Instructions for creating a metal pergola with your own hands

A metal pergola, like a wooden one, is also made after a preliminary drawing of the future structure. After acquiring the necessary material, we cut the pipes into fragments according to the specified parameters - for racks, crossbars and stiffening ribs. It is advisable to treat the pipes with special compounds against corrosion, thereby increasing the service life of the structure.

If there is a welding machine and a specialist who understands this, then the assembly of the structure will take place quickly and without any problems. You can also use another option for reliable fastening - using bolts.

- At the location of the support posts, we make holes with an average depth of 60 cm. The diameter of the holes is 15–25 cm. An ordinary garden drill will facilitate the work.

-

Small gravel and sand are poured into the depression, to the very bottom. Stand pipes are placed and leveled using a level. Using the boards, the pillars are fixed in the desired position and then poured with concrete.

- The next stage can be started no earlier than a week later, since the concrete should harden and become a reliable support for the pillars. After making sure of the strength of concrete hardening, you can begin to make transverse structures. To do this, pipes are first welded to the racks in a horizontal position, and the crossbars are welded to them. The construction for decorating the site with climbing plants is ready.

The upper part of the pergola made of metal

To make the vegetation more lush, you can stretch a steel wire over the metal structures, stretching it from vertical posts to the earth's surface with a step between elements of 15–20 cm. Green plants will tightly wrap such a pergola, leaving almost not a single centimeter for the scorching sun to penetrate. Beauty, coolness and fresh air - all this can be "obtained" being in the shadow of this building.

A great place to relax - a metal pergola

Functions and structure

Translated from Latin, pergola is a canopy, an extension. So, this structure looks like an arched structure on supports with a lattice roof. It can stand both separately and join residential buildings, for example, close the terrace of a house, serve as a kind of corridor between buildings, and can also decorate a garden path from the house to a gazebo or pool.

Today pergolas are used for the following purposes:

- support for climbing and climbing plants;

- protection from the sun, partly from wind and light rainfall;

- creating a place for comfortable rest and privacy;

- territory zoning;

- increasing the decorativeness of the territory;

- connection of two functional areas of the site;

- hiding unattractive areas of the garden, outbuildings.

Pergola in the design of the site.

Pergolas can be made from a wide variety of materials: metal and wood, stone, brick and concrete. Also, the design can be of different types:

- Screen (trellis). It has the appearance of a mesh partition, which is ideal for zoning a garden and covering unattractive areas of the yard.

- Awning. Such structures can stand alone or be attached to a building. They look like a round or square gazebo. Also used to create a shadow over a car or over a children's play area. The roof is usually openwork, so a slight partial shade is obtained below.

- Tunnel (corridors). Usually used over garden paths, they connect two buildings or two areas of the territory. They can be created from broken or curved lines with a common guide.

- Canopy. Attached to the facade or installed over windows for shading.

Given the variety of building materials, the possibility of their combination, as well as the versatility of forms, decorative plant sheds can have a completely different look, from the most laconic to pretentious and luxurious, for example, with a base made of natural stone and wooden carved arches.

Pergola with arched top.

Construction of an upgraded version

We make a pergola with a bench in the same sequence as the construction of a classic building.

Step-by-step instruction:

In the upper part of the support posts, we make recesses for the subsequent fastening of the rafters.

Then we attach the seat frame made of wooden blocks to the racks.

When constructing the frame, it is important to ensure that all corners are straight. To connect the seat frame with the racks, we drill the guide holes, and then screw in the self-tapping screws.

We attach the back to the rear pillars

To do this, we make horizontal guides from bars, which will serve as the basis for installing vertical slats.

Experiment with pergola designs

Experiment with pergola designs

- We create a spike at the ends of the posts, and grooves in the horizontal ones that coincide with the holes in the posts. They must be secured with galvanized self-tapping screws.

- Due to the back and seat, the pergolas will gain additional stability. Now you can install the rafters. Mark the cutting line with a pencil and make the workpiece with a jigsaw. We install the rafters in the pre-prepared recesses and cover with stain.

