List of favorite materials

The selection of material is the first stage of thinking, because a rocking chair must be very reliable, durable, but light, as the owners will quickly get used to "carry" this furniture with them. Therefore, more often the gaze is stopped on plywood, wood, vine. Metal often joins this rocking chair candidate list too.

- Plywood. Such furniture will be practical, light, beautiful, but it has a significant drawback - the fear of water. Therefore, a rocking chair "resting" in the open air must be watched vigilantly, since a sudden rain is a big threat to it.

- Wood - beech, oak. Correct pre-processing of this material is the key to the durability of the product. It is attracted by ecological cleanliness, excellent appearance. The main requirement is minimal carpentry skills, since the work is not so easy.

- Vine is a leader if we consider furniture from the point of view of lightness and beauty. Fasteners do not take part in the creation of furniture, since glue becomes the only assistant during weaving. Cons - fear of moisture, fragility, labor intensity.

- Metal is an almost eternal material. For all its positive qualities, he has a huge drawback - heaviness. In addition, such a massive rocking chair can present an unpleasant surprise - to roll over, and this threatens with serious injuries.

There is another material that attracts a low price - plastic, however, for self-production you need special equipment, the strength of such a structure is not up to par. For the frame and runners of the rocking chair, they often prefer to take profile or plastic pipes.

You can also compare prices for rocking chairs:

The main types of rocking chairs

By type of design, all rocking chairs are usually divided into the following types:

- Rocking chairs on simple radius runners;

- Rocking chairs on runners with variable curvature;

- Rocking chairs on the so-called elliptical runners;

- Glider;

- Vanka-vstanka;

Let's take a closer look at each of these types of rocking chairs.

Rocking chairs on simple radius runners

Arcs, rocker arms, and also skis can act as simple radius runners. This type of rocking chair appeared before everyone else and has not lost its relevance to this day. However, this type of swing has a significant drawback, which is that in the case of too much swing there is a high probability of falling. It is for this reason that the vast majority of rocking chairs on simple radius runners have a low seating position in order to ensure a greater excess of the center of the generating circle over the center of gravity. In addition, there are models that have a closing arc of the horizontal type. For the manufacture of such models of rocking chairs on simple radius runners, individual drawings are required.

Rocking chairs on runners with variable curvature

This type of rocking chair completely eliminates the possibility of falling. Their length does not allow the rocking chair to tip over backwards. And when leaning in front, they simply push the person out of the seat. In the process of manufacturing this type of rocking chair, it is best to use a ready-made drawing.

Rocking chairs on the so-called elliptical runners

As the main distinguishing feature of this type of rocking chair, it should be noted that they swing very smoothly. The overwhelming majority of rocking chairs on the so-called elliptical runners are equipped with bumpers on the rear side, and on the front side with springs or a footrest.A model for springs cannot be made independently, because this requires the use of materials such as a rubberized metal strip or expensive wood species.

Glider

Gliders are sliding rocking chairs. The design of this type of rocking chair differs from the designs of other types of rocking chairs by immobility. Rocking of this type of rocking chair is carried out due to a special pendulum-type mechanism. If you are just taking the first steps in the field of self-manufacturing rocking chairs, then this option is not for you.

Vanka-vstanka

This type of rocking chair is considered a garden option. As the main distinguishing feature of this type of rocking chair, it should be noted that they do not lose their stability in absolutely any position. This is mainly due to the fact that the runners act simultaneously as a seat. If you lean back very much, then the chair will take an almost horizontal position, but it will not turn over, and in the case of a little effort, it will return to its original position. It is rather difficult to make a drawing of this type of rocking chair. For this reason, it is best to use a ready-made drawing.

Rocking chair examples

Metallic

Let's start our review of rockers with metal ones. making rocking chairs out of it is justified in few cases. Forged rocking chairs, imitating the classic wicker wicker or rattan, as requiring special equipment, forge, etc. qualifications are not concerned. But a metal rocking chair "for a braid" can be made by welding from a profile pipe; preferably elliptical. In this case, it is necessary to choose the kinematic scheme of the rocking chair-nirvana as the least sensitive to the excessive elevation of the central center over the central heating, it also corresponds well in design to wicker rockers, see Fig. The seat, in order not to increase the moment of inertia, is made braided from cables, belts, etc.

