The advantages of glazing

Gazebos and verandas that are glazed have many positive qualities:

- The ability to use them all year round.

- Protection against unpleasant weather conditions.

- Preservation of the look and architecture originally conceived.

If the main pastime is being in a suburban area, then a gazebo glazed with sliding windows is what needs to be done, not least.

The sliding window system is a lightweight design that is very practical and easy to use. It has excellent sound insulation, excellent thermal insulation, is environmentally friendly and has a presentable appearance.

Among the main characteristics of sliding systems:

- high tightness;

- the sash moves easily along the window;

- low installation cost makes them more and more popular;

- additional protection against burglary and unwanted penetration.

Sliding sashes, which have a single layer of glass, are the simplest and easiest to install. Such metal-plastic windows can be easily opened in the intended direction. Another plus to the fact that they are excellent protection against drafts, rain and wind is the low installation cost. Any person can afford to make glazing in this way.

The design of sliding metal-plastic windows with double-glazed windows will not only provide excellent protection from bad weather, but will also allow you to use the room until the very cold weather. In order to be able to spend days and evenings in a glazed gazebo in winter, it is necessary to insulate the walls and floor, install additional heating devices, and place a fireplace.

Sliding window designs can be developed individually. A project created specifically for a specific gazebo will be a little more expensive, but at the same time it will become a highlight on a suburban area and will give a special charm and respectability. Among such original solutions, for example, the use of semicircular windows, which create a semblance of a bay window structure.

Among the materials of profiles for sliding windows, aluminum is especially popular. It is the most popular for small architectural forms, including a gazebo and a veranda. Such sliding systems are also suitable for glazing rooms that will be used throughout the year, provided additional heating is provided. This creates a comfortable temperature for staying inside.

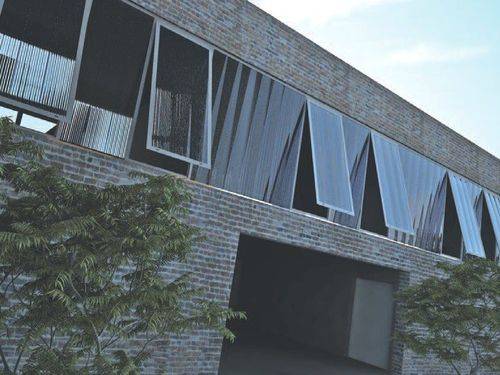

The advantage of aluminum systems is that they are applicable for both conventional and panoramic glazing because of the thin profile that does not interfere with the view. They are equally often used for glazing gazebos made of various materials, it can be wood, brick, metal, and plastic.

The advantage of aluminum systems is that they are applicable for both conventional and panoramic glazing because of the thin profile that does not interfere with the view. They are equally often used for glazing gazebos made of various materials, it can be wood, brick, metal or plastic.

Advantages of aluminum sliding windows:

- anti-corrosion properties;

- strength;

- long service life;

- ease of care;

- lightness of designs;

- acceptable price.

Aluminum profile systems can have the color of natural metal or be laminated with a film of different textures and shades.

Frameless glazing

To equip an outdoor area, you can use a beautiful glass wall. Frames or racks do not spoil it, and the solid canvas easily moves along the guides, completely opening the terrace space. Window sections are folded in the wall like a book. The functionality of this system is largely ensured by the use of tempered glass with excellent performance properties. Designers love the design because it doesn't take up space at all and gives you crazy visibility.

Installation of frameless glazing:

It is important to take measurements correctly in order to avoid gaps in the structure of the frameless system;

The upper profile is fixed with anchors, after which the latter is leveled using metal plates;

Next is the turn of the lower profile;

Then sequential installation of glasses on the guides by means of hinges;

After installing all the glasses, all the fittings are installed.

The convenience of sliding structures, as well as the undoubted elegance of design, have led to the growth of their popularity all over the world. Designers in every possible way welcome this type of glazing, since in this way space savings are achieved, and a gorgeous view opens up.

