Making metal rocking chairs

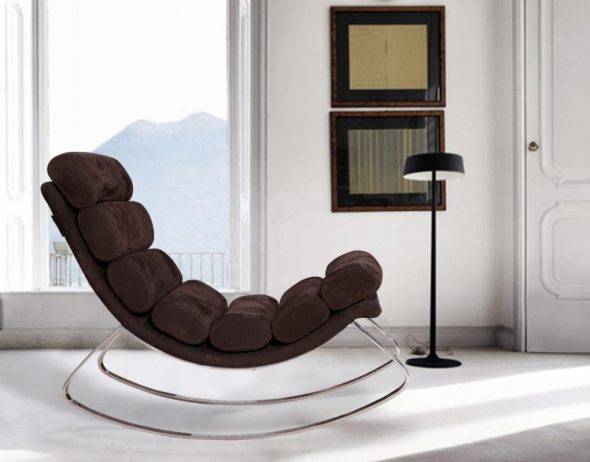

Of course, when it comes to metal armchairs, the first thing that comes to mind is the superb designs with graceful forged elements. However, such masterpieces require real skill and special tools, so we will talk about more simplified options. For example, you can make a chair by welding from metal pipes. This design is more like a chaise lounge, as it has a fabric seat.

It is necessary to prepare 22 mm metal rods, a welding machine, paint and a piece of thick fabric. To begin with, we make calculations, draw up a diagram and cut out the rods of the required length. Next, we weld the structure in stages. The most difficult moment will be bending the metal rods. You can do this, as shown in the photo, using a sturdy tree with a branched trunk. One end of the rod must be inserted into the bifurcation point of the trunk, and on the other, a lever pipe must be put on, by moving which, you can achieve the desired bend. When the structure is completely ready, it should be painted. Then we make a pattern and sheathe our structure with a canvas-seat.

How to choose a rocking chair in a store

A wide variety of materials are used in the manufacture of such interior items, including natural wood, reliable metal and durable modern plastic. The most common furniture from Italian manufacturers, the design of which is characterized by the presence of arched supports installed on both sides.

This feature of the chair allows you to swing on it. Less common are models with a solid rounded base. Also, a feature of the rocking chair is the presence of a comfortable back and armrests, and in some models there is a comfortable footrest.

Depending on the scope of application, the sizes vary, and all models can be divided into home, outdoor or country-garden and office. The classic version is represented by relatively light, simple in shape and affordable garden models. It is not advisable to use wicker products for a long time in outdoor conditions. Natural materials such as vines or rattan quickly deteriorate as a result of direct sunlight.

Experts recommend giving preference to rocking chairs made of the most resistant materials in the form of metal, plastic and synthetic fabrics for outdoor use. The design of furniture for home use can be selected depending on the characteristics of the interior in the room. Among other things, all types are divided into children's and adult models. The first option has small dimensions and is often presented in a playful way, so it can look like a swinging horse, dog or bird.

Varieties of rocking chairs

Consider the main types of products:

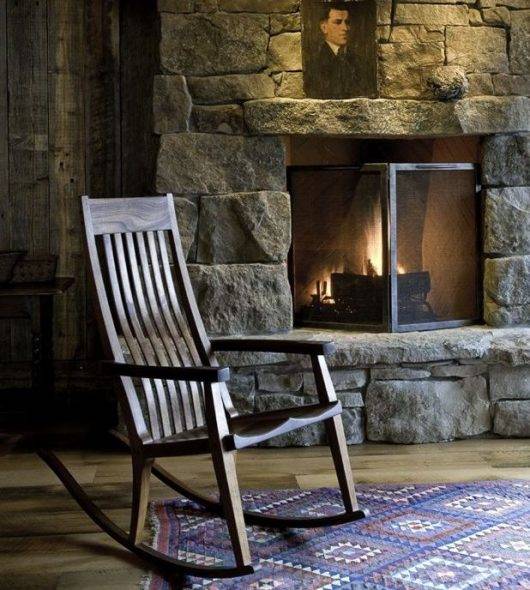

Classic rockers on ordinary runners - they are in harmony both in the modernist style and in the classics. Manufacturing technology does not require a lot of experience in furniture production, but the basics of practice must be present. The skids swing smoothly with a small radius, with strong swing there is a risk of overturning.

These chairs are made with a low seating position for a more stable position.

Rockers on runners with bumpers. If a classic chair needs to be made with an average (normal) landing height - it is recommended to equip the arcs with bumpers - the runners are designed so that the ends are bent in the opposite direction.

In this version, the arches prevent from overturning, but lifting from the chair is uncomfortable and hard due to the presence of these bumpers.

