How to sheathe a gazebo with your own hands

It is quite simple to sheathe a gazebo with your own hands. However, first it is necessary to draw up a drawing of the future building, then pour the foundation, if any. Then you need to install the frame. It can be made from wooden beams or shaped pipes. After the structure is installed, you can begin to sheathe the walls and cover the lid with building material. To do this, you need to prepare the tools in advance and choose the right casing.

Find out how to properly install a polycarbonate greenhouse on a timber.

Required tools and materials

For working with polycarbonate, it is better to choose tools that are suitable for processing wood and plastic.

Tool list:

- electric drill equipped with metal drills;

- screwdriver;

- jigsaw;

- hacksaw;

- a circular saw;

- roulette;

- thermal washers;

- silicone;

- waterproof tape.

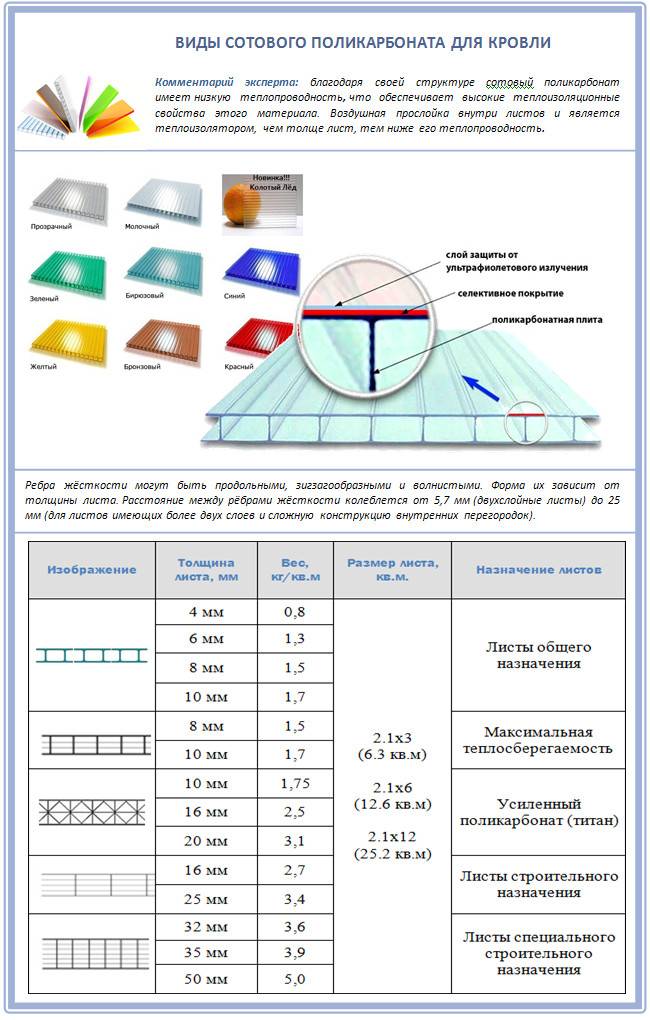

Next, you should decide on the choice of material. Cellular carbonate with a partition thickness of 4–16 mm is better suited for roofing. For wall cladding, you can use straight monolithic sheets of transparent structure up to 0.6 cm thick.

Read about the use of various small architectural forms in site landscaping.

Rules and step-by-step instructions for covering the gazebo

It is not difficult to work with polycarbonate, but it is still worth adhering to some rules.

Plating recommendations:

- It is necessary to drill and cut the sheets only with sharp tools, taking care not to damage the protective film covering the material.

- It is not advisable to fix the cladding material close to the frame structure, since polycarbonate tends to expand when heated. A distance of at least 1 mm must be observed.

- It is better to fix the skin in parts. This will make the job easier.

- Instead of screws and bolts, it is better to use special thermal washers. Unlike the former, they do not form cracks.

Having prepared all the necessary tools and having decided on the material, you can start working.

Having prepared all the necessary tools and having decided on the material, you can start working.

Step-by-step instructions for covering the gazebo:

- Lay out the polycarbonate sheet on a flat surface.

- Mark the sheet by measuring the parameters of the frame with a tape measure.

- Cut the material with a hacksaw or jigsaw, according to the markings.

- Drill the screw holes with a screwdriver.