Welded metal rocking chair

It also makes sense to make garden tumblers out of metal, see below, due to its strength and resistance to wear. But a welded frame like the one in pos. 1 fig. on the right - the solution is not optimal, it is too complicated, labor- and material-intensive. It is much easier to make a steel frame for a garden rocking chair of the Concept type, pos. 2. Pipe - round from 40x2. The bed itself can be sewn like a hammock; balancing - by changing its tension and, accordingly, sagging. As a result, the work and costs are much less than the repetition of the established forms of rockers coming "from the tree", and the comfort is no worse.

Steel Tube Garden Rocking Chair Structures

Here you can see another curious variant: a rocking chair frame. Concept made of ... gymnastic hoops. Only not aluminum or propylene, but carbon fiber (carbon). Strength - monstrous, resistance - absolute, weight - scanty. Which, however, cannot be said about the cost.

Vanka-vstanka

Recently, garden rocking chairs - tumblers have gained popularity. If in this one lean back completely and curl your legs, it falls back almost at 90 degrees, without losing stability; the rider will be kneeling on his back to the zenith. And if you stretch your legs forward, the rocking chair - the vanka-stand up becomes in the usual position and then you can swing as always.

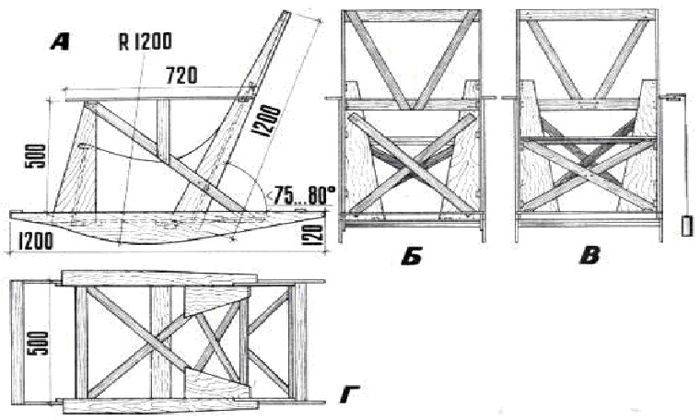

Sidewall of a garden rocking chair-recliner

The toy vanka-stand with a spherical bottom sways quite sharply. Comfortable rocking of the tumbler-rocking chair is achieved by profiling its runners according to a complex law. It will not work to build their sidewalls "in school", as described above. You need to be guided by verified samples and draw the markings on the grid, see fig. The inset version, with planks of 30-40 mm thick, is more costly, but less laborious. It also allows you to lengthen the rocker arm by placing intermediate runners.

Rocking bench

Wallowing with your heels in the heavens, throwing your hands behind your head and admiring the clouds floating in the blue heights through the quivering foliage is a heavenly delight, but not everyone's satisfaction. Someone desires to look more impressive while resting. This is more suitable for a garden bench - a rocking chair, see fig. It is a little difficult to swing on it, its own moment of inertia is great, but it also swings for a long time. The maximum span between supports with runners is 750 mm when sheathing with 40 mm thick slats. The back paneling is decorative.

Garden rocking bench

Sunbed with awning

Both those and other requests will be satisfied with a garden rocking chair-lounger on elliptical runners and with an awning. The dimensions of its sidewalls are given in Fig. their material is plywood 24 mm. The width of the bed is up to 900 mm, its sheathing is made of 50x50 slats. The sidewall locations, marked with gray circles, are connected by round wooden crossbars with a diameter of 60 mm or more.

Dimensions of the sidewall of the rocker-lounger with an awning

Rocking chair

Here we are not talking about rocking horses, they are toys, not furniture. But resting, swaying, is also not harmful for children, so it makes sense to make the child a rocking chair. Its proportions will be slightly different than for adults, due to the influence of the square-cube law.

