Manufacturing steps

When creating furniture from solid wood with your own hands, it is important to correctly prioritize, you should take into account all the nuances of the process, study the stages of manufacturing and assembly of the constituent elements of the structure, as well as the importance of the final stage - covering the surfaces of the finished furniture with a protective layer of varnish

Drawings and diagrams for the manufacture of a durable and beautiful product

Any hand-made thing starts with paper and pencil. The first step is to draw a drawing of the room and a visual representation of the future product on it. Only then we remove all the necessary dimensions and make a detailed diagram with details and removal of the composite mobile elements, the attachment points for the side walls, bottom and top, the location of fasteners and other small parts.

Already at this stage, you need to take into account the use of color in the interior of the room, carefully draw the facade of the furniture so that you can immediately see its impact on the environment.

Assembly

After all the details have been cut and polished according to the scheme (this stage can be entrusted to specialists or implemented at home), you need to prepare the necessary tool for making furniture and assembling it at home: a screwdriver or drill, a set of screwdrivers and curly keys, brushes, etc. rollers for paints and varnishes. In addition, you will need fittings such as handles, curtains, brackets and various fixing consumables.

Wooden furniture is fastened with self-tapping screws or bolts with nuts, to fix right angles, plastic corners of different widths are used. In the case of a large dining table, the legs will need to be attached using special metal adapters and additionally reinforced with jumpers.

First, the body of the product is assembled. Then the moving parts and internal components are hung.

The final stage

The final stage is the treatment of wood with water-repellent and thermal protective agents, impregnation with liquids like a stain to give the desired shade. Then you need to cover the wooden furniture with several layers of varnish. This will not only give the surface an expensive appearance, but also serve as high-quality protection against the effects of negative factors.

After the treatment products have dried, decorative and functional fittings are attached.

Advice

- When choosing materials, you should not immediately run to a hardware store. Take a closer look at what you have in stock. Perhaps you or your friend have had beams and planks for several years that are a pity to throw away. Stumps and driftwood that get in the way on the site can also become a unique item or part of it. Remember if you have some hunting trophies on the mezzanine? Horns, skins and other paraphernalia will harmoniously fit into the interior of your recreation area.

- Pallets (pallets) can be bought for little money at construction sites, in stores or online. You will save a significant amount of cutting and assembly time with these versatile designs.

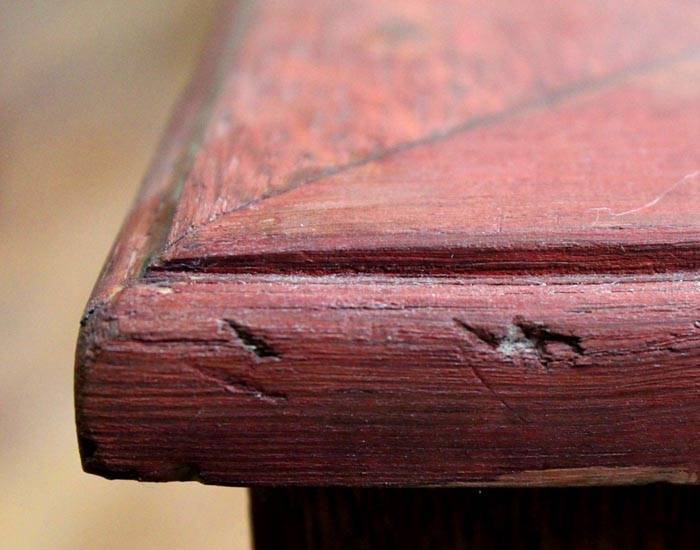

DIY wood furniture restoration: the procedure is curled from defects

No matter how carefully the owners treat their furniture during operation, minor mechanical damage will surely appear on its surface, impairing the appearance of the product. If the strength characteristics of the product are not lost, everyone will think about how to update wood furniture with their own hands. The procedure will depend on the nature and depth of the defects that have appeared.

Old furniture can be restored

We remove scuffs and shallow scratches

Small defects can be removed with special touch-up markers and pencils. These items are sold in specialized stores and come in a variety of colors. For the restoration of a certain surface, it is worth choosing a product that is similar in tone.

