Little things for the interior

- From scraps of products, you can design an organizer for an office or workshop. The reliability of the craft is determined by the connection options: by self-tapping screws to the surface of the table or wall, or by gluing together structural parts. The first option will be stationary, the second - mobile (portable). It is better to take pipelines in white or gray;

From plastic pieces of small diameter, you will get a beautiful and original stand for a tablet or netbook;

What else can be made of pipes? For example, shelves for books in modern or high-tech style, photo frames or mirrors;

Large-diameter scraps will make a shoe shelf with compartments, smaller pieces - a flower stand. In order to make flower pots with your own hands, you will need products of a very large diameter - from 100 mm and above. Such country crafts made of polypropylene pipes can be installed both in the house and on the street; Usually these are elements of the sewage system;

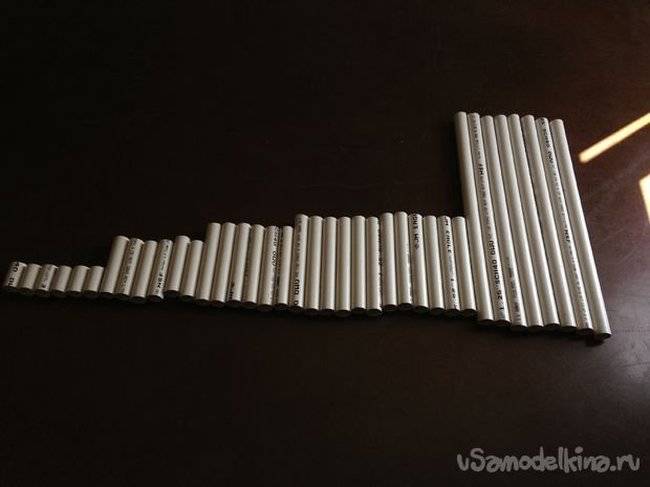

A floor vase of any length, decorated with any patterns, can even serve as a gift for a friend. To make a vase, take pipes for water supply or sewage systems of medium diameter, and you can make such a type-setting vase - insert the trimmings one into one, using each next segment of a smaller diameter;

An indoor or outdoor spotlight with a minimum of decorations will perfectly fit into a techno-style interior;

A hanger, a holder for things, a chair or a table, a rack, a shelf, a bookcase, a shower, a watering pad - there are so many ideas for a country house that you can't remember everything, it would be a fantasy;

The garden house can be equipped with a homemade storm drain made of pipes, sawn in half lengthwise, and connected with glue or bolts into one long drain.

What can be made from plastic pipes

If desired, and with a good imagination, crafts for giving from plastic pipes can take up a significant part of your household, both in the house and on the backyard or in the garage. Products of different sizes and diameters can be bought at any construction market: their usual purpose is water supply and sewage lines, heating and irrigation systems, and it often happens that after the main work, pieces of polypropylene pipes of different lengths and diameters remain. If you have not thrown them away yet, then you can make very original and even useful crafts from plastic pipes with your own hands.

Sections of polypropylene pipes are best suited for the manufacture of artistic objects - they are rigid, they are easy to connect to each other using nozzles and adapters, so that later the structure can be disassembled. Scraps will also serve well for a summer cottage or playground, a children's room or a car repair shop. The main thing is to see how they can be used. Polypropylene products are well connected by soldering: a non-separable, but very strong and durable structure is obtained.

Connection options

Not only handicrafts for summer cottages, household items or furniture, but also more complex structures can be made from plastic pipes. The main thing is to firmly connect the parts of the product. Connect them in such ways:

- One piece is inserted into the socket of the other through a rubber seal;

- Blanks of plastic pipes are connected with glue;

- Details are connected to threaded hardware.

The first option is the simplest, but not reliable and tough enough. The contacting surfaces must first be cleaned of dust and lubricated with silicone or graphite grease (maybe even soapy water or liquid detergent). The section is inserted into the socket to the end, and then pulled back a few millimeters.

Such a construction of water pipes is easily disassembled, therefore it is suitable for seasonal use: this is how you can make children's swings, chairs, water supply for the garden, etc.