Design and detailing of a child rocking chair

The device of a child rocking chair, its assembly diagram and the specification of parts are given in Fig. material - wood. It will not be difficult for an experienced home craftsman to build a rocking chair for a child, guided by these data, and beginners can first watch a master class on making almost the same rocking chair.

Simple swing from an old chair with your own hands

This model of a hanging chair or swing chair is good in that it uses that part of the old chair that usually remains from it, namely a seat with a back, because the legs of chairs, as a rule, are the first to become unusable and break, it is quite problematic to restore them

Of course, we skin the old part of the chair, and for aesthetics and durability we cover it with paint or stain. The most "difficult" part of making this swing chair is to make two boards with two holes in each, in order to put our chair on them and tie the ropes to below. It is important, immediately before attaching, to center the boards under the chair so that your fifth point is in the center of gravity when sitting on the chair in a suspended state.

DIY materials and tools

Which material to choose for making a homemade rocking chair depends on the skills and experience of the master with the materials. Round or shaped metal pipes are used for the manufacture of furniture frames that will be used outdoors: steel treated from rust will serve in the open air for decades. There are several disadvantages of such options:

- an impressive mass will require a couple of people to move the chair;

- the floor covering must be super wear-resistant, or you will have to solve the problem of finding softening linings on the runners;

- for apartments, a thin-walled small diameter pipe is used, which is difficult to weld without special semi-automatic equipment.

Wood is great for home furnishing options. If you have certain skills, the workpieces can be bent, getting an exclusive outline of the frame. Installation in the open air will require the use of antiseptic and paint-and-varnish coatings of special strength, otherwise the chair's age will be short-lived.

Plywood is the best and least expensive option for the first experience. A minimal set of tools and devices is used in the manufacture, the finished product is easy to decorate.Moisture-resistant plywood will withstand a short exposure to sunlight and rain.

Rattan, bamboo, willow branches and reeds are used to make wicker furniture. Blanks are purchased in a building materials store, willow can be assembled on your own, but for weaving you will need to study technology and develop skills.

Polypropylene pipes are capable of supporting a person's weight when used to make runners or as a frame. The appearance of such a product is unusual.

Plastic bottles are exotic in furniture, but there are also such designs. Most often, bottles are used to create a seat and back, and the base is made from more durable materials such as wood or plywood.

Natural wood

Plywood sheets

Natural rattan rods

Artificial rattan

Polypropylene pipes

In preparation for work, the available tools are revised, if necessary, they buy, rent or lend the missing ones:

- For metal structures, a welding machine, mask, and angle grinder are required. A master cannot do without a pipe bender. It is not difficult to make it with your own hands - it will be cheaper than contacting a metalworking workshop. The cost of a purchased device is comparable to the price of a factory chair.

- To work with wood you will need: an electric jigsaw or a hacksaw with narrow replaceable blades. You will have to cut the wood up and down, and for this, different configurations of teeth on the saw part are used. An angle grinder with a special attachment will help you polish the surface faster. This can be done with a drill, which will be required. For decoration, you need to prepare brushes and containers for varnish, stain, paint.

- The frame made of plastic pipes is welded with a special tool - "iron", soldering iron, welding.

- For rattan weaving, special hooks are purchased.

- A standard set of carpenters is also prepared - a chisel, a hammer, a rubber or wooden mallet.

It is difficult to say what comes first - the choice of material for the furniture or the preparation of the tool. More often they proceed from the available inventory - it is impractical to buy electrical devices for one-time use.

Required tools

Welding machine

About materials

Rocking chairs are mostly made of wood. Metal, for all its manufacturability, low waste and greater durability in the open air, is too heavy. The influence of the chair on the overall CG is significant, the moment of inertia of the system is large and, as a result, the rocking is too sharp. Or you have to set an extremely small initial elevation of the central heating over the central heating, risking that the rocking chair will overturn under someone. However, we will return to metal rockers in the course of considering individual samples.