- You need to fasten the profile sheets to the rafter leg with self-tapping screws with special thermal washers at a distance of 30 cm from each other.

- You should start sheathing the gazebo from the bottom, gradually moving higher. Last of all, the upper part of the structure is sheathed.

- A transparent sealant (silicone) must be applied to the joints.

Roofing

The roofing pattern is identical to the wall cladding. However, when working with a roof, some nuances should be taken into account.

Roof covering recommendations:

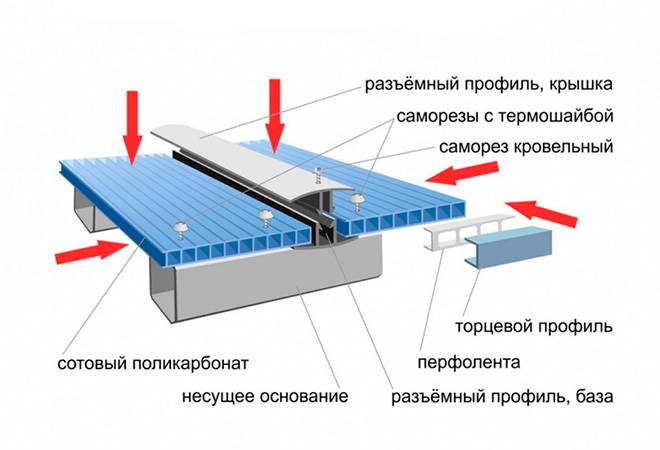

- It is necessary to connect the fragments of the product using plastic or aluminum profiles.

- The optimum roof slope in mild climates is 5 °. In regions where snowy winters prevail, it is advisable to sheathe the structure at an angle of at least 45 °.

- All joints and ends must be covered with waterproof tape so that water does not seep through the roof.

- It is necessary to sheathe the roof of the gazebo with cellular polycarbonate so that the cells are located along the length of the sheet. This is necessary so that moisture does not accumulate inside the material.

Did you know? The industrial production of polycarbonate began in 1960, and it entered the Russian market in the 2000s.

Polycarbonate is a durable and practical building material that is great for self-covering a gazebo. The variety of types and colors offers a large selection of products for every taste. The structures lined with carbonate are light enough and can be moved if necessary.

How to choose

Before starting the process of installing polycarbonate, it is necessary to prepare a roof project and choose the right roofing material. Depending on the roof model, the frame and the fastening system are determined. If you plan to install a completely monolithic roof that does not have joints, then it is recommended to purchase not only a profile sheet, but also carbonate racks. Thus, the coating will take on a cast look.

A huge role in the choice of material is played by its thickness, on which the endurance of the loads on the structure will depend.

Most often, sheets of a certain thickness are used to cover roofs.

4 mm. Suitable for finishing small areas with a rounding. Typically, such polycarbonate is purchased for the design of visors or individual roof parts.

- Cloth with a thickness of 6-8 mm is used to cover buildings that are exposed to snow and wind loads. In addition to residential buildings, the sheets can be used to cover canopies for swimming pools and cars.

- Layers of 10 mm are usually used for the arrangement of buildings that are located in areas with extreme climatic conditions and require protection from the negative effects of the environment.

The material should beautifully emphasize the external finish of the building and harmoniously combine with the overall design

Therefore, it is worth paying attention to the main background of the structure and, already focusing on this indicator, decide on the color of the coating. Recently, bronze, green, milky, blue and brown panels have been widely used.

As for yellow, orange and red, it is recommended to use it only if there are materials of the corresponding shade under the canopy.

For roof mounting, you can choose from transparent, silver or black sheets. Such panels will shade the inner space of the rooms as much as possible. At the same time, for original projects, it is best to give preference to monolithic polycarbonate, which opens up huge opportunities for design.

How to distinguish quality material from "freebies"

There are several tricks that will help you "by eye" determine high-quality or cheap polycarbonate. To do this, you will have to do some manipulations with the material, so some indicators will have to be checked manually.

These problems are best avoided by purchasing quality carbonate.

Fragility

Try pushing through the polycarbonate on both sides with your fingers. Strongly bends, breaks, crumbles? Probably the quality of the material is poor.

It is quite difficult to push high-quality polycarbonate, even with a small thickness of 4 mm, for this you need to make a certain effort. Therefore, if under your hand the 8 mm honeycombs of the material have completely caved in, then it makes sense to refuse the purchase.