The second option is more reliable, but more labor intensive. Before gluing the scraps of sewer plastic pipes, the joints are also cleaned, sanded with fine sanding paper and degreased with a solvent or methylene chloride. The glue is applied to the entire outer surface and 60% of the inner surface of the parts to be glued. Then the products are inserted into the socket and rotated 90. Methylene chloride dries quickly - 60 seconds, so gluing must be done quickly.

The third option is to mark products and drill bolt holes. Such hand-made pipe crafts are considered the most reliable, and they can always be disassembled for storage or alteration.

To connect the corners of structures or several sections in one place, fittings are used - tees, adapters, couplings. Therefore, structures of any complexity can be made from PVC or propylene pipes. Consider crafts for children and adults that you can make with your own hands from pvc pipes.

How to bend a pipe

Products made from this material look unusual. They will look even more interesting if they consist of curved parts. For example, a table with curved legs. In addition, various decorative elements are made from pipes, which come in different shapes. In such cases, it is simply necessary to bend the pipe.

For this you will need:

- funnel;

- sand;

- Scotch;

- plate;

- metal containers;

- gloves;

- saw (hacksaw);

- knife (scissors);

- sandpaper;

- a device for bending pipes (it can be different, mostly used materials are used).

The process looks like this:

- cut a piece of the required length;

- seal one end with tape;

- use a funnel to pour in as much sand as will enter;

- Heat the measured amount of sand in a metal container;

- wear protective gloves for safety, carefully pour sand into the pipe through the funnel;

- seal the second end with tape, then the sand will not spill out during the bending process;

- leave for a while, it will warm up from the inside;

- when it heats up, start bending;

- give the pipe the desired shape;

- at the end of the work, tear off the tape, pour out the sand;

- when the pipe cools down, it will have the required shape.

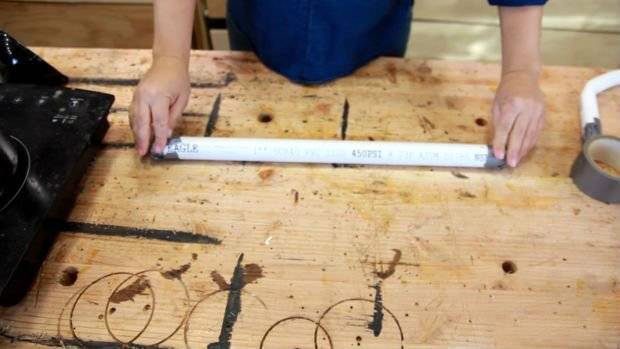

One end of the pipe is sealed with tape

One end of the pipe is sealed with tape

Use a funnel to fill the pipe with sand

Use a funnel to fill the pipe with sand

After measuring the required amount of sand, pour it into a metal bowl and heat well

After measuring the required amount of sand, pour it into a metal bowl and heat well

Using the same funnel, pour the prepared sand back into the pipe.

Using the same funnel, pour the prepared sand back into the pipe.

Cover the other end of the pipe with tape. This is necessary so that the sand does not spill out during work.

Cover the other end of the pipe with tape. This is necessary so that the sand does not spill out during work.

Leave the pipe like this for a couple of minutes. During this time, it will warm up from the inside. The material will become soft and pliable.

Leave the pipe like this for a couple of minutes. During this time, it will warm up from the inside. The material will become soft and pliable.

While the sand is still hot, you can shape the cut pipe into the desired bend or shape. Then remove the tape and pour the sand back.

While the sand is still hot, you can shape the cut pipe into the desired bend or shape. Then remove the tape and pour the sand back.

Types of plastic pipes

There are several different types of plastic pipes - the main elements from which the structure will be made. Below are some of the features and differences of these materials.

Did you know? Polypropylene was discovered in 1954 by the German organic physicist Karl Zickler and the Italian chemist Giulio Natta. The last of the two, for this discovery, received the Nobel Prize in Chemistry for 1963.

Polypropylene

Polypropylene pipes have a number of advantages, among which the following should be highlighted:

- resistance to mechanical damage;

- can function at both low and high temperatures;

- have a long service life;

- quite environmentally friendly material.