- We install the seat on the frame, attaching boards to it using galvanized self-tapping screws. We lay out the boards in such a way that there is a gap between them.

- To make the structure complete, a lattice should be placed on its lateral sides. The frame made of bars can be fixed on the racks with self-tapping screws, and inside the frame you can put a finished lattice and fix it with finishing nails.

We start construction

When building a wooden pergola, the problem of insulating wood from the ground arises - for its greater durability. Also, to increase the service life, you can treat the tree with an antiseptic. Today the following solution is used. This is a metal glass or U-shaped structures, metal fittings are welded to them. This reinforcement is placed in the foundation, and the timber racks are installed in the glasses. At home, to implement such an idea, you can use pipe cuttings and a square profile of a sufficiently large section. You can also use multiple corners. That is, it is necessary to cut the corner into two pieces of 50-60 cm. Further, according to the size of the timber, the racks are driven into the ground so that the rack is firmly held between these corners. After that, the corners are fixed by welding with metal fittings near the surface of the earth.

When using a bench with a curved design, the back row of benches was originally used as a support for the pergola itself. For the supports of a circular structure, a beam of small thickness (50 × 50 mm) is usually used, since this shape is well resistant to strong winds. It is attached to the legs of the bench, which have the shape of the letter G, using self-tapping screws. It is also necessary to put a stone under the support - for isolation from the ground. After the lawn grows, there will be no noticeable gap between the pergola and the ground, and there will be a feeling that it is dug into the ground. This gap increases the durability of the wood. After complete installation of the support, the top must be cut off at an angle of 30–40 degrees, and the entire support must be impregnated with an antiseptic solution.

Further, all other supports are installed in a similar way. The thickness of the timber will differ only at the central support - it is equal to 100 × 100 mm. In this support, a special device is made for fastening all horizontal rafters. Here we are not talking about the ideal horizontal rafters. They are attached at a slight angle to the main support. This place will be the highest. Accordingly, the main support should be higher than the rest.

Making a pergola made of wood in the garden with your own hands (with photo)

In any garden, you can find a place to place light and graceful DIY garden pergolas. Plants climb along these beautiful frames, creating protective screens from the sun and wind. Externally, the pergola resembles an unfinished room - several racks support an uncovered lattice roof. However, nothing else is required: between the racks they stretch a wire or stuff trellis, along which creeping plants rise, forming green walls.

You can build a pergola as a separate structure, or you can attach it to a building.

Look at the photo - often garden pergolas play the role of a green room in the patio:

Structurally, the pergola is a series of arches, frames or paired pillars placed one after another, tied from above with a crate, under which there is a place for rest. The most widespread are wooden pergolas for summer cottages - with pillars, supports and lathing made of wood, as well as mixed ones - with metal or brick supports and wooden lathing. The best building material for a garden is traditionally wood. But with the appropriate layout, pergolas for summer cottages made of metal can also look extremely impressive.

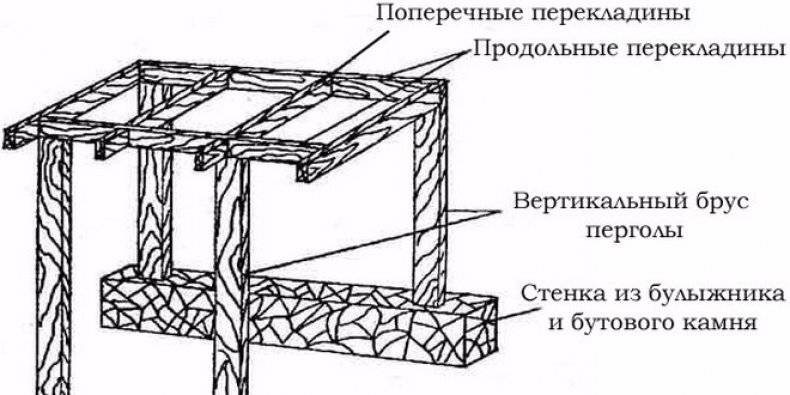

How to build a pergola with your own hands, spending a minimum of effort? The simplest structure can be assembled from two pairs of poles dug vertically into the ground, which are connected from above by longitudinal crossbars of poles with plank struts. A rare flooring (also made of poles) is laid across, forming a kind of roof frame. Poles are suitable for poles with a diameter of 8-15 cm, for beams - about 8 cm. Between the posts and the ceiling, you can stretch synthetic cords or wire for more support for climbing plants, which over time form a beautiful green tent. It should be borne in mind that such a pergola will harmoniously fit into the style of the site, where there are details from poles in the construction of the house and the fence.