Polycarbonate veranda windows

Insofar as the veranda is attached to the house and in fact is its addition, it should be warm enough, and the glazing should be airtight and heat-insulating. Therefore, the polymer is perfect for these purposes. Among the advantages of such a window for a gazebo, in addition to its insulating properties, weight also stands out - such a system will weigh much less than a metal-plastic or glass one, therefore the load on the structure is reduced.

When purchasing polymer for future glazing, the seller will pack the material in the form of a roll. You cannot store the purchased material in this form for more than a day - the material is flexible enough and can take shape. Therefore, at home, the sheets are laid out on a flat surface, one by one, it is desirable that the surface with a protective film is on top, even if sunlight does not enter the storage room. It is impossible to store polycarbonate vertically - a crack may appear along the entire length of the sheet.

Aluminum windows

A very practical option for a summer cottage or a city house is windows with aluminum frames. These are often installed on unheated verandas. Among the advantages of aluminum structures:

- Long service life. A properly installed structure will not require replacement for 50 years.

- Attractive appearance. Windows do not need to be painted every 2-3 years, they do not fade or deform.

- Ease of installation and maintenance.

- Light weight, not creating additional load on the foundation.

Despite the many advantages, aluminum windows also have disadvantages. The construction is not cheap, the first generation profiles quickly heat up in the heat and freeze in the cold. The tightness of the windows provides warmth and protection from noise, but requires frequent ventilation of the room. It is better to install aluminum windows on verandas made of materials that allow air to pass through: wood or brick.

There are 2 options for the aluminum profile on sale: cold and warm. The first is suitable for unheated verandas, which are used only in summer. They provide single glazing without additional insulation. Windows with a warm profile are suitable for houses in which they live all year round. Such windows are equipped with special gaskets and inserts that guarantee excellent sound and heat insulation. It is not necessary to make all windows sliding. A more convenient option is a combination of fixed and sliding glazing.

Features of the polycarbonate window

A polycarbonate window consists of the sheet itself and the frame. The latter can be metal or wood. The material is resistant to almost all types of impact, loyal to temperature differences and their changes. When used to cover greenhouses, special additional polycarbonate films are often used. They are necessary in order to neutralize the effect of UV rays on plants. Some polycarbonate sheets are sold with a pre-applied film, which is ideal for home glazing.

Due to the presence of air pores in the structure of the polycarbonate plate, the material has high sound-proof and heat-insulating properties, although these parameters will ultimately depend, of course, on the correct installation.

Euro window - what is it and how is it done

Perimeter fittings are prefabricated railings, assembled from several parts, mounted along the entire perimeter of the profile. It provides locking of the sash at several points, using one handle, which allows you to achieve the most snug fit and eliminates blowing. Thanks to these fittings, a window with an opening sash can operate in two modes - pivoting and swing-out. In the pivoting mode, the window opens only by turning, in the combined mode, the sash opens and tilts.

The fundamental structural difference between "euro" and ordinary windows is one frame, in which several double-glazed windows can stand. The main of the technical characteristics of "Euro" is complete tightness, achieved by means of various seals. Thermal conductivity will depend on the number of air chambers, and on the type of glass in the glass unit, and on the correct installation of the window. Therefore, the material from which the profile is made does not play a role, the functionality of the structure and its characteristics are important.

Construction of sliding windows

When glazing a gazebo with polycarbonate, you need to accurately determine the dimensions of the frames and other measurements by which it is necessary to calculate the number of doors and material consumption. For clarity, you can draw up drawings. You should also decide on the type of materials - wood or aluminum profile, two-layer or monolithic polycarbonate. The sliding system itself can be designed for a cold or warm room, since in the presence of heating it has certain technical features.

According to the principle of operation, such systems are divided into:

- lifting and sliding;

- parallel sliding;

- folding ("accordions").

