Project development

When choosing a project for a future attic, first of all, one should take into account the mutual dependence of its dimensions on the slope of the roof. The mentioned residential part of the house must reach a height of at least 2.2 m, although with straight roof slopes, one should not be surprised at the decrease in the width of the room, which we have just mentioned.

To maximize the living area, with the desired ceiling height in all places, you should consider the option of a gable sloping roof, when the lower rafters are placed at a 60-degree angle, and the angle of inclination of the upper ones is selected according to individual preferences and climatic characteristics of a particular area.

Do not forget about taking into account the distance between the floor and the ridge, the value of which should be about 2.5-2.7 m.With lower numbers, it is impossible to call this space an attic.

For an accurate calculation of the parameters of each structural element and its correct drawing, it is necessary to proceed from rectangular figures - the section of the future attic. Given the width and height of the planned room, it is almost impossible to make a mistake in the angles above the roof slopes, the dimensions of the ridge, rafters and other important structural elements.

If you find it difficult to navigate in all the necessary values, then you can start measuring from the middle of the width of the front part of the wall. It is from here that you can calculate the height of the ridge, the placement of wall racks, calculate the size of the eaves and the height of the ceiling in the room.

Also, when performing all calculations, it is imperative to take into account the weight of the roof, the expected load from snow, the weight of the lathing (together with the counter-lattice), insulation, steam and waterproofing materials, the angles of the slopes, the total span length, the pitch of the lathing and rafters.

Important! Each individual structure has its own individual number of different connecting points, of a very different structure. In order to better understand the peculiarities of the connection of all elements converging at a specific point, it is advisable to draw each such bundle separately .. Even if you are completely sure of the correctness of the developed project and the accuracy of all measurements, before taking on the work, it is advisable to show your drawings to a specialist, who will be able to notice even the smallest inaccuracies that can reduce the quality of the final result

Even if you are completely sure of the correctness of the developed project and the accuracy of all measurements, before taking on the work, it is advisable to show your drawings to a specialist who can notice even the smallest inaccuracies that can reduce the quality of the final result.

Tips & Tricks

- Self-tapping screws for roof construction must have the manufacturer's brand and EPDM gaskets with a thickness of ≥ 2 mm, otherwise leakage of the roof cannot be avoided;

- Poor-quality protective coating of fittings under the influence of weather conditions will quickly deteriorate, which will lead to leakage at the attachment points, and an ugly appearance in the form of rusty or dirty spots;

- The absence of a snow retention system is the possibility of unexpected snow melting from the slopes, which can lead to failure of the roofing and drainage system;

- Poor ventilation is the formation of condensation in the under-roof space.

Pediment and cornice

The pediment is sewn up after the completion of the construction of the truss structure. Modern materials are increasingly replacing traditional wood when sheathing gables, and now they use clapboard, siding, corrugated board, and other durable decorative finishing materials. Any cladding material is attached to the frame, which is mounted in advance. Regardless of whether or not there will be a room or an attic in the attic, a window opening must be left in the pediment - for ventilation and minimal natural lighting of the space. Arrangement of the pediment

Arrangement of the pediment

The cornice must be equipped around the entire perimeter of the house - it is necessary for moisture and wind protection of the truss structure, the walls of the house and the foundation. Since every self-respecting owner necessarily makes drainages around the perimeter of the house, they are also attached to the cornice, and drain pipes to the walls. The plastic drainage system is mounted on plastic clamps. From the bottom of the cornice board or the cornice frame is painted, sheathed with siding, clapboard or corrugated board - in unison with the trim of the pediment. Gable roof cornice

