcement around the perimeter

You can replace concrete structures with metal rods or a corner, which are important to be connected by welding or simply tied before use. After the installation of the reinforcement, the ditch is laid out with stones mixed with chipped bricks and even construction waste.

From above, the stone pillow is poured with concrete or cement mortar

For solidification, the foundation needs about 3 - 4 days, depending on the quality of the concrete. At this time, periodically water the base with water - this will improve the cementing process and speed up the process.

Second stage: step-by-step construction of the gazebo

After the foundation has frozen, we proceed directly to the construction of a summer gazebo. This is the most critical stage that requires special attention and organization. Now you need to assemble the frame and install the roof. The builder will be required to be precise and accurate in actions.

We begin the assembly of the frame with the construction of corner beams. For this, you can use both quadrangular and octagonal beams. Subsequently, we will install the roof of our building on these carriers.

The easiest way to make a roof is to do everything using logs that will follow its shape and configuration. Make sure you strictly adhere to the chosen design while working, otherwise the result may not be what you expected.

We connect the wooden guides to each other. This is necessary to ensure the rigidity of fastening the structural elements to each other. To do this, we install special vertical crossbars made of wooden beams.

When the frame is assembled, we proceed to sheathing it with sheet metal. Keep in mind that the metal roof echoes the raindrops, making a rather noticeable noise, and quickly heats up under the scorching sun. If such shortcomings play an important role for you, then opt for a plywood roof, and cover the base with a soft roof on top. When choosing a material for building a gazebo, consider such important characteristics as strength and durability. As a roofing material, you can also use traditional slate, wooden boards, metal tiles and other analogues.

We will separately dwell on the construction of a gazebo with barbecue. The construction of a summer house of such a design also does not take much time, and even a family with modest incomes can handle the financial costs.

Such a gazebo is performed in the form of a canopy, which is held on brick, metal or wooden supports. For the barbecue, it is very popular to use brick - a beautiful and inexpensive material. It will not be difficult even for a novice stove-maker to fold a brazier made of bricks.

The only thing we advise you to pay attention to when building a gazebo with a barbecue is the need for a monolithic foundation under the stove. Such reinforcement of the mortgages is due to the large mass of the hearth, therefore this option is preferable to laborious work associated with pouring a concrete base.

As you can see, the construction of a gazebo at a summer cottage is not a super-complicated and unrealizable process.Of course, there are nuances that you have met and have probably already decided on a step-by-step sequence for the implementation of this venture. Following the instructions, you can quickly and efficiently do this work and decorate the garden with a magnificent gazebo built with your own hands. In it, you can comfortably and conveniently enjoy communicating with nature and loved ones in any weather, without the risk of getting sick and getting wet.

Various gazebos and tents for summer cottages have now become an obligatory decoration of the courtyard and a place for family tea drinking and making barbecue. Such a place near the house will provide you with a good rest, which is so necessary after a week of work.

Where is the best place to install?

Before you start working on the swing, you should choose a suitable place for it. The structure can be installed anywhere, but if beauty and comfort are needed, it is worth thinking about choosing a place.

Such swings are quite spacious, adults and children can be on them. Where they are installed, a convenient outdoor recreation area is formed. There may be a dining area nearby, a barbecue area with an oven and barbecue. Or emphasis is placed on aesthetics: the swing is placed in the center of a fresh lawn or surrounded by flower beds, near a decorative fountain, pond, waterfall.

The place itself for mounting future swing can be open, closed or semi-closed. Open structures are installed in a free area of the garden or in front of the house. The maximum that they can have as a roof is a small canopy equipped on the structure itself.

Semi-closed areas include terraces, a pergola, where several conditional walls covered with vegetation are erected. Sometimes the swing is placed in a closed space - on a veranda or in a gazebo. When choosing a place for a frame swing, certain nuances should be taken into account:

- you can not put the structure in a low place in order to avoid dampness;

- the place should be level, or it should be leveled;

- the swing needs a shade from a tree, buildings or a canopy, but at the same time, places with drafts should be avoided;

- near the recreation area, the growth of poisonous plants, as well as allergens and melliferous plants, should be excluded.