Using plywood to make rocking chairs

Plywood is a completely different matter, especially for novice carpenters. Firstly, performing the rocking parts with 3-layer glued ones, it is possible only with the help of a jigsaw to make accurate and strong thorn-groove connections, on the left in the figure, if you follow the trace. regulations:

- The plywood of the middle layer is taken twice as thick as for the extreme. For example, if a total thickness of 20 mm is needed, then 5-10-5 mm are glued.

- Parts are assembled from blanks on a 2-component waterproof glue. If on PVA, they must be reinforced with small nails.

- The joints are assembled with gluing (wedging in this case is unacceptable) and reinforced with diagonal pairs of self-tapping screws from 2 sides.

- The supporting surfaces are protected by overlays made of thin (6-10 mm) laths of solid durable wood or dense rubber sheet with a thickness of 4-5 mm. Plywood under concentrated load splits very well from the end.

Secondly, plywood makes it possible to apply non-standard technical solutions, for example. as on the right in fig. Such a rocking bowl made of plywood can be made using, again, only a jigsaw. Convenience - high, absolute stability, and can serve as a hanging hammock chair or swing chair.The thickness of the lamella boards is from 12 mm; connecting half washers on poles - from 24 mm.

How to apply overlays

Wear-resistant wooden pads on the runners of the rocking chair are installed trail. way:

- Turn the chair over with runners up;

- We thoroughly warm the blank bar with a construction hairdryer;

- We put the workpiece on the runner and tightly fasten it along the entire length with cotton braid. Do not burn yourself, the wood is very hot!

- We also grab the second workpiece onto another runner;

- After the strips have cooled completely, we remove the bandages from the braid and glue the PVA overlays on wood or with 2-component glue;

- We attach the ends of the planks with small nails until the overlays fit snugly along the entire length. Place washers or pieces of plywood under the nail heads;

- After the glue is completely dry (2-3 days), we remove the temporary fasteners. We drill blind holes for self-tapping screws and finally fix the ends;

- We wipe the holes with the fastener heads with a putty from sawdust of the same tree, thickly mixed with PVA.

Photo of rocking chairs

We also recommend viewing:

- Wooden armchairs

- Kindergarten beds

- Bed for girls

- Hanging chair

- Children's bed with sides

- Bed height

- Bed in the nursery

- Metal bunk bed

- Boy's bed

- Children's bed with drawers

- Car bed

- Double bed

- Bed frame

- Children's beds IKEA

- IKEA Beds

- Convertible bed for a small apartment

- Wardrobe bed transformer

- Loft bed with work area

- Bed for three children

- Assembling a baby bed

- Solid wood bed

- Bed with a soft headboard

- Pallet bed

- Folding bed

- Baby cot with a pendulum

- Bed with table

- Bed without headboard

- Playpen bed

- IKEA bunk bed

- Bed in the bedroom

- Armchair with armrests

- Rattan armchair

- Single bed

- Slide bed

- Orthopedic mattresses

- Spring mattresses

- Pull-out bed

- Canopy over the bed

- Bed podium

- DIY headboard

- Leather armchair

- How to make a chair

- Loft bed

- Wrought iron beds

- Chair cover

- Lifting bed

- Chipboard bed

- Upholstered armchair

- Children's mattresses

- Loft bed for adults

- Feng Shui bed

- Metal bed

- Bunk bed transformer

- Computer chair

- Niche bed

- Pine bed

- Do-it-yourself transformer bed

- Bed in the wall

- Orthopedic bed base

- Bed with box for linen

- Loft bed for children

- The best mattresses

- Bag chair

- Provence style bed

- Office chairs

- Round crib

Views

In everyday practice, the following product options are very popular:

- rocking chair of the glider type;

- rocking chair for giving;

- chair for nursing mothers;

- rocking chairs with a recliner.

Each model deserves to be part of the interior.