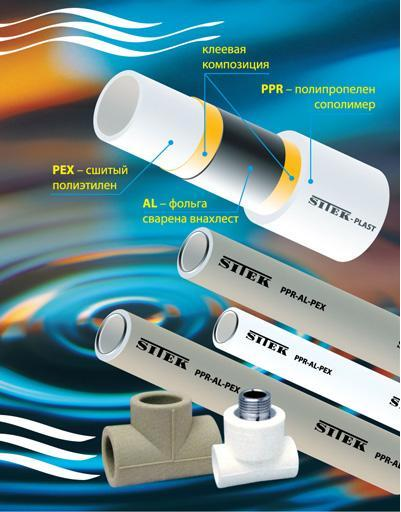

Polypropylene recovers well after deformation.In addition, there are reinforced pipes, the strength of which is given by aluminum foil and a layer of fiberglass.

Polypropylene recovers well after deformation.In addition, there are reinforced pipes, the strength of which is given by aluminum foil and a layer of fiberglass.

The material is intended for use in the temperature range -20 ... + 95 ° С, although it can withstand + 140 ° С. Such pipes are used mainly for plumbing, both hot and cold water, and heating. They are mounted using welding and fittings.

Reinforced plastic

The most expensive of the materials considered, but also the most reliable of all. It is a kind of sandwich, inside and outside of which there is plastic, polyethylene, and between them there is an aluminum pipe. But that's not all: the metal is bonded to the inner and outer layers with a special glue. Pipes made of metal-plastic practically do not change the diameter in the specified temperature regime.

Important! For correct bending of metal-plastic pipes (so as not to bend), a special spring is required. They are internal and external .. They are resistant to external and internal aggressive environment, and in addition, they have the following advantages:

They are resistant to external and internal aggressive environment, and in addition, they have the following advantages:

- absolutely impervious to oxygen;

- are not afraid of water hammer;

- do not rust;

- such pipes can be bent, that is, during their installation, fewer connecting elements are needed;

- can be used at + 95 ° С, etc.

Polyvinyl chloride (PVC)

PVC pipes are made from a special type of polyvinyl chloride that does not emit substances harmful to the body.

Such pipes are used in the following cases:

- plumbing systems;

- for the organization of watering;

- gravity sewerage;

- rainwater runoff.

Read on for how to properly plan your small backyard landscape design.

There are two main types of pipes:

- nPVC (PVC-U) is an unplasticized polyvinyl chloride with high resistance to various chemicals. Its operating temperature range is 0 ... + 60 ° С. Such pipes are used to pump corrosive liquids, alkalis and acids.

- PVC (PVC-C) - chlorinated polyvinyl chloride, a material with a very high melting point - about + 500 ° C, and has mechanical strength and chemical resistance. It is used in the same areas as the previous material, in addition, it is used in the transportation of any liquid food products.

Both materials are safe for humans. Such pipes are connected with glue (in the event that a large internal pressure is possible in the system) and PVC fittings. Pipes made of this material are cheaper than the previous two.

All of the above features of materials, by and large, are important when using pipes for their intended purpose - for transporting liquids. But in this case we are talking about a completely different field of application, so products from any material will suit you. Only some of the design nuances during their installation may differ slightly.

Did you know? In 1835, French chemist Henri Victor Regnault synthesized vinyl chloride and left a transparent container of liquid on the windowsill. After some time, a white precipitate appeared in the solution (probably under the influence of sunlight), which did not react with anything - the scientist accidentally discovered polyvinyl chloride, PVC.

Plumbing from metal-polymer pipes

In addition to polyethylene or polypropylene materials, composite metal-polymer pipes are often used to equip a home water supply system. Many experts insist that in terms of performance, installation cost and durability, these options are best suited for building a home plumbing.

Structurally, a metal-plastic pipe consists of three layers:

- The outer protective layer is made of cross-linked PEX, which provides reliable protection of the inner reinforcing layer from impacts and abrasive wear;

- The inner aluminum layer provides high strength at temperatures up to 130 ° C and an operating pressure of 15 At;

- The inner polymer layer of polyethylene protects the aluminum from the oxidizing effects of water.