Gable roof cornice

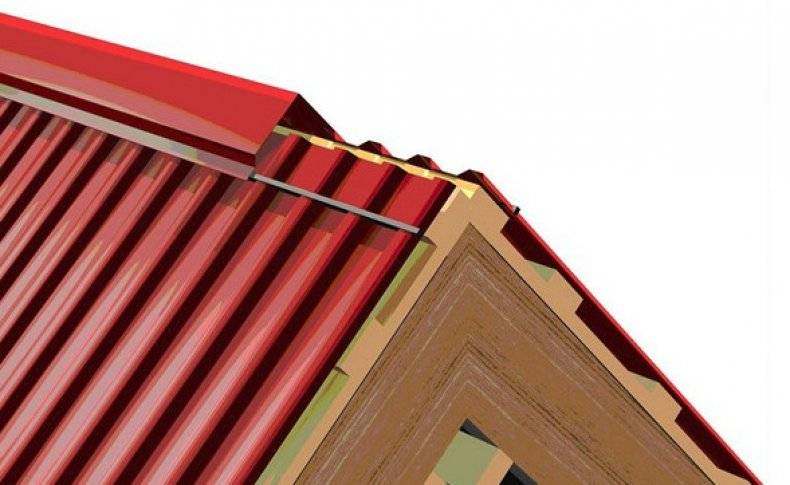

The roof is mounted on a lathing, and, based on the type of roofing materials, sheathing is first done with vapor barrier, hydro and heat insulating materials. For the roof, you can use ondulin, metal tiles, ceramic materials, soft tiles, etc.

Installation of rafters

The rafters of a gable roof are several identical wooden beams of the same length and section. After the installation of the floor beams, a ridge beam is attached, for which beams with a section of 100 x 50 mm are fastened with spacers along the central longitudinal axis of the house. The height of the racks in a typical gable roof scheme is equal to the distance from the floor to the upper surface of the Mauerlat. Instead of a skate bar, boards with a thickness of 50 mm can be used.

Before installing the rafter system, it is recommended to make a large-scale template. To do this, the board from the rafter structure must be attached with one end to the beam, the other to the ridge, and mark its length. This will be the template length of the rafters. Fastening the rafters

Fastening the rafters

The rafter system is also mounted according to a template, observing the sequence of processes. After installing and securing from the lower end of one rafter, you must immediately attach the opposite rafter, and connect the beams with the upper ends to each other through the ridge. The rafters are nailed to the ridge beam, and to the floor beam - with steel brackets or a corner, self-tapping screws or anchors. For a roof of any shape with two symmetrical or asymmetrical slopes, boards are attached along and across the rafters to give the system rigidity.

Features of structural elements

A gable roof does not require the creation of particularly complex foundation systems and other elements. To build a reliable and durable roof, it is enough to take into account the features of the main components of the rafter and Mauerlat system. The first component of the roof includes a set of elements that ensure the strength of the structure. Mauerlat, on the other hand, is the base of the roof, to which the rafters are attached, resting on the walls.

The project includes drawings that show the features of the connection of important elements

The project includes drawings that show the features of the connection of important elements

Rafter system options

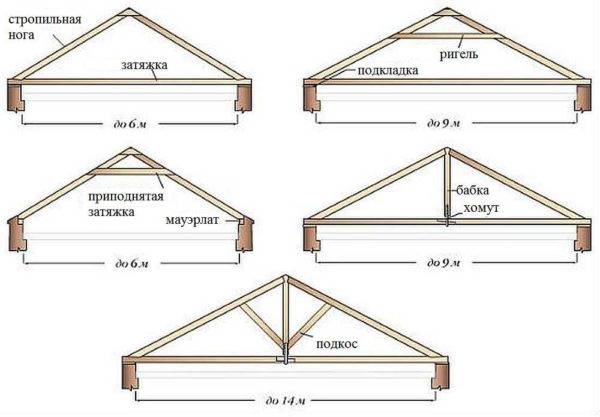

Rafter systems can be hanging and layered. The main difference between these types lies in the method of attaching the rafters to the Mauerlat, as well as in other features. Hanging rafters of the roof with two slopes rest on the side walls, creating a bursting force. As a result of this, the supporting walls are subjected to an increased load, and to eliminate the negative effect, the rafter legs are connected with a special tightening. This reduces the load on the load-bearing walls.

The diagram shows the main elements of the hanging rafters, which must be erected during the construction of the roof

The diagram shows the main elements of the hanging rafters, which must be erected during the construction of the roof

An additional tightening from the top helps to ensure the strength of the hanging system. At the same time, a distance of 50 cm from the rib or ridge of the gable roof is maintained. Hanging systems are optimal when the distance between the external load-bearing walls is not more than 10 m. In this case, there should be no internal load-bearing wall. Thus, the hanging structures will be reliable and will provide protection for the house.

