Instructions on how to weld a metal porch

Usually, for summer cottages and private houses, the metal frame for the porch is made by hand from an equilateral corner of 40 * 40 mm, if the porch is made of a profile pipe, then you need to choose rolled products with a cross section of 20 * 40, 40 * 40, 45 * 45 mm. The thickness of the metal must be at least 3 mm.

To make a welded porch with your own hands strong and stand for more than a dozen years, first of all, you should take up the foundation, what kind of foundation is decided on the basis of geodetic research, we will focus on the pile. Drawings are transferred to the terrain, the perimeter is marked with columns, the cord is pulled, the geometry of the marking is checked, the angles must be strictly 90 °, unless otherwise provided by the design.

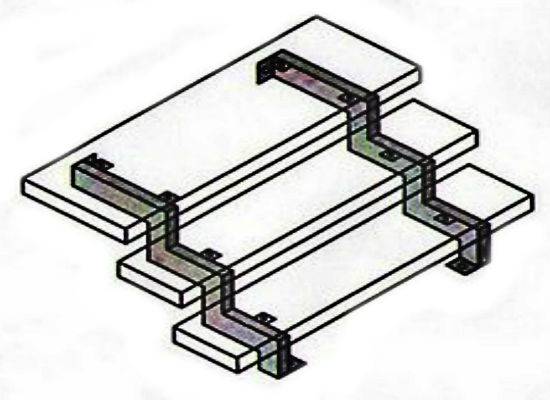

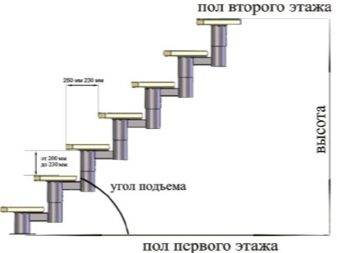

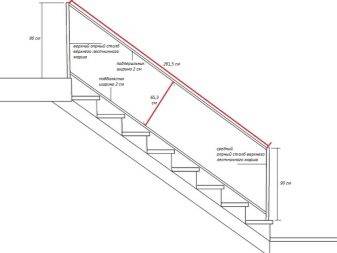

The kosour scheme from the corners for a small ladder

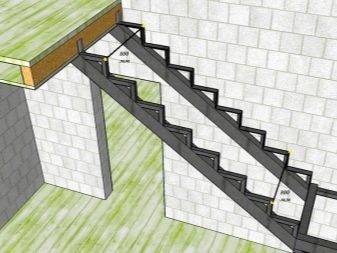

Piles are driven in at the corners of the upper platform, and at the corners of the last, lowest step. If the width of the metal porch is more than 2 meters, then the piles are also arranged in the middle, between the already driven ones. Watch the vertical, check the level of each pile. When the length of the metal ladder is more than 3 m, intermediate vertical supports are also driven in, for the strength of the structure, so that no sagging occurs during operation.

The length of the piles on the outside for the upper platform should correspond to the height of the porch minus the deck and the thickness of the platform frame. For the last step, the length of the outer part of the pile can be flush with the ground, or protrude slightly, if provided for by the project.

If the piles are short, they are trimmed flush with the ground, and metal posts of the required height are welded to them, on which the metal frame will hold. Piles or racks along the perimeter of the upper platform, as well as the lower ones, should be tied together with a corner or a channel along the heads in order to preserve the geometry of the welded metal porch.