All three layers are glued together under pressure with a special organosilicon compound.The result is a very strong and rigid structure that can be bent into the desired configuration, like an aluminum wire.

For your information! Reinforced-plastic pipes are ideal for arranging collector types of water supply systems.

Low coefficient of thermal expansion and high strength allow for hidden installation of water pipes. The lines are simply placed in a niche in the wall and covered with gypsum plaster. But on one condition - there are no more tie-ins or connections on the pipe section connecting the inlet manifold of the water supply and the connection point. Otherwise, the hidden wiremap cannot be used.

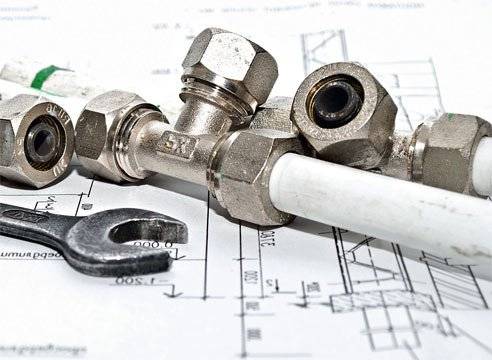

To connect and connect a water supply system from metal-plastic pipes, self-tightening metal fittings, corners and couplings are used, without any welding and glue. The stripped end of the pipe is inserted into the fitting, crimped on a silicone gasket and everything can be connected. The process takes 5 minutes at most.

It is enough to simply bend the pipe at the desired angle. To do this, a special device in the form of a coil spring or a silicone rod is inserted inside, and you can bend without fear that the water supply will break.

Crafts for the playground

Original handicrafts made of PVC pipes will also work for the yard playground: a small playpen for a baby, a developing collapsible rug, light swings for children under 5-6 years old, plastic sleds of an original design, collapsible gates for playing hockey or football, a small playhouse, outdoor shower for summer use, theater screen for impromptu home theater performances, and much more.

A playpen made of plastic pipes can be assembled in a couple of hours if you have a special soldering iron. You only have to buy the required number of corners and crosspieces to connect the partitions to each other. The design is simple in that you don't need to make a floor for it.

Plastic swing must be assembled from polypropylene pipes with a diameter of 32-55 mm, or from large-diameter metal-plastic pipes. For the rigidity of the structure, metal rods of a suitable diameter are inserted into the supporting pipes - they will not make the portable structure too heavy, but will make it as safe as possible for children. For a chair of such a swing, you can cut a sheet of OSB, and bolt it to the frame. To make a stationary swing with your own hands, it is enough to drive iron rods into the ground, on which the main skeleton of the structure will be mounted.

PVC pipe sleds look very original, and the same OSB or chipboard sheet will serve as a seat for them. Due to the small length of the connected segments, such sleds will turn out to be very durable. You can bend the polypropylene segments on the front of the sled with boiling water - you need to lower a piece of pipe into boiling water, keep it in it for 20-30 minutes, and then, while it is hot, put the pipe on an iron rod and quickly bend it as needed ... Leave for a few hours until it cools down, and the bent element of the sled is ready.

A playhouse made of plastic water pipes can be complicated to a castle - make a drawing, and your kids will have a transforming house, from which you can assemble anything - from a swing to a crib. The roof and walls of the house are made of thick fabric or opaque polyethylene. And so that the children feel in such a house as in the present, bring lighting there and make furniture - two or three chairs, a table, a cabinet. Children will be interested!

It is quite simple to make a shower - assemble a quadrangular frame on squares, and you do not even need to mount a sprayer - it is enough to drill many small holes on the long sides of the upper pipes through which water will create many jets.And the pipes of the frame made will serve as a water supply line - connect water to it from a house or an outdoor storage tank with a pump to create pressure. And if you make this structure higher, then you yourself can freshen up in it.

Manufacturing and assembly process

Below are the diagrams, drawings required for the manufacture of furniture from pipes. With their help, you can make armchairs, chairs, beds, shelves, tables, a huge number of decorative elements. The products are interesting, durable and safe.

Armchair

The original way to use plastic pipes is to make a chair out of them. There are many options for making it. It all depends on the desire, capabilities and imagination of the master. Plastic piping can be used to make the chair. It can be made using pvc pipes, a knife and glue.