The construction of the hanging rafters is simple, but the calculation of the load on the walls is necessary

The construction of the hanging rafters is simple, but the calculation of the load on the walls is necessary

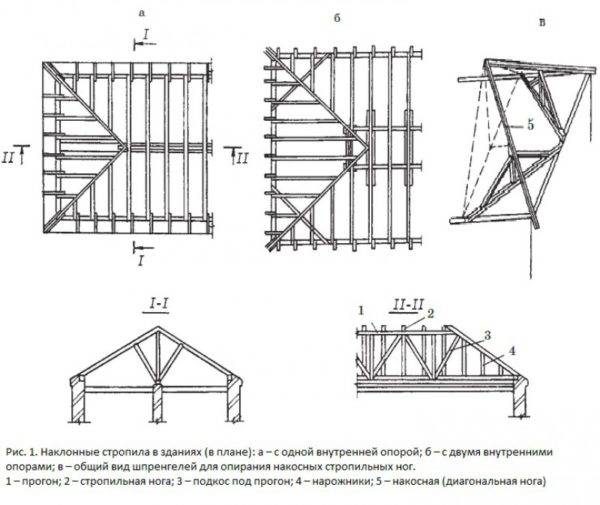

The overlapping version of the rafters is created when there is another load-bearing wall between the outer walls. In this case, there is a support beam that transfers the weight of the roof to the supporting structures. Columns may be present instead of an inner wall. At the same time, different types of rafters alternate, that is, layered elements rest on the columns, and hanging elements are mounted between the supporting elements.

The drawing allows you to determine the features of the rafters for different buildings

The drawing allows you to determine the features of the rafters for different buildings

The rafters are supported by a ridge beam and a Mauerlat. In this case, the load is distributed not only to these elements, but also to the internal supporting structures.

The procedure for calculating the roofing cake

As an example of calculating a roofing pie, the installation of a sloping roof using metal tiles is taken.

The following materials are required:

- waterproofing;

- heat insulating;

- vapor barrier;

- roofing;

- fasteners;

- additional elements;

- drainage products.

It is planned to use Izospan B for vapor barrier; its standard roll has a width of 160 centimeters. According to the manufacturer's instructions, the size of the overlap should be at least 10 centimeters, hence the working width is 150 centimeters. Taking into account the standard roll sizes, this results in 70 “squares” of material. After that, the area of the roofing surface is divided by the area of the roll and the required number is determined.

The material for waterproofing when a gable or single-pitched sloping roof is being built is calculated in the same way.

A one- or two-slope sloping roof can be insulated in one of two ways: the material is laid either on its entire surface or only on the walls and ceiling of the attic room. The second method is cheaper in cost, but since the insulation is placed between the rafters, the rupture of the material layer contributes to the formation of cold bridges. When choosing a tiled "Ecover Light 35", which has a thickness of 5 centimeters, a width of 60 centimeters and a length of 1 meter, you need to divide the roof surface area by the area of one sheet and multiply the result by 3, since the thickness of the insulation layer must be at least 15 centimeters.

To calculate the required amount of metal tiles, when a one-, two- or four-slope sloping roof is created, you need to know the parameters of a sheet of roofing material. If you plan a gable roof, you need the length of the lower and upper slopes, the length of the side girders and the ridge. Then, for the outreach for the rafter leg, add 7 centimeters to the length of each of the slopes (read the article: "Building the roof of a private house - preparation").

The rafter system of a sloping roof, see the video:

The length of the side run, as well as the ridge, is divided by the working width of the metal tile sheets (it is determined by subtracting the size of the side overlaps). As a result, you get the number of pictures to be laid along the width of each of the slopes.

To calculate the sheets according to the length, take into account that the length of the picture (maximum) is 6.1 meters, the standard length of the sheet is 2.95 and 2.25 meters, the overlap at the end is 15 centimeters, and 7 centimeters must be added to the overhang. Given that the height of the side run usually corresponds to a room height of 2.5 meters, it is advisable to use sheets with a length of 2.95 meters.

Varieties

All mansard roofs can be classified into 4 categories with different designs. Moreover, such attics are single-level or two-level. It is easier to build a single-level attic. As a rule, such a design involves the construction of a conventional gable or broken roof.

Two-level mansards are more difficult to build. This design involves the construction of 2 rooms at different levels. In this case, the method of combining supports is used.

In the photo of the attic roof, you can clearly see the options for the execution of such structures. Additionally, you can provide a balcony. It is constructed by analogy with a window opening.

But, this possibility depends on the bearing capacity of the walls. If it is not enough, the balcony can be built using additional supports.