Weight / h3> Since carbonate of the same thickness can weigh and cost differently, it is necessary to know the specific gravity of 1 sq. meter of finished polycarbonate products. The table below shows the standard indicators that all leading manufacturers and suppliers are guided by.

Installation features

During any construction, there is always a struggle: on the one hand, I want to save money, on the other, to make it beautiful, high-quality and reliable. In the case of polycarbonate, it is better not to save money. Firstly, the quality strongly depends on the manufacturer, and secondly, even buying a thin sheet, you will save a little in the end. After all, the step of the lathing depends on the angle of the slope and the thickness of the polycarbonate: the smaller the thickness, the more often you need to install the lathing. Well, and a number of other reasons why this should not be done, we discussed above.

Each manufacturer has a similar table. But already from this it is clear that the thinner the sheet, the more often it is necessary to make the crate

What can be the basis for polycarbonate? Any material: wood, plastic, metal. If polycarbonate is mounted on a tree, it must be treated with antiseptics that will prevent fungi and bacteria from multiplying. This is due to the formation of condensation between the plastic and the wood. The increased humidity also creates conditions for the development of fungi.

The ends of the slabs must be closed

When laying on metal, another problem may arise. It gets very hot under the sun; plastic heats up in small areas from it. This phenomenon leads to the fact that it swells over the metal frame. To avoid local overheating, a thin layer of heat-insulating material is glued to the metal. If you buy polycarbonate from a well-known manufacturer, self-adhesive thermal insulation tapes are included in the kit. If the material is "unknown", any dense and flexible material with appropriate characteristics can be used. Rubber and cork come to mind first, but a strip of felt, thin foamed polyethylene, etc. may work. You will have to glue it on the sealant.

If the base is plastic pipes, there are no problems: the materials have similar characteristics, coexist without problems.

Canopy making process for a car from polycarbonate is described here.

What and how to cut

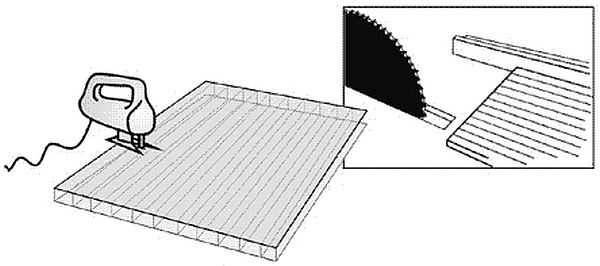

You can cut polycarbonate sheets with any tool that works with wood. This is a hand saw, a jigsaw, a grinder with a disc for wood.

You can cut both along and across the honeycomb. The ends of the cross-sections must be sealed. When buying branded materials, you will be offered a sealing (glued to the upper cut) and perforated tape (covers the cut at the bottom, and perforation - to remove water vapor or condensation drops), which are glued to the cut. If you do not have such tapes, you can cover the honeycomb with a transparent sealant, but so that there are no cracks.

Cut sheets with a jigsaw or grinder

Why can't they be left open? Firstly, dust, debris gets into them, which over time makes the roof or walls untidy and almost opaque. Secondly, when air enters, condensation forms on the walls, and microscopic green algae perfectly reproduce in it in the light. And the polycarbonate becomes a strange color, and at the same time ... ugly.

After the sheet has been cut, the honeycomb must be cleaned of dust trapped in it. This is best done with a vacuum cleaner. Then close up the honeycomb.

How to fix

During installation, it is important to remember that polycarbonate for the roof on one side has a protective coating against ultraviolet radiation. It cuts off the harmful spectrum

On this side, manufacturers stick a film with logos. When installing roofs or walls, this film should be on top. It is removed immediately after the end of the editing. Not "before" - so as not to scratch, and not in a week - the film will stick to the light, and it will be problematic to remove it.

For fasteners, special thermal washers with plugs or bolts with a mandatory metal and rubber washer are used. A hole is pre-drilled for each fastener. Its diameter should be 3-4 mm larger than the diameter of the fastener. If a thermal washer is used, it has a rather thick leg. Therefore, the hole diameter must also be larger.