Wooden swing

Consider the technological sequence for making a wooden structure that several children can sit on. Dimensions can be reduced / increased as needed. Pine, spruce or birch wood can be used as a starting material. So, you will need:

- boards with a section of 100 × 25 mm with a length of 2.5 m - 15 pcs.;

- board with a section of 150 × 50 mm 2 m long - 1 pc .;

- self-tapping screws 52 × 3.5 mm - 250 pcs.;

- carbine - 6 pcs.;

- welded chain 5 mm thick, length equal to the height;

- galvanized screws: 2 pcs. - 12 × 100 mm and 2 pcs. - 12 × 80 mm.

Of the tools you need to stock up on:

- square;

- drill with a set of drills;

- tape measure;

- circular saw;

- pencil;

- a plane;

- hacksaw;

- hammer.

Step-by-step instruction

By following the plan, getting the job done accurately is easier. Therefore, before starting the manufacture of a swing, prepare its project.

Installation of supports

Installation of supports

Make blanks of 1.5 m, cut at an angle of 90º. For seating, use a board that is 20 mm thick. In this case, the thickness of the board for the back can be in the range of 12-13 mm. For the design we proposed, you need to make a seat, for which you will need 17 planes 50 cm long and 15 slats 45 cm wide.

Supports concreting

Supports concreting

If you want to make a more comfortable back, then make it curly. To do this, you will need to use the thickest board - 150 × 50 mm. You should have 6 blanks. With a pencil / marker, draw the outline of the shape of the workpiece.

Determine the angle of the backrest attachment. The planks should be fixed at the same pitch. To screw them evenly, fasten the ends on both sides, and then in the middle. To make the swing more comfortable, make armrests. For these purposes, a bar of any width will fit. One end must be screwed to the backrest frame, and the other to the seat.

Bolted

Bolted

Then you can attach the chain to the frame. It is best to do this towards the bottom of the armrest, where it connects to the seat.The other end of the chain is attached to the top of the frame base on the backrest. Secure the chain with nuts and washers. Otherwise, the nut can enter the wood, which will spoil its integrity. A special element with a ring on one side, and with a thread on the other, should be fixed to the seat frame and to the crossbar.

Support making

Assembling the frame

Assembling the frame

An A-post or support is reliable enough to withstand significant loads. To work, you will need the same set of tools as for making a seat, if we are talking about a stand made of wood.

Roof fabrication

Roof fabrication

Make two identical posts that are the same size. Ultimately, they will be installed at the distance you need, which depends on the width of the seat. The uprights / supports are connected by a crossbar.

Exactly calculate the angle of connection of the vertical parts of the uprights. At the top, the posts must be securely connected. Over time, they should not start to diverge. Set the crossbar to 1/3 of the height of the support legs. For these purposes, use metal corners and self-tapping screws. The crossbar must be installed on the uprights at the same height.

Roof fixing

Roof fixing

The structure should be installed in the ground. Dig holes up to 80 cm in depth. Make a 20 cm sand cushion of rubble. Insert the posts and fill them with concrete. To prevent the racks from rotting, they must be insulated before pouring. This can be done by impregnating or wrapping the wood with a waterproofing material, for example, roofing material.

Finished swing

Finished swing

Instructions for assembling a two-seat structure

The construction of a two-seat structure will not take a lot of time and effort if you use step-by-step instructions developed by professionals in your work. It provides:

Several logs, two to three meters long, with a diameter of 10 to 15 cm, are required.

We cross the tops of the logs at the attachment points.

From the outside, top and bottom, attach fasteners to strengthen the structure.

Next, you need a threaded spoke. Its diameter should be about 10 mm. Holes must be drilled in the attachment points. Insert a knitting needle into them, after which we cut off the protruding part of the knitting needle with a grinder.

We screw the nuts on both sides of the spoke, after which we tighten them.

Be sure to make sure the side posts come out symmetrically.

