Required tools and materials

Since the pergola will be completely made of wood, you will need a regular carpenter's tool to work. The main thing that you definitely can't do without:

- hand saw or power saw;

- plane (manual or electric);

- a set of chisels;

- electric drill;

- hammer and nails;

- screwdriver and self-tapping screws;

- varnish or paint and a few brushes;

- tape measure, joiner's square, level.

If the pergola will be installed on piles or a foundation, it is additionally necessary to prepare a trench tool (bayonet and shovel), it is convenient to make holes in the ground under the piles using a drill.

Of the material, first of all, lumber is needed. For the manufacture of racks, a bar with a cross section of at least 80 x 80 mm is suitable; a rail or a thin board is suitable for creating jumpers and lathing. Of the fasteners, metal brackets are needed; you can strengthen the butt joints with the help of steel corners.

When choosing lumber for a pergola, you should not buy planed boards and beams, it is much cheaper to take the material immediately after cutting, you can give the blanks an attractive look yourself using a planer. You will have to spend a little time on this, but a price gain is guaranteed.

A unique place to watch the skies

The lack of a cozy dacha outside the city is not a reason to abandon your home paradise. It can be placed on the roof of a residential building. In megacities, this type of recreation has been practiced for several decades. Therefore, brave guys equip a pergola on the roof of the house in which they live.

A miniature gazebo made of metal rods, against the background of concrete slabs, will seem like a real oasis of pleasure. They decorate it with ampelous flowers that exude a delicate aroma and create a light shadow. In the daytime, in such a "tent" you can watch the clouds, and at night you can contemplate the majestic stars.

Decorative stands for climbing plants

Some craftsmen make small pergolas from reinforcement on their sites. Their advantage is that such a design can be made of any shape and even a collapsible type. To do this, washers are welded in the places of the main attachment and fixed with nut bolts. In addition, such pergolas can be decorated with forged decorative details. They are often used as a support for climbing plants.

For several centuries, gardeners have come up with all kinds of designs for gazebos, awnings and openwork arches to decorate with lush greenery and flowers. And today, even novice craftsmen can easily make a pergola for climbing plants with their own hands and install them in a garden area.

This structure is a structure that is used to protect the area from the scorching sun. With its help, various types of garden landscapes, green fences and even car shelters are created.

To create a pergola, it is necessary to connect several repeating arches with transverse beams. In addition, the structure can be independent and adjacent to the building. It all depends on the wishes and preferences of the master. It can be made even from the following materials at hand:

- wooden beams;

- metal fittings;

- plastic;

- shoots of plants.

Let's take a closer look at some of the species.

There is no waste in the garden

An original pergola from branches is made using simple materials and tools (ax and rope). To do this, one of the edges of the shoots is sharpened, after which they are tied with a strong rope and set up in the form of a tent. The climbing plant will be able to freely climb the structure, creating shade on a hot day.

Openwork designs for green design

From metal reinforcement or wooden slats, a wonderful circular column is obtained. First, the main elements are exposed in a circle. Then connect them with a strong rope. The result is an original support for climbing garden plants.

Arched pergola for the garden

For the construction of the structure, the following materials are used:

- metal fittings;

- wooden beams;

- plastic pipes.

The arched pergola is installed as an amazing support for climbing plants to highlight the beauty of the garden landscape. It serves as an excellent entrance or entrance to the courtyard and a wonderful seating area.

Pergolas with crate

Such structures are made of wooden slats, which are treated with an antibacterial agent before assembly and a layer of varnish is applied. The finished product is attached to the building with screws and dowels.

Features of buildings adjacent to the house

The buildings adjacent to the house are of different sizes and configurations: made of wood and polycarbonate, open and glazed, with a barbecue or barbecue.

Direct communication with housing construction is the main advantage of the extension. There is no need to complete a covered platform across a courtyard or walkway that stays dry in the rain. The garden structure in the country house, attached to the main building, makes it possible to relax in the fresh air right in your home clothes, without risking getting dirty. Dishes and food will be easier to carry into an outbuilding than into an individually standing building, and in case of rain, furniture or food can be easily brought into the house.