To get an unusual chair, you need to do the following:

- first, cut into segments of different lengths. The main thing is that the longest segments should be the same length. They will act as supports;

- long ones will be needed for the back, armrests;

- further, the segments are glued together so that the surface of the armrests and the back is on the same level. To the bottom, the length of the segments changes.

Thus, an interesting armchair is obtained that will decorate any room in the house. To make it even more comfortable, pillows are placed on it or sheathed with foam rubber. It is pleasant to spend time in such an armchair, read a book, watch TV.

The parts under the letter "A" define the width and depth of the seat. The length of the pipes "B" determines the height of the seat from the ground. Details under the number "C" are the height of the armrests, and under the number "D" the height of the back.

The parts under the letter "A" define the width and depth of the seat. The length of the pipes "B" determines the height of the seat from the ground. Details under the number "C" are the height of the armrests, and under the number "D" the height of the back.

Bed

A table, a bed are made in the above way. Different segments are glued together - you get the base of the bed. On top of it you need to put a comfortable mattress, pillows, blanket. This is a perfectly suitable place to sleep and rest.

In addition, cribs are made from this material. To do this, you need to study the diagrams and drawings. Then prepare the segments of the desired size. They are connected using fittings. If you fasten the parts together with glue, they will be very strong and durable. Without the use of glue, the structure will turn out to be collapsible and can be removed at any time. The baby's bed will be unusual, reliable and durable. If the family has more than one child, multiple beds can be made.

Table

You can make such furniture from polypropylene pipes with your own hands, like a table. Its frame will be made of pipes, and the tabletop will be made of any other material. At the same time, it must be remembered that pvc pipes are not suitable for heavy loads. The lighter the countertop, the better.

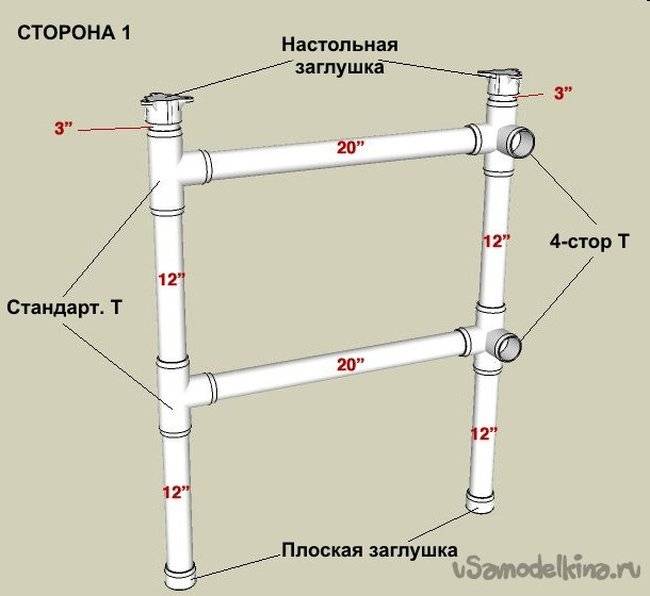

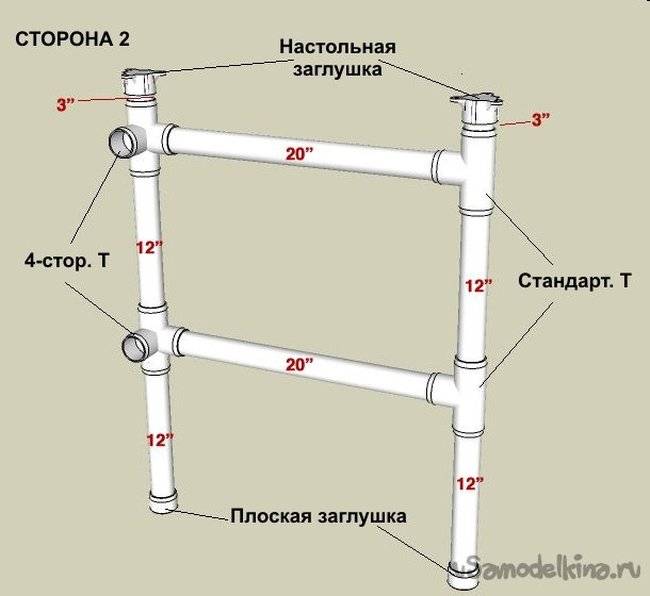

The size of the countertop in this case will be 91.5 x 203 cm. You will need the following materials and tools:

- door leaf as a table top;

- fasteners for connecting parts;

- drill;

- saw.