Removing scuffs is easy

Manufacturers offer:

- Retouching markers consisting of opaque quick-drying enamel in different shades. Such compositions are not afraid of the effects of detergents and allows you to do without applying a protective layer of varnish. If the desired shade is not commercially available, the desired color can be obtained by applying several layers of marker;

- Alcohol based retouching pencils. Leaves the wood texture visible. Does not harm the base. The base of the pencil is an alcohol stain. To increase the durability of the formed coating, the restored surface should be covered with a layer of protective varnish;

- Retouching texture pencils. Created specifically for drawing wood texture. Thin rods allow you to repeat the contours of any defect, including those located in a hard-to-reach place. After application, it should be rubbed with wax or covered with a layer of varnish.

Special markers and pencils will definitely help

Getting rid of deep scratches and chips

Deep scratches tend to be long. If you use a special wax, the damage will be almost invisible. Manufacturers offer various formulations that differ in color and hardness. When using a transparent composition, a subsequent application of a layer of enamel or tinting varnish is required.

Chipping based are removable

Wax will help remove deep scratches

To hide more chips and dents, you will need wood putty. You should choose a composition close to the base color. The putty is applied in several layers, after waiting for the previous composition to dry completely. After removing the defect, the bases should be leveled with fine sandpaper. After that, an additional layer of varnish is applied.

Putty will restore chips

Removing stains

Gasoline will certainly help to get rid of traces of obscure origin on a polished base. This requires:

- Soak a rag in gasoline;

- Wipe the stain;

- Repeat if, after drying, contamination is present;

- Wipe the base with a rag;

- Restore damaged polish with denatured alcohol or linseed oil.

Stains can be removed

The sequence of actions is described above.

Save time: select articles by mail every week

Benches and tables made of hemp and logs

Log elements are connected with dowels: through holes made with a 20-25 mm Lewis drill. The cups in the logs are made incomplete. For shops, trunks are selected without resin pockets and a minimum number of knots, resin particles are also removed from the surface. It is better to refuse conifers in principle, especially if there are no special wishes about them. On the adjoining halves of the table, chamfers are removed, and then they are rigidly attached again with wooden dowels. Stumps are used in different ways to create furniture. Firstly, after the cut down trees, stumps remain on the territory itself, which at any moment will "become" a chair or its semblance. But benches with tables are collected from snags and stump cuts. The tops of the stumps are decorated with mosaics. Wide cut so that there is both a seat and a back. A croaker is placed on top of the stumps - the bench becomes usable.

Work zone

When there is lumber and tools, then you need to find a place to make wooden furniture. Otherwise, the housing will be clogged with dust, shavings and other waste.

A good workshop can be organized in the garage, basement, on the balcony. Here, in addition to tools, at least minimum working conditions must reign:

- Workbench;

- Vice;

- Shelves-boxes for storing tools and consumables;

- Seat (better adjustable);

- Lighting.

When improving your workshop, you can gradually add different machines to the above list - wood turning, drilling, sharpening, etc.

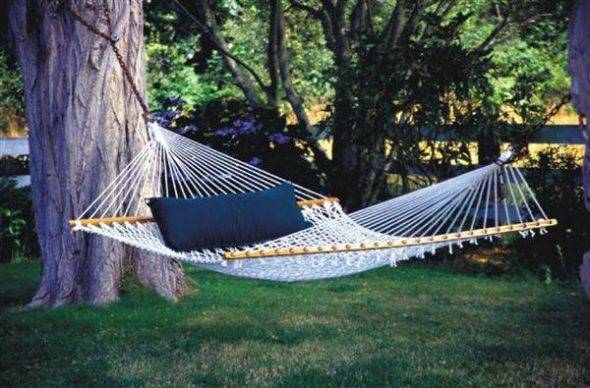

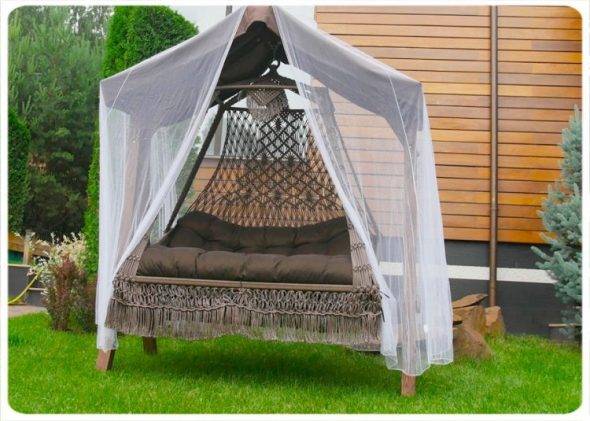

Wicker items

You can rest in a hanging bed with a canopy. A non-standard idea is to weave a hanging bed on your own.

