Varieties

Rocking chairs are different in the following ways:

- By design;

- By material of manufacture;

By design

The oldest and most popular is a rocking chair with runners: it is a chair with a large back, which is placed on a rounded, double base. The runners make the chair strong and create a good swing.

It is surprisingly comfortable to relax in it, read a book or indulge in sweet, addictive and enveloping laziness.

It is surprisingly comfortable to relax in it, read a book or indulge in sweet, addictive and enveloping laziness.

In addition, if you put it on an uneven or flat floor, then your rocking on the chair will remind you of a trip on a country road.

Rocking chairs in stores are not cheap, moreover, it is not always possible to find furniture that ideally suits the interior of the room.

Rocking chairs in stores are not cheap, moreover, it is not always possible to find furniture that ideally suits the interior of the room.

If you are looking for a more stylish or newer chair, then the glider chair is worth choosing. This chair has a number of interesting features, namely:

- The coverage does not matter. Whether it is a carpet or an uneven floor, the swing will still be uniform, since the main mechanism is a pendulum, which is located inside the chair;

- Swinging is quiet and without knocks and squeaks;

- These chairs have a retractable footrest. They are called a recliner;

- The chair can be controlled by: electronics, levers, sensors;

- It is possible to adjust the back;

Those who love something unusual should prefer a chair with a spring. The base is a ring that is large enough and completely motionless. There are large springs in its leg, which make the wiggle, they, like traditional ones, are inertial. You make a beat and it works.

A universal spring is installed in one wide leg, which works according to the inertial principle.

A universal spring is installed in one wide leg, which works according to the inertial principle.

Its uniqueness is that:

- Exotic armchair. It is round and oblique;

- Strength. It can bear 150 kilograms;

- The spring is closed, so children can freely use the chair;

- An environmentally friendly basis for the manufacture of dense rattan branches.

The chair has a spring mechanism that allows the chair to both swing and rotate.

The chair has a spring mechanism that allows the chair to both swing and rotate.

By material of manufacture

In the manufacture of used:

Wood. This crafting base has great strength. From it you can make a high-quality place for the elbows that make up the runners. They are easy to decorate. To protect against pests, disinfectant impregnations are used;

For the manufacture of rocking chairs from solid wood, conifers are preferably selected.

For the manufacture of rocking chairs from solid wood, conifers are preferably selected.

Plywood for furniture. To assemble the rocking chair, use plywood of the required thickness. The necessary and durable parts are obtained from it.

Plywood is best suited for such a product due to its ductility.

Plywood is best suited for such a product due to its ductility.

Metal. This option is mainly used for the garden. It turns out to be strong and not bendable. Also, this option allows you to make beautiful forging. It weighs a lot.

A metal rocking chair is made at home with the necessary experience and tools.

A metal rocking chair is made at home with the necessary experience and tools.

Network. For this version of the chair, it is possible to use bamboo, rattan, willow, reed, hevea. These materials are lightweight with tremendous strength. I can also use artificial analogs, since organic material is quite expensive and capricious to care for.

The rattan rocking chair is very popular due to its characteristics.

The rattan rocking chair is very popular due to its characteristics.

Choosing a size

The dimensions of the rocking chair can vary depending on where you would like to use it.It is recommended to make garden ones a little wider than standard sizes, more compact ones will perfectly fit into the home interior. A standard chair based on an ordinary chair has the following dimensions:

- height - 1020 cm;

- width - 720 cm;

- the length of the product in cross-section is 1500 cm.

It is necessary to make a drawing of a square seat, about 60 cm in size. The thickness of the seat can be taken approximately one and a half centimeters. For the legs, you will need bars with a height of about 110 cm, the height of the front legs is usually taken up to 60 cm.According to your preferences, these parameters may vary.