Do-it-yourself pergolas located in an open area should be durable, since curling greenery creates a large load under the gusts of wind. In this case, beams with a cross section from 100 x 100 to 150 x 250 mm are usually used for the frame, and thinner moldings are chosen for filling roof elements and trellises. All lumber intended for work must be treated with protective agents against decay.

As you can see in the photo, when building a pergola with your own hands, it is important to observe the proportions:

The most appropriate height is within 220-250 cm. Too low pergola causes a feeling of crampedness and discomfort, however, an excessively high structure does not look better, although it must be remembered that, intertwined with climbing plants, it seems narrower and lower than it actually is.

In the manufacture of a pergola made of wood for a summer residence, the support pillars are installed in two rows at a distance of 2 m from each other. The distance between the rows is 2-2.5 m, but it can reach 3 m, it all depends on the general proportions of the garden. The sizes are due to the fact that the corresponding plants (grapes, lemongrass, actinidia, clematis, etc.) are planted near the pillars, which then braid the pergola.

The following is a step-by-step instruction on how to make a wooden pergola with your own hands, standing separately from the building.

Self-made roof

At the ends of the bars 150x50 mm, oblique cuts are made at an angle of 45 ° with an indent of 50 mm, as in the photo.

From the top of the pillars, 14 cm are measured and under this line, 60-cm pieces of 5x10 cm board are screwed onto the screws.

Prepared crossbeams 150x50 mm are installed on temporary supports. After that, at the place of their joint with the pillars, two holes for galvanized bolts are made with a drill.

A similar double bar is made on the parallel side of the pergola. Then the remaining bars 15x5 cm are evenly spaced across the already installed beams.

Fixation of the upper crossbars to the lower bars is carried out using self-tapping screws screwed in at an angle of 45 °.

All existing boards 2.5 cm thick and 10 cm wide are attached on top of the ceiling frame. The distance from the edge is 20 cm on each side.

The next step is to cut two three-meter boards 5x10 cm to 275 cm, that is, cut off a small piece of 25 cm from each.After that, 15 cm is measured from the bottom edge of the double crossbar and under this mark the trimmed boards are fixed on self-tapping screws.

Two bars with a thickness of 20x20 mm are sawn into 8 parts, the edges are cut at an angle of 45 ° and, in an amount of 4 pieces on each side, the segments are screwed to the inner edge of the double beam and the crossbar underneath with self-tapping screws.

The perimeter of the pergola can be left unpaved, or a small border can be made of 5x10 cm boards fastened with self-tapping screws.

Backfilling the surface with gravel involves removing the surface soil, making a preliminary cushion of sand with watering and tamping. On a platform leveled in this way, you can pour gravel with a fraction of up to 2 cm, so that it is convenient to walk on it.

A pillow made of small stones can be laid with thick carpet or other material. The resulting site is furnished with comfortable furniture to the taste of the owners.

How to make a pergola with your own hands: diagrams and drawings

After familiarizing yourself with the features and types of a pergola, you need to have information on how to make a pergola with your own hands, and the proposed step-by-step instructions will become an indispensable assistant.

Made of wood

For the construction of a classic wooden pergola, the following materials will be required: support and cross beams, crossbeams, posts, adjustable anchors, tubular formwork, self-tapping screws of different sizes, cement, sand, gravel.

Work begins with the outline of the future pergola. In the corners, formwork is buried in the previously prepared pits so that they are all at the same level. Pits are poured with a small amount of concrete. Until he fully grasps, anchors are installed.

After the concrete has completely solidified, wooden racks begin to be installed. For them, take the bars of the desired size and use a level to place them vertically, fix them in two directions using hexagonal screws made of wood.

