The better to insulate the veranda: types of materials

There are many materials that allow you to insulate the veranda with high quality. But among the large selection, there are several that have proven themselves better than others.

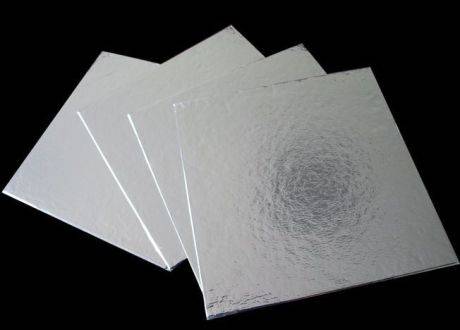

Penofol

- This insulation has a foil layer, which is an additional protection from the cold in a wooden veranda.

- Penofol can be used both independently and combined with other similar materials.

- The insulation is environmentally friendly, does not emit toxic substances.

- It is easy to install and is considered a fire safe product. It is great for insulating a veranda in a wooden house.

- It reflects well the cold air from the street.

Styrofoam

- Styrofoam is perfect for both floor insulation and walls and ceilings.

- Thermal insulation of the veranda with foam is quite simple. Installation of panels can be done both with mechanical fasteners and with the help of special glue.

- Due to its structure, this insulation creates coolness in the room in summer, and keeps warm inside the veranda in winter.

- This material is non-toxic, insects and fungi do not like it. Therefore, it is often laid under the floor screed or drywall. Penofol can be used as additional insulation of the veranda.

Expanded polystyrene

This product is similar in properties to foam. It is very durable and easy to process. An excellent product for veranda insulation.

Mineral wool

- This insulation is considered "breathable". It provides additional air exchange, thereby reducing the humidity in the room.

- Minvata is an environmentally friendly insulation. It is absolutely harmless, odorless, does not emit toxic substances.

- Mineral wool is a fire-resistant material. It is especially good to use it for warming the veranda if the building is wooden.

- Such insulation has proven itself well in the field of water resistance. It is capable of repelling moisture, which allows you to regulate the internal microclimate of the room.

- Also, mineral wool is an excellent sound insulator. It dampens the noise in the veranda coming from the street, thereby providing additional comfort. This insulation is used to insulate walls, floors, ceilings, ceilings. A wide assortment range allows you to choose the most optimal option. With this product, you can both insulate the veranda and the wooden house as a whole.

Basalt wool

This insulation is in no way inferior to mineral wool. It also perfectly protects the house from cold and noise. Excellent chemical and biological resistance. Warming the veranda with this product has proven itself well in severe frosts

Polyurethane foam (PPU)

Such insulation can be purchased in three types: rigid panels, flexible plates and inflatable. The advantage of this material is its low weight and ease of installation. But it is poorly tolerated by mechanical stress, and has a high price.

Linen, tow, moss

Such heaters are used when the veranda is wooden. It is difficult to stack such materials. If it is planned to insulate the veranda with this raw material, then it is better to do this even during the construction of the veranda.

Synthetic insulation for construction

Artificial material has more durable characteristics than natural. A similar material is used to insulate the veranda from the inside and outside. It is successfully used to insulate walls, ceilings and floors.

3 Outside insulation - tips for home craftsmen

Having decided on the suitable thermal insulation materials, you can begin to insulate the terrace from the outside. With your own hands, such activities are best performed at freezing temperatures outside. Professionals advise to carry out thermal insulation of the ceiling with mineral wool slabs

It is important to take care of the high-quality protection of this material from steam (for example, with roofing material or special vapor-tight membranes).It is even better to insulate the ceiling with penofol with an additional layer of foil

Then you do not need to install additional moisture protection.

Wall surfaces outside are most often faced with polyurethane foam boards

Wall surfaces from the outside are most often faced with polyurethane foam, expanded polystyrene or mineral wool slabs. They can subsequently be covered with almost any finishing material, from PVC panels, log products to metal cladding. Installation of heat-shielding plates on concrete or brick walls is carried out according to the following scheme:

- install the selected insulation (usually glue is used to fix it);

- mount a reinforcing mesh on the heat-insulating material;

- paint, plaster the heat-shielding panels or install the chosen cladding on them (siding, lining, and so on).

After such work, the terrace will not be afraid of the winter cold. You will receive a full-fledged room at your disposal. There it will be possible to equip an entrance hall or a chic winter garden.