All systems consist of a base frame and a movable frame and also have track rollers. Some can use a retractable mosquito net. "Accordion" consists of several doors and is mounted for unheated rooms, because it insulates poorly. When assembling such windows with your own hands, it is best to buy and mount ready-made kits for such systems to the frames.

Learn how to properly lay polycarbonate in your greenhouse.

In addition to the material itself for sliding systems, it is necessary to purchase related tools:

- polyurethane foam;

- protective tape;

- sealant (silicone);

- fasteners (anchors, screws and screws);

- washers.

Equipment required for work:

- screwdriver;

- drill;

- hacksaw or jigsaw;

- pencil;

- measuring devices (tape measure, square, level);

- construction knife;

- circular or hand saw.

Assembling frames and sashes

First, the supporting frame is installed according to the principle of window frames. Then the web is collected and a roller system is attached to it. With the help of a construction knife, polycarbonate is cut along the markings and inserted into a wooden frame. Cutting can also be done with a circular saw. Before installation, the ends of the polycarbonate sheet are sealed with a special tape or closed with an end strip, which is attached with silicone. The frames are inserted into the grooves and nailed down with glazing beads, and then a sealant is used.

Important! When marking and cutting polycarbonate sheets, it must be taken into account that they must be installed so that the air channels are located vertically. Otherwise, liquid from condensate will be clogged in them.

Frame installation procedure

The wooden supporting box is mounted depending on the existing arbor frame.

There are two ways to nail it:

- self-tapping screws - to the wooden perimeter;

- with anchors - to concrete, stone or brick.

All cracks are sealed with polyurethane foam. In its lower part, with a jigsaw or a hacksaw, guide strips are pre-cut according to the size of the rollers. After installation, they are fixed together with other elements of the sliding system and inserted into ready-made window frames. Seals can also be used around the edges of the sliding window.

Installation and adjustment of sashes

The position of the flaps is adjusted using the bolts located on the roller mechanisms. If rollers are not provided, but a simple mechanism is used, then the movable structural elements should move well along the previously cut grooves. A locking mechanism can also be installed on the sashes.

Did you know? Primitive sliding doors have been used since ancient Rome. This is evidenced by excavations in the city of Pompeii.

Polycarbonate windows

For wooden, brick or siding-clad terraces, simple, inexpensive and easy-care polycarbonate windows are suitable. You can use different types of this practical and modern material. Cellular polycarbonate has excellent heat and sound insulation properties, it is very durable, not subject to weather changes, and withstands low temperatures well. An additional advantage is the affordable price. Solid polycarbonate is tough and requires more care when cutting. The material does not differ in high transparency, ready-made windows will create a slight darkening on the terrace. This option is suitable for buildings facing the sunny side.

The polycarbonate sheet resembles ordinary glass. It is absolutely transparent, flexible, suitable for creating fancy windows with small sashes. There are different shades on sale, which significantly expands the capabilities of the designer. The disadvantage of this type of material is a rather high price.

Pros of sliding structures

Sliding windows for the terrace have many advantages, among which it is worth highlighting:

- Their installation will allow rational use of the inner space of the terrace. Doors and windows do not take up space and do not interfere with the installation of furniture close to the wall.

- The sashes are securely fixed in the frame. This excludes their unauthorized movement under the influence of a draft.

- The designs are very simple and easy to use. The flaps are easy to move. They don't need any special care.

- Warm sliding windows allow you to create a beautiful and unusual interior.

- Affordable price. When compared with swing structures, they are somewhat cheaper.

- Mosquito nets move according to the same principle as the sash. As a result, there is no need to take them off to go outside.

Thanks to these advantages, sliding window and door designs are widely used on terraces and verandas. They are also installed in winter gardens.

Sliding terrace windows have different design features. It all depends on the type of system. To date, the following designs are used for glazing verandas:

- Lift-and-slide design. It works like a wardrobe. Raise the fold slightly before opening. As a result, the pressure from the bottom is weakened, which makes it easy to move the sash. The frame is equipped with a rubber profile seal, which makes the system tight when closed.