The next step is to attach the side posts. We put one of the logs on top and fasten with knitting needles.

In order to make the swing more durable, we need to add two inclined stops.

Prepare a wooden bench in the following sizes. The frame beams are 5x7, and the boards are under forty.

Next, you need to take care of the appearance. They can be polished, painted or varnished

It is important to remember that it is best to use specialized tools. They will give the wood a healthy appearance for years to come.

The foundation issue is also important.

Pour cement at the entry points of the foundations into the ground. We also insert metal bases there, to which we can then attach our legs. Let the cement harden.

Such a swing can be assembled by yourself

Such a swing can be assembled by yourself

The swing is ready to use!

Instructions for assembling a two-seater structure with a table

For an outdoor picnic, a table must be set up. Its installation is much easier, as most of the work has already been done.

- The table must be fixed to the moving base of the swing.

- On a small beam from above, attach the workpiece under the top of the table and screw it securely.

Instructions for assembling a double structure with an awning

To avoid capricious nature or the merciless rays of the sun, it is worth adding an awning roof to the structure.

- Find a durable, waterproof tarpaulin material.

- Prepare a timber frame to support the solid shape of the roof.

- Take a measurement on a wooden frame and sew a cover for it.

- Use wood or metal strips to screw the frame to the top.

A tremendous job has been done, but it is definitely worth it!

Making a swing from metal for a summer residence

To make a swing from metal with your own hands for a summer residence, they take a corner, round pipes or brands. Craftsmen prefer a profile pipe as a strong and reliable material.

Apply:

- square or rectangular profile for racks, spacers;

- oval for bent elements;

- flat - for auxiliary parts.

By fixation, stationary and portable products are distinguished. In the first case, the devices are placed on concrete racks, in the second, the supports are attached to a frame buried in the ground. A portable iron swing is convenient if it is taken into the house for the winter.

The design is chosen in the form of the letters "A", "P"; L-shaped supports are used for portable products. The seats are suspended from clamps, anchor bolts or ball bearings. Parts for hanging are checked for strength, lubricated.

Required tools and consumables

To build a metal outdoor swing for a summer residence with your own hands, you will need:

- welding machine;

- electrodes 2.6 mm;

- shaped pipes with a wall width of 40-70 mm, a thickness of 1-2 mm for the construction of racks, crossbeams;

- wooden bar for a bench 30x30 mm (section can be more or less);

- ropes, chains;

- 6 eye bolts with washers, nuts for fixing;

- paint, varnish.

Metal swing drawings

Thinking over how to make a welded swing, proceed from the parameters of the width of one seat - at least 0.5 m per person. The height is at the choice of the owner, and between the supports and the bench a distance of 35 cm is left for a rope attachment, 25 cm for a chain one.

A simple drawing looks like this:

Step-by-step assembly instructions

How to make an A-shaped welded structure:

- 4 pipes of 2.5 m are cut for racks. The crossbars are made 2.1 m each.

- The edges of the pipe are cut off at an angle of 30 degrees, welded in pairs in the form of an isosceles triangle.

- Set aside 2 m from the top, weld a horizontal jumper with a length of 1.038 m.

- A horizontal crossbar is welded to the tops of the racks, divorced by 2 m, so that the ends protrude from both sides by 5 cm.

- A bar for the bench is cut, sanded, varnished, dried.

- The timber is attached to the seat frame. Fixing on bolts in increments of 2 cm.

- The seat is hung on the crossbar. Fastened to the eye bolts, having previously drilled holes in the crossbar.

To put an adult or children's swing for a summer residence with your own hands, do this:

- dig 4 holes up to 50 cm deep;

- make a concrete mixture from ready-made powder or cement, water, sand (1: 2: 3);

- sand is poured on the bottom of the pits with a layer of up to 10 cm;

- put supports;

- the space between the supports and the ground is covered with stones and poured with concrete;

- allow the concrete to dry for at least 3-4 days.

After drying the solution, the structure is tested and painted.