Rocking chairs with elliptical arcs - the chairs guarantee soft gentle rocking, but with a large swing there is a risk of overturning, because of this it is recommended to equip them with bump stops, as in the previous version. For garden plots, a variant of elliptical rockers with an awning is offered, with which overturning is excluded.

A rocking chair can be small and tidy.

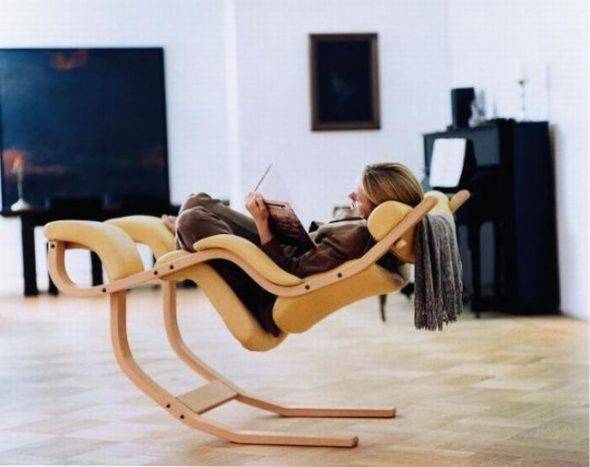

Multifunctional rocking chairs 3 in 1 - when landing, it looks like a standard chair for an even sitting, when leaning back, the runners switch to rocking mode, with further reclining, the chair turns into a lounger.

However, visually, such a chair looks bulky and the process of transition from one function to another is inconvenient, sharp jerks of the body are necessary.

Having considered the main options for chairs, in the absence of experience in furniture production, we recommend that you take a closer look at the classic version, making a rocking chair is not as difficult as it might seem.

Having decided on the model, it is important to make a decision on the materials

Step-by-step instructions for performing a model on three legs

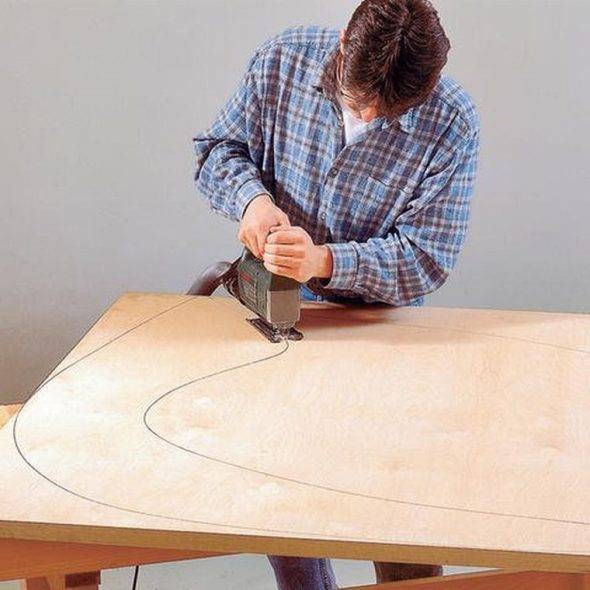

To make a do-it-yourself chair out of plywood, you can use the available scheme of a hemispherical model with three legs. The project includes 1 piece with two legs, 1 with a rear support, 2 armrest elements and 9 semi-circular blanks for assembling the seat and backrest.

Cutting is done with an electric jigsaw. At the same time, all movements should be smooth, without stopping and increasing speed, because they will be clearly visible and will require long grinding. After all the blanks are ready, their edges are treated with sandpaper, antiseptic and wood glue to prevent damage to the material.

The assembly is carried out in the following sequence:

- A workpiece with front legs is inserted into the second groove in front of the middle part with a rear support, obtaining a stable structure, with which it will be convenient to work in the future.

- Then, semicircular identical parts are mounted in the remaining 9 grooves.

- Finally, the edges of the seat elements are connected to the armrests.

Before installing all the components, the opposite grooves are abundantly greased with wood glue or PVA, and fixed with clamps. This model does not require the use of screws as fasteners, since after drying, the joints are strong.

The finished chair is covered with a layer of varnish. You can complement the furniture with soft pillows and a cover.