- Tilt and slide. To open such plastic windows, you need to pull the sash towards you, and then move it to the side. The system is equipped with a locking device, the same as in conventional plastic windows. This allows the sash to be locked in a certain position. You just need to turn the knob to a specific position. This allows you to put the system on micro-ventilation. To ensure heat and sound insulation, a rubber seal is installed in the frames.

- Sliding foldable design. The accordion system consists of several leaves. When opened, they fold up, which opens the opening across the entire width. If necessary, only a few leaves can be opened.

- Frameless structures. Glazing of the terrace with sliding structures is carried out using impact-resistant glass, which is highly resistant to mechanical damage.This ensures reliability and safety in operation. The canvases move along special guides in one direction. When open, they are located against the wall and take up little space.

When choosing a design, it is worth considering the features of its installation and operation. This is especially true for the "accordion". It does not provide full heat and sound insulation, which is necessary for the use of the premises in all weather conditions.

Types of sliding windows by material

The choice of material is directly influenced by the financial capabilities of the owner, from which the house and the veranda itself are built, as well as a number of other aspects. Below we will talk about the most convenient and reliable ones.

Aluminum

This material is considered one of the most practical; it is often installed on terraces where there is no heating. On sale you can find two options for sliding aluminum windows: with a cold and warm profile. The first one is suitable for unheated verandas that are used only in summer and therefore do not require additional insulation, and the second one is suitable for houses that are in operation all year round.

Did you know? The first written mention of window glass dates back to 1240 — it was called "Roman", and the text itself described the church, which was built by Prince Daniel Galitsky.

- Among the advantages of this material are:

- long service life - the glazing system does not need to be changed for half a century, or even more;

- attractiveness of appearance;

- no need to refresh the color every few years;

- ease of installation and further maintenance;

- tightness;

- no heavy load on the foundation due to its low weight.

There are also a number of disadvantages. For example, many people may be put off by the high cost of aluminum sliding windows, they heat up quickly in summer and cool down in autumn and winter. Although tightness is truly considered a plus, there is a frequent need to ventilate the room.

There are also a number of disadvantages. For example, many people may be put off by the high cost of aluminum sliding windows, they heat up quickly in summer and cool down in autumn and winter. Although tightness is truly considered a plus, there is a frequent need to ventilate the room.

Plastic or PVC

Plastic sliding structures have frames made of multi-chamber PVC profiles. The obvious advantages can be considered a relatively low cost, non-susceptibility to aggressive weather and weather conditions, strength, durability, and ease of maintenance.

Important! In sub-zero temperatures, the plastic tends to shrink in size, which makes the connection of the flaps less dense.

There are not so many disadvantages - the massiveness of the frames, which do not burn with an open fire, but melt, exuding a smell that is unsafe for human health. Unlike aluminum sliding windows, this design received a second name "warm glazing", since they are equipped with double or even triple glass units that do not conduct cold.

Materials used

Unlike an open or semi-closed canopy, a closed garden gazebo can be used at any time of the year. Such buildings combine functions summer kitchen and areas for rest and pleasant pastime with the family, therefore, the choice of glazing of the object plays an important role.

Polycarbonate sheets are a synthetic thermoplastic polymer made by organic synthesis of carbonic acid. Polycarbonate is not hazardous to the environment. Due to its safety and environmental friendliness, polymer plastic is used in the construction industry, the national economy, instrument making and medicine.

There are two types of polymer plastic: monolithic and honeycomb.

When choosing a window material, do not forget about the conditions of the location where you live

When choosing a window material, do not forget about the conditions of the location where you live

Monolithic polycarbonate is a solid sheet, the main technical characteristics of which are called high impact resistance, resistance to temperature extremes and maximum light transmittance.

Cellular, or cellular polymer plastic consists of two panels connected by perpendicular bridges. The degree of flexibility of a material, its strength and endurance is determined by the number of internal ribs.