Glider

The rocking chair modification is an improved model, the prototype of which was invented back in the 20th century. It is based on wooden runners, on which the pendulum swing mechanism is rigidly fixed. At the same time, the chair continuously moves forward and backward, which is accompanied by an additional rocking effect. The process can be stopped using a special lever, by means of which the movement is completely blocked (locked).

For nursing mothers

The devices are equipped with an oscillating mechanism, which is optimal for the care of babies. The design provides for an anatomical back that follows the contours of the body, as well as a mechanism for changing the angle of inclination, which completely relieves tension from the spinal muscle.

In addition to traditional armchairs, models equipped with a rounded cushion are known.They are mounted on a wooden frame and provide comfort and comfort for mothers. Products can be equipped not only with runners, but also with special spring mechanisms.

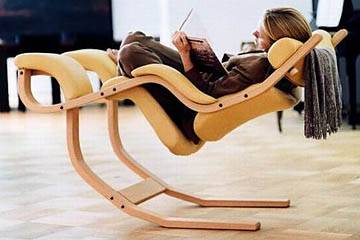

With recliner

The devices provide maximum comfort to its user. Their name comes from the English recline, which means "laid back." The mechanism built into the chair allows it to be transformed into a comfortable chaise longue at the touch of a button. With its help, it is possible to ensure complete relaxation of the body in its various positions (lying, reclining and sitting).

Types of rocking chairs

You need to comply with your own requests already at the stage of choosing a prototype. There are several types of rocking chairs, aimed at users with different habits and needs. The main types of rockers are shown in the photo. The first to appear in everyday life are rocking chairs on simple radius runners (arcs, rocker arms, skis). They are in use to this day, both in a modern and in a classic look, pos. 1 and 2. Their main advantage is their constructive and technological simplicity.

The main types of rocking chairs

Smooth and soft rocking radius skids provide only for relatively slight rocking, and with strong rocking they do not guarantee against overturning. Therefore, rockers "on radii" are made with a low fit, which ensures a large excess of the center of the generating circle (CC) over the general center of gravity (CC); see below for more details on rocker kinematics. If a seat of normal height is required, then the runners are equipped with bumpers, pos. 3. The jolts of the bumpers on the floor noticeably give off at the "fifth point", and in any case, you have to get out of the rocking chair on the radius runners, somewhat straining.

Rollover is excluded in rockers on runners of variable curvature, pos. 4. All of them are comfortable enough for riders of different constitutions. Themselves gently land the rider, who has risen and leaned forward, of a rocking chair of the nirvana type on runners of variable curvature, pos. 5 and 6. It is also possible to design them for any, within acceptable limits, landing height, by changing the progression index in the law of change of the generating radius (see also about kinematics).

Nirvana rocking chairs on elliptical runners, pos. 7, provide light swinging truly blissful, but do not prevent overturning when strong swinging, therefore they are equipped with bumpers; the front is often combined with the footrest. Garden rocking chairs with elliptical awning, pos. eight.

Spring rocking chair

Nirvana rockers on springs, see fig. on the left, swing as softly as on ellipses, because the mechanical characteristic of the springs is progressive. But making a spring chair with your own hands is difficult: you need either high-quality boards of special types of wood (teak, boxwood, dogwood) or rubberized, so as not to scratch the floor, a strip of spring steel. In addition, dirt accumulates in the gap between the spring and the runner and it can be very painful to pinch your finger in it. For the latter reasons, spring armchairs are now very rare on sale.

Rocking chair 3 in 1

Finally, there are also multifunctional rockers "3 in 1" on runners with smooth kinks, see fig. on right. When seated upright, this is an ordinary chair; leaning back, it can be switched to rocking mode at radii, and leaning back even more, it can be turned into a lounger. But the dimensions of the 3-in-1 rocking chair are too big for apartments below the business class, and the transitions from mode to mode are accompanied by rather sensitive jolts. In unsuccessful models, for this you have to either get up at all, or twitch, wriggle and fidget like a puppet on strings. Therefore, rocking chairs 3 in 1 are a piece of furniture for an amateur.