On wooden walls, heat-shielding products are installed on a pre-prepared crate - slats, to which a heater is attached with umbrellas-dowels, then the structure is covered with a waterproofing membrane. The latter is fixed with staples (a construction stapler is required).

Note! If you are planning to really warmly insulate the terrace and make a living room there, it is imperative to insulate the window and door openings. Doors protect against cold penetration with foam rubber

It is attached to the structure, and then covered with dermantine. The windows are insulated from the outside with a simple polyethylene film. You need to stuff wooden slats onto the frames, and then attach a heat insulator to them.

Insulation materials overview

What properties do heat insulators have?

Heat insulators are distinguished by their structure: some resemble wool, while others have tiny cavities - pockets filled with air, which has a low thermal conductivity. The former include common mineral fibrous materials produced in rolls or in the form of dense "felt" slabs. The second is polymer-based insulation, produced in the form of panels or foams.

Most wood-based products, such as MDF, plywood, fiberboard, also have low thermal conductivity. Therefore, wooden doors, MDF wall decoration, clapboarding of the hatch to the attic help to keep warm. Some sealants also "work" as heat insulators. Cracks and gaps are filled with them. One of the cheapest sealants is papier-mâché and is easy to make from paper and wallpaper glue.

Good insulating materials not only slow down the process of heat loss, but also have other important properties: fire resistance, indifference to chemicals, wear resistance, non-toxicity, antimycotic (prevent mold growth). However, another significant factor is cost, therefore, when choosing thermal insulation materials, they are guided by the notorious price / quality ratio. Do not forget about the requirements set out in the regulatory documents (GOST 16381-77, GOST 22950-95, GOST 31913-2011 and others).

What materials are used to insulate the veranda

Most often, the following are used to insulate walls, ceilings, floors, windows and doors of a terrace:

- Mineral (glass, stone, slag) wool is a fibrous material that is resistant to high temperatures. Thermal conductivity depends on the density of the cotton wool.

- Expanded polystyrene (foam), including extrusion, is an inexpensive, fairly durable heat insulator, the main disadvantage of which is its high fire hazard. Gives off toxic substances when burned. They produce modified self-extinguishing polystyrene foam with fire retardants (marking "C"). Fire-protected boards are much denser and heavier than the polystyrene grades used for packaging. Extruded polystyrene foam is 50 percent more efficient (at the same thickness) than standard mineral wool products.

- Penofol - foamed polyethylene, covered on one or both sides with a layer of aluminum foil. These "sandwiches" of metal foil and plastic insulator are used to reflect the radiated heat.

- Polyurethane foam in the form of panels or polyurethane foam (expanded polyurethane foam) - a material with low thermal conductivity (0.03-0.04 W / (m • K) and high adhesion. Foam is formed by mixing chemicals. When solidified, it "locks" in tiny pockets of air Since foam can fill cracks and crevices, it is used to seal existing building structures, which helps to eliminate drafts.Foam adhesive tapes are used to insulate windows, doors, and attic hatches.

- Cork sheets made from cork oak bark are an environmentally friendly but very expensive heat insulator.

- Expanded clay - porous granules obtained by firing clay. Used as a backfill for floor insulation, ceilings.

Foil penofol reflects about 95 percent of thermal energy

Foil penofol reflects about 95 percent of thermal energy

Vacuum insulation panels - an innovative technology in insulation

A relatively new material, successfully used in Europe and gradually conquering the domestic market, is the VIP vacuum insulation panels. They help out in cases where space saving is the main factor affecting the choice of material. The minimum insulation thickness allows the ceiling height to be maintained and eliminates the need for a threshold between the terrace and the adjoining room.

The thermal conductivity of the panels is 0.007W / (m • K). In terms of thickness / degree of insulation, this is the best of all available materials for insulation. VIP systems usually consist of highly insulated vacuum panels and sealing strips of appropriate thickness. Such panels are usually installed along the outer edge. Vacuum panel manufacturers supply kits with attached instructions showing the optimal placement of panels and sealing strips to help keep the thickness of the insulation system to a minimum. The new heat insulator has one drawback - the material is expensive.

VIP ultra-thin vacuum insulation panels are 20 times more efficient than traditional insulation materials

VIP ultra-thin vacuum insulation panels are 20 times more efficient than traditional insulation materials

Ceiling insulation

To insulate the veranda to be really effective, the ceiling should also be insulated. This kind of work is considered quite difficult. The main thing is to choose the right technology and insulation. There are two ways to insulate the ceiling: along the "floor" of the attic or to knock down the ceiling in the extension.