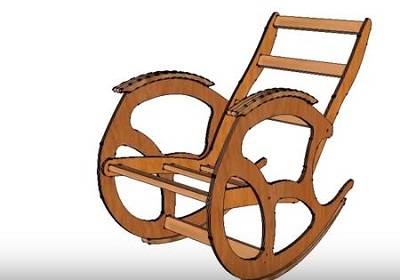

Full-fledged chair with runners

This is the most common type of rocking chair that you can buy at the store. The only difference is in the configuration of the sidewalls. The set of tools for the construction of a rocking chair is similar to the previous one, there are exceptions - this is the need for a construction hair dryer and a stapler, and the following materials will be required:

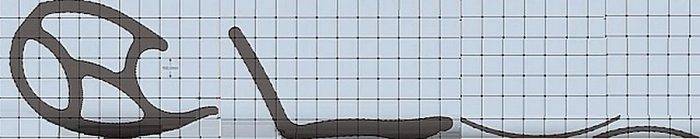

- Plywood sheets, each with a thickness of about 20 mm. For 2 sidewalls: 700x1100. For back and seat: 600x1200 mm. For overlays: armrests (the last small detail in the drawing) and runners (third from the left) - 200x1200 mm.

- 6 bars (20x30 mm) for sidebars, length - 600 mm. A bar (20x50 mm) for connecting the sidewalls for stiffening, the length is the same.

- 2 sheets of fiberboard for the seat (600x700 mm), pieces of filler (usually foam rubber) of the same size, 2 pieces of fabric for upholstery of the back and seat (700x800 mm);

- Nails, screws, dowels, metal corners (30x30 mm).

The size of each cell in the drawing is also 100x100 mm.

Cut open

It is made in a manner similar to the previous one, but in this case, the places for the fastenings are immediately marked, then the holes for the dowels are drilled. Paired parts, folding, are fitted to each other, all the edges are slightly rounded using a router. The drawers and the lintel of the sidewalls are carefully ground.

Assembly

The seat and back are formed: the side parts (the second element in the drawing) are connected with drawers using dowels, but additionally reinforced with metal corners. Then connect the resulting element with the sidewalls. In these places, through holes are made for fasteners - screws with washers and nuts. Last of all, the lower jumper is attached between the sidewalls, 2 self-tapping screws are used on each side.

Installation of overlays

The chair is turned over with runners up. The part intended for the linings is heated with a hairdryer, fixed on the runners with twine or braid. When all the parts have taken the desired shape and cooled down, they are disconnected, coated with glue. The edges of the elements are nailed with several nails, which are provided with thick washers to facilitate their removal. After the operation, the rocking chair is left alone for 2-3 days.

Then the nails are pulled out, the surfaces are sanded. At the ends of the overhead parts, small holes are drilled for self-tapping screws, which are also sunk into the material. The grooves are camouflaged using filler with sawdust. They act in a similar way, attaching the armrests of the chair, but here the screws are screwed not only from the ends, but also along the entire length, the step is 60-80 mm.

Upholstery, seat, back

Pieces of foam rubber are glued onto fragments of chipboard, covered with fabric on top, which is attached from the back with staples. The elements are attached to the side bars, through holes are used, the fasteners are screws with wide heads, covered with the same material. Another option is to fix chipboard parts without upholstery - immediately with self-tapping screws (furniture nails) to the tsars. In this case, removable covers are made, filled with padding polyester. They are fastened with ribbons sewn around the edges of these makeshift pillows.

Rocking chair: drawings and dimensions are a question that many can answer, but it is better to show and talk about the process itself to someone who is engaged in the manufacture of such furniture himself.You can take a look at this video:

Methods for making plywood rocking chairs

Plywood is the most convenient material for making furniture at home. With its pliability, it makes it possible to embody any design ideas, for example, to make not only an ordinary structure, but also a hanging hammock chair, a swinging bench or a comfortable lounger. For work, you will need plywood sheets (15–20 mm thick), a jigsaw and an electric drill, sandpaper, thin nails with large heads, stationery (pencil, tape measure).