Making a canopy for a summer swing

A canopy or canopy will protect from the sun, rain. The easiest option is to pull a woven fabric in the shape of an awning over the structure. These are used by installing a swing sofa for a summer residence. Reiki hold dense fabric, preventing it from shifting.

The second option is a polycarbonate sheet fixed to a metal profile. The shape is determined by the side parts of the canopy - classic pyramid or semicircular. For the second option, the profile is bent with a pipe bender.

For the construction of a canopy, the transverse profile strips are fixed to the main beams by welding or bolts. Then a canvas is pulled onto a wooden frame, a polycarbonate sheet is fixed (on press washers, bolts). Holes are made in the structure of the top of the swing, the canopy is fixed.

Swing from an old tire

What do you need

- Tire;

- bicycle camera;

- rope;

- insulating tape;

- steel washers for the diameter of the rope;

- staples-clips;

- drill;

- drill;

- knife;

- thin cord or fishing line.

How to do

1. Estimate the approximate length of the rope so that there is enough from the branch to the ground, and add 1 m in reserve.

Rewind it in the right place with electrical tape so that the edges do not fray, and separate the piece with a sharp knife.

2. Cut the bike tube and slide it over one end of the rope.

3. Tie this piece to form a camera-wrapped loop. This will protect the rope from chafing and prevent it from bumping into the branch.

4. Pass the rope over the branch and tighten the loop. For convenience, you can use a thin cord with a weight attached to it.

5. Form a knot approximately 1.5–1.7 m above the ground.

6. Cut two more pieces of rope, each about 2m long. Thread them into a knot on the hanger, and then tie one knot at their ends to secure.

7. Tighten the knot on the main rope from the branch. You should have three ends to hold the tire on.

8. Divide the tire into three roughly equal parts and drill holes with a diameter across the thickness of the rope, stepping back from the edge of the tire. On the back of it, make a few more holes for rainwater drainage.

9. Insert the ropes into the holes, put on the washers and fix the ends with the clamps.

10. Let go of the tire and try wobbling.

What can be changed

- Instead of clamps, you can simply tie knots that will prevent the rope from falling into the washers and will reliably hold the entire structure.

- If desired, the tire can be easily painted so that it looks more aesthetically pleasing and does not stain clothes.

Swing made of disc and one rope

What do you need

- 4–5 boards 30–50 mm thick and 400–500 mm long;

- thick rope;

- hammer;

- nails;

- brush;

- paint or varnish;

- clamps;

- glue;

- drill;

- drill for wood;

- roulette;

- thread;

- pencil;

- jigsaw;

- sander or sandpaper;

- file.

How to do

1. Build a platform from the boards. To do this, smear the side ends with glue, connect them together and tighten with clamps. A simpler option: nail two bars across the boards, stepping back 10 cm from the edge.

2. Sand the top of the pad by hand with sandpaper or a machine.

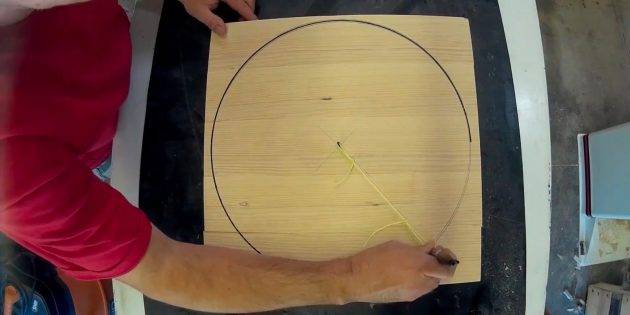

3.Using a tape measure, locate and mark with a pencil the center of the pad. Also draw a line 10 mm from the edge of one of the sides.

4. Drive a nail into the center, tie a pencil to it with a thread and draw a circle with a radius length along the mark at the edge of the pad. Pull out the nail; you won't need it anymore.

5. Saw a circle with a jigsaw and smooth out any sharp edges with a file or sandpaper.

6. With a drill, make a hole in the center with a diameter of 2-3 mm larger than the thickness of the rope of the future swing.