When choosing a material for glazing, it is recommended to take into account its technical characteristics and features. So, for regions with severe frosts and gusty winds, a monolithic canvas is suitable. Cellular polycarbonate keeps heat better and has high noise insulation performance.

In this video you will learn how to install polycarbonate windows:

Which double-glazed window to choose

The greatest demand is for single-chamber and double-glazed windows. One chamber means that the window structure consists of two panes, between which there is an air cavity. It prevents cold air from entering. Single-chamber glasses can be installed in a gazebo, which will not be used in winter.

If you plan to create a year-round gazebo, then it is best to use two-chamber glazing. Such canvases include three glasses, between which there are two air cavities. It is this design that will provide the best protection against cold weather.

Such a gazebo with sliding windows will be functional and comfortable.

Gazebo made of plastic windows

A gazebo with plastic windows may involve the use of such windows as a frame. This means that the structure will not have the classic pillars. All its walls will be presented exclusively by plastic windows. Sliding windows into a gazebo of this type are also possible.

- Such buildings have certain features that need to be specified in more detail:

- Plastic gazebos need a foundation. After all, windows themselves made of plastic with a PVC or aluminum profile cannot serve as a support for the entire structure. They cannot be simply placed on the ground or otherwise secured;

- The configuration of glazed arbors can be any - rectangular, square, with six corners, and so on. But creating a round gazebo will not work, since the profiles will inevitably create many angles. But outwardly, such a design will be very similar to a round one;

- Plastic windows must be installed on a solid foundation. For this, you can use a wooden bar. Such logs are laid directly on the foundation. They are strong enough to support the weight of the structure;

- When erecting such gazebos, it is necessary to make the foundation correctly. It is on its strength that the durability of the building and its stability will depend.

You need to know that the base for the gazebo should be larger than its borders. That is, the dimensions of the base should exceed the dimensions of the gazebo by 50 cm on each side. At the same time, the gazebos made of plastic windows are very beautiful. They let in a lot of light, leave room for decorating the interior space with decorative elements. At the same time, the gazebo with plastic sliding windows retains heat perfectly. If you arrange a hearth or a stove inside, then the structure can be used in any weather.

Installation of windows in a polycarbonate gazebo

The glazing can be solid. In this sense, the use of polycarbonate should be noted. This material can simultaneously act as glazing and as the walls of the gazebo.

The construction principle will be standard. It is necessary to fix the polycarbonate fragments that were made in advance to the support pillars.

Such gazebos have a number of significant differences. They need to be described in more detail:

Floor and foundation will be important elements. For the construction of the foundation, it is necessary to use columnar technology. They consist in the construction of low brick posts, on which wooden logs are subsequently laid

The columns should be raised above the ground level by 30 - 40 cm;

In addition to the foundation, serious attention must be paid to the construction of the floor.The basis will be horizontally laid logs from a bar

On the indicated logs, a board and moisture-resistant plywood are laid;

Supports for attaching polycarbonate are attached to horizontal joists using corners and brackets.

Installation of windows taking into account the roof

Since plastic windows or aluminum profiles cannot withstand high pressure, heavy roofing materials should not be used. It is not recommended to use metal tiles, natural tiles.

Polycarbonate or soft roofing is ideal. If you plan to install natural tiles, you should make a solid top strapping from a bar. It will be able to withstand the load of a heavy roof and protect the frame made of plastic windows from damage.

In this case, glazing can be combined with a wooden fence. It can reach one and a half meters in height. An aluminum profile or plastic windows are installed on this fence as a frame.

Installation of windows is carried out using construction foam. This is a versatile option for such designs.

Maintenance of sliding structures

In order for the installed system to serve for many years and not lose its newly purchased appearance, it is recommended to study and take note of a number of care rules:

- Once every 2-3 years, it is necessary to disassemble the sashes and clean them with a damp cloth or vacuum cleaner from accumulations of dust and dirt.

- If you have a “cold” aluminum construction, a thorough cleaning of the slotted seals is required every year, as there is a lot of dust accumulating there.