It is better to attach a garden structure to a wall with a window or direct exit from the kitchen.

The outbuildings adjacent to the house are very versatile and variable. There are a huge number of possibilities for arranging such spaces - from a place for gatherings to a full-fledged guest bedroom.

Pergolas are unique decorative and functional buildings. This element of landscape design will become a real highlight of a country house with proper placement and landscaping. Fast-growing climbing plants are best suited for decorating a pergola.

Flowers, lemongrass, hops or grapes can be planted around the graceful design. A rose garden will look spectacular and elegant in the design of the pergola

It is very important to protect plants from drought, timely fertilize and prune, so that their beauty will delight you and your guests at the country estate for a long time

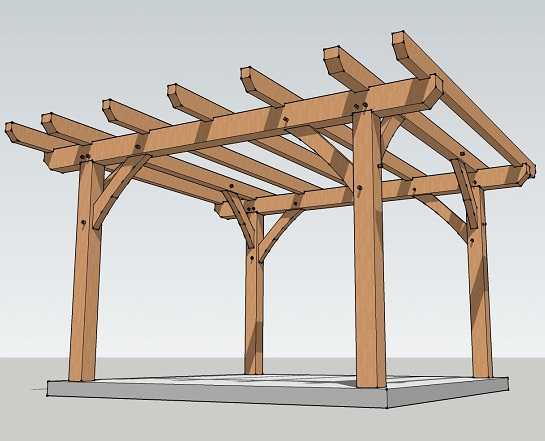

Main nodes

Despite the fact that the design is simple, it is necessary to correctly assess the load that plants can create. For our country, it is not worth dumping the scales and snow pressure. Especially after the plants have braided the structure. Therefore, all connections, fastenings, are made reliable, it is better to play it safe and put corners than to disassemble a blockage of plants and a collapsed arch. In this regard, the supporting columns and beams of the arch must be strong and reliable.

If you plan to build from wood, support posts for a medium-sized pergola use at least 200 * 200 mm. Beams - from a board of at least 40 mm thickness. Be sure to make stops and jibs: they will give rigidity. If the support pillars will be built of brick or stone, they are placed around a pipe - round or square - your choice, but it should be.

Dimensions (edit)

A little about the size of the pergolas. They should be in proportion to the area. If it is small, then the distance between the posts can be one and a half meters. You should not do less: taking into account the foliage, only one person will pass through such a passage. For larger areas, a wider width is required - too narrow will seem scanty.

The standard height of a garden pergola is 2.2-2.4 meters. Then the whole structure is harmonious, and foliage and flowers will not crush.

How to connect the parts at the top

When building an arch, special attention should be paid to the connection points. How to make them look at the photo

The easy way to connect the uprights to the main beams

For those who are not very good at carpentry, it can be difficult to cut the recesses for the installation of beams. There is a simple and reliable way to do without this work: connect the uprights and main beams using a decorative buttress. This is not only decoration, but also a way to make the connection more reliable.

A beam is laid on top of the support post (rack) and nailed through with nails or long self-tapping screws. However, with lateral forces, they can be turned inside out. To eliminate this, after the auxiliary beams are laid and fixed, a decorative buttress is nailed. It holds the three elements together. Even greater rigidity of the structure is given by a spacer set obliquely, which is often called a jib.

In the simplest case, a pergola consists of four posts connected by main and auxiliary beams.