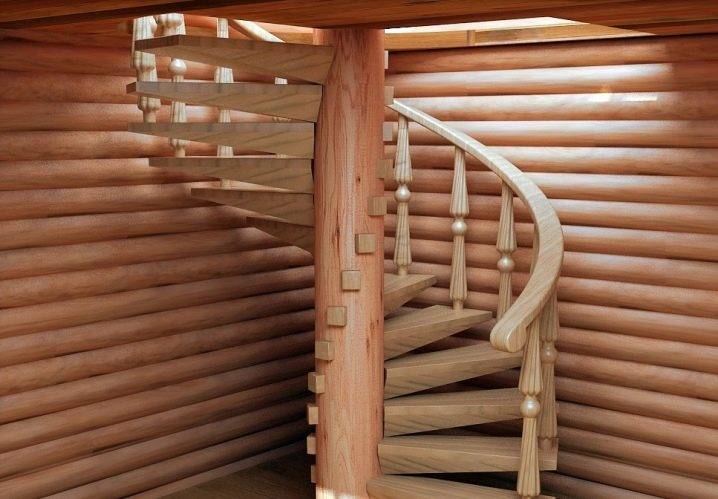

The metal porch described in the article

When the base is ready, the distance along the hypotenuse from the upper platform to the lower pile is measured, then the rolled metal of the required length is sawn off, this is the side part of the ladder (bowstring), onto which the steps will be welded. Requires 2 bowstrings, cut out the parts and weld them to the finished structure.

Next, cut the parts from the equal angle corner, taking into account the weld:

- the size of the steps;

- the size of the steps;

- a size equal to the width of the stairs.

The number of blanks should be equal to the number of steps multiplied by 2.

Important: To ensure the high quality of welding, the seam is smeared with kerosene on one side, and with a chalk suspension on a chalk base on the other. The procedure must be done 2 times, with a period of 10 minutes.

If at subzero temperatures no spots appear at the joints in a few hours, then the quality of welding meets the highest requirements.

Workpieces of various types (risers and treads) are welded to each other along the contour strictly at right angles, and L-shaped parts should be obtained. Since we took the corner as a basis, do not forget about the left and right sides.

The assembly of the metal porch begins from the bottom step. Weld the L-shaped piece along the contour to the left bowstring, measure out the horizontal, do the same operation with the right bowstring. Next, we connect the upper corner of the elements with an equal-flange corner, which is welded to two elements along the contour, with shelves inward. We connect the bottom of the steps (inner corner) in the same way, but with the shelves outward. The rest of the steps are welded using the same algorithm.

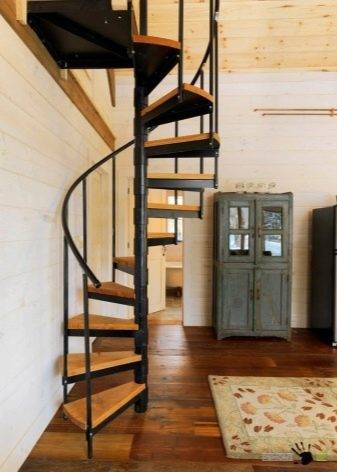

Lightweight metal porch without foundation

When the metal frame is ready, you can install steps from different materials. The floor is laid on the upper platform. Then, if necessary, the railings are welded for safety, and a visor is attached to protect the metal porch from precipitation.The finishing of the entire structure depends on the design of the entrance group. All metal parts and seams are cleaned of scale, oil stains and rust, and covered with paint for outdoor use.

Do-it-yourself outdoor metal staircase

The process of making an iron staircase for the street requires experience, knowledge and skills in working with metal structures. If you have not previously encountered such work, then it will be difficult to make an outdoor metal staircase with your own hands. After all, looking at projects on the Internet is not enough, you need to know what all the designations mean and at least approximately understand the intricacies of installing such products. But nothing, now you will find out everything.

Drafting of an external staircase and calculation of dimensions

Before proceeding, directly, to the creation of a structure, try to carefully draw up a project of an external staircase, make a drawing, prepare all the materials that will be required in the process.

Video: rules for drawing up a project (drawing) stairs

So that in the future there are no problems during operation, it is necessary to calculate the dimensions of all parts in such a way that quality and safety do not suffer for the sake of a stylish appearance. Sometimes it is very difficult to combine a design idea with the existing standards.

Video: how to calculate a ladder

Making an outdoor metal staircase with your own hands

If you are determined to make an outdoor metal staircase with your own hands, first prepare the metal, a welding machine and other auxiliary tools that you may need in the process.

An excellent choice for the manufacture of steps will be reinforcement rods, which will be welded to the base at a certain interval. In our country, the use of such elements is especially important, because in winter, precipitation will not accumulate on its surface, which will avoid "icy". In addition, such steps are easily cleaned of dirt. However, do not forget that during operation, the external staircase to the attic or the second floor of the house must be regularly treated with a special anti-corrosion coating.