A wicker hammock will look unusual.

The canopy can also be made wicker or hang ordinary tulle.

Thus, you will also create a separate seating area.

It is not necessary to weave small furnishings and accessories. Designers have learned to create wicker furniture with foam rubber, including sofas.

White, weightless foam cushions remain a constant addition to the magnificent sofa frame.

Make such a creation using video tutorials or step-by-step instructions.

From pallets

Pallets are also called pallets. They are large enough trays that are usually left over from building materials. If you do not have the funds to buy garden furniture and even blanks for making it yourself, then we suggest you use pallets for these purposes. You can buy them at a very affordable price in hardware stores. There is enough of this good.

Boards in pallets are not stacked closely, but at a distance equal to half the width of the board. Pallets also have sides with a height of 10 to 14.5 cm. There is no uniform size of pallets, but in our country there are usually 100 × 120 cm and the European standard - 80 × 120 cm (they can have a continuous laying of boards).

Pallet handling

Regardless of which piece of garden furniture you have to make, they must be pre-processed. First, you need to remove the dirt from the tree, then dry it and sand it.

Tools / Materials

It is not enough to buy pallets to make garden furniture. You will also need thin, not very long nails. In addition, you need to purchase furniture fittings, such as wheels, handles, etc.

You will also need varnish / paint, glue, glass, small lights, and cloth. The composition of this additional set, of course, depends on the design of the furniture.

Making a coffee / dining table

Making a coffee table

Making a coffee table

The simplest pallet garden furniture options are dining and coffee tables. To make them, you just need to connect 2 pallets, placing them on top of each other and connecting them with nails. A fiberboard sheet, glass or thin wood can act as a tabletop. The coffee table is ready for this.

More pallets are needed to make a dining table. For the table top, you will need 2 pieces, and for the manufacture of the legs, you will need 1 pallet, which you will need to saw into 4 parts, stretching vertically and nailing in the corners.

Dinner table

Dinner table

Another option for the legs is to take 2 pallets, place them vertically and nail them whole on the sides. This will create a large dining table. If this table height is not enough, then you will have to stack 1 more row of pallets.

Sun lounger

The relaxation area can be decorated with sun loungers. To make them, you will need 3 pallets - 2 rectangular and 1 square (it will be 10 cm wider than the rest).

Place rectangular pallets together and nail them together. Initially, pallets need to be sanded and then painted. Now you need to make the back of the chaise lounge. At this stage, you will have to work a little more. Disassemble the wide pallet: remove the bottom layer and partly the middle one (1-2 pieces of it should remain). The top layer of the pallet will serve as a base. Remove 2-3 boards from the backrest blank. They will still come in handy for you, so disassembly of the pallet should be carried out very carefully, nothing needs to be broken.Saw one of the planks you removed in half.

Now set the square pallet at an angle to one side of the rectangular pallets. This will form the back of your chaise lounge. Fix it with the screws removed from the pallet earlier. A thick fabric or mattress can be thrown over the finished product.

Making a sofa

Making a sofa is very simple. For its base, you will need 3 square pallets and 2 rectangular ones. As sidewalls, you can use 1 pallet, previously sawn into 2 identical parts so that you get 2 thin pallets. Whole pallets can act as a backrest. For fastening, thick screws / nails, metal corners are used.

Use foam, such as a sitting mattress and back cushions. So, you get a cheap, but very original sofa.

Choosing material for work: useful tips

In order not to miscalculate with the choice of material, it is recommended to use the following tips:

it is necessary to carefully inspect the wood, there should be no cracks in the end part (only very small ones are permissible);

it is better if the seller knows the age of the wood, because it should not be too old;

the natural massif should be normally dried, undried or overdried materials are not suitable for creating furniture;

if you plan to use several types of wood in the manufacture of structures, then options with a similar structure should be chosen, because they will shrink equally;

it is desirable that the annual layers are parallel, otherwise the material will crack during operation.

it is important to pay attention to the wood cut - if it is too bright or spotty, then most likely the wood is affected by a fungus and is not suitable for creating furniture.

Using this information, you will be able to purchase only a high-quality array.

Experienced experts recommend rechecking the quality of the material several times and paying attention to important nuances

Wood waste materials

Quite often, MDF and chipboard boards are used in the manufacture of furniture - they are made from wood chips. Materials have lower strength compared to natural solid wood, but at the same time more favorable cost.