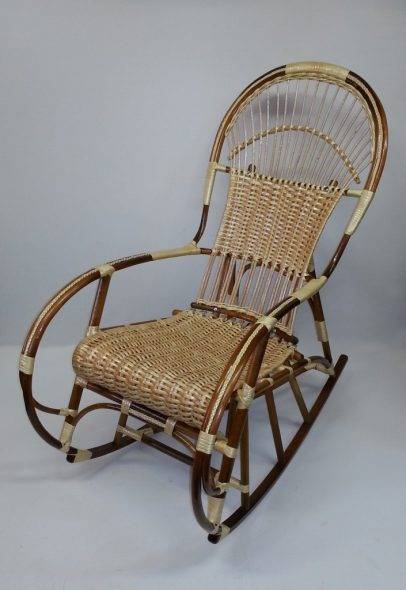

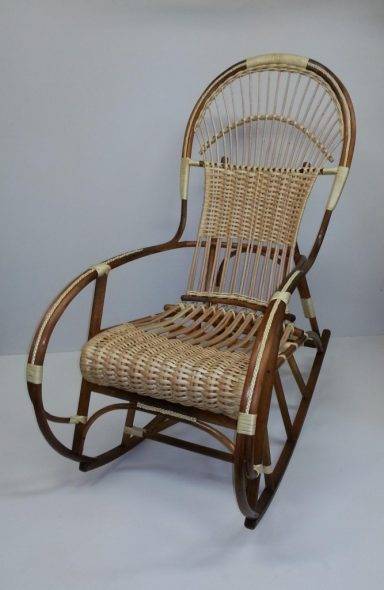

How to make a rocking chair from a vine at home

Ideal for weaving flexible branches of bird cherry or willow. The design of a wicker rocking chair is presented:

- lower bench;

- seat;

- back;

- armrests.

Manufacturing technology:

- preparation of 25 long rods, the diameter of which is 30mm and a large number of thin rods, 5mm thick;

- thick rods are bent by means of a zhamka;

- frame legs are fixed on the crosspiece and frame with thin rods;

- leggings are fitted;

- shots are set;

- the upper part of the back is mounted;

- the transverse rods of the seat are mounted;

- armrests are woven from rods;

- with the help of studs, the armrests are attached to the firing points;

- the upper part of the armrest bars is attached to the side skirts;

- preparation of typesetting rods and their installation on the back of the seat.

At the final stage, all elements of the wicker chair are decorated with decorative weaving from a thin cut ribbon.

Rocking chair manufacturing process

A do-it-yourself rocking chair in a classic style with curved runners will be an excellent option for your first furniture making experience. We will also use cane braided elements, which will create beautiful patterns and a comfortable fit.

A rocking chair can be easily made at home.

So, we need a 3-ply maple plywood, on which we will overlay the pre-created templates, and make the frame of the product. You can create a drawing of a rocking chair yourself or search the Internet for ready-made form options.

We cut out all the elements using a jigsaw and a grinder.

It is very important to carefully process the surface of all wooden elements, they should turn out smooth, without burrs and rough areas, therefore, in order for the templates to take the required form, they must also be sanded

We connect the parts with screws.

Do not forget that the back and seat of our chair will be decorated with reed patterns, so we leave the central part empty. That is, we create only a frame from plywood. Along the entire perimeter of the resulting frame, we make small identical holes at a distance of 1.5-2 cm from each other.

In the future, we will fix the reed threads in the holes.

After our base is ready, we start working with reeds. We intertwine it with threads vertically and horizontally along the entire surface of the seat as weaving and fix it with strong knots in the holes drilled earlier.

We perform similar actions with the back of the product.

When the product is formed, all wooden elements must be treated with a protective coating at least 2 times.

After drying, we fix it with a double layer of varnish.

Consider another simple version of the original plywood rocking chair. The chair consists of two boomerang-shaped sidewalls and transverse guides from wall to wall in the amount of 14 pieces.

The armchair is made of 15 mm plywood.

To begin with, we will draw 2 sidewalls of the chair according to the template and carefully cut them out according to the markings with a jigsaw. All edges of the sidewall must be sanded with sandpaper.

You should get 2 big "boomerangs".

Then, from the same plywood 15 mm thick, we make 14 rectangular strips 59 cm long and 6 cm thick.We also cut small blocks as supports, their length should be 5 cm each.

We glue the supports to the sidewalls with wood glue and, for reliability, fix each of the bars with a self-tapping screw.

We also attach our guides to these supports with self-tapping screws.

After completing all the above steps, we will have the frame of our rocking chair ready. We treat the sides of the chair with a stain in two layers, you can proceed to the second layer only after the first one is completely dry.

The ends of the sidewalls can then be varnished or painted with glossy paint.

Our chair is ready.

It remains to decorate it. To do this, we take soft pillows of the required color or a small flexible mattress and fasten it to the frame with ties. Soft items can be purchased in the store or made by yourself. To do this, it is better to take natural fabric as upholstery and 5 cm thick foam rubber.