Then they begin to install the support beams. Here you need to purchase boards, the size of which depends on tastes.

It is important to consider that they should protrude beyond the perimeter of the building by 30 cm. Before fastening, they are leveled horizontally and only then fixed with clamps.

At the end, through holes are drilled at the junction of the beam and the rack and the bolts are inserted.

Install transverse beams from the boards. They should be straight. The amount of light depends on the distance between them. Most often, the gaps are 30 cm. For fastening, two notches and guide holes are made at both ends. Now everything is fixed with long screws.

Finally, the cross beams are attached, which increase the rigidity of the structure. Holes are drilled on them and fixed.

Important! To build the correct design, you need to know that in order to check that all corners are straight, one rule should be taken into account: "3-4-5" (32 + 42 = 52). In which case, you need to immediately make adjustments

After all the work, the structure is covered with several layers of varnish.

Also, on your site, you can arrange a beautiful front garden and decorate the area with a hedge.

Made of metal and plastic

Do-it-yourself pergola arches can be made of metal. Like wooden, metal is made only after a preliminary drawing of the future structure and the designation of the contours of the building.

In addition, working with metal requires some skills in working with a welding machine. You will need a profile pipe, cement, building level, welding material, paints and varnishes.

All work is divided into several stages:

- Cutting out parts. Parts are cut from shaped pipes, the diameter of which varies depending on the length of the product. You need to make all the details that are needed for the construction. So that the parts do not corrode in the future and the entire structure does not collapse, everything is treated with paint.

- Fixing the supports and installing the rafters. The supporting pillars must be fixed in the ground, the depth of the pits must be at least 50 cm. A gravel pad is poured onto the bottom of the recess, and then a small amount of concrete is poured. After it dries, a support is installed and poured with concrete to the edges of the pit. Rafters and crossbars are welded to the top of the support only after the concrete is completely dry. Stiffeners are installed last, which will provide the structure with strength.

Construction of a pergola made of wood

For the construction of a wooden structure, you will need a carpentry tool, an antiseptic wood preservative, a drawing and high-quality material. In the construction of support pillars, a beam with a section of 150x150 mm is used, and boards of 50x150 mm are suitable for transverse beams. The crossbeams are made of 50x100 mm boards. The elements are fastened using self-tapping screws with a length of 150 mm and 75 mm.

For the screen, you can use boards with the same parameters as for the canopy.

The creation of a wooden or metal pergola involves concreting the support pillars. To do this, you need a garden drill, a container for mixing cement mortar. The complex of works is as follows:

-

At the site of the future construction, the outline of the structure is marked using a rope and pegs. At the same time, the exact location of the corners is noted by placing pegs in place of the pillars.

-

In place of the future pillars, holes are dug about 70 cm deep, and the diameter of the recesses should be 10 cm larger than the diameter of the pillars. Gravel is poured onto the bottom with a layer of 5–10 cm, and then a formwork of asbestos pipes or rolled roofing material is placed. The evenness of the formwork is checked with the building level, and then the forms are poured with concrete, installing adjustable anchors for the subsequent installation of pillars.

-

The concrete dries out for several days, but for now a pergola is made from a bar. For supports, parts with a section of 100x100 or 150x150 mm are used. They are sawn off according to the required height of the structure. After the concrete has dried, the racks are mounted on the anchor with special screws, which are called "wood grouses".

-

The roof support beams are made of 50x150 mm boards. Their length should be 60 cm greater than the width of the pergola, since on each side of the beams they protrude about 30 cm. The ends of the elements can be shaped using a jigsaw.

-

The beams are fixed with self-tapping screws or bolts and the evenness of the installation is checked using a building level.

-

Cross beams are made from boards of 50x150 mm. The number of such elements is determined depending on the fact that the distance between them should be 30 cm. On the lower part of the crossbars, grooves with a depth of about 3-4 cm are cut out.

-

The crossbeams are fixed with self-tapping screws 150 mm long. Thus, these elements are placed throughout the roof of the pergola.