You will also need segments in size:

- 30 cm - 10 pcs;

- 7.5 cm - 5 pcs;

- 50 cm - 4 pcs;

- 75 cm - 4 pcs.

To assemble the frame, prepare:

- t-shaped fittings - 4 pcs;

- plugs for pipes, fittings - 10 pcs;

- 4-way fitting - 4 pcs;

- cross fitting - 2 pcs.

First, assemble the side elements according to the scheme. Then proceed to the back of the table

Pay attention to the stability of the structure. All details must be the same

The last step is to collect all the elements into one structure. Inspect the product for irregularities, sharp parts. Handle everything carefully, glue the connections. In such a simple way, a table is made.

Tool

Tool

Materials (edit)

Materials (edit)

Preparing parts of the right size

Preparing parts of the right size

Connecting fragments

Connecting fragments

Table top fixing

Table top fixing

Rack

Chairs, beds, tables - not the whole list of products that can be made from this material. Another useful piece of furniture is a shelving unit.The design parameters can be very different. It all depends on the size of the room where it will be installed and the wishes of the master.

The first step is to make a drawing, a diagram of the future product. Next, prepare the required amount of a certain size of parts for them. Connect everything together. The base of the shelves can be plywood or other material. The only thing to remember is that the materials are not suitable for heavy loads.

These racks are used for flowers, toys in the children's room. Shelving units can be installed in the garage. There, products will become a great place to store tools and other things. You can place garden tools on the shelves: pots, tools. PVC products look unusual, neat, do not require additional decoration. Plastic shelves, racks do not harm the health of others, they are durable and environmentally friendly.

Choice of construction and design

Glamorous Pink Plastic Tube Laptop Stand

Furniture production begins with the choice of design and options for its design implementation. It is necessary to start from the function that the furniture will perform. Then the design parameters are selected:

- collapsible or one-piece;

- dimensions of the entire product;

- the number of elements and their sizes;

- a method of connecting parts of a structure.

Convenient bar counter for giving from plastic pipes

When thinking about a design, you can be inspired by looking at furniture magazines and catalogs, furniture sites on the Internet. This will not necessarily be furniture made of polypropylene pipes. Original ideas can arise when viewing options for rattan, wood, metal furniture.

Plastic pipe storage rack for boiler room

This stage of work ends with drawing up sketches, determining the necessary materials, drawing up a cost estimate. At the same time, it is necessary to take into account how you can use those materials that are already in stock, as well as availability, if materials need to be purchased.

Large and beautiful table with PVC pipe legs

What materials are needed

Necessary materials for creating furniture from PVC pipes

After the design is selected, it is necessary to draw up a list of materials and tools needed to create the craft. For this you may need:

- plastic pipes;

- fasteners: glue, screws, screws;

- fitting.

Stages of the plastic pipe welding process

Plastic pipes are easy to cut. After that, a sharp edge with burrs remains, which must be cleaned. Just cut the threads. When heated, polymer pipes bend well, retaining a new shape after cooling. Sometimes it is easier to bend the frame rather than assemble it with pieces of pipe and fittings.

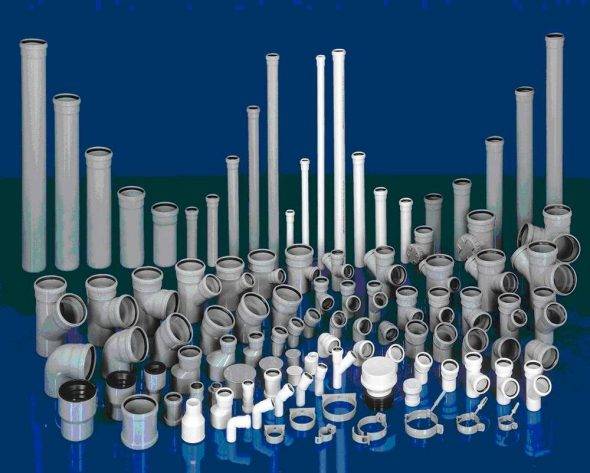

Plastic pipes of various shapes and fittings for them

They are divided by purpose:

- plumbing

- sewer.