It is best to use an ordinary metal profile as a base for reinforcing bars - a channel mounted on an edge. It is to them, with the help of welding, that the so-called "filly" are attached, acting as a support for the steps.

For those who are not satisfied with the option with rods, there is a wide selection of other, equally attractive solutions. For example, perforated and embossed steps will help prevent slipping. You should not use materials with smooth surfaces, otherwise throughout the winter, climbing the external stairs to the second floor, you will be forced to frantically cling to the railing so as not to fall.

To obtain a durable and reliable structure, all connections must be made by welding. And only competently made seams will give you complete confidence that it is safe to navigate this staircase.

Railings and railings for outdoor metal stairs

We must not forget about such important elements as railings and railings for outdoor metal stairs. It is they who ensure the safe operation of the product and create an original appearance.

As a rule, handrails made of wood or PVC are installed on the stairs. But there are times when bare metal is left, for example, on forged products. The gaps in the railings are filled with posts or shields.

After installing the outdoor ladder, be sure to grind all irregularities and welds with an emery wheel (grinder). Cover the product with primer or paint. This will help keep the metal in good condition.

What foundation is needed

If the porch is planned to be light - wooden or metal - the foundation is most often made pile or columnar. Specifically selected based on geological conditions. On well-draining soils with a low groundwater level, a columnar foundation is sufficient, with a tendency to heaving, a pile foundation is needed, possibly TISE.

For a heavy porch - made of brick or monolithic concrete - a strip foundation or a monolithic slab is made. The type of foundation is most often the same as the one on which the house is built.

Types of foundations under the porch

Then you need to decide if you will tie the porch foundation to the house foundation or not. Decisions are made based on the planned mass of the extension and the type of soil. Both options have drawbacks. If there is no connection, cracks often form at the junction of the porch and the house; due to frost heaving, the porch can warp. Owners of summer cottages often face such a problem - basically, the porch to the cottages is made wooden and incoherent. After the ground thaws, it may itself "sit" in place, or may require some additional measures.

When the connections are made, cracks can also form, but not only at the junction, but also in the "body" of the extension. This happens if the reinforced ties arranged cannot compensate for the uneven load created by the house and the extension. Therefore, a connected foundation for a porch is made if it is attached to a heavy house and itself is heavy and massive, made of reinforced concrete. The second difficulty with such a decision is to make the connection of high quality. For this, ribbed reinforcement with a diameter of 12-16 mm is used, for which holes are drilled in the foundation with a given diameter. They clog the reinforcement and, on its basis, knit a frame for the porch.

Building codes

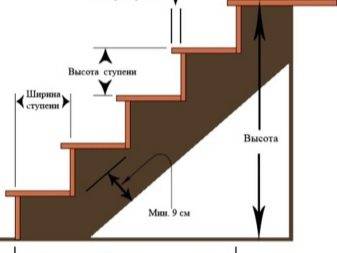

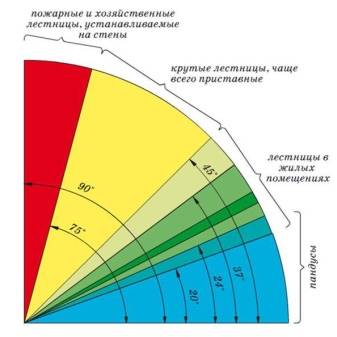

During construction work, any structure must meet certain standards.

The same is the case with the stairs. It must be strong to withstand human loads, and safe so as not to be injured when moving.

And also, it should provide convenient and comfortable movement to the required floor of the building.

You must make the steps of certain parameters, since a narrow step will interfere with a comfortable positioning of the foot, which can lead to injuries. If the step is very high, then it is inconvenient to step from one to another.

Therefore, such a project must be approached according to the rules, everything, having accurately calculated and determined in the drawings.

Varieties and design options

We will consider the most popular types of metal stairs further. Note right away that the frame can be open and closed. Closed processing after assembly is not necessary, and open requires grinding and cleaning. And now about the varieties.