7. File away the sharp edges formed in the center with a file so that the rope does not fray when swinging.

8. Paint or varnish the resulting seat and wait for everything to dry.

9. Thread the rope through the hole and tie a couple of knots to keep it from falling through.

10. Secure the free end of the rope to the tree.

What can be changed

- The round seat is easy to replace with a fairly sturdy rectangular board. Riding from this will not deteriorate at all.

- In order not to fiddle with splicing boards, you can take a piece of plywood that is suitable in size.

Do-it-yourself garden swing made of wood: photos and drawings, sizes and modifications

If you decide to start creating a swing in your summer cottage yourself, first of all you should decide on the type of structure that you want to install and determine a suitable place for its placement. To facilitate and speed up the design and preparation stage, use a photo of a do-it-yourself swing made of wood, of which there are a lot of drawings on the Internet.

Drawing of a wooden swing of the optimal size for one person

Varieties of garden swing with their own hands made of wood

The classification of garden swings is quite extensive. In this case, the main types of structures are presented:

family - have a high capacity. The design is based on a long bench, which plays the role of a large seat that can simultaneously accommodate up to 5 people.In most cases, a swing of this type is equipped with its own canopy that protects from sunlight and bad weather;

Family-type swing can comfortably accommodate 3-5 people

children's - designs can have a significant number of modifications. Most often, the main components of such a product are supports, a small seat and fasteners.

At the same time, it is important to ensure a full level of safety for the child. For these purposes, protective elements must be provided in the design that will prevent the baby from falling

Such elements include a comfortable backrest, handrails on the sides, a partition located in the front, seat belts that secure the child inside the seat;

Original children's swing made of wood in the form of a horse

portable - products with compact dimensions and light weight. These characteristics make it possible not only to move the swing around the site, but also to put it in a car for transportation to another place during rest. As a rule, the fastening of such products is carried out on a tree branch or on a pre-fabricated support.

Portable swing can be rearranged anywhere on the site, depending on weather conditions

Choosing a place to place a children's swing with your own hands made of wood

Any type of construction that is carried out on the territory of a suburban land plot begins with the design stage and the selection of an appropriate place.

Simple swing for children, made using a wooden board and rope

As far as possible, a plot with a flat surface should be selected on the backyard territory. It is desirable that this area be sheltered from the sun and precipitation. The ideal place to create a swing is under a tree, where a thick shadow falls. Installation on a porch protected by a canopy is allowed.

All these conditions directly affect the level of comfort of use, since it is unpleasant and inconvenient to sit on a swing seat, hot in the sun. And unhindered exposure to rain can damage the structure.

When placing a children's swing in the garden, it is necessary to provide enough space for swinging.

It is also worth taking into account the fact that as the sun moves across the sky, the shadow cast by a tree or other objects will move. For installation, you should select a place where the shadow will stand at noon.

During this period of the day, the sun has the strongest and most aggressive influence.

Drawings and photos of a garden swing with your own hands from a tree for a summer residence

If we talk about universal structures, then a suspended swing, installed on A-shaped supports, will become a real recreation object for the whole family. Moreover, they can be installed both in large summer cottages and in small gardens near the house. And the process itself is not costly in terms of time and effort resources.

Swing chair design with soft cushion cover

The list of required tools for work should include:

- tape measure and pencil (tape measure can be replaced with a measuring tape);

- jigsaw of a mechanical type or electric;

- circular saw;

- hacksaw;

- angle square (combined type);

- rafter pins;

DIY swing bed

- checking square;

- sawing goats;

- thicknesser and planer;

- hammer, screwdriver, clamps, wrenches;

- chisel (25 mm);

- an electric drill with a set of drills (10, 8 and 4.5 mm);

- a block for grinding.

Simple Wooden Swing for Kids Outdoor Play

A swing in a quiet corner of the garden will allow you to enjoy the aromas of greenery

Simple

From wooden pallets with a mattress

From wooden pallets with a mattress

You still have a wooden pallet after the delivery of building materials, why not use it as a base? Agree that this is not difficult, and not worth the big investment! All you need is a pallet, strong rope and a tree trunk to hang the structure. You can make supports from strong pillars. How to do this will be discussed a little later.