The main advantage of laminated chipboard is that as a result of processing, the material has become moisture resistant. In addition, it does not deform even with temperature changes.

MDF and chipboard are often used to create various designs, both by professional furniture makers and beginners.

How to give new life to an old board countertop

Old table top made of boards

The table top is made of pine planks. A big plus - they are in fairly good condition, they have not cracked, they have only lost their visual appeal. In this state, the table, which is more than 100 years old, is unlikely to be liked by anyone, unless you cover it with a beautiful tablecloth. How can you proceed?

-

The old coating should be removed: you can use a varnish remover, but it's easier to just sand the parts.

-

The table top is milled.

-

A special high hardness (white) parquet oil is applied to the table top and legs, intended for the finishing of sanded wood surfaces. It is used for application to indoor structures. The composition of the composition includes natural oils enriched with resins, wax and pigments that are resistant to light. You can apply the product in 1 or 2 layers.

-

Legs are screwed to the table top.

After the restoration work, we got a table that can decorate any interior.

As you can see, an old, well-worn piece of furniture made of boards can be given a new life. What methods are used to restore furniture?

Methods for restoring the appearance of furniture

There are several ways to restore and restore the attractiveness of wooden structures.

-

Mechanical method. By sanding (first with a nozzle with a coarse abrasive, then with a fine one), you can remove the top layer of wood with traces of biological damage and wear, remove the old coating and make the surface smooth. After processing, the product must be protected with an antiseptic agent, otherwise it will not last long. The paintwork can also be removed with a construction hairdryer.

-

Compositions for restoration. Depending on the condition of the surface, you may need: putty on wood (to eliminate cracks and chips), touch-up pencils (to mask small abrasions), wax filler (to eliminate scratches).

-

Decorative means. You can update and give the surface a new look with varnish, paint, impregnation, stain, varnish, oil, wax, etc.

-

Aging of wood. This, quite popular recently, method of changing the appearance of wooden products and coatings includes: brushing, which consists in treating the surface with coarse metal brushes in order to expose the relief of wood and coating with special compounds, craquelure (applying a product to the details, after which the boards covered with a mesh of cracks), burning with an open flame (it was used in the manufacture of hangers) and treatment with caustic chemical liquids that corrode the soft fibers of the boards.

The use of all methods and means allows you to radically change the appearance of furniture, especially that has lost its attractiveness.

Upholstery

It is better to sew covers according to patterns already prepared in advance. When this is not possible, you can, instead, apply the fabric to different elements and immediately stitch or lighten the task and tighten it, tucking it at the corners, but this method is not reliable. It is better to entrust the matter to professionals and contact the studio, where they will do all the work for you.

After all this, the easiest thing remains - to collect. It only takes 2-3 days of hard work.

When assembling a sofa with their own hands for a summer residence, people want to use any available materials without special costs. Then, cheap or unnecessary parts can serve as a substitute for expensive ones. The result is a result that combines original design, style and functionality.

For example, you can take wooden pallets. They are sold for pennies in construction markets, for example. Used pallets should be thoroughly cleaned and washed. Then, even new panels should be sanded, if necessary, treated with a moisture-repellent primer or painted.

An unusual design move will be to make it from an old, worn out bathtub. To do this, you must remove the legs from it, clean the surface of paint, cut off one wall with a grinder and grind the irregularities.

The entire product is painted, the legs, processed separately, are returned to their place. It remains only to attach the seat and, if you want, to decorate the walls with soft components.

What to make

Everyone can find more or less suitable materials. Wood, metal, plastic and unnecessary old things contained in a basement or garage, one way or another, are stored for later use, but sometimes these materials are forgotten. The first step is to carefully inspect all storage facilities. There will definitely be blanks for several original homemade products. Old fabrics are useful in creating screens, curtains, seat upholstery. Sheets, boards, beams, cuts and solid wood are sold in most household goods stores, although sometimes you have to order blanks, and sometimes it makes sense to make it yourself. The metal structure you need is more difficult to find.Metal products stored on site, as well as their parts, only occasionally suit the shape, quantity and aesthetics of the coating. Additional materials and fasteners are selected in advance, almost simultaneously with the main blanks.

Metal

The best solutions for handcrafted manufacturing:

- bronze;

- aluminum;

- brass;

- steel;

- stainless steel;

- copper;

- cast iron;

- iron.