- The mechanism must be lubricated to ensure good performance.

- Be extremely careful with the flaps, especially if a lift-and-slide system is installed.

- During severe frosts, the shutters often freeze and it is simply impossible to open them, however, it is strictly forbidden to use brute force. Instead, it is worth keeping a special tool on hand - a glass defroster. If its purchase is not possible, you can use a hairdryer, warming up the required area.

There are very few rules, but following them you can significantly save money and time for calling the masters and repairing broken mechanisms.

There are very few rules, but following them you can significantly save money and time for calling the masters and repairing broken mechanisms.

Polycarbonate windows: cheap and practical

Polycarbonate has distinctive features, thanks to which it can be used for the manufacture of windows. This material is capable of transmitting light through its surface, blocking the flow of ultraviolet radiation and withstanding onslaught and impacts of various strengths. Moreover, its cost is quite low.

Cellular polycarbonate windows

Do-it-yourself constructions for a gazebo or veranda made of this material can have an arbitrary appearance or be placed in a metal-plastic, wooden or metal frame. Frameless structures can be easily bent, which allows for curved shapes.

What are the different types of polycarbonate for windows? Allocate:

- cellular polycarbonate,

- monolithic systems.

The first type, shown in the photo, has a high level of noise and heat insulation. It has a high density, due to which the room can be very dark. Due to its attractive appearance, this material will harmoniously suit any interior, and you will have the opportunity to create new design ideas. With the help of cellular polycarbonate, you can decorate an office, a balcony, and also form canopies and roofs for a gazebo or veranda.

A monolithic block, as in the photo, has a higher cost, but it stands out for its great strength, low weight, safe operation and high ability to transmit sunlight.

Polycarbonate facade

To make polycarbonate windows with your own hands, you need to take care of the availability of such consumables:

- polycarbonate sheets of the required color, size and type;

- protective tape;

- several end and connecting profiles;

- a sufficient number of screws, anchors and self-tapping screws;

- sealing washers for sealing;

Also, the following tools should be available:

- puncher, which is necessary for drilling holes;

- pliers - will be needed during installation;

- screwdrivers, screwdrivers - will be needed to screw in anchors and screws;

- a clerical knife - will be needed during the execution of installation work, as well as to eliminate excess polyurethane foam after it has hardened;

- building level - necessary to correctly set the location of the windows during their installation;

- nail puller, scrap - will be used when removing old frames;

- saw - needed to align the edges of the frame;

- a tape measure will allow you to correctly take all measurements for the frame;

- polyurethane foam will be used to seal the structure;

- circular saw - to cut polycarbonate blades.

Preparatory stage

If weight, price and insulation are the main factors, the obvious option would be to use cellular polycarbonate for veranda glazing, which is 13 times lighter than conventional glass of the same thickness. If strength and transparency are important to you, the choice falls on the monolithic option. The monolithic version is more expensive and heavier than its cellular counterpart, but still several times lighter than ordinary glass.

The preparation of the veranda glazing begins with measurements of future windows and the acquisition of the required number of polymer sheets. Further, in accordance with the selected type of windows, related parts are purchased: aluminum tape, runners, hinges, self-tapping screws, thermal washers. Then you can start marking and cutting. Polycarbonate at home, depending on the thickness, is cut with a clerical knife, jigsaw or grinder. Do not forget that the honeycomb polymer is sensitive to orientation in space and should be positioned so that the cells are located along the window opening with a protective anti-UV coating outward.

There are some nuances when installing such windows.

Do not forget that you need to drill 10-15 mm more holes for the thermal washer to compensate for the thermal expansion of the polycarbonate panels.

Glass or polycarbonate: what to choose

Ordinary window glass, plexiglass or polycarbonate can be inserted into the frames. Each material has its own advantages and disadvantages. The glass is transparent, for the terrace you can choose transparent, tinted, matte versions. However, this material is quite heavy and very fragile and requires special cutting skills. It is difficult for a beginner to avoid a high rejection rate. If it is decided to use glass for decoration of the terrace, it is better to choose an impact-resistant material, although it will cost a little more.