Baby rocking chair

The easiest way to make a comfortable structure is to make a rocking chair without nails for a child. Four main parts must be cut out of plywood sheets: two sides, a back and a seat. We collect everything into a single structure and glue it together for reliability. When installing the seat, you must additionally secure it from the back with a peg. If you are already confident in your abilities, you can start making a more complex structure, consisting of many parts.

A very original option, which, no doubt, will appeal to any kid is a rocking chair in the form of some kind of animal, for example, a funny elephant. You will spend a little time on making it, but what a pleasure such a swing will bring to your child! Paint the chair in bright, saturated colors and don't forget to take care of the ponytail.

Traditional rocking chair

A standard rocking chair can be made using the diagrams below. First you need to make patterns on large sheets of paper or cardboard. The templates are then transferred onto plywood sheets and cut out. If the plate is not more than one and a half centimeters, work can be carried out using a manual jigsaw, and for thicker sheets, use an electric one. In this case, the movements should be smooth, since any jerk or abrupt stop will certainly leave a mark. It will not hurt to remove roughness from the finished parts with sandpaper, then they are treated with antiseptics. Then the products are assembled according to the scheme and painted or opened with varnish.

Latest articles

-

16 suitable projects for a summer residence that will help decorate the yard and not spend a fortune 05/19/2020, 10:53 PM -

7 innovative summer cottage tools that will be much more pleasant to work with 05/19/2020, 22:00 -

Yula from a gear from a clock, or What analogues of modern spinners Soviet children had 05/19/2020, 20:10 -

Mini-house built in 2 weeks using a 3D printer and a car robot 05/19/2020, 18:24 -

10 mistakes that are often made when choosing colors in the interior 05/19/2020, 16:35 -

How to make a netting from an ordinary plastic bottle: master class 05/19/2020, 15:02 -

How to make an efficient garage heating stove from old batteries 05/19/2020, 13:17 -

12 modern interior trends used by successful designers 19.05.2020, 11:44 -

Why the talwar saber was considered a symbol of valor among Indian warriors 05/19/2020, 10:37 -

Five topical reasons why tires wear out too quickly 05/19/2020, 09:28

All articles

Wooden model

In most cases, a rocking chair is made of wood. It is easy to build and has good performance properties. The construction of wood comes in different variations: without armrests, with a backrest with a bend. Or, more simply: with elements that are straight lines.

Most often, a garden rocking chair is made of wood, it is ecological, easy to install, durable

Most often, a garden rocking chair is made of wood, it is ecological, easy to install, durable

Of the tools you will need:

- hacksaw;

- jigsaw;

- sandpaper;

- screwdriver;

- hammer;

- level;

- brushes.

It is better to prepare everything in advance to save time.

How to make a project

Drawing up a drawing is a responsible process. The speed and correctness of construction depends on this. There are many already completed projects on the Internet. Choose a ready-made drawing or make it yourself - it's up to you.

For the chair to be comfortable, to match the size, you need a minimum of knowledge of kinematics. The stability of the chair depends on the location of two centers: the person's gravity and the generating circle. If they coincide, dead equilibrium occurs, the structure is motionless. If the center of gravity is above the circumference, the chair will be unstable. To avoid such a mistake, the rocking chair is designed for the tallest and heaviest person in the family.

Mounting

For the first experience, choose a classic-style rocking chair with curved runners. It's easy to make, comfortable and looks great.

The first thing we need is 3-ply maple plywood. We will impose pre-designed templates on it, make a frame. We draw up the drawing ourselves or find a ready-made one on the network.

The wooden rocking chair must be cleaned and sanded

The wooden rocking chair must be cleaned and sanded

We will focus on the need to properly treat the surface of the wood with protective agents. The material should be smooth. Use sandpaper for sanding.

Decorate the back and seat with reed patterns. Therefore, we leave a free space in the center. So far we only use plywood under the frame. We make miniature identical holes along the frame at a short distance from each other.