-

In the next row, the crossbeams are mounted with a step of 60 cm. Grooves are made in the elements, and during installation they are additionally fixed with self-tapping screws. The final stage of work involves painting, design design.

Top assembly

Capitals are put on over the columns, after which the extreme beams (50x250) are installed, marked on the diagram with the letter "E", which are fixed with steel corners.

Two beams F1 and an average F2 (50x250 mm) are docked to them with the help of corners and self-tapping screws. After installing these three beams, guides 25x50 mm are screwed to them along the entire length. Self-tapping screws should grab the guides every 20 cm.

Crosswise (50x200) are installed on guides and on each side are attached to the main beams with three self-tapping screws.

Sidewall manufacturing

The sides are cut according to a template from a board of the same size as the crossbars (50x200). Then the strips are screwed to them from above, and the whole structure is attached to the beams and crossbars using self-tapping screws.

After placing the sidewalls, the upper strips are installed. Their number can be arbitrary in accordance with how shady you want to make the area under the pergola.

At the end, ventilation holes should be made in the column plugs and PVC pipe with an angle fitting should be installed in them on the sealant.

Before painting the pergola, do not forget to putty and sand the heads of the screws.

Based on materials from The Family Handyman magazine.

You may also be interested in:

- 8 mistakes in the construction of frame houses (photo)

Pergola and its purpose

In the garden or just in a suburban area, a pergola is often installed. This structure is a kind of gazebo, consisting of upper floors and supporting pillars. The roof can be horizontal or slightly sloped, and the walls are often presented in the form of a grid or shaped lattice.

Pergola made of wood - an environmentally friendly and beautiful design option

The design of the pergola is quite simple and multifunctional. The construction of a pergola is often carried out for the following purposes:

- organization of a place for rest;

- addition of landscape design;

- zoning of the site space;

- camouflage of technical or economic buildings;

- addition of home design;

- support for climbing plants.

The functionality and simplicity of the design make the pergola a versatile, practical and convenient solution for a suburban area. From a wide variety of options for structures, you can choose the optimal one depending on the area of the site, design style and other factors.

Design advantages and disadvantages

A simple version of the pergola consists of support pillars and a lattice-shaped roof. There are various variations, but the gazebo most often has no walls and is a kind of canopy. The role of the walls can be played by lattice supports, along which plants climb. In this case, the pergola is more closed than the version with simple support posts.

Pergola can perform various functions

The general structure of the structure is simple, and the appearance and design of the pergola is created with the help of decorative elements, beautifully shaped details. The material from which the structure is made has a significant impact on the appearance of the gazebo. For this, metal or wood is often used. The first option serves as the basis for creating graceful wrought iron pergolas. The advantages of metal structures are expressed in the following:

- reliability, durability;

- the graceful shape of the structure, decoration with forged twisted patterns;

- resistance to mechanical stress and climatic factors;

- the ability to paint in any colors.

Metal gazebos also have disadvantages. One of these qualities is expressed in the complexity of self-construction of structures. A wrought-iron pergola cannot be built independently, and a simpler option requires complex actions, for example, welding metal elements.

Forged pergolas effectively function as a gazebo

A simpler and more convenient pergola made of wood. Construction from such material does not require special knowledge and tools, and the positive qualities are expressed in the following:

- environmental friendliness and pleasant structure of the material;

- easy processing, simple installation;

- the ability to create original designs;

- resistance to climatic factors.

The wood is comfortable to use, but requires careful processing, involving the use of antiseptic agents to prevent rotting. In harsh climates with changeable weather, it is not recommended to install wood pergolas or they should be disassembled for the winter. This is due to the fact that the material is prone to cracks and deformation.

The choice of a particular material depends on financial capabilities, personal preferences, and material properties. If you need a construction that is practical and does not require special maintenance, then metal is the best solution.

Photo gallery: options for pergolas from different materials

Massive pillars accentuate the graceful roof of the pergola

The stone pillar structure looks impressive and is suitable for a spacious area

Cozy pergola is a good place to relax

Pergola is a great place to relax for a company or family.

A cozy gazebo decorates the garden

Metal wrought iron pergolas perfectly complement the landscape design

Long pergola makes the site cozy