The swing can be made from a solid pallet, fixed on the sides with four ropes. Everything, you can ride. If you want more comfort, place a mattress on a pallet and cover it with a sheet, and put a few pillows on top. Now you can start reading in the shade of a tree, and you can also take a break from the midday heat, lie down and even sleep here.

The simplest rope swing

The simplest rope swing

If you have 2 pallets at your disposal, then you can create cute designs with a back. To achieve greater aesthetics, first clean the parts and sand them, and then fasten and paint (cover with a moisture-resistant varnish) the finished structure. Now your nondescript pallets have turned into a very attractive country swing!

"Planks" is the simplest idea. On the sides of the board, it is necessary to fasten one more board so that the rope is frayed less, then drill 4 holes, insert the ropes into them and tie them to strong knots. You can fix such a structure on a tree or a U-shaped support.

Another idea is with a rope. To do this, 4 grooves should be made in the board: 2 at the end and 2 at the edges closer to the corners. The board can be rectangular or semicircular. Although the grooves are open, the rope still does not jump out. The pulling force only fixes the position of the rope, which makes the structure even more reliable.

From a skateboard

From a skateboard

Do you have an unusable snowboard? Then use it instead of a seat! Drill holes in it and secure the ropes. Now it remains to hang the finished structure on a reliable support!

Another version of a tire swing

Another version of a tire swing

Do you have old tires? Do not rush to throw them away, because they can be used to build a wonderful swing for children! To do this, you will need a tire and rope. If you want to create some special shape, to improve structures from a tire, then you will need a sharp cutting tool, for example, a construction knife. You can paint the tire to make it even more fun. For best results, you can draw a model of the structure on paper or mark the notches on the tire itself. Below are the ideas for implementation from tires.

If there are 2 small round logs lying around in your yard, then align them, clean and tie them together with a strong rope, and then tie them with a sea knot to the support.

Material required for construction

With a wide variety of materials, structures are made mainly of several types:

- metal;

- plastic;

- wood;

- a combination of these options.

Let's take a closer look at each option.

Metal

Products made from this material are stable, durable, and reliable. Thanks to a special coating against corrosion, the product is not afraid of weather conditions and temperature drops. They are installed for a long time, and they do not need to be removed to a warm place for the winter.

This design has one drawback - it is heavy, which reduces mobility. To rearrange the structure, you need to disassemble it. Another disadvantage is the high cost, but this can only be judged by the buyer.

Forged metal swing gazebo - a fashionable and modern attribute

Original designs on the walls and backs will constantly attract the attention of guests

Wood

This option can be called ideal, but without metal parts, it is impossible to correctly make a stable structure.

If your main building is built of wood, then such a gazebo will fit well into the interior. Especially if the roof is made of the same material. In addition, wood is a strong and durable raw material. Metal and wood structures are the most popular.

Combined

Such structures are made from two of the most demanded materials.Support posts are made from metal profiles or pipes. It is also advisable to make a wall frame from metal. The appearance, made from rods or pipes, looks strict and repeats geometric shapes. Metal gazebos looks light and airy.

The seat itself is made of wood of the required type and shape. It is advisable to choose a shape for the table and seats from the same breed. We fix all the products on the flooring and hang them inside the metal frame. This frame easily supports the weight of the timber structure. The roof is made of the same material as the main structure or alternatively polycarbonate.

Preparation method

To form a swing gazebo, an accurate calculation of all dimensions (height, length and width) will be required.

Next, you need to do the following:

- draw up a drawing of a swing and a gazebo;

- it should, determine the place on the site where the structure will be;

- make a list of the materials you need and their quantity (make a small stock);

- the required tool is being prepared.

Wooden structure production method:

- using an end saw, we make blanks of the required length;

- using a circular saw, we make for saws for spikes for locks and clean them with a chisel;

- we select the slots for the locks using a drill or a hand cutter.