Plexiglas is much stronger, has good light transmission, and is suitable for panoramic and frameless glazing. It can be used for cold and heated verandas, gazebos and other buildings. Plexiglas perfectly withstands heat and the scorching sun, is quite cold-resistant, does not require additional protection from ultraviolet radiation. The material is cheaper than polycarbonate and ordinary glass, suitable for self-installation.

The main advantage of polycarbonate is its increased strength. Having installed such windows on the terrace, there is no need to worry about their safety. Falling icicles, hail, sharp gusts of wind will not harm the windows. Polycarbonate is easy to cut and install. Among the downsides is less transparency.

Varieties by type of construction

In order for the selected windows to ideally meet the requirements of the owners, all attention must be paid to the mechanism of movement of the sashes. There are four main types of structures on the market today: lifting, tilt-and-slide, sliding and frameless

All of them are at approximately the same level of demand.Basic information on each type is provided below.

Lift-and-slide system

This design works on the principle of a wardrobe: you need to open the window slightly by raising it, thus reducing the weight on the lower sashes. The mechanism is simple and comfortable to use.

The disadvantages are the high cost and the inability to open the window to the full width of the opening, since the sashes move one after the other.

The disadvantages are the high cost and the inability to open the window to the full width of the opening, since the sashes move one after the other.

Tilt and slide system

This option is similar to ordinary plastic windows, but the main difference is that tilt-and-slide windows can open both towards themselves and to the side. Such a system can sometimes be found on tourist buses.

Did you know? PVC, which is the material for the manufacture of the profile of plastic sliding windows, is considered one of the safest and most environmentally friendly materials. In medicine, it is often used to create blood storage containers.

- Advantages:

- the highest level of heat, sound and waterproofing;

- rational use of space in a small room;

- the mechanism allows you to fix the sash open for ventilation;

- the presence of an opening limiter: you can leave the sash in any desired position;

- in the price segment takes the middle place.

The only significant drawback can be considered the mandatory presence of a threshold that cannot be stepped on: polyvinyl chloride quickly deteriorates if it has a lot of weight. However, you can additionally acquire specialized pads that will protect it from damage.

The only significant drawback can be considered the mandatory presence of a threshold that cannot be stepped on: polyvinyl chloride quickly deteriorates if it has a lot of weight. However, you can additionally acquire specialized pads that will protect it from damage.

Sliding foldable design

This glazing system is popularly called "accordion", as it consists of several doors that fold, allowing you to open the opening to the full width. The advantages of this design can be considered the ability to zoning the space, good heat and sound insulation, the ability to let in the sun's rays, the system is made of different materials (PVC or aluminum), opening one or two doors.

No obvious disadvantages have been identified.

No obvious disadvantages have been identified.

Frameless glazing system

The design appeared in the CIS countries relatively recently. The main distinguishing feature of glazing is the absence of any partitions and frames, so it looks light and does not burden the interior.

In addition, unlike the above-described varieties, the frameless system involves the use of thicker glass 6-12 mm. The design works like a wardrobe, the windows are opened by sliding the segments on rollers along the runners of the lower part of the profile in one direction.

Also learn how to make your own veranda roof.

- Advantages:

- can be used for all types of terraces and balconies, regardless of shape and size;

- the presence of impact-resistant glass and reliable fasteners;

- the inner space is filled with sunlight as much as possible;

- thorough protection from wind, precipitation and dust;

- ease of care;

- installation at any time of the year.

- Disadvantages:

- low thermal insulation;

- the noise level behind the glass is reduced by no more than 10–12 dB;

- the need for thick curtains, blinds or tinted glass in the mass, so as not to be in full view of your home all the time;

- it is undesirable to install this system on heated loggias and balconies;

- the temperature difference between the room and the street differs by only a couple of degrees.