A long service life paired with the anti-corrosion qualities of modern products - this is what makes the material suitable for manual assembly and, accordingly, additional savings. Metal tables and chairs fit perfectly into the green background of bushes and trees. It is better to assemble your own products from aluminum - it is not for nothing that it is considered the best. The seats are often made of plastic or wood, but the qualities of aluminum are also suitable for creating a comfortable seating position. The legs can be made from heating pipes. Fasteners will need welding or bolts. The pipes are bent with a car disc. To prevent the workpiece from cracking, sand is poured into the cavity and covered with small bars. For countertops, a QSB sheet and impregnated boards are suitable. The seats are often made of foam rubber, sheathed with vinyl leather or dermantine.

Wood

The popularity of wood is guaranteed by its natural beauty and environmental friendliness. Wooden products remain one of the most prestigious. For garden furniture, slats, bars and boards are usually chosen, that is, the materials with which it is easiest to work. In an open space, it is not recommended to use coniferous wood, as it spoils clothing with the emitted resin. The raw materials can still be simply degummed. Massive benches are made from logs. It is not easy to work with the material, but during preliminary processing it is possible to assemble mobile structures, sometimes without a single fastening element. Coffee tables, armchairs and sofas can be assembled or trimmed using stump slices. Some develop the idea and drive the stumps themselves into the ground, processing them accordingly to ensure a tight connection. Solid wood, snags and firewood will make interesting designer furniture, you just need to add imagination.

Of unnecessary things

Old, unused items will further simplify your gardening task. Shabby and broken furniture, thanks to the thoughtful presentation, will become the hallmark of the yard. Beds will make low fences, wardrobes - doors or wickets. The broken piano will play the role of a secret bar, the curbstone is a tiered flower bed. Old racks are turned into stands for flowerpots. A skilled craftsman will assemble a whole set and medium-sized furniture from tires: tables, chairs, sofas. The tires are converted into comfortable poufs, after having pasted over with a rope and installed on the legs. There is definitely a place in the yard for an additional table from the old door. And if desired, a trellis from the door leaf can be installed on the site. If there is a sufficient amount of raw materials in the country, a gazebo, a country shower, and houses for animals may appear.

Design ideas

More and more often, on the pages of designer publications, you can see non-standard solutions using the most unexpected materials: wall shelves made of old boards or building pallets, dining sets made of raw wood, a table in a country house made of a wire spool.

The basis of all these ideas is a natural material - wood, which has been used in various fields and is no longer needed. But its availability has opened up ample opportunities for the experiments of specialists and fans of creating original interior items.

Epoxy resin is an innovative step in the creation of original and economical interior items.It is poured into waste of wood production, just hemp or small pieces, and get a solid piece of furniture.

Wardrobes and cabinets made of artificially aged wood, headsets with carved ornaments and other products from a luxurious and irreplaceable solid wood will never go out of fashion.

Made of wood

Wood furniture is environmentally friendly. It is distinguished by its laconicism, beauty and relative ease of manufacture. Not only a man, but even a woman can cope with this task. Garden furniture can be made in many different ways.

It is easier to work with ready-made, pre-processed slats, bars and planks. There are both simple and complex schemes for making wood furniture. To organize a recreation area, it is better to make benches with comfortable backs; for a feast, you will need a whole set. It is very easy to make a swing out of a bench without legs. To implement these ideas, you need to connect your imagination, have basic carpentry skills and acquire the necessary source material.

Wooden furniture

Wooden furniture

To do this, you can use one of the compositions:

- Mix acetone and water in a 1: 4 ratio.

- Mix acetone and rubber soda in a 5: 1 ratio.

The surface of the tree must be treated with one of the solutions, and then rinsed with water and dried. Then the tree is treated with antiseptics and varnished.

Benches made of logs and hemp

Monumental shops can be made very quickly. To do this, you will need several logs, depending on the required number of benches. The easiest option doesn't require a lot of intelligence - just lay a large log and throw a few pillows on top of it. But perhaps, for arranging a garden / gazebos / terraces / patios, it is better to come up with something more aesthetic and original.

Hemp furniture

Hemp furniture

You can use hemp to organize a dining area in the garden. Small hemp will act as chairs. And for the table, you will need a more massive stump. To make it convenient to eat, the stumps need to be fixed. For example, they can be dug into the ground or placed on a flat surface - a small area on a lawn or a pedestal on a terrace.