Thermal washers provide a secure fit for polycarbonate

When installing the fasteners, the main thing is not to overtighten. The plastic should not bend. When using a thermal washer, its leg serves as a limiter, and with self-tapping screws, you will have to control the effort.

For the joint of the plates, special profiles are used. They compensate for thermal expansion (approx. 3 mm per meter of length) and at the same time guarantee a secure fit.Details about the profiles and all the intricacies of installation are described in the video.

How to make a polycarbonate roof?

To erect a translucent roof or a canopy over the porch with your own hands, you should perform a design calculation taking into account external loads. First of all, you need to decide on the material from which the roof frame will be made. The appearance of the structure and the technology by which its installation will be carried out depends on this.

The wooden frame is relatively easy to install with your own hands, since you do not need to use special equipment and all elements can be adjusted directly during the installation process. But when performing the calculation, it must be borne in mind that a massive frame reduces the efficiency of the translucent coating

When choosing the angle of inclination of the slope, the slope of the dome or arch, one should take into account the low weight of the coating itself - this significantly reduces the overall load on the rafter system. At the same time, the roof frame of a closed building or an open shed must withstand the weight of the snow cover (if the angle of inclination of the roof is small) as well as people performing installation, repair or maintenance work.

The exception is the canopies above the porch.

The metal frame made of steel or aluminum profile looks more elegant. To do it yourself, you can use a welded or bolted fastener. In the first case, the manufacture of a frame involves the use of a welding machine, which requires certain skills and qualifications. Metal structures are irreplaceable if you plan to install arches or a round roof.

The slope of the dome should be calculated in such a way as to minimize the possibility of snow accumulation in the upper part of the translucent roof.... Arches can be located parallel to the horizon line or with a slope - the angle is determined depending on the features of the roof design, the prevailing wind rose and other factors. Very often, polycarbonate on a metal frame is used to make an arched canopy over the porch. The manufacture of roofs with large spans requires the installation of a steel frame. The installation of small roofs or a canopy over the porch makes it possible to get by with a light aluminum structure.

To make a completely translucent roof with your own hands, you need to fix the polycarbonate elements to each other using a special transparent profile made of the same material. The slope of the slope of such a roof or the slope of the dome and arches must be large enough so that the structure does not experience high external loads. There are two types of polycarbonate profiles available - split and one-piece. The polymer profile allows for hermetic fastening of polycarbonate sheets.

Cellular polycarbonate

It got its name from its honeycomb-like structure. It turns out as a result of joining several layers of polymer with a large number of stiffeners, which are located along the sheet. There is air between them, which provides the material with good thermal insulation properties, as well as resistance to mechanical damage.

Its functional purpose depends on the thickness of a sheet of cellular polycarbonate, for example, a material with a thickness of 4 mm is perfect for greenhouses, greenhouses and sheds that are not exposed to aggressive weather conditions; for a harsher environment, a material with a thickness of 6 mm is used. But polycarbonate 8 mm and 10 mm is used for the construction of large-scale buildings, including winter greenhouses. The densest cellular polycarbonate with a thickness of 12 mm is used as a roofing material.

Cellular polycarbonate is lightweight, perfectly transmits light (at least 80%), while it distorts the image, which is important when erecting fences, has good thermal insulation properties, as well as a relatively low cost

How to properly care for a polycarbonate greenhouse?

One of the mandatory things at the end of the summer season is the processing of the polycarbonate greenhouse in the fall. But at other times this building requires maintenance.

The disadvantages of the material include difficulties in the installation of structures, tk. it is necessary to use special tools (roofing screws), observe the cladding steps, and also strictly monitor the tightness of polycarbonate honeycombs. Otherwise, if water gets inside, it can lead to the proliferation of algae and, ultimately, your greenhouse will turn green.

Ultraviolet light is harmful to polycarbonate. Therefore, a special protective coating is necessarily applied to one of its sides (manufacturers usually mark the side on which it is applied). When installing, be very careful and lay the sheets so that their protected surface is on top. If the sides are confused, your polycarbonate will deteriorate very quickly.