Variety of types of plastic pipes

From the point of view of the manufacture of furniture and useful household appliances, sewer pipes, in contrast to water pipes, benefit from a lower price. They are manufactured in large diameters.

By the type of polymer from which the pipes are made, they are divided into:

polyvinyl chloride (PVC);

PVC pipes of different diameters and colors

polyethylene (PE);

Large diameter polyethylene pipes, straight and corrugated

polypropylene (PP).

Polypropylene pipes and fittings for them

They differ slightly from each other in properties. Polyethylene behaves worse at elevated temperatures and under the influence of sunlight, it is elastic. Polypropylene pipes are stronger and more rigid. The positive quality of PVC pipes is increased resistance to chemical attack and reduced flammability. They perfectly tolerate ultraviolet exposure.The difference in the performance characteristics of polymers in most cases will not be critical for the manufacture of furniture. Differences in price, however, are a factor to consider. The most expensive are polypropylene. The optimal price-quality ratio for creating furniture structures is possessed by PVC pipes.

In addition, pipes can be reinforced and unreinforced. Polymer pipes are most often reinforced with fiberglass or aluminum. The reinforcing layer is soldered between two layers of polymer. This is done to increase strength, rigidity, and reduce linear expansion when heated. Reinforced polypropylene pipes are used for hot water supply. The letters RC are added to the reinforced pipe designation. They can also be distinguished by their appearance. In addition, some manufacturers apply a colored stripe along the pipe, informing about the scope of the product. Pipes with a blue stripe are used for cold water supply, with a red stripe for hot water or pipelines with a heating medium. The presence of both strips indicates the versatility of the pipe. It should be borne in mind that reinforced pipes, although stronger, are much more expensive. Decide on the advisability of additional costs for the master.

Trolley with fixing made of plastic pipes

What covering material for greenhouses to choose

After assembling the frame, it must be closed, covering material will be needed. Glass for covering a greenhouse from pipes is not suitable, since it is heavy and fragile.

Cellular polycarbonate is suitable, it does not break, it is simply cut, it is easy to attach, it can withstand small deformations and has less heat transfer.

An excellent option for a greenhouse is polycarbonate, which has a thickness of 4 - 6 mm, but in this case, pipes should also be taken from polypropylene with a diameter of 32 mm or more. Despite the fact that polycarbonate is quite expensive, it will last longer.

You can buy a cheaper option for covering a greenhouse, these are:

- polyethylene film;

- reinforced film with a thickness of 11 mm - it is stronger than polyethylene, so it will last longer;

- bubble - is an excellent heat insulator;

- non-woven (agrospan, agrotex, spunbond, agryl) - more durable compared to the film, it keeps heat well and lets rain through, not transparent, which will save plants from excessive sun.

We attach to the frame

The method of covering the greenhouse depends on which material you choose:

-

- Film - there are several ways to attach it, using ropes, tape, mesh or self-tapping screws. When using self-tapping screws, you can put linoleum or pieces from plastic bottles as a washer to protect the film from damage. You can purchase special clamps, they will simplify the work, and provide a reliable fastening. In addition, unlike self-tapping screws, some of them can be removed during the day to open the greenhouse. And the film is attached to the wooden box with a rail. The film should be cut immediately on the greenhouse, the stripes are made a little longer than the size of the edges, this is required for fixing.

- Polycarbonate - to be attached to the frame with special thermal washers, at a distance of 0.3 - 0.5 meters from each other. Polycarbonate leaves are connected to each other by a profile. It is necessary to lay polycarbonate so that its internal channels are located vertically. The edges of the sheet must be closed with plugs.

-

-

- Non-woven fabric - the fastening methods are the same as for the film.

-