DIY construction of a sloping roof

Roof trusses can be assembled on the ground. But then, for their delivery to the roof, lifting equipment will be needed, which an individual developer does not always have. Therefore, in private construction, the truss system is mainly built right on the spot:

-

The upper edge of the outer walls is covered with roofing material, after which the Mauerlat is laid on them. If it consists of several short bars, they must be connected with an oblique cut and bolted. The Mauerlat can be attached to the wall with anchor bolts with a diameter of 12 mm, but it is better to pre-wedge studs of the same diameter into the wall. In any case, the fasteners must be embedded in the masonry by 150–170 mm. Also, sometimes an annealed wire with a diameter of 3-4 mm is embedded, with which the timber is tied up.

- Next, the floor beams are laid. Their ends rest on the outer walls and are fastened to the Mauerlat with staples or corners. If the beams also rest on internal walls, they should also be covered with roofing material.

-

Having retreated to the left and right from the middle of the beam, a distance equal to half the width of the attic room, install the racks. Those should be located strictly vertically, so they must first be "grabbed" with nails and only after leveling with a plumb line or level should they be finally fixed. Wooden plates and special corners are used as fasteners.

-

Having installed both racks, they complete the creation of the U-shaped element by installing the upper crossbar (it plays the same role as tightening in a conventional rafter system). The crossbar is fastened to the posts using shaped corners.

- On both sides of the U-shaped element, side rafters are installed. For installation on the Mauerlat, a groove must be cut out at the bottom end, which will ensure the reliability of the connection. Each rafter lath is attached to the Mauerlat with staples.

-

In the event that the length of the side rafters exceeds the maximum allowable for the selected combination of the cross-section of the beam, the load and the inter-rafter pitch, struts should be installed under them. In addition, scrapes and additional racks can be used to strengthen the rafter structure.

- Having finished work on the lower tier, they move on to the upper one: ridge rafters are installed on the U-shaped element. The place where they abut against each other should be fastened with bolts (instead of washers, steel plates are often used) or steel plates.

- Further, the junction of the ridge rafters (ridge knot) and the middle of the crossbar of the U-shaped element are connected by a vertical bar - a headstock.

- Having completed the construction of one truss, they move on to the next. The trusses are erected in this order: first, the extreme ones, between which the threads are pulled, then along these threads - intermediate ones.

-

Finally, the trusses are connected with horizontal girders.

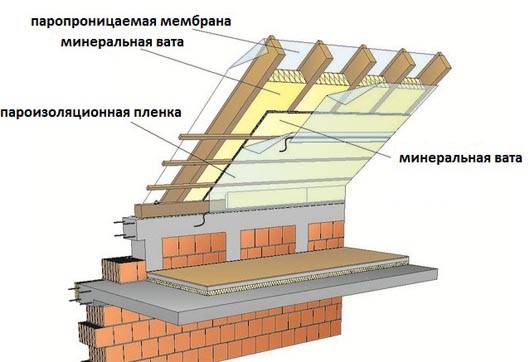

Subsequent manipulations with a sloping roof - installation of roof sheathing and insulation - are no different from those performed on a conventional roof:

- The rafters are covered with a waterproofing film, which is fixed with a counter-lattice (boards stuffed on top of the rafters parallel to them).

-

A crate is stuffed across the rafters on the counter-lattice.

- Roofing is being installed.

- Insulation plates are installed in the rafter space, after which the racks are sheathed with boards or drywall.

The counter lattice provides a blown gap under the roofing material, due to which steam condensation on it is excluded (moisture will be removed by a draft).If a vapor-proof film is used as waterproofing, then there must also be a gap between it and the insulation.

The gaps must be ventilated: holes must be left in the cornice and under the ridge, which will ensure air circulation.

If the cross-section of the holes is not enough (during the design, a separate calculation is made for roof ventilation), devices are installed on the roof to improve circulation - aerators.

Installation of a roof truss system

Installation of a truss system with a residential sub-roof space requires careful preparation. It is necessary to install comfortable scaffolding, decks and ladders, as well as provide workplaces with safety ropes. Workers must be provided with overalls, protective equipment and serviceable equipment. On the ground, you need to choose a level place for pre-assembly of trusses, marking of corners and making templates. All wooden elements must be treated with antiseptic and fire-fighting compounds.

After that, you can start work, which takes place in the following sequence:

-

The Mauerlat is mounted on walls with walled studs along the perimeter. If there is a load-bearing wall inside the building, we lay a bed or a run of the same height with a Mauerlat on it.