Roof selection

What influences the choice of roof

- It is best to choose materials that are light, but strong, so that they do not give a strong load on the foundation, which the gazebo may not have;

- Before building, you need to take into account the slope of the roof, it is better if it is flat. You can carry out special calculations, or even create a building according to the project. In this case, the gazebo will meet all the requirements and will delight you with an individual design;

- When placing a gazebo next to a pond, it is better to select materials that are moisture resistant, so cellular polycarbonate will be quite appropriate here;

- Do not forget that when building a barbecue inside the gazebo, you should think about how to protect the material from open fire, which means you will need an additional roof inside the gazebo;

- If the building will be operated in the winter, then it is worth considering how the room will be heated, because the stove must be put on, the pipe must be brought to the roof.

That is why, when choosing cellular polycarbonate as a roof, it is better to think over all the nuances of using a gazebo in advance.

Which is better: polycarbonate or glass?

When choosing a material, many consumers find it difficult to choose: glass or polycarbonate? Both materials have both advantages and disadvantages. The idea of them will help you make a choice for your own needs. The following parameters are usually taken into account:

Transparency. Regular glass allows almost all the light to pass through. Light transmittance of polycarbonate is 85-88% on average. Both materials can be of different colors. Regular glass does not transmit ultraviolet light (you cannot get a tan under it). Polycarbonate has a special coating on one side, which also blocks UV radiation.

Strength. There is no point in talking about how fragile glass is

As a result of careless handling, natural phenomena (for example, hail), glass can break or get chips, cracks. In addition, glass can have a so-called point of internal stress (appears as a result of disruption of technological processes during production)

A light blow to this point destroys the entire sheet.

Polycarbonate is 200 times stronger than glass. It perfectly withstands various shocks, abrasives, pressure (for example, snow). Even in the case of penetration, only a hole is formed commensurate with the object, and the entire sheet remains intact. Regarding chemical resistance, ordinary glass is superior. It can only be exposed to hydrofluoric acid. Whereas polycarbonate is more vulnerable. For example, some sealants decompose in the sun, releasing substances that in turn have a destructive effect on this material. Therefore, mounting polycarbonate on a sealant is not recommended.

The weight. Everyone knows that glass is a heavy material. It is difficult to transport, lift. Glass roof supports in gazebos, greenhouses or sheds must be of adequate strength.Especially if you use thick durable glass. Polycarbonate is 2-16 times lighter than glass of the same thickness and sheet size (depending on the structure). Accordingly, a polycarbonate roof will have a much lower weight and will not require particularly strong supports.

Ease of processing. Glass is cut using a special tool - a glass cutter. The process itself requires certain skills. The thicker the sheet, the more difficult it is to cut it. And it is almost impossible to adjust the dimensions by a millimeter or two. In the event of a mistake during work, there is a high probability of splitting the entire sheet. In addition, old glass often breaks when cutting, even by specialists. Special drills are also used to drill holes. After cutting, sharp edges remain that are easy to cut, although they can be sanded if necessary. The dimensions of the polycarbonate sheet, if necessary, are very easy to reduce even by 1-2 mm. This material is easy to cut even with a fine-toothed hacksaw or jigsaw. You don't need special skills for this. The cut edges are much less hazardous and do not require any special processing.

Flexibility. Polycarbonate bends well, so the panels can have a curved surface. Glass surfaces can only be flat, which makes it quite problematic to make a canopy or roof in the form of a dome or arch. To do this, you will have to make a relatively complex frame structure in order to attach glass sheets of a strict geometric shape to it. While, for example, a semicircular polycarbonate canopy over a porch can be made from one sheet of a suitable size.

Thermal conductivity. Compared to glass, polycarbonate retains heat better. In the case of using this material for glazing greenhouses, it is necessary to provide for sufficient ventilation so that in the warm season the plants do not overheat and do not die.

Types of modern roofing polycarbonate

But let's first figure out what kind of polycarbonate you can use for your roof.

Monolithic polycarbonate is a solid plate with a thickness of 2 to 12 mm. It is much stronger than glass, but at the same time it is many times lighter, which is why it tops the rating of modern anti-vandal plastics.

Monolithic polycarbonate for roofs is produced in molded or corrugated form.

Corrugation is a profile that we see in the form of a wavy shape or a square outline. It's not only beautiful! A carefully selected profile allows you to make such material 2-3 times stronger, plus rainwater rolls off much easier. But attaching one to the roof, of course, is more difficult - you will have to use additional silicone supports.

Modern roofing polycarbonate sheets are mainly produced in three types of cross-section:

- U-shaped.