Upon completion of the preliminary work, we proceed directly to the assembly of parts according to the prepared drawings:

- For spike-groove connections, we use epoxy glue, coat the locks and clamp them until they are completely dry. Where the fixings are on dowels, polyurethane glue is used.

- We hang the swing on the beams using chains of the required length and pre-prepared bolts and rings. A reliable, durable cable can also be used.

- We process all wooden elements with varnish or paint for protection and decoration.

After completing all these steps, you can relax with the whole family on a new piece of garden furniture.

For an overview of one of these homemade swing gazebos, see the video below.

Preparatory stage

First of all, decide on the place of installation of the swing:

- you must not lose sight of the child;

- choose a site away from the road, electrical wires, a reservoir, building materials and other dangerous objects and structures;

- there should be no thorny and poisonous crops, as well as allergenic plants near the swing;

- the ideal option is a leveled area in diffused shade, protected from gusts of wind.

The swing can be made from different materials:

- metal parts will cost more, but they will allow you to build the most durable structure - it can be stationary or portable;

- the tree serves less, but costs less - no less solid frame swing can be built from such material;

- wood, along with plastic, is also used for the construction of suspended temporary models;

- plastic is the most suitable option for babies under 5 years old.

The height and age of the child will help determine the dimensions of the structure:

- the optimal frame height is 2-2.5 m;

- the acceptable width of a single seat is 0.4-0.5 m;

- the optimal distance from the seat to the ground depends on the child's height: for a toddler with a height of up to 80 cm - 0.5-0.55 m, for a child with a height of 100-120 cm - 0.7-0.75 m, for children with a height of 130-140 cm - 0.8-0.85 m;

- the child will probably swing while standing - the crossbar should be at least 1.5 m away from the seat.

If there are several children in the family, make sure that each child has fun activities. Increase the length of the frame's top crossbar to accommodate 2 or more single seats. An alternative option is to make a swing bench 1-1.2 m long.

Before starting the construction of children's fun, make a design drawing, which should include:

- frame dimensions;

- places for fastening props;

- the number of seats and their sizes;

- the length of the suspensions.

Installation from a profile pipe

To make the garden swing strong, but not look cumbersome, we will choose a profile pipe with a cross section of 40–70 mm with a wall thickness of approximately 1–2 mm.Its main advantages: resistance to fracture and any weather conditions, easy installation, light weight, strength, budget cost.

For installation, you need the following tools:

- grinder for working with metal parts;

- welding machine;

- level and tape measure;

- saw;

- Sander;

- hammer;

- screwdrivers, bolts and nuts;

- drill.

Don't forget about the appropriate tool

Don't forget about the appropriate tool

Blueprints

At the initial stage, the area for installing the swing is selected, the dimensions are determined. The most suitable hanging bench size is 1.5 m. This is enough for two adult skiers.

According to the drawings of the garden swing, from the profile, the design diagram includes the following elements:

- support frame in the form of a rectangle at the base;

- side elements made of iron pipes, welded together;

- horizontal bar for fixing the bench.

If the width of the base is chosen correctly, the product will turn out to be strong and stable. It is necessary to follow the rule: the greater the angle at the apex of the triangle between the base and the side supports, the more stable the structure will be.

Frame

To assemble the frame, you need to start with the side pieces. On the basis of the drawings, markings are applied to the pipes and cutting is performed with a grinder. We check the dimensions before assembling. All four side support elements must be equal. Then they are connected in pairs by welding, resulting in two identical elements in the shape of the letter L.

The sharp end of the upper part of the parts is sawn off at the same level in order to form a small support to strengthen the horizontal bar.

The width of the support should correspond to the distance that is formed between the paired pipes of the side structure. By means of welding, the sidewalls are welded to the support frame, then a horizontal crossbar is installed on top of the side posts.

All stages of the assembly should be carried out observing the laws of geometry: the side supports stand vertically, the horizontal crossbar for hanging the bench is parallel to the base. A building level is used to control all stages of the assembly.