Once we have finished with the base, we start working with the reed. We intertwine it vertically and horizontally. We fix it with tight knots in the holes drilled earlier. Once again, the formed product will be treated with a protective agent.

The final stage is decoration. You will need pillows or a compact, comfortable mattress. We fasten them to the frame with strings.

How to design correctly

There are several types of rockers that suit different needs and user habits. The first models that appeared in everyday life were equipped with simple arches and skis. Do-it-yourself rocking chairs can be made according to a ready-made drawing. But you need to know that these drawings were created for an individual person and may not suit others. First of all, the product should be comfortable and meet your own needs.

What you need to know when designing a product:

- When making a chair, it is required to take into account that the center of gravity of the rocking chair must be correctly located in relation to the center of the rocking chair circle. Then the product will be comfortable and stable.

- The rocking chair made of wood will not move if these two points converge at one.

- The product will be unstable if the center of gravity moves higher in relation to the center of the circle.

The main uses for rocking chairs

Depending on where the rocking chair is used, it is customary to subdivide them into rocking chairs intended for indoor use and rocking chairs intended for outdoor use (for example, in a country house or in a garden area). If you plan to use a rocking chair outdoors, you will need to ensure that it is protected from direct sunlight, from the effects of various types of precipitation, as well as from temperature changes.

Rocking chairs, which are made of such a variety of materials as metal, are resistant to changes in atmospheric humidity. It will be enough just to treat such a rocking chair with any of the special anti-corrosion compounds. Because rocking chairs, which are made of such a material as metal, weigh quite a lot, it is best to put them on a stone base, because a wooden base, not to mention loose soil, will simply push through with its weight. The best option in this case would be a metal rocking chair with a wooden seat or with cushions that can be removed if necessary.

Rocking chairs, which are made from various types of wood, must be treated with some kind of special waterproof coating.This also applies to rocking chairs, which are made from a material such as plywood. Even before assembly, it will be necessary to apply drying oil on the ends of each of the parts of the rocking chair, which are made from various types of wood species. After that, the parts are flattened with a hammer so that water cannot get inside. After completing the procedure, the rocking chair, which is made from various types of wood species, will need to be coated with a waterproof varnish.

Rocking chairs, which are made of various kinds of wood species, are highly discouraged to keep outdoors all the time, because this has an extremely negative effect on the presentability of their appearance.

The most suitable option for outdoor use is considered to be rocking chairs, which are made of a material such as plastic. This type of materials absolutely does not lend itself to decay, is absolutely not afraid of the wind, is resistant to direct sunlight, and also does not require treatment with any special protective compounds. In addition, rocking chairs, which are made of such a variety of materials as plastic, have such advantages as a high level of structural strength, lightness of construction. If necessary, they can be very easily rearranged to another place.

In the open air, it is highly discouraged to use rocking chairs that have soft upholstery. For this reason, it is best to cover them with a blanket or use removable pillows. In the rain, the upholstery will get wet and, accordingly, deteriorate.

How to make a rocking chair with your own hands

The selection of high-quality material determines how high-quality and durable your chair will be. After all, the material should be lightweight and durable, since the owner of this chair may get used to dragging it along. Those who do not want to pay big money for such a thing ask themselves how to make a rocking chair with their own hands at home while choosing the most suitable and high-quality materials. Therefore, when choosing materials, we advise you to make a rocking chair out of wood, reed, and vine. Also, sometimes the chair is made of light metals.

A rocking chair is the perfect way to create an atmosphere of comfort and tranquility.

A rocking chair is the perfect way to create an atmosphere of comfort and tranquility.

Plywood rocking chair

Plywood - can fall apart due to water, but it is also an excellent option for creating an armchair. Because of this, many are interested in how to make a rocking chair with their own hands, drawings from plywood. We advise you to make such chairs for your home or apartment. Therefore, if you want to make such a chair, then you should follow it closely if it is in the yard.