- Trapezoidal.

- In the form of a slate wave.

Moreover, it is no more difficult to work with corrugated polycarbonate than with cellular or monolithic ones.

Profiled monolithic polycarbonate has many more advantages than sheet polycarbonate:

- Higher strength, like a metal profile.

- Service life up to 30 years.

- High wear resistance.

- Transparency level up to 92%.

- Ease of installation and processing.

- High plasticity.

- Lightweight - only 1.7 kg per square meter.

- Wide range of colors.

- Resistant to temperature extremes, burnout and adverse precipitation.

And finally, aesthetic appeal!

Separate corrugated sheets are produced in shades of gray, bronze, milky white and opal: these perfectly protect against the harmful effects of ultraviolet rays. This means that under such a roof, various materials will burn out and collapse less.

Cellular polycarbonate, which is slightly less transparent than monolithic, is also valuable as a roof covering. But it has an important function - the scattering of rays. You will choose just such a roof covering if, for example, you are building a winter garden or a greenhouse: direct rays burn the delicate leaves of plants. The same applies to utility and storage facilities - not a single item will last under the scorching sun.

Diffused light is also considered more valuable due to the fact that it penetrates more into the dark corners of the room and does not give a chance for such nasty things as fungi and mold to survive there. But how does this happen? The fact is that monolithic polycarbonate has an integral and transparent structure, and therefore the light beam that passes through it only slightly changes its angle, and that's it. And the cell phone is made not only of horizontal planes - there are many vertical partitions in it. As a result, the passing beam is split into thousands of smaller ones, each with its own angle. This is the diffused light.

Cellular polycarbonate for the roof is produced today of the following types according to the type of internal structure:

- Single chamber standard, with a thickness of 4 to 10 mm.

- Two-chamber standard, with a sheet thickness of 16 mm.

- Reinforced hardened, but with a thickness of 4-6 mm.

- Four-chamber, with a sheet thickness of 25 mm.

Cellular polycarbonate consists of two panels, which are interconnected by stiffening ribs. Therefore, in essence, most of the cellular polycarbonate is air.

Internal stiffening ribs give polycarbonate special strength, thanks to which it can easily withstand severe wind and snow loads. Extreme temperature range - from -20 ° to + 80 ° С. What other roofing covering has similar parameters?

Cellular polycarbonate, the honeycomb of which is filled with airgel, is a new type of product. It has high impact resistance and thermal insulation, which surpassed three-chamber double-glazed windows with argon.

Flat roof gazebo

One of the options for a shed roof, differing only in zero slope

Since snow will accumulate more on such structures, and the likelihood of leaks is high, special attention is paid to the reliability and strength of the selected materials and coatings. Consider the following nuances:

- The calculation of the rafters showed that an increase in the section of the board or a decrease in the installation step is required. Most often, they resort to the second option. The usual installation step does not exceed 40-50 cm.

- As a coating, a soft surfaced or membrane roof is used, which is characterized by high tightness. The use of metal tiles or metal profiles is allowed, but only when mounted with one sheet along the length.

We recommend using this option only in extreme cases; other constructive solutions are still preferable for gazebos. In this case, laying a soft roof on the roof of the gazebo is also not worth it, it is better to abandon coatings from small-piece elements.

Which polycarbonate to choose? ↑

As a roofing material for buildings, two types of polycarbonate sheets are used: honeycomb and monolithic. To choose what you need, it is worth understanding the classification of materials.

Cellular

sotoviy-polikarbonat

sotoviy-polikarbonat

terrasy-iz-sotovogo-polikar

terrasy-iz-sotovogo-polikar

Such panels are the most common and are used as covering carports, gazebos, verandas and others.

The material is a sheet consisting of two layers and stiffening ribs between them, forming cavities (the so-called honeycomb). Panel thickness is within 4-12 millimeters. There are also thicker samples (up to 20 mm), but already having two or three layers with honeycombs between them.

On a note

In cross-section, the honeycomb panel looks like corrugated packing cardboard!

The advantage of this type is that:

- It has a very low weight, which means that during construction, the assembly of serious load-bearing structures is not required. Veranda cellular polycarbonate can be mounted on lightweight aluminum profiles.