Making a garden chair (vanka-vstanka)

To make a rocking chair from plywood with your own hands, you must use high-quality material. The drawing can be supplemented with your own hand, if everything is calculated correctly and you use a ready-made version.

Tools and materials

Before starting work, you need to prepare the appropriate tools and materials:

- Electric jigsaw.

- A sander that has various attachments.

- Drill or screwdriver.

- Hammer.

- Brush.

- Plywood sheet 20 or 30 mm thick.

- A 50 x 25 mm bar that will be used as cladding.

- Three connecting bars 30 x 50 mm.

- Self-tapping screws.

- Joiner's glue.

- Antiseptic with which the tree will be treated.

- Primer.

- Dye.

- Roulette or meter.

- Pencil.

- Graph paper.

When everything you need is at hand, you can start direct manufacturing.

To begin with, we process the plywood with the help of an antiseptic. And while you are working on the drawing, the sheet will have time to dry out enough.

Making a circuit

A garden chair is also called a vanka-vstanka, and does not require taking into account any individual parameters. If you wish, you can make any edits to an already finished drawing. For example, if necessary, you can make a double chair.

DIY rocking chair (drawing from plywood):

The drawing must be transferred to graph paper, and then thick paper in the full size of the parts. We cut everything out and transfer it to plywood. The sides are made of plywood, and the fasteners are made of bars. Slats can be prepared as cladding. Both sides must be exactly the same. And also you need to make sure that there are no irregularities or bulges over the entire surface, otherwise the surface will not be smooth and the rocking chair will lose its basic properties.

Manufacturing of parts

With an electric jigsaw, we cut out plywood along the markings. The most optimal connection of parts in a rocker is a spike. If it is not provided in the drawing, then it is necessary to make spikes and cuts under them in the sidewalls. We cut the facing strip from the slats. If there are any leftovers from the wood, then you can save them, as they will come in handy if the chair needs to be repaired.

With an electric jigsaw, we cut out plywood along the markings. The most optimal connection of parts in a rocker is a spike. If it is not provided in the drawing, then it is necessary to make spikes and cuts under them in the sidewalls. We cut the facing strip from the slats. If there are any leftovers from the wood, then you can save them, as they will come in handy if the chair needs to be repaired.

Now we use a grinder or regular sandpaper and process all the chamfers with high quality

Particular attention must be paid to the ends. We will break their fibers with a hammer so that moisture does not penetrate into them.

All elements must be well painted and primed, the ends must also be given special attention when painting.

Assembly

We connect the sides with the help of bars. If there is a spike connection, then the spikes are inserted into the cuts, which are pre-lubricated with wood glue. If they are not there, it is necessary to mark the joints on the sidewalls and make a hole using a drill 8 mm, and at the ends of the timber - 5 mm. We use Euro screws and tighten everything.

We connect the sides with the help of bars. If there is a spike connection, then the spikes are inserted into the cuts, which are pre-lubricated with wood glue. If they are not there, it is necessary to mark the joints on the sidewalls and make a hole using a drill 8 mm, and at the ends of the timber - 5 mm. We use Euro screws and tighten everything.

Now all that remains is to attach the cladding strips. So that they lay down evenly, we first mark everything. Each board should have 4 marks, that is, two on each side. To facilitate the work, we make a template from the trims of the rail, drill 2 holes in them, and the work will go much faster. To prevent the bar from cracking, when we fasten it, we pre-drill the hole with a thin drill, and then we screw the screws to the sidewall along them. The distance between the slats should be approximately 15 mm.

Now all that remains is painting. We use high quality primer and paint. The chair is ready and can be tested.

You can experiment with a garden chair, make a small child for two (the child will have a lot of fun swinging in it), as well as purchase or make a massage back. Imagination is unlimited here. And if the skills allow, then it is quite possible to try to weave a rocking chair from a vine on your own.

You can experiment with a garden chair, make a small child for two (the child will have a lot of fun swinging in it), as well as purchase or make a massage back. Imagination is unlimited here. And if the skills allow, then it is quite possible to try to weave a rocking chair from a vine on your own.