A do-it-yourself rocking chair in a classic style with curved runners will be an excellent option for your first furniture making experience.

A do-it-yourself rocking chair in a classic style with curved runners will be an excellent option for your first furniture making experience.

To create a simple and comfortable rocking chair, you need to prepare:

- For the sides: plywood sheets (1200x1400 mm, a moisture-resistant type of plywood would be an excellent option) 30 milliliters thick;

- For the base: 3 boards (20x150x800 mm);

- For seating: 32 small boards (15x39x1200);

- Portable router;

- Screwdriver;

- Electric jigsaw;

- Portable electric machine for grinding;

- Self-tapping screws (20 pieces);

- Wood glue;

- Putty;

- Varnish.

Making a rocking chair with your own hands is not at all difficult, a minimum set of tools and a great desire are enough.

Making a rocking chair with your own hands is not at all difficult, a minimum set of tools and a great desire are enough.

Sidewalls

To begin with, the side parts are prepared, which, along with this, are also runners, as well as the base for the chair. Two parts are cut with a jigsaw.

To begin with, we will draw 2 sidewalls of the chair according to the template and carefully cut them out according to the markings with a jigsaw.

To begin with, we will draw 2 sidewalls of the chair according to the template and carefully cut them out according to the markings with a jigsaw.

Frames

In this case, actions are created with markings on the sidewalls, which are drilled (20x150x800 mm). One of the main conditions for this operation is its accuracy. After that, grooves are made that correspond to the grooves of the jumpers. They are 5 mm deep. Before installing the frames, coat these holes with glue. So that the material does not burst under it, holes are made in advance.

All edges of the parts must be sanded with sandpaper.

All edges of the parts must be sanded with sandpaper.

Planking

Holes are marked in the planks (15x39x1200) that make up the seat. From each edge mark 20 cm, outline the lines where the screws will be fixed. The distance between the parts is 1 cm.

We glue the supports to the sidewalls with wood glue and, for reliability, fix each of the bars with a self-tapping screw.

We glue the supports to the sidewalls with wood glue and, for reliability, fix each of the bars with a self-tapping screw.

Finishing elements

It is made with putty dissolved with sawdust, they hide the holes where the boards were attached, level the surface. Grind after the putty dries. Then they are varnished on the water, after which you can put a mattress or carpet on the chair for convenience. It is better to do this, because the stationary mattress will be wet from the rain.

The ends of the sidewalls can be varnished or painted with glossy paint.

The ends of the sidewalls can be varnished or painted with glossy paint.

How to make a rocking chair out of wood

Many, when starting to create a chair, ask the question: how to make a rocking chair out of wood with their own hands, while finding suitable drawings and dimensions? They search for a long time on various sites, ask on forums, and so on. In this section, we will tell you how you can make it high-quality, reliable, convenient and modern.

These rocking chairs are beautiful and will be able to decorate your interior in the apartment, on the balcony or in the yard of the house.

These rocking chairs are beautiful and will be able to decorate your interior in the apartment, on the balcony or in the yard of the house.

In order to create a chair, you will need:

- a hacksaw with fine teeth;

- a plane to handle the structure;

- belt machine for grinding parts;

- folding milling machine;

- plumb line;

- screwdriver;

- hammer;

- portable ruler and pencil;

- clamp;

- brush.

The drawing can be created at your own discretion and to your size, or you can find it on the Internet.

The drawing can be created at your own discretion and to your size, or you can find it on the Internet.

To begin with, in a wooden board measuring 4.5 by 4.5 centimeters, make grooves 1 meter. Grind the ends of the boards to fit in the slots of the runners. Place the runner boards in hot water until the wood is pliable to bend. Use the tool to bend the board to a suitable radius and set aside until it is completely dry. Put the dried runners on their legs, having previously processed the grooves with glue.

Everyone can make a new homemade rocking chair at home

Everyone can make a new homemade rocking chair at home