- The second positive point is its excellent flexibility.The honeycomb sheet can be easily molded onto the frame of a terrace with a polycarbonate roof without the need for heating or equipment.

- A significant advantage of such a sheet is also in its strength. They are quite capable of withstanding significant loads (for example, a certain amount of snow in winter).

- An important feature of cellular polycarbonate in its light transmittance, up to 80% of sunlight passes through it freely, and it is scattered, increasing illumination, and harmful ultraviolet radiation is cut off.

- Also, the material is shockproof and absolutely non-flammable.

Among the disadvantages are:

- The presence of protection against ultraviolet radiation is mandatory, since the honeycomb sheet is very quickly destroyed under its influence.

- It is also very easy to scratch the surface of the panels, this should be especially taken into account when snow falls in winter, which must be removed immediately.

- The material does not tolerate aggressive chemicals: acetone, acids and alkalis, this is worth remembering when cleaning and washing surfaces.

However, in general, if we take into account the disadvantages, cellular polycarbonate has more advantages than disadvantages, and, importantly, an acceptable cost.

Monolithic polycarbonate

monolit_polikarbonat

monolit_polikarbonat

terrasy-iz-monolitnogo-poli

terrasy-iz-monolitnogo-poli

This type of material is a solid sheet without any voids. The characteristics of monolithic panels are comparable to those of ordinary glass, but at the same time they are much more durable.

On a note

If we compare various transparent materials, then monolithic polycarbonate surpasses them all in its strength characteristics with higher endurance and service life.

Of the advantages of the material, the following parameters can be listed:

- The transparency is almost comparable to window glass, the monolithic sheet allows 90% of natural light to pass through. It also has the ability to perfectly diffuse sunlight.

- Strength has simply fantastic indicators, it is almost impossible to destroy a sheet in domestic conditions. The strength of a monolithic panel is more than 200 times higher in comparison with silicate (window) glass, and several tens of times higher in comparison with plexiglass. Such parameters make polycarbonate for the veranda roof one of the best materials.

- Monolithic polycarbonate withstands climatic and weather changes very well. It can withstand extremely low temperatures and too high, even when loaded on its surface.

- The panels have a fire safety level corresponding to the standards, and with constant strong burning, polycarbonate does not emit highly toxic substances.

The monolithic panel also flexes well, but thermoforming may be necessary to create complex configurations.

But, for such quality you have to pay a higher price in comparison with cellular material, but the quality fully justifies the money spent.

When choosing one or another type of material, it is worth focusing on the design of the planned polycarbonate terrace, as well as the possible impact factors that the roof will be exposed to.

Features of fastening to metal

Installation of polycarbonate through a split profile

Installation of polycarbonate through a split profile

Installation of sheets is carried out through a special split profile. Let's consider how the process of installing a polycarbonate sheet on a metal structure looks like. The construction process consists of several stages, which are performed in the following sequence:

- Preparation of tools, necessary materials. When the construction process is thought out to the smallest detail, the construction time is reduced, there are no hesitations and stops. Everything, down to the screwdriver battery, must be ready for use.The homeowner needs to stock up on polycarbonate plates, connecting and end profiles in advance. You will also need self-tapping screws with washers, self-adhesive tapes with dust protection function.

- The main profile is fixed with self-tapping screws at the edge of the roof.

- Take a protective film, remove the bottom layer from it.

- The holes of the cellular polycarbonate material are sealed. This is a necessary measure so that the polycarbonate roof with your own hands is reliably protected from moisture.

- The polycarbonate sheet must be inserted into the profile.

- For fastening the canvas, self-tapping screws are used with a special thermal washer. If there are no such screws, you can limit yourself to ordinary roofing ones. The fixing hole must be larger than the rod itself. In this way, you can smooth out the effects of possible expansion of the material as a result of heat exposure. And it will definitely not burst.

- The base profile is closed by the roof clamping profile. Be sure to check how well the lid lies at the base.

- The procedure is repeated for all sheets. Do not overdo it - due to deep twisting and strong pressure, the polycarbonate board may burst.

Correct fixing of polycarbonate with self-tapping screws

Correct fixing of polycarbonate with self-tapping screws

The protective film from the inside is removed before the start of construction work, and the outside - after completion. If this is not done, under the influence of the sun's rays, it will literally be welded to the front surface. Removing such a film will be problematic.