- Puffs with eaves are attached to the Mauerlat parallel to the short wall.

- On the puffs, vertical racks are exposed, limiting the attic room.

-

The racks are connected with a tie that serves as the ceiling of the attic room. The trusses installed in this way are interconnected by horizontal girders.

- The lower, and then the upper rafters are installed, which are attached to the ridge part.

- To strengthen the lower and upper rafters, struts, headstock and beads are used.

-

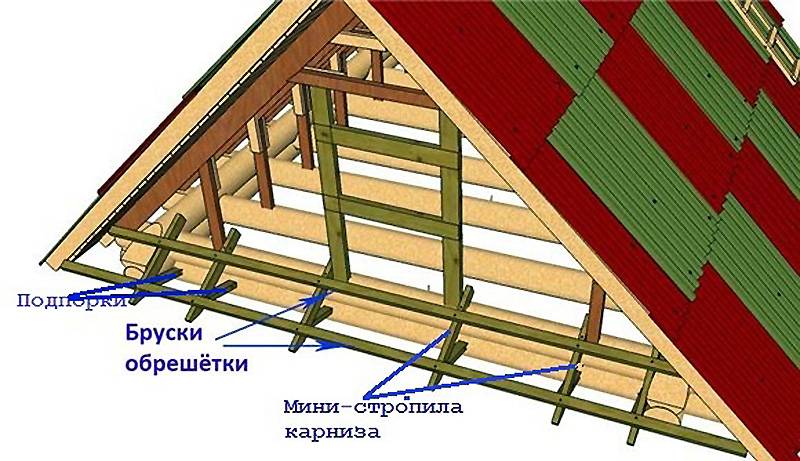

The lathing and the frontal board are mounted on the eaves overhang.

We examined the assembly of the truss system using the example of a sloping mansard roof. The construction of other structures consists of similar operations and mainly consists in performing work according to the design installation diagram, which reflects the methods of connecting the elements of the rafter system. In the presence of carefully calculated drawings, a team of four people is able to mount a roof with a rafter system of any complexity.

Video: installation of a mansard roof

We examined the rafter group of the attic roof, its structure, calculation, as well as a diagram and description of the main units. They offered a variant of the step-by-step installation of the attic supporting structures, attached illustrations and videos that explain the assembly procedure for the attic roof structural elements. Now, its successful erection depends only on the thoroughness of fulfilling the requirements of instructions and technologies and the availability of certain skills in carrying out construction work by the performers. We wish you every success.

Calculation of the rafter system

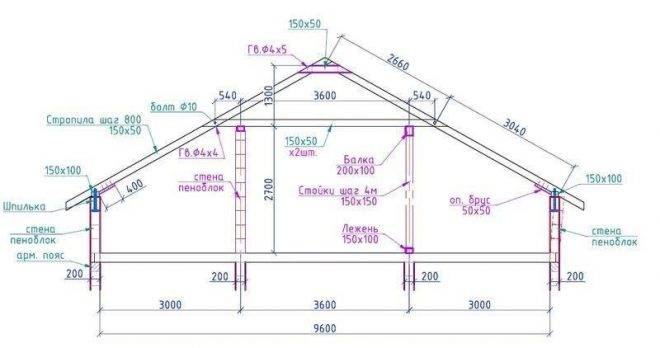

The initial data for the calculation are taken from a pre-developed project. For example, consider the scheme of the roof device in the presence of an attic.

The design drawing indicates the dimensions, installation locations and material of all elements of the roofing system

The main indicator, calculated in the first place, is the pitch of the rafters, depending on the planned topcoat. So, for the installation of ceramic tiles, the rafter pitch should be no more than 60 centimeters, and if you plan to install a plastic covering or soft roof, this figure can be increased to 120-150 centimeters. Again, you need to take into account the nature of the loads - the combination of wind and snow effects - and establish the optimal angle between the roof slopes.

The procedure for calculating the number of rafters

For example, consider a roofing device for a house 10 meters long.We accept, as a first approximation, the distance between the rafter legs equal to 80 centimeters. Then you will need them: 1000: 80 + 1 = 13.5. Since the number of rafters must be an integer, round the result to 13. In this case, the exact distance between them will be 1000: 13 = 769 (millimeters). This is the exact value of the spacing between the axes of the rafter legs.