But remember that for the first option, you should not be smart and start making some homemade papasan.First, make the simplest design in order to fill your hand.

Step-by-step instructions for making a rocking chair

The most common material from which furniture is made is plywood. If we compare plywood with wood, then the first is 2 times stronger and more expensive. Due to the high moisture resistance of the material, the plywood rocking chair has a long service life. It is easier to repair or decorate such a product, since it lends itself to any processing. It can be painted with various paints or varnishes, sanded and covered with a film. To make a chair at home you will need:

- plywood 3 sheets measuring 1520 × 800 mm (the thickness of each sheet is different - from 4 to 15 mm);

- timber 53 cm long;

- glue;

- jigsaw;

- screws.

Before making a rocking chair with your own hands, you need to prepare a drawing.

Frame fabrication

To make a rocking chair from plywood yourself, you need to prepare templates and apply them to the material. The finished drawing is transferred to a sheet of paper. The paper is preliminarily marked into cells. The size of each cage should be 10 × 10 mm. Then the cells are enlarged to the required size and, together with the painted details, are transferred to plywood. Drawings from plywood are cut out with a jigsaw. In doing so, the following must be taken into account:

- It is quite difficult to assemble the back and seat. It consists of several elements, so their base is cut out from a thin sheet 4 mm thick. From a 10 mm sheet, 18 strips (540 × 30 mm) and 16 crossbars (500 × 30) are prepared. The slats are used for the backrest, and the crossbars for the seat. The uprights, seat supports, slats (470 × 45 mm) and the sides of the chair are cut out of 15 mm thick plywood. All parts are made in 2 pieces.

- A hole is made in a wooden beam for screws. This part will serve as a footboard.

- Before proceeding with the assembly of the structure, all elements are cleaned with sandpaper.

- To give the structure a curved shape, thin strips (10mm) are glued to the back and seat, which were made of 4 mm plywood. All elements are fixed with waterproof PVA glue.

- The cross members are mounted on the back and seat base. Then install the footboard and sidewalls. All elements are fixed with washers and screws.

- The product is ready. To keep the back and seat soft, they are covered with padding polyester and covered with fabric. Natural or artificial leather looks good. The pattern is made according to the size of the chair. The seat and back are covered with an adhesive, then materials are laid in layers: burlap, synthetic winterizer, fabric. They are fixed with a furniture stapler.

If you follow all the rules for the operation of a furniture product, then it will last a long time.

Making skis

The comfort and smoothness of the chair rocking depends on the runners (skis). They can be made in two ways:

- According to the drawing, 2 blanks are cut out of plywood and sanded. The plywood must be at least 15 mm thick. The skis must be installed in the grooves symmetrically with respect to each other. For this, grooves are made in the legs of the product. Their depth should be from 7 to 10 cm. In the place where the legs of the chair and skis are adjacent to each other, through holes are cut. A wooden spike is inserted into them, after having greased the holes with glue.

- For the manufacture of skis, 2 square bars 1 m long and 45 mm thick are used. Grooves are cut in it, into which the legs of the chair will be inserted. To give the runners the required shape, the bars are soaked in hot water. When they soften, the material will become elastic and bend slightly. When the skis are dry, they are placed on the legs. The parts are fixed with glue, so all joints are pre-lubricated with a substance.

Balancing Recommendations

When the chair is made for the first time, not everyone is able to achieve its balancing. Often the product sways weakly or tilts too deeply. Balancing tips:

- If the chair sways slightly, then the rear overhang needs to be slightly weighted. For this, the ends of the runners are equipped with a U-shaped beam. Weighting agents (weights) are placed inside the beam.

- If the chair falls backwards, then it is weighted in front with a footboard or load.

- The shape of the runners is completely changed if the weighting materials did not help to solve the problem.

If the classic model is improved with additional bearings, then you get a pendulum chair. It works silently because the base of the chair remains motionless. In such models, it is good to rock small children.