We cut out the part we need in size from the foam rubber and put a pre-sewn cover on it.

We are sure that making one rocking chair with your own hands will push you to conquer new heights, and you will want to make a similar or another rocking chair with your own hands for all family members so that you can get together on quiet, cozy evenings and talk about events and plans. for the future, slowly swaying on their own made chairs.

A rocking chair will help you to relax quickly and fully.

You can make such furniture according to individual sizes, including children's sizes for the smallest family members. Such evening or morning motion sickness creates a relaxing soothing effect that is so necessary for a person in the modern world. These chairs are environmentally friendly, as they are made of natural materials.

They are beautiful and will be able to decorate your interior in the apartment, on the balcony or in the yard of the house.

Most rockers do not require any special care and can easily tolerate cold temperatures. Some materials do not tolerate strong moisture, therefore, such furniture cannot be left outside for the winter.

We are sure that every owner of a rocking chair will consider it their favorite pastime.

Making a rocking chair with your own hands is not at all difficult, a minimum set of tools and a great desire are enough.

Care rules

Caring for rocking chairs of various modifications comes down to the following mandatory procedures:

- when using the product with soft covers, it is necessary to remove dust or dirt from them in a timely manner, using a household vacuum cleaner or damp rags;

- if it is heavily soiled with the same rag soaked in soapy water, try to remove the stains, and then let the wet places dry completely;

- armchairs wicker made of willow are not recommended to be left in open sunlight (it is advisable to choose shaded and protected from precipitation places for their placement).

Removable covers made of various fabrics (suede) are recommended to be washed in soapy water, after which they should be thoroughly rinsed and dried in the open air. Expensive leather upholstery, in addition to regular wiping with a damp cloth, it is advisable to cover at least once a year with a layer of glycerin or stearic ointment.

Choosing a material

Material selection, from which the rocking chair is made, depends not only on your own preferences, but also on the conditions in which the furniture is to be used. Quite popular is the wrought-iron chair, which is assembled from metal rods and strips. This model is brought to life not only by forging, but also by conventional welding. A wrought-iron armchair is most often installed on the street, porch or spacious terrace. The material used is characterized by increased strength and long service life, in addition, it is not subject to the negative effects of weather conditions.

Nevertheless, metal chairs have a number of disadvantages. They weigh too much, and therefore do not differ in any kind of mobility. Manufacturing will not be possible without special equipment. Finally, for some people, forged designs do not seem comfortable at all. In this case, you will have to additionally buy a soft mattress and armrests.

There is also an option for making a rocking chair from a plywood board. This option is the simplest and most budgetary, available for implementation by any person with basic carpentry skills. The advantage of this design is its low weight and the ability to bring any ideas to life due to the linear dimensions of the plates and their differing thicknesses. To extend the service life of the plywood rocking chair, additional processing is required using a polymer emulsion or acrylic-based varnish.

Wooden furniture is a fairly traditional option, which looks appropriate both on the street and in any interior. The wood itself is an environmentally friendly product that is easy to process and inexpensive. However, in comparison with the same plywood, the service life of such a chair will be longer. A chair made of profile pipes can serve for many years, including in conditions of constant stay on the street.

It is better to choose parts with an elliptical section and do not forget about the need to use a welding machine with a pipe bender. The finished structure must be covered with paint or varnish with anti-corrosion properties. To make the rocking chair convenient to use, you will need to make the seat and armrests from a board or plywood, and then cover them with fabric or leather.

A rocking chair made of polypropylene pipes looks quite creative, but not suitable for home use. Since the material is characterized by increased resistance to weather conditions, it can be used outdoors, putting it indoors during frosts and hiding it from direct sunlight.Separate parts of the structure are assembled using a soldering iron. The more connectors are used, the more stable the chair will be.

A willow vine rocking chair looks very beautiful, but it is quite difficult to manufacture without certain weaving skills. However, the result is a lightweight and comfortable design that can be operated both indoors and outdoors. It will also be possible to weave a rocking chair from bamboo, rattan or reed. Furniture made from a cable reel turns out to be very unusual. This element is disassembled, after which a groove for the boards is cut in the circles, and the rods are rearranged under the soft seat.

Some craftsmen use an old chair with runners on the legs. In such current styles as Scandinavian or eclectic, rocking chairs, connected using the macrame technique, are often found. Furniture is also assembled from pallets, polypropylene pipes, plastic pipes or PVC pipes. When choosing a material for manufacturing, several aspects should be considered. From wood, it is recommended to give preference to dense species, for example, oak, ash or larch.