When calculating the need for materials, you need to take into account their cutting ability. In the case of wood materials, their length can be 4 or 6 meters. In the design process, you need to select the size of the parts, taking into account the formation of the least amount of scrap. Softwood trimmings are unsuitable even for firewood for stoves.

Materials for the truss structure

Composite profiled materials made of wood are becoming more widespread. These include:

-

Wooden I-beams. These products are interesting in that they are made mainly from wood waste. Water-resistant plywood support surfaces and OSB wall. Such structural materials have a bearing capacity no less than a solid bar. The requirements for antibacterial fire-fighting treatment are much milder, the material has already passed all protective treatments during the production process. Moreover, it does not undergo cracking, and its mechanical properties are the same in all directions.

-

Wooden channels. They are produced in the same way as I-beams. The main application is load-bearing elements of wooden structures. The strength characteristics of such a profile are higher than those of natural wood and wooden I-beams. Often such products are made from solid coniferous wood. This significantly reduces the weight of the structures and the load on the foundation.

- Glued timber. This material is not often used for the installation of rafter frames. Its main application is the laying of log cabins. For them, a beam with a core of ordinary needles and extreme plates of expensive types of wood: oak, larch and other valuable materials is used. For rafters, a beam of uniform plates of increased length is used in highly stressed sections of the system.

-

Metal profiles. For the assembly of rafter frames, they are not used so often. The most convenient material for installation is a profile pipe. The disadvantage of a metal profile is the need for periodic measures to protect against corrosion. Elements of the rafter system, as a rule, are tightly closed with a roofing pie and interior decoration of the attic room, which greatly complicates access for maintenance.

Projects of houses with different types of sloping roofs

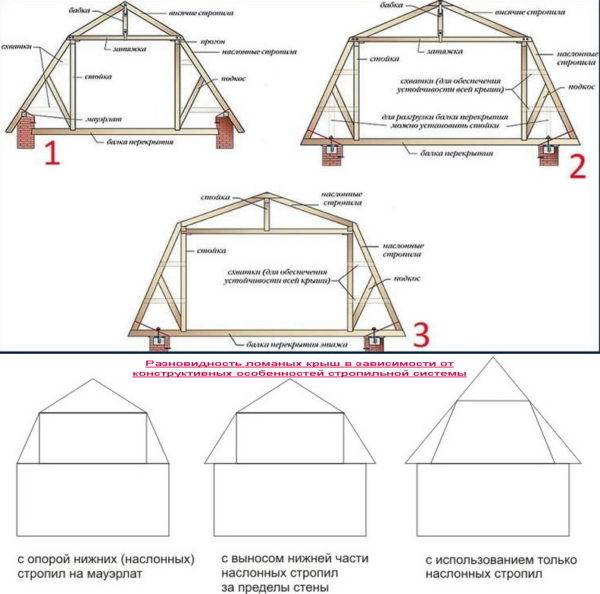

Due to the design features, sloping roofs differ in appearance:

- with the support of the lower rafters on the Mauerlat;

- with the removal of the lower part of the layered rafters outside the wall;

- using only layered rafters.

Depending on the features of the rafter system, sloping roofs have a different look

Depending on the features of the rafter system, sloping roofs have a different look

In the first version, the floor beams are installed so that they do not slightly reach the walls of the lower floor. The lower part of the slopes consists of layered rafters and is attached to the walls of the building with a Mauerlat. The frame of the attic is made of vertical elements (racks). It turns out the constituent elements of the roof in the form of triangles along the walls, connected by fights. And already to them are attached the upper parts of the slopes from the hanging rafters resting on the tightening.

In the second version, the lower edges of the rafters are brought out outside the house, which makes it possible to increase the size of the attic. And the larger the takeaway, as mentioned above, the wider you can make the room under the roof. In this case, the support for the rafters is not the Mauerlat, but the floor beams that are held by the Mauerlat. The rafters are supported by struts. The posts are recessed into the ceilings, but no more than 1/3 of the thickness.

In the third version, there are no hanging rafters. The upper slopes also consist of layered ones, which are supported by tightenings.

Roof structure without vertical elements

There are also other versions of the broken roof, one of which is quite interesting - in this configuration there are no vertical posts, and the rafters are all the same length. Outwardly, the roof resembles an octahedron. The ceiling of the under-roof room will be in the form of a four-sided vault.