The simplest pergola design

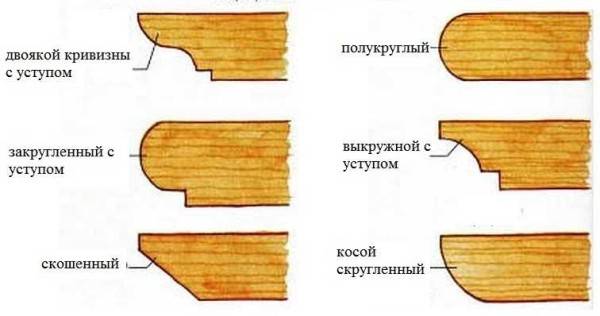

Beam edge decoration

You can slightly diversify the appearance due to the different design of the ends of the auxiliary and main beams. Several ways to wash down are shown in the photo below. To make them all the same, make a template from a small piece. Then you apply it to the workpiece, trace with a finely honed pencil as close to the template as possible. Cut along this contour.

How can the edges of the beams be made

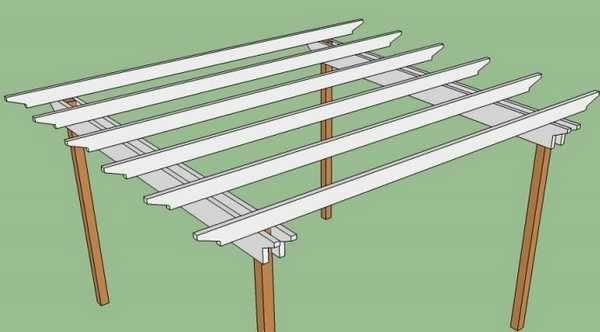

Reducing the cost of construction

The beam for the columns must be of a large section, and this is not cheap. The main beams should also be of the same size, which further increases the cost of the structure. But you can save money if you nail two thick boards from both sides to the racks at the top. How it looks from above, see the following figure.

To reduce the cost of the quality of the main beams, you can use two boards

You can connect them with nails-screws, or you can use bolts. This is even safer: the bolted connections can be tightened if necessary. Look at the photo to see how such a structure looks "live".

Pergola with double planks instead of main beams

Preparation for construction

You can build a simple pergola on the site with your own hands, but this requires certain preparatory work. This allows you to make not only a beautiful and comfortable, but also a durable gazebo, taking into account all the features of the site.

The place for the gazebo can be laid out with stone or sidewalk tiles.

One of the important points of construction is the determination of the location for the installation of the structure. Previously, it is worth choosing an image of a pergola that corresponds to personal preferences, landscape design and other features of the site. If the gazebo serves as a support for the plants, then you need to provide enough space for their growth. There are the following types of structures:

- the screen is a semi-closed structure that serves as a corner for privacy, quiet rest;

- the tunnel looks like many arches forming a "green corridor". The option is appropriate for decorating the path leading to the house;

- the awning or canopy does not protect from the wind, since it is a roof on the support pillars;

- the visor has two support pillars on one side, and on the other, it is attached to the wall of the house above the door, window.

Pergola material

The construction of a canopy gazebo can be carried out from two materials: metal and wood. For simple and light buildings, wood is often used, which is more convenient to work with than metal. Custom wrought iron pergolas look more impressive than wooden structures. Thus, when choosing a material, you need to take into account the advantages, properties, features of using the structure with your own hands.

Wood is easy to handle and create practical designs

To make the choice of material, it is worth familiarizing yourself with the technologies for building a gazebo made of metal and wood. This will allow you to determine all the features of the use of materials.Of particular importance is the quality of the structures for the construction of the pergola. The wood must not show signs of decay, deformation and cracks. Any wood species can be used, but larch and oak are the most durable. For a metal structure, profile pipes of different sizes are used. Wood and metal must be coated with antiseptic and anticorrosive agents, respectively.

Construction tools

Mounting a pergola made of wood or metal requires a certain set of tools. To work with wood, you will need tools such as an ax, hammer and saw. Nails are used to fasten the elements, and self-tapping screws and a screwdriver will provide reliable fixation. You can check the evenness of the structure with a building level; a tape measure is also necessary for work.

Making a pergola out of wood requires simple carpentry tools.

It is very difficult or even impossible to make a forged pergola with your own hands in the absence of certain skills and equipment. Therefore, a metal structure is often a complex of shaped pipes welded together. For work, you will need a welding machine, as well as a building level and a tape measure, chalk or a marker for marks.