From cuts

The saw cut of a tree can serve as an original table top and even a seat for a chair. For example, a saw cut with a larger diameter can be installed on a stump of a smaller diameter. They can be secured with waterproof glue or regular nails.

Of the tools you will need:

- boards;

- hacksaw;

- sandpaper;

- electric saw;

- wood varnish;

- hammer and fasteners;

- tape measure and pencil.

Remove the resin from the wood first. How to do this has already been mentioned above. Before placing on a tree stump, the stool cover or table top must be sanded. You can make such a simple set right in the garden or in the gazebo. If it will be installed in the garden, then take care of mounting the beach umbrella in the table, for example.

Furniture from processed boards

Working with prepared materials takes less effort, and, therefore, you can work on the final result longer and more thoroughly. An example of a processed material is planed boards. For the assembly of garden furniture, dry solid sawn timber of the highest or first grade is chosen. Then the boards will not warp and lead. For a garden close to an expensive home, furniture is assembled from radial cut boards with a minimal texture. Common garden options are made from tangential or semi-radial cut fragments. To emphasize the natural beauty of the wood, radial saw boards with distinct concentric rings are used. They are additionally varnished or coated with wax, but almost never painted.The material makes beautiful tables with attached chairs, armchairs, partitions, shelves and stools, as well as gazebos and sandboxes.

The use of chipboard and MDF for production

Before starting the production of natural wood furniture, you should consider other widely used materials: MDF and laminated chipboard.

Chipboard is a special board made of wood shavings, which is covered with a paper-resin film. The basis of the coating is a paper sheet impregnated with melamine resin and attached to the chipboard by means of an adhesive bond (lamination) or under the influence of high temperatures and pressure (lamination).

As a result of processing, the material becomes moisture resistant, not exposed to temperatures and mechanical damage. During the manufacturing process, it can be given any color and structure. The disadvantages of laminated chipboard include low environmental friendliness and difficulties in spot processing.

MDF has a lot in common with chipboard. However, the compositions of these products are different. When gluing shavings in MDF boards, environmentally friendly natural resins are used. For this reason, MDF furniture can be used even in children's rooms.

The positive characteristics of furniture boards include high resistance to moisture, temperature extremes, and damage. Unlike chipboard, they lend themselves well to fine processing.

As practice has shown, MDF interior items are not inferior in their characteristics and appearance to natural wood, and they can last longer than homemade wooden furniture.

How to care for wooden garden furniture

Wood reacts actively to weather shocks as well as to abrupt changes in environmental conditions. After frequent rains, combined with high temperatures, mold develops. The scorching sun promotes fading of color, drying out of wooden furniture, and the formation of cracks. Periodic processing of all wooden surfaces will not cause difficulties. Caring for different types of wood is almost the same, but the compositions are used only for a specific option. In any case, the furniture is first washed from dirt, sometimes it is immediately wiped with vinegar to "drive out" the pests. When everything dries up, a special oil is applied to the tree - its own for each species. The procedure is not required if the furniture is covered with paint. Sometimes a plaque forms on the surface of the tree - the problem will be solved by wet wiping, followed by the use of fine-grained sandpaper. Additionally, agents are used to create a protective film.

Comfortable recreation area in the country: the choice of practical furniture

For furnishing and equipping a comfortable recreation area, you can use furniture of different configuration and style of decoration.

Most often, standard kits and kits are used, which are not difficult to make at home from simple and affordable materials at hand:

- a small table with a wear-resistant table top;

- armchairs or chairs, with a comfortable and soft seat;

- hammocks and sun loungers, suspended and floor structures;

- benches and benches with or without backs or armrests.

All such furniture is sold individually and in whole sets in specialized stores and is quite expensive, which makes you think about saving.

Conclusion

Garden furniture is a wide range of items and auxiliary elements. Additional accessories transform the square near the house from a simple garden into a place for receiving guests, rest, cooking, family entertainment, and sports games. People prefer to buy all these accessories in the store, and only a part of them tries to save money, doing everything with their own hands. Further opportunities for the arrangement of the territory directly depend on their own diligence, so the second option deserves a more serious attitude. For work in summer cottages, wood, metal and PVC are often used. From the same raw materials are made pieces of furniture for the garden or vegetable garden.You will have to buy something, but a lot will be at hand. Some materials will leave a whole "field" for the realization of creative potential. Popular ready-made options are suitable for those who do not have enough experience or are in doubt when making decisions.