The key feature of such a device is to increase the bearing capacity of the rafters, for which purpose 2 metal plates (metal thickness 3 mm) are fixed on each of them at the fracture point on both sides. In addition, crossbars are installed in the upper part of the structure, due to which the load is additionally removed from the flatter part of the broken roof. This solution makes it possible to strengthen the rafters, redistribute the load of the bearing elements, remove the racks and thereby significantly expand the room.

Sloping roof with attic

There are a great many houses with an attic, because they are:

- an attractive silhouette of the roof, and with it the whole house;

- increasing the usable area through the rational use of the available;

- fast erection and low costs.

The construction with a hip-type sloping roof attic allows maximum use of the internal space of the attic

The construction with a hip-type sloping roof attic allows maximum use of the internal space of the attic

Attic houses with a sloping roof look especially unusual, where one slope is with a break and the other is straight. Such an architectural technique is used when the asymmetry of the pediment is conceived according to the project and it is necessary to move the attic room to one or the other wall. Outwardly, such a house looks stylish. It is easy to install solar panels, climatic or heating systems and other technological equipment on an asymmetric roof.

The sloping roof is wonderfully combined with various futuristic shapes, including asymmetry

The sloping roof is wonderfully combined with various futuristic shapes, including asymmetry

Ridge attachment

A ridge is called a rib located at the very top of the roof, formed as a result of contact of the roof slopes. Various parts attached to the edge can also be attributed to the constituent parts of this element. It is at this point that the roof roof is ventilated.

Did you know? For the first time, people learned about corrugated boarding back in 1820, for which today we must thank Henry Palmer, a British engineer and architect who first began to engage in corrugation.

The process of installing the ridge is also the process of arranging its run, connecting the ramps of the rafter systems.

The installation method of this element directly depends on the type of roof, which means that it is worth thinking about it even when choosing a specific coating material. For example, when buying asbestos-cement sheets. Shaped elements resembling a gutter are ideal for them.

They are fixed on boards or a ridge beam by means of nails for attaching slate sheets, with a rubber gasket on them. Waterproofing of all elements of the coating is also mandatory, and the ridge beam is covered with roofing tape.

To fix all the ridge elements, first mount a special bar with a section of at least 70 x 90 mm. Further, on both sides, two crate bars are attached to it, and to simplify the task of assembling parts, special brackets can be attached to the central wooden bar in order to hang the walking bridges to them.

Important! When choosing a ridge board, keep in mind that it should be 10-15 cm thicker than the sheathing boards.

The ridge bar is attached to the central one, and for the convenience of performing this task, its upper edge should be rounded. This shape guarantees a more durable attachment of all parts of the ridge, and to prevent decay and the development of mold of wooden parts, it is better to upholster them with ordinary roofing material along the entire length, applying enamel or paint on top.

The ridge overlap is obtained by combining two skates placed on adjacent slopes, after which the main ridge is fixed, lengthened by 10 mm.

Consider the option of mounting a ridge on a metal flooring:

- On the two skates, holes must be made, exactly the same as on the flat bar side.

- Then two holes are drilled and on the longitudinally placed axis of the line of the squared hump. Just make sure that on the cuffs they cross the wave crests of the cover.

- The installation of the ridge is carried out over the butt-end strips, and its edge should extend outward by at least 2-3 cm.

- When installing a flat element, it is necessary to ensure that all parts must be joined with an overlap of about 10 cm or even more.

- In the process of connecting the elements of the semicircular ridge, the connection is made along the stamping lines.

- Be sure to consider the possibility of combining the ridge strip with the angle of inclination of the covering material. If necessary, you need to adjust the angle of the plank to the angle of the slope (if necessary, you can safely bend and unbend it).

- It is quite possible that an additional installation of a ridge board will also be needed, which is placed slightly higher than the upper sheathing board, but while maintaining an 80 mm gap between the slopes themselves and their ridge boards for good ventilation of the free space under the roof.

Video: installation of corrugated board and installation of a ridge

The final installation of the ridge strip is carried out by pulling with self-tapping screws to the highest parts of the metal tile sheets. The pitch of the self-tapping screws is usually within 0.8 m.

On this, the independent organization of the attic roof is considered fully completed, and the end result will depend on the accuracy of all the above actions.

Of course, doing the work with your own hands seems to be a more profitable option than paying workers, but in some cases, the opinion of specialists is really important, which you should never forget.