Drawings of structures made of wood and metal

It is quite easy to make a canopy pergola out of wood, which is installed in the place designated for the gazebo. Previously, the site can be laid out with paving slabs, which will make the area more comfortable.

The drawing of the canopy pergola is simple, but it is important to take into account all the features of fastening the elements

The drawing marks the dimensions of all the main parts.

It is easy to make a drawing of metal structures of a simple type yourself. In this case, the option of fastening all elements, the angle of their fixation, and the dimensions of the parts are taken into account.

A metal gazebo of a simple design does not require an extremely accurate drawing

In the absence of skills in drawing up drawings, you can take a ready-made scheme as a basis, supplementing or excluding any structural elements. The dimensions of the gazebo are selected individually, depending on the area of the site, the purpose and type of pergola.

How to build a metal pergola for a summer residence (with photo)

Traditional pergolas are most often made of wood, and to ensure their strength, parts of a sufficiently large section are used, which often spoils the appearance of the site, and also increases wind loads.

The way out can be the manufacture of a structure from metal parts: The proposed pergola from metal is welded by hand from reinforcing rods and an iron strip. Structurally, the pergola consists of uprights, fixed with anchor bolts on concrete bases, and arc-shaped trusses. In this case, only one end of each truss rests on the rack, and the second is fixed with a flange on the brick wall of the house using dowels and wood grouse screws. The flange is a 4mm steel plate measuring 150x285mm with 10mm holes. The trusses are attached to the uprights with bent steel strip brackets and bolts with nuts.

To build a metal pergola with your own hands, you will need the following materials:

- 17 reinforcing bars 16 mm and 6 m long;

- 28 belts 120 x 120 mm from a strip 4 x 20 mm;

- mm from a strip 2 x 20 mm;

- 30mm staples from 3 x 30mm strip;

- 8 flanges 150 x 150 x 4 mm;

- 2 flanges 285 x 150 x 4 mm;

- 4 anchor bolts М16х200mm;

- 4 nuts М16 with washers;

- M6 bolts with nuts;

- wood grouse screws 10 x 100 mm.

Each post is welded from four 016 mm reinforcing bars with 120 x 120 mm belts welded from steel strip. The lower end of the post has a flange with a 16.5 mm center hole for anchoring to a concrete base. The upper ends of the struts are widened.

Conductors in the form of rectangular plates with 016.5 mm holes, into which the bars of the rack are threaded, will help to weld the pergola racks.The steel belt of the rack is fixed with clamps next to the conductor, and then welded to the reinforcing bars. After welding the next belt, the conductor is moved further to the place of the next joint. Conductors can be cut, for example, from flat slate. It is not worth using plywood conductors - they will catch fire very quickly.

The trusses also consist of four bent reinforcing bars welded together with rings and spacers. To facilitate the bending of the reinforcing bar along its entire length, at the points of attachment of the rings, cuts are made with a depth of 4 mm with a step of 300 mm. Bend the bar in a vice by hand, using a hammer if necessary. Rings 100 mm bent from steel strip 20 mm wide.

The side of the pergola truss is welded, focusing on a cardboard template drawn in a 1: 1 scale. The parts are fixed with heavy blanks and clamps, and gaskets made of non-combustible material are placed between the cardboard and the place to be welded. To weld other identical parts of the pergola, you can use the first welded part as a template.

As shown in the photo, for a metal pergola, prepared structures before installation are cleaned of rust, scale, primed, and then painted:

To check the horizontal position of the trusses fixed on the pergola racks, a long even bar or metal profile will help, which is placed in the plane of the mounted structure, and a building level is placed on top.

The pergola posts with flanges welded to the base are fastened using concreted M16 anchor bolts and nuts. The trusses are fixed to the racks using steel brackets and M6 bolts with nuts. The truss is attached to the wall with a wall flange using dowels and wood grouse screws.

Watch the video "Do-it-yourself pergola" to get a better idea of how such a building is being erected: