How and how to paint a log house outside

Painting is the final stage of processing a log house outside and inside. Today there are many different paints and varnishes. For exterior paint, choose a coarse and durable compound. Consider the popular types of funds:

- Glazing transparent varnishes will preserve the color and accentuate the texture of the wood, protect the surface from moisture, mold and rot;

- Covering opaque varnishes will help to achieve the desired shine and shade, protect against insects, high humidity and ultraviolet radiation;

- Oil paints penetrate deeply into the structure of the log, keep the surface from moisture and dirt. But they dry for a long time (two weeks) and eventually lose their color !;

- Water-based acrylic paints and varnishes are natural, safe products that provide a dense, elastic coating. They protect against moisture, cracking and fungus. Such compositions give the tree “breathe”, but are expensive;

- Alkyd varnishes form a hard and even surface, retain their color for a long time and provide protection from moisture. However, such means do not allow the wood to “breathe”, which over time causes the log to dry out and crack;

- Yacht varnish is suitable for places with high humidity and high rainfall. It is a reliable protection against moisture, which is not affected by weather and temperature extremes. Such varnish does not fade and prevents yellowing of wood, however, it emits an unpleasant odor during painting;

- Stain is an affordable and cheap way of finishing a log house inside and out. It protects against fungus and pests, does not disturb the wood grain and makes the color more intense. However, the stain requires subsequent varnishing;

- Oils and wax are environmentally friendly safe products that are deeply absorbed into the wood and protect the logs from moisture and dirt. The wax will give the surface a translucent matte sheen.

To paint the log house with high quality, wait until the primer is completely dry. Stir the composition thoroughly before painting. First, paint is applied in two or three layers. Wait until the previous coat is completely dry before applying each new coat. For painting use a roller, for hard-to-reach places, corners and ends - a brush.

When using a spray gun, it is not always possible to achieve an even and smooth coating. In addition, unpainted areas may remain. Apply the last coat of paint in a thin layer from top to bottom.

After the paint has completely dried, the varnish is applied in two or three layers. For an even coating without build-up, let each layer dry and apply in long, even strokes. For decorative coating, you can use only varnish or only paint. However, the use of both means will consolidate the result and enhance the effect, enhance protection and increase the service life of the wood.

If you do not know which product to use for treating the inside or outside of the house, contact MariSrub for help. The company's masters will help you choose the right materials, quickly and efficiently process and paint a wooden house or a bath!

Impregnations for interior work

For interior work, the best impregnation is acrylic. It is harmless and non-toxic. But when working with a spray, special protection is required, since particles of the solution will get into the air.

Acrylic impregnations with priming properties have a short duration - from several months to a year. They are used immediately after the start of work, as a protective layer before applying stain or varnish. Biocidal solutions are suitable for an intermediate stage, do not have UV protection. Up to 70 ml / m2 are consumed; before applying the next layer, it is necessary to wait 8-10 hours.

More durable water based antiseptics with polyurethane. Such a coating will be moisture resistant, durable, the tree will not be actively affected by sudden temperature changes. Impregnations of this kind are used for all types of wood, including tropical.

The solutions are used to give strength and protection to the wooden sheathing of walls and ceilings during interior work, wooden furniture, where a moisture-resistant, wear-resistant and dust-repellent coating is required. There are universal compounds that can be applied throughout the room, and there are special impregnations for wood flooring.

Modern acrylic mixtures based on propylene glycol, wax and boric acid are harmless and capable of penetrate deep up to 15 cm. This is quite enough for using them in the processing of wooden sheathing and log cabins inside a house or bath. The addition of wax creates the effect of a glossy silky wood structure.

The consumption is higher - up to 100 ml / m2, but the drying time is shorter: 6-8 hours. Glazing impregnations can also be transparent or have any shade.

If you choose the right impregnation and varnish, the room can be given a unique look, even using inexpensive wood. Thickened formulations will not smudge on ceilings or walls.

Also, in the absence of a note that the solution has fire-resistant properties, additional processing with special means will be required for internal work, provided that the temperature does not drop below 0С. If there is such a mark, the normative documents to which the manufacturer referred and the mark in the passport must be given. Fire protection for wood cladding or log cabins is very important, since wood is a highly flammable material.

Internal impregnation is applied in the same way as external impregnation on prepared, cleaned dry (no higher than 28% moisture content) materials in two layers. They wait for the specified time, and then decorate with varnishes, stains, paints. When using a compressor, 8-9 liters is enough for 36 m2.

Comparison of brands: which manufacturer to give preference to?

If you have already considered antiseptics in any building supermarket, then you probably noticed that different manufacturers still write about their products about almost the same: the same service life, protective properties against fungus, mold, wood-boring beetles and ultraviolet radiation. Then which one to choose?

- Economy class budget antiseptics are Aquatex and Senezh.

- More expensive antiseptics - Tikkurila, Belinka and others.

- And finally, the professional ones are Dulux, Dce, Teknos, Woodworks and the like.

It is logical that the more expensive the composition, the longer it is designed for. The difference here is significant: budget antiseptics are designed from one to three years, the middle class - from 5 to 6 years, and professional - up to 12 years.

The secrets of the latter are that they consist of several components at once: tinting compounds, primer-impregnation and varnish with a special ultraviolet filter. But it will also take more time to apply them, because here each must be laid separately.

Let's look at some of the features of today's popular antiseptics. So, preparations for external use "Senezh" include borates, copper and chromic acid salts, water and other additives:

- Borates are known as one of the oldest disinfectants, but they are certainly not the strongest among modern ones.

- Chromic acid is an extremely toxic carcinogen, therefore it is rightfully considered the most effective antiseptic.

- Hydrofluoric acid salts are also toxic and even stronger than chlorine.

That is why any preparations that are intended for processing wood from the outside should in no case be used inside the house due to their toxicity.

The next antiseptic is XM-11, which contains a mixture of copper sulfate with potassium dichromate. It is cheap, effective and toxic.

But "Neomid" contains insecticides for repelling insects, is of little danger to humans, but does not particularly affect mold.It contains azoles - special antifungal drugs that stop the development of fungi. Also "Neomid" includes biocides that inhibit the growth of organisms. That is, "Neomid" differs from "Senezh" in that it uses more modern chemistry, bordering on pharmacology.

Study and Apply!

Types of impregnations

In addition to the mechanical method of protection by raising the boards above the soil level with the help of a foundation and a plinth, arranging ventilation, as well as tarpaulin substrates, the wood must be impregnated with an antiseptic to prevent decay. With proper processing, the life of the tree is extended at times.

Impregnations are divided into antiseptics that protect against mold and mildew, fire retardants that prevent the material from igniting, as well as moisture-proof ones on a water, oil and organic basis. The safest, and therefore the most popular are water-soluble moisture-proof compounds.

Alkyd impregnations

Deep penetration alkyd impregnations have four functions, protecting against:

- exposure to moisture;

- vital activity of insects;

- fire;

- mold.

The effectiveness of the solution for closed rooms is less than 5 years, and with an additional moisture-proof coating - up to 15 years. The consumption of such impregnations is 75-125 ml / m2. Drying time at a temperature of + 24C and 60% humidity - 24 hours. Works are carried out at + 5-28C.

The composition of the solution includes an alkyd resin, which forms a film, biocidal additives that prevent rotting and the development of mold, as well as dye pigments. White spirit is used as a solvent.

The appearance of wood treated with impregnation is gloss. Alkyd compounds do not change their integrity when exposed to different temperatures, are resistant to moisture, can simultaneously be a primer, a protective impregnation and a finishing varnish coating. Colorless solutions, give the wood shine, with the addition of pigments for elite wood species - create a presentable look to the room.

In order for compositions based on alkyd resins with a coloring element to lay down evenly, it is better to use a spray bottle and monitor the dryness of the wood (preferably 95-100%). Irregularities can also occur if the impregnation is not stirred every 4 minutes or the structure of the tree is very uneven.

How oil protects wood

In the understanding of most people who first encounter the intricacies of processing wooden building materials, the combination of the words "oil" and "wood" has nothing to do with the concept of "protection".

Rather, on the contrary - it is assumed that the clothes of everyone who touches it must be protected from the oiled surface, and the impregnation of walls, floors and furniture with oil looks, to put it mildly, unnatural.

Let us explain how this effect is used to protect log or squared houses.

As you know, the main enemy of construction timber is seasonal changes in internal moisture, which are the main cause of mechanical deformations and the development of microbiological diseases of the tree trunk.

The main channel for moisture penetration into the log is the capillary network, due to the porous structure of the wood. Oil impregnation reduces the throughput of this network several times, while maintaining the effect of vapor permeability.

The oil penetration depth depends on the processing method and in some cases can reach 15 mm in cross-section. The outer layer of impregnation, upon contact with UV rays and air, turns into a completely inert film, which is identical in its properties to a varnish coating.

It is believed that the deeper the oil penetrates, the more effective the protection created. In this connection, the most effective methods of impregnation are considered to be prolonged digestion in oil or vacuum saturation of wood with a protective composition.

It should be noted that the purpose of this treatment is not complete polymerization of the impregnation along the entire depth of penetration. Despite the fact that after drying, the treated board or log is completely inert on the outside, the oil in the inner layers can remain in a liquid state for many years.

An important factor that significantly influenced the explosive growth in the popularity of oil impregnations was the original decorative effect, emphasizing the internal structure of wood. As a result, oil protection today is considered not only as a technical measure, but also as an option for painting houses made of timber or logs.

Summarizing what has been said, we list the main advantages of wood processing with oil:

- the moisture level of the tree stabilizes (as a result, the coefficient of seasonal deformation decreases);

- protection against microbiological damage is created;

- oiled logs and boards are less attractive to woodworm bugs;

- "For the same money" a beautiful aesthetic effect is created.

Among the disadvantages, it is worth mentioning the fact that the oil protection is relatively short-lived. The interval between repeated treatments is about 2-5 years. But from a technological point of view, reapplication of impregnation is an order of magnitude easier than a similar operation for traditional paints and varnishes.

Flame retardants to protect against combustion

Speaking about wood as an excellent building material, one should not forget about such property as - high flammability

For this reason, it would not be entirely correct to ignore the compounds that protect wood from burning.

NЕОMID 450

This formulation is an effective form of protection and is intended for both indoor and outdoor use. The impregnation components, in contact with wood, give a material that is poorly flammable and burns.

Also, the impregnation is endowed with high rates of antibacterial protection. The manufacturer guarantees seven years fire resistance and ten years fungal resistance. It is realized both in a bleached version and in a tinted one.

A clear advantage of the composition is the double surface protection. Of the minuses, only a long drying period can be noted - about two weeks.

"Snow Firebio Prof"

This impregnation is also a whole complex for impregnating wood. In addition to protecting against fire, it creates a good barrier to the penetration of biological threats. It also protects against water and temperature fluctuations.

An example of color change under the influence of impregnation

It is not advisable to process parts that have direct contact with the ground.

It is worth noting that when the surface is impregnated, it somewhat changes its color, but the texture does not suffer. The composition is intended for impregnation of already affected surface areas

When working with impregnation, there is no smell at all and it can be applied by any method. Of the minuses, there is a fairly high consumption during use.

Below are the reviews of experts confirming the advisability of using antiseptic impregnations for wood.

Andrey, 42 years old

I have been working with wood for more than 10 years, our company is engaged in the installation and maintenance of wooden log cabins, these are such small houses made of logs. According to our technology, the final stage in the construction of such a house is always the treatment of logs with Pinotex Ultra antiseptic impregnation. For all the time of my work in the company, I personally have never encountered complaints about the appearance of harmful insects, peeling and cracking of wood. As a rule, for re-processing, we are contacted no earlier than after 5-6 years, as provided by the manufacturer of the drug.

Nikolay Stepanovich, Rostov

Despite the fact that there are legends about the efficiency of wood processing with impregnations of well-known brands, I made my choice in favor of a domestic manufacturer, and my wooden shed serves as an irrefutable proof of the competitiveness of domestic protective drugs.Four years ago, the structure was treated with an antiseptic for outdoor use "Senezh Bio" and is quite pleased with the result. I plan to renew the coverage not earlier than in a couple of years.

Viktor Dmitrievich, Kursk

I would like to share my impressions of working with the Aquatex exterior impregnation. The rafter system was processed five years ago and during this time did not notice a single woodworm. I haven't found any cracks or other defects either. The performed preventive examination showed that there is no need to re-impregnate it, at least for another 5 - 6 years. I am very satisfied with the drug, I recommend it to everyone.

There are quite a few similar reviews on the Internet. Less common are negative and sometimes angry reviews, but their nature, most often, indicates the acquisition of a cheap liquid of very dubious origin under the brand name of a well-known company. High-quality impregnations fully correspond to the characteristics declared by the manufacturer.

The use of wood impregnations for outdoor use is an effective method of protecting wooden structures from most adverse factors. Timely processing of the material with such compounds helps prevent rotting, bugs and mold formation. In addition, modern impregnations significantly increase fire safety, reduce the harmful effects of ultraviolet radiation and atmospheric influences.

How to properly process a log house outside

For the first time, the log house is treated with antiseptics inside and outside immediately after assembly

Pay special attention to the processing of ends and logs in contact with the foundation. Antiseptics are applied in two layers;

Primary processing should not be desired at temperatures below 10-12 degrees!;

The next processing is done after the logs are completely dry and the log house has shrunk.

This takes 6-12 months. This finish implies the final complex and multi-layer processing of the house, which will ensure the protection of the log for a long time.

It is important to apply antiseptics to a dry and clean wood surface !;

Before processing, the logs are sanded to remove the top layer, in which fungus and microbes have gathered during shrinkage. It will remove the defects of the log and level the surface

Sanding of wooden walls is imperative for an old house, since it is important to completely remove the old coating;

The best colorless antiseptic impregnations for wood

Such products are used to emphasize the natural beauty of wood, without giving it an artificial shade. The impregnation is applied to new items or on the removed top coat.

Most often it is used for external work when finishing facades, but internal use for lining, doors, walls is also allowed.

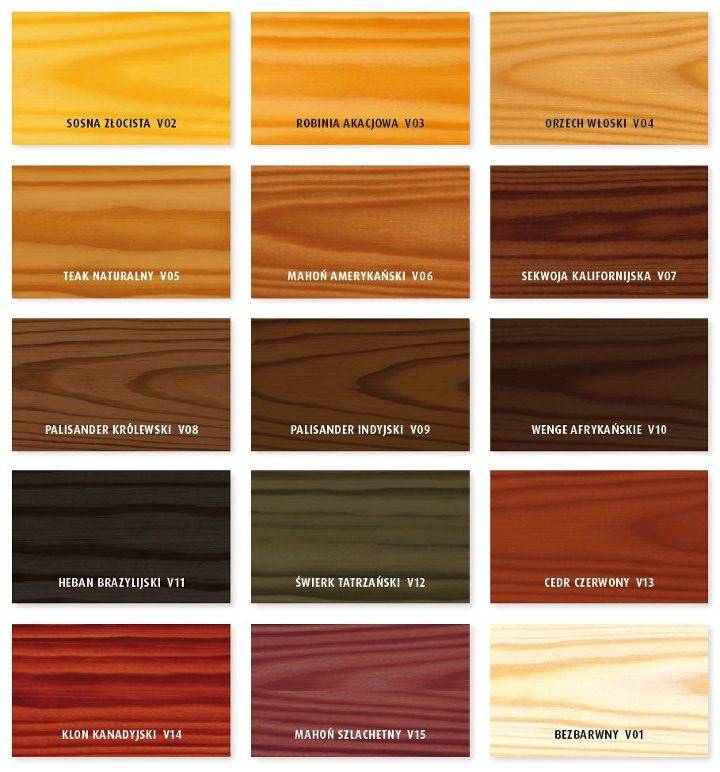

Veres Classic Lazura No. 1 colorless - for a bath

It is the best colorless impregnation for covering the walls and seats of the bathhouse, since it is completely transparent and retains the original color of the wood finish. The product is delivered in metal containers of various packaging, which is convenient to choose based on the scale of work.

The substance is especially resistant to parasites and moisture, therefore it effectively protects the wood and preserves its beauty. After application, it forms a thin film with the possibility of water evaporation from the inside.

Pros:

- creates an elastic thin layer with a visible natural wood grain under its base;

- prevents the appearance of mold, insect reproduction in its structure and blue stain;

- semi-matt shine is pleasing to the eye;

- suitable for outdoor use and protects wood from ultraviolet rays;

- the product in the bank is already ready for use;

- does not form smudges, because it is quickly absorbed and dries thanks to driers and additive emulsions;

- easy application with a roller or brush;

- the applied layer does not crack from temperature changes;

- protection time up to 8 years, with the possibility of extension with repeated processing;

- good viscosity due to the presence of an alkyd resin in the composition;

- due to silicon oxide it has increased coating strength;

- the substance contains linseed oil, which softens wood;

- economical consumption covers up to 12 m2 with one liter of the product;

- high adhesion.

Minuses:

- for the best effect, a transparent primer is needed;

- non-volatile substances up to 30%;

- complete drying time 24 hours;

- the substance is harmful to the respiratory system during use and needs good ventilation of the room;

- cost from 350 rubles for 900 ml.

Transparent Dufatex aqua - for beehives

This is the best impregnation with a transparent antiseptic, which is valued not because of the preservation of the natural beauty of the tree, but due to its high environmental friendliness, which allows it to be used to cover hives without harm to their inhabitants.

The substance is water-based, making it safe for both exterior and interior decoration. Impregnation is produced in iron containers with a deep rim under the lid, which is convenient for tightly sealing the residue and opening.

Pros:

- resistant to ultraviolet radiation;

- does not splash when applied due to its dense structure;

- suitable for all types of wood;

- high environmental friendliness and compliance with German quality standards;

- has special recommendations for decorating objects and walls in kindergartens, schools and hives;

- allows the tree to "breathe";

- the appearance after processing has a silky gloss;

- does not form visible transitions when working with a brush;

- acrylic dispersion in the composition increases the protective properties of heat transfer;

- 1 liter is enough for 12 m2 when passing in one layer;

- does not have an unpleasant odor.

Minuses:

- not suitable for floors due to the weak strength of the upper layer of the formed film;

- after 2 years it needs repainting;

- cost from 300 rubles for 750 ml;

- you need at least 2 layers with a gap of 14 hours for processing;

- can not be applied if the temperature outside is below +7 degrees;

- needs dilution.

Oil-wax impregnation

The oil-wax impregnation not only protects the wood, but also enhances its natural charm. The mixture can drastically change the color of the wood or highlight its naturalness. Oil-wax is an impregnation of natural composition, it is harmless for internal work. But the "faceless" boards after such processing become much more interesting and effective.

Coating with a solution based on oil and wax, gives the tree protection from external influences, but at the same time allows it to "breathe". After such impregnation, additional varnish treatments are not required in rooms with low humidity. Since the wax is excellent at repelling water, keeping the wood dry even with damp cleaning.

An important detail is the absence of paraffin and harmful resins in the composition. Oil-wax is easy and safe to use for residential applications. The complete absence of toxic vapors when heated allows the use of solutions for rooms with special requirements without health risks. In terms of cost, oil-waxes are expensive impregnations, but such processing will be durable and of high quality.

Photo impregnation for wood

We also recommend viewing:

- The best vapor barrier for your home

- How to choose drywall

- Which cement is better to choose

- Types of fasteners for drywall

- Extruded polystyrene foam

- Dry backfill

- Application of concrete contact

- Types of insulation and their properties

- Brick masonry mix

- The best grout for tile joints

- Types of anchors for concrete

- Best dry putty

- What plaster mixes are better

- Review of the best concrete additives

- Sizes of asbestos-cement pipes

- How to choose ceramic tiles

- What is the best laminate underlay

- Review of the best waterproofing materials

- Which brick is better

- Types of profiles for drywall and their application

- How to choose roofing material for the roof

- Which tile adhesive is better to choose

- Facade finishing materials

- The best assembly adhesive for foam blocks

- Wall primer

- Why do you need quartz sand

- Glass fiber in the interior

- Types and properties of sealant

- How to choose drywall

Help the site, share on social networks

Why wood is antiseptic?

What is antiseptic treatment? This is the impregnation of wood with various chemicals that preserve it from the inside.But why should such a convenient building material be “canned”? Now we will try to explain.

Interesting fact: wood is similar in structure to a reinforced concrete structure. It also consists of "reinforcement" and "concrete" - the two main compounds, cellulose and lignin. Cellulose is a polymer with a linear structure, but lignin has a developed multidimensional structure. Lignin, like concrete, has high compressive strength, while cellulose provides wood flexibility.

That is why, when building a house out of wood, it is important to remember that you are working with living material, and all living materials obey the laws of nature. In the process of its development, a tree from inorganic compounds form organic ones, and after the end of its life, tissues begin to be processed by saprophytes, popularly called fungi

The fungi feed on dead wood fibers and convert them back into minerals. At the same time, the mushrooms secrete special enzymes and grow mycelium with the help of spores, which requires a certain temperature, oxygen, nutrients and water.

Moreover, these mushrooms are divided into two main groups - wood-coloring and wood-destroying.

The former develop only on wood of natural moisture and give it a shade of blue, red, yellow or green along the way, remaining mainly in sapwood and only occasionally penetrating into the core. They die when heated above 80 ° C, and during their life they do not have a significant effect on the strength of wood, because they are not able to destroy lignin. Therefore, the very presence of an ugly shade of wood is more likely a sign of a violation of the mode of transportation and storage of lumber.

But the presence of wood-coloring fungi in wood often indicates the risk that the same material is also infected with wood-destroying fungi of the same kind. Also remember that wood-coloring fungi often mask rot with their color. But just wood-destroying fungi are able to destroy wood completely, transforming it into dust and humus, and this is a natural natural process, as you remember.

That is why, even in the process of producing building material for a house, it is subjected to conditions unfavorable for the development of fungi: harsh drying, high temperature, as well as the use of carefully selected chemicals.

Here we are talking about antiseptics:

Impregnation from decay

Many people know that wood absorbs moisture strongly. As a result, over time, it begins to rot. And in order for such a house to stand longer, it must be treated with special impregnations.

For such works it is recommended to impregnate the company "Senezh", which has a positive effect on the surface. This paint is used as a stand-alone product, and can also be used as a bio-protective primer, which should be used before painting.

An antiseptic is used for both primary and secondary treatment. "Senezh" does not lose its properties even on a surface on which water-repellent and film-forming agents were previously applied. The main advantage of impregnation is that the protection, even in adverse conditions, does not lose its properties for up to 35 years. Therefore, "Senezh" is one of the most effective remedies for moisture.

Beeswax

Very often, flaxseed oil with the addition of beeswax is used for wood processing.

Properties:

- Safe for health.

- Thanks to the wax, the surface becomes water-repellent and scratch-resistant.

- The waxing procedure makes the wood shade more expressive and gives a dark, noble, slightly golden hue.

- The texture of the wood is more pronounced.

- Waxed material continues to breathe, unlike varnishes

- Very pleasant smell.

- Wax in combination with linseed oil has even higher water resistance properties.

- It is used for any wood surface: houses, floors, doors, furniture and even toys.