Straight staircase with metal stringers

In this case, steps and components of the fence are installed on the kosour.

How many kosour will be depends on the width of the flight of stairs, as well as the level of load on it. Kosour can be one, as in the example below, or several.

This type of construction has several important advantages:

- ease;

- visually does not clutter up the space;

- increased strength (can be used in industrial facilities);

- if necessary, you can use any decor for decoration.

Inclined stairs on bowstrings

This is a structure in which the steps are supported by beams placed on the sides of the march.

Design advantages:

- many options for implementation;

- strength;

- metal base can be used to make spiral and straight staircases.

Staircase with soaring steps - cantilever

First of all, it simplifies the space. Steps that are frozen in the air are perfect for minimalist houses.

Combined option

Combining consoles + stringer frame. The steps are "airy", but at the same time they have a reliable base in the form of a metal stringer, which is installed along the wall.

Spiral metal stairs

In this case, the steps are placed in a spiral around the central pillar. Such ladders are highly reliable, and they can be made from a profile pipe. Even if their production was carried out according to a standard design, the appearance will ultimately be completely different due to coloring and other decor.

Ladders of this type are used more often in small rooms, the cost is relatively low.

Modular designs

Fits into any interior from modern to classic. Staircase elements are versatile, styles are varied. You can assemble such a ladder yourself, it only takes a few hours.

Marching stairs

Marching stairs are the simplest similar products in design. It is easy to fit in any size room. It is considered the safest construction.

Metal stairs with glass steps

Working with this design is complicated by the presence of a large number of glass elements. Glass is used only the most durable glass that fully meets all safety requirements.

Two-flight stairs with a platform

This type stands out separately, as it has a serious advantage over other structures: an intermediate platform between spans.

In addition, there are the following positive qualities:

- it is easy to design;

- no need for large labor costs in the manufacturing process;

- significant savings on building materials;

- high degree of comfort;

- operational safety;

- presentable appearance.

In the process of building two-flight stairs, it is better to combine several materials in order to optimize the cost and develop a successful style solution. For example: the frame will be metal, and the decorative elements will be wooden, or the cladding will be made of stone.

Almost all types of stairs, which we talked about above, can be prefabricated. Their plus is that they can be assembled, even if the house has already been finished with fine finishing of the walls and covered with floors.

If you are far from being professional in the manufacture of stairs, you can choose a ready-made one. They are modern, lightweight and fit perfectly into the interior of any private house.

The design of the staircase largely depends on the area of the room in which it will be located. It should complement the overall picture, not fall out of it.

In classic interiors, it is better to place expensive staircases with natural wood trim or luxurious metal forging.

But in the case of minimalism, unnecessary details are useless, you can make a staircase made of plexiglass.

Attention should be paid not only to the staircase itself, but also to the space under it. If possible, you can arrange a place for reading and rest there.

Installation of steps and railings

The steps can be mounted directly on the stringers. You can also use additional wooden parts - filly. You can fix the steps with nails or screws.

It is recommended to use triangular fillets to increase the strength of the structure. They are mounted with dowels, so you need to make the appropriate grooves in advance. For mounting fillies in stringers, grooves of the required shape must be provided. You need to fasten the parts with glue and screws.

After installing the steps, you can proceed to the fastening of the railing baluster. It is advisable to cover the assembled structure with a protective paint and varnish material. This will protect the product from the negative effects of moisture and pests.

Recommendations

A compact and cozy spiral staircase is not a magazine cover advertisement or a fantasy of an expensive designer. Experts keep several effective secrets to help bring all this to life with minimal material costs.The only thing that is required to the maximum extent is desire, diligence and scrupulous execution of instructions. And to make it easier to cope with this task yourself, re-read the main recommendations for this process.

The length of one turn of the staircase should be at least two meters so that it is comfortable for a person of any height to move along it.

When finishing woodwork, pay special attention to the painting process. If the natural pattern of the material more than suits you, then you can get by with a two- or three-layer coating of yacht or parquet varnish.

Before you start painting or varnishing the surface, be sure to clean it from construction debris, dust and other types of contamination.

Then you will have a long-lasting quality finish.

Pay attention to the angle of inclination of the steps. Ideally, they should be parallel to the floor so that there is no risk of feet slipping and injury.

Materials for the manufacture of stairs must be of high quality, strong and durable

When selecting, take a close look at all the components and accessories.

- Fire safety comes first. All materials must be heat-resistant impregnation and processing.

- Moisture is also a poor companion for spiral staircases of various materials. Therefore, you should immediately clarify the question at the selection stage, whether the structure is treated with a special moisture-resistant coating.

- All fastening tools must be in place and be securely screwed in, driven in, fixed. The plane of the steps should be perfectly smooth without any unpleasant protruding additions.

- In the process of marking and creating drawings of the future structure, be sure to take all measurements several times, double-check yourself. Incorrectly specified dimensions can lead to uncomfortable operation: distortion, squeak, rapid wear of components.

- If it becomes necessary to replace a step, fastener, railings, balusters, etc., do it immediately. Otherwise, both the entire structure as a whole and the person himself who climbs or descends on it may suffer.

- Take constant care of your spiral staircase: clean, tint, repair if necessary on time.

Other things to consider: professional recommendations

For those who decide to start creating a staircase for the first time, experts recommend choosing marching stairs (rotary or straight). These types of stairs are easier both in calculations and in manufacturing. More complex designs, especially asymmetric ones, should not be done by beginners, as you may have to call professionals to redo them.

In addition, professionals advise the following:

use patterns to create kosour;

it is better to pull the structures on the bowstring with metal rods - to give strength;

it is very important to carry out the final processing of wooden structures (after installation, clean all the parts with sandpaper, vacuum) and only then varnish.

Varieties of frames from a profile pipe

It is impossible to ignore the question of what kind of frames for stair flights made of a profile pipe can be. The material seems to be the same everywhere, but the principles of the structure of the structure have significant differences.

Stair tread prices

steps

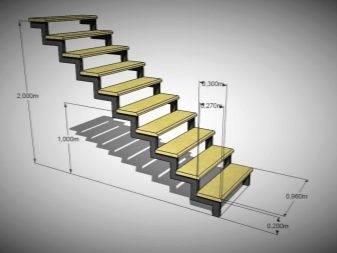

The most economical option for using a profile pipe in the manufacture of stairs is a frame on the central stringer. This option can be made in two versions - a broken kosour, repeating the shape of the steps, or a straight one, made of a single-piece profile pipe along the entire length of the march.

Broken-type staircase with a central stringer

A broken stringer is more difficult to manufacture, as it is assembled from separate pipe sections, cut at the right angle, which are connected to each other into a common part by welding.Then, on each of the horizontal surfaces of the kosour, the so-called "sole" (mounting platform), made of sheet metal with a thickness of 3-4 mm, is welded. Tread boards will be fixed on this "sole". To fix them, four to six holes are pre-drilled in metal plates. Through them self-tapping screws will be screwed into the wood. For this design, a profile pipe with a cross-sectional size of 80 × 60 mm may well be suitable.

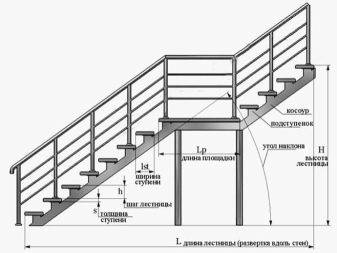

Sketch of a flight staircase with a central straight stringer from a profile pipe

The second version of the central stringer is made from one pipe, usually with a cross-sectional size of 100 × 50 mm, which is cut only at the ends, at a certain angle. Then, plates or peculiar legs are welded to the end parts of the pipe that forms the span, with the help of which the stringer will be fixed to the ceiling and to the floor.

And this is how a staircase with a central straight stringer can look "live"

On the stringer pipe, markings are made, along which supports for the installation of steps will be welded. The stands consist of a leg, also of a section of a profile pipe, with ends cut at the desired angle (depending on the steepness of the staircase), on which "soles" are welded with holes for fixing the tread boards on them.

Marching staircase with two straight braids and a frame structure of steps

For massive stairs, a more reliable version of metal structures is usually chosen, consisting of straight stringers, onto which the frames for the steps are welded. For their base, a pipe of 80 × 60 or 100 × 50 mm is used, and for the manufacture of a frame for steps - a profile of 25 × 25 mm or even a corner with shelves of the same size, which gives a certain saving in metal costs. In the lower and upper parts of the frame, supports cut from a metal sheet are fixed by welding.

This illustration is a good demonstration of the principle of installation of such a ladder frame.

A more complex version of a ladder made of a profile pipe is a broken structure consisting of two stringers, in some cases, fastened together by jumpers.

Sketch of a staircase with two broken stringers

How frame structures of this type are made and assembled will be discussed in detail in the instruction table below.

Manufacturing

It is recommended to practice before starting work, get your hands on it, get used to the device: all these actions should be carried out on third-party objects. After you have mastered the basic techniques for performing welding, only then should you start finishing work.

A certain sequence should be observed in the work:

- cut the workpieces to size;

- manufacturing of knots for fastening steps (filly);

- corners should be welded;

- install stringers;

- steps and fencing should be welded;

- stripping, grinding;

- priming and painting.

First of all, we make knots for fastening steps (filly) from the corners. In order not to spoil the stairs, distortions should be excluded. The filly must be identical and mirror-like relative to each other. We make filly from a steel corner, for the beginning of the selection it is worth cutting out, then the corners should be joined together.

As a result, L-shaped welded joints should come out with shelves in depth and downward. The shelves inward and upward of the filly are welded for concrete steps, as well as for decorating with porcelain stoneware or ceramic tiles. For this design, 14 pairs of these nodes will be required - in any pair, one support will be right, and every other support will be left. We weld the fasteners of the step and the cross member between each pair of corners.We also make the crossbar from the corner.

We mark along the edge of the profile square pipe and weld the filly to the edge of the stringer along it. We attach the second to the first stringer with the filly attached, and accurately transfer the markings. This is how we get the correct geometry for all parts. Our width is 900 millimeters, and two stringers will be enough for us. We weld the filly to the second stringer. We control them by level. Then we weld the stringers with the lower end to the main platform.

In dwellings with a concrete base, the main platform can be supplied in concrete. We fasten the upper end to the support post, which is fixed to the overlap between the floors with metal anchors. Once again we control the filly by level.

The last step is to weld the steps to the filly. You can also fix them with bolts, in this case you need to close them up with wood. Another option is to install wooden steps directly onto the filly using screw-like connections.

The upper step is placed at the smallest distance from the wall. It is necessary that a sheet of paper be laid between the wall and the step - facing work is ahead. The railing is welded near the metal ladder so as not to diminish its width.

All components of the structure in the welding areas are ground (seams, notches), later the metal particles are swept away with an iron brush, the metal ladder is primed: we apply a primer for metal, then it is painted in the chosen color. Wooden steps are placed after the paint has dried.

The decoration of a metal staircase to the next floor, including the sheathing of the steps with wood, is appropriate to carry out at the stage of finishing work in the housing.

With an apparent simplicity, the work on the construction of an interfloor structure made of metal calls for care and accuracy. Well-done welding works ensure a long service life of the structure.

Once you've built a solid and solid frame, you can eventually decorate it with wood, ceramic tiles, stainless steel fencing components and other cladding materials to your liking. And the structure, which at the construction stage looked too large and unpresentable, will receive an excellent external appearance.

The main reason for the benefit of building a metal staircase to the second floor with your own hands is saving significant funds that you will need to complete the rest of the work in the house.

For information on how to properly install a metal ladder with your own hands, see the video below.

Project creation

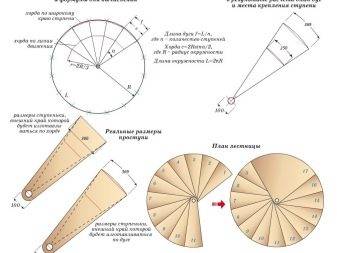

Special programs change firms, with the help of which a 3D design is carried out. In such a model, it is easy to resize some of the individual elements. After the option has been approved, the working drawing and the specification of the ladder are made by the program.

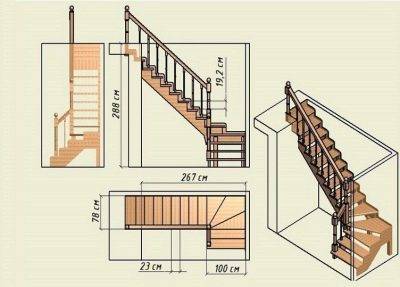

Without the help of the program, we have to do the calculations. Consider a simple design option - a single-flight straight staircase. We know the usual requirements for step height and depth. The best tilt angle is 30 to 45 degrees. Measurements are carried out between two points: from the beginning to the end of the stairs at floor level (denote a) and the height between floors (b), then the length is equal (d). It is necessary to determine the length of the stairs.

Using the equation: (a) squared + (b) squared = (d) squared - our length is calculated. The required number of steps is calculated using this formula, as a result, the step height will be 179 mm or 167 mm. The overhang is the part of the upper step that hangs over the lower one. The optimal size of the overhang is 3-5 cm. The size of the steps will be increased by the width of the so-called overhang. We get the basic parameters that we need to determine the amount of materials. For two stringers, we need a profile pipe. From the corners, which we reinforce with reinforcement for reliability, we will weld the supports for the steps (filly). We make these steps and risers from 4-mm iron and then sheathe them with wood.

First of all, you have to prepare a modular scheme of work. It is necessary to calculate the amount of material that you need. Such a step-by-step instruction, created on the basis of the recommendations of specialists, will help you complete the work not only efficiently, but also quickly.

We design and calculate the load

Is it possible to design a staircase structure yourself? Of course, for this it is enough to know the school geometry course. In addition, there are special computer programs and online calculators.

To calculate the stairs, it is important to take into account the features of the layout of the country house and the size of the premises in it. The location and type of future structure will depend on this.

In turn, it must be remembered that for a comfortable and safe staircase it is important to provide sufficient opening on the upper floor. It is also important to comply with all technical standards and take into account the basic parameters for the elements: length, width, angle of inclination, depth and height of the steps.

Ladder calculations should include the following points: steepness, size of steps, their number, width of the march. Let's consider each of them in more detail.

- Steepness (angle of inclination). The best can be considered an inclination in the range from 25 to 37 degrees - this is both convenient and safe. However, a staircase with such an inclination can take up a lot of space, therefore steeper stairs with a slope of 40-45 degrees are often used in small country houses.

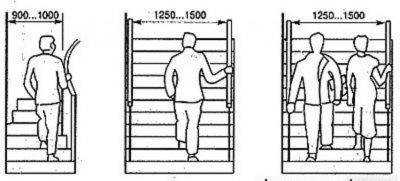

- The size of the steps and their number. In each march, the number of steps should be at least 3 and not more than 18 - for comfortable movement it is better to set an odd number of steps. The optimal step parameters are in the following ranges: width 27–28 cm, riser 17–18 cm, overhang of the nose of the step - no more than 4 cm. All steps must be the same in height and width, otherwise it will be inconvenient to move up the stairs.

For stairs with a turn of 90-180 degrees, there are some nuances of the calculations:

- the length of the platform between marches should not be less than 140 cm, the width should be equal to the width of the march;

- a staircase on winder steps with a turn of 90 degrees must contain at least three such steps;

- optimal parameters of winder steps: the width on the larger side should be at least 40 cm, in the middle - at least 20 cm, in a narrow place - at least 14 cm.

Features of calculations for screw structures:

- steps are made in the form of a trapezoid with bases of at least 20 cm (for a smaller one) and 40 cm (for a larger one);

- for comfortable movement, the height of the steps is better to be made less than for straight stairs;

- the interval between each turn must be at least twice the diameter.

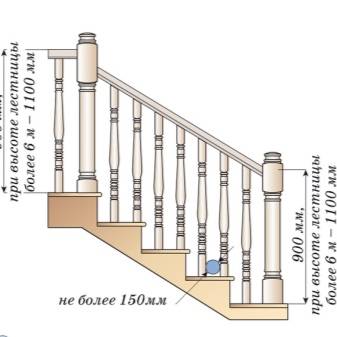

When all the basic calculations with the parameters of the stairs have been done, you can start designing and calculating the railing. To do this, you need to decide on:

- the height of the fences (or balusters);

- length and width of handrails and railings;

- the height of the supporting pedestals (extreme balusters).

Optimum performance for fences:

- for comfortable handrails and handrails, the width is about 10 cm;

- the height of the safety barriers must be 90 cm;

- to calculate the heights of the support pedestals, you need to take into account the way they are installed: if they are installed on the steps, then the height will be identical to all other balusters, and if they need to be mounted on the floor, then the interval from the floor to the first step must be added to the calculations;

- the length of the handrails and railings will correspond to the length of the flight of stairs.

Features of installing a metal staircase on the street

Any design, be it a street staircase to the second floor in a city hypermarket or a staircase on the street in a private house, requires compliance with certain measures, rules set out in regulatory documents (SNiP and GOST). This fully applies to the installation of ramps for the disabled, the installation of an external fire escape. Work begins with the creation of a project: it determines the place of installation of the stairs, taking into account the regulated parameters of the width of the march, steps, the dimensions of the ramps for the disabled, the material is determined, and the calculated part is necessarily contained.

In addition, the designed structure must be suitable for the building in terms of:

- appointment;

- design;

- security.

For example, special smoke-free staircases differ significantly in characteristics from a concrete staircase for a pool with wooden steps or an external boltseva. Another aspect of the problem concerns the fact that it is sometimes very difficult for a designer to combine a design idea and sober calculation, creating beautiful and functional solutions at the same time.

It is required to take into account the methods of attaching the external stairs for the porch to the building, which are their components among themselves. It is also important to create a stable foundation if the structure provides for the support of the external metal staircase for the entrance to the second floor not only on the elements of the building, but also on the ground. For this, external iron supports are built, which, in turn, rest on a separate foundation, independent of the foundation of the house.

Important! Work on the creation of a flight of stairs connecting the second and basement floors, a metal street staircase for evacuation, is unthinkable without a project: this is a prerequisite, the fulfillment of which is not discussed. Most often, a specialized company practicing the development of external, internal staircases for summer cottages and country houses has several standard projects at hand.

They take into account the requirements of regulatory documents, which are important to observe (basic dimensions, combination of proportions), material and purpose, as well as the safety of the product.

Most often, a specialized company that practices the development of external, internal staircases for summer cottages and country houses has several standard projects at hand.

They take into account the requirements of regulatory documents, which are important to observe (basic dimensions, combination of proportions), material and purpose, as well as the safety of the product.

It is necessary to take into account what can be manufactured, implemented in practice, and what will remain at the project stage. It is also necessary to provide for a special coating of the steps - wear-resistant, providing reliable grip at any time of the year and, if possible, aesthetic. For example, metal step bases and stone linings.

And, in general, you should use publicly available materials that make it possible to make an external metal staircase inexpensive and convenient to use. And the external ladder for the porch should fit into the general style, not sound like a disharmonious note in the general ensemble. There is so much to consider when designing a staircase.

In addition to the above, the features of the installation of a metal staircase include reliable fastening of elements to each other, to the platforms and load-bearing structures of the building. You can attach the product to the wall - you get a boltz scheme, if you "twist" around the central support - a screw. But in both cases, the distance from one site to another in the march span, the height and step of the steps are taken into account.

Welded seams must be strong enough, made with scrupulous adherence to technology - the stability of the frame and its elements as a whole, the safety of people depends on this.

It is necessary to establish a strict sequence of installation, assembly of the flight staircase with platforms, calculate the weight of each element (especially if installation is planned without the use of mechanisms). At the final stage, the metal is covered with an anti-corrosion compound - enamel with the required characteristics and color. Subsequently, it will be necessary to monitor the condition of the coating, the appearance of foci of corrosion for their timely localization.