Attic ceiling insulation is usually done when a veranda is being built. But you can do it over time. This option is considered the best for the reason that the height of the room does not "sneak" and the installation is carried out much faster. Styrofoam or other insulation is simply placed in the rafter frame and covered with a film.

The technology of insulating the veranda from the inside is somewhat more complicated. But such ceiling insulation can be done in several ways. On our website, you can just watch the process of ceiling insulation in the video.

Method one

- First, a frame is made on the ceiling from a bar of 30 * 30 millimeters.

- Insulation of the same thickness is placed in the space between the beams.

- Further, the ceiling is sheathed with thin drywall.

- At the last stage of warming the veranda with your own hands, the ceiling is either plastered and painted or covered with siding.

Method two

- The old ceiling is replaced with plywood or OSB.

- Then the hydro-barrier film is attached.

- Further, a frame is made of a bar, into which foam plastic or other insulation is installed.

- At the next stage, the timber structure is closed with a film and lined with clapboard.

Method three

The simplest ceiling insulation technology is frameless.But only a hard insulation is suitable for her. The foam slabs are installed directly on the ceiling without additional structures. After that, the surface of the ceiling is closed with a special mesh and putty.

The process of warming the veranda

It is quite simple to insulate the veranda with your own hands if you understand well all the stages of the work being carried out. Basically, the terrace is being built on the same foundation as the house. Usually these are concrete slabs or a cast-in-place concrete base. In winter, 20% of the heat leaks through it, therefore, before insulating the veranda, it is necessary to insulate the foundation of the structure. This process is carried out without much difficulty. It is required to glue polystyrene foam boards to the surface of the base.

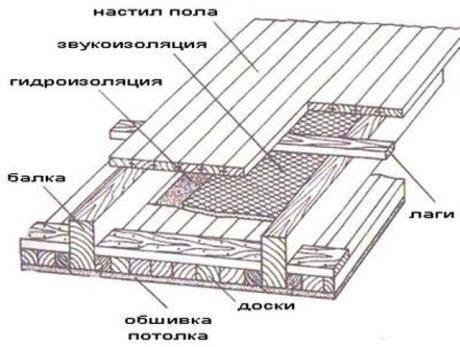

Floor

First of all, when the terrace is insulated, the floor is insulated. Some people do not attach much importance to this process, limiting themselves only to the processing of ceilings and walls, believing that it is not necessary to insulate the surfaces of the floors and are deeply mistaken. In wooden verandas, the floor is often laid as follows: logs are laid on the ground or a concrete base, on which boards are then laid and installed. For insulation, the following steps must be performed:

- remove the boards;

- between the installed lags, it is required to fix wooden beams with screws;

- insulation is placed in the resulting compartments - mineral wool, polystyrene foam or foam plates;

- when settling mineral wool, additional insulation is required when using foil or film, which will exclude the possibility of getting wet;

- the remaining empty spaces are sealed with foam for installation;

- the floorboards can now be laid back.

Sheathing inside

Insulation of the veranda can be performed both from the outside and from the inside. When insulated from 2 sides, it will be possible to achieve an exorbitant level of protection of the terrace during winter frosts, while retaining much more heat.

- All existing gaps are initially sealed.

- Then it is necessary to build a frame from a wooden bar.

- Further, a special waterproofing film is attached to the beam. It is better to install it from the inside with a construction stapler, thanks to which the process will take less time and will be much more convenient.

- After these procedures, a frame is constructed from a bar or a metal profile, which is filled with foam or other similar material. It is desirable that the distance between the metal profiles correspond to the width of the insulation itself.

- Drywall is installed on top of the frame.

- The finishing stage is plastering, painting or installing artificial turf on the surface of the walls.

Ceiling insulation

To achieve an effective level of insulation of the veranda, the ceiling of the room must also be insulated. This procedure is rather laborious. For high-quality work done, you should initially decide on the insulation and the technology of application or installation.

Thermal insulation of the ceiling in the attic is mainly carried out during the construction of the terrace, but if it was not there initially, then it can be built some time later. Sheets of polystyrene or other insulation material and vapor barrier are settled in the underframe.

It will be a little more difficult to insulate the terrace from the inside. The thermal insulation process can be done in one of several ways.

First way:

- First, a frame of 3 × 3 cm beams is constructed on the ceiling.

- Insulating material with a similar thickness is settled into the formed cells.

- After that, the ceiling is sheathed with plasterboard.

- The final stage is painting or plastering the surface.

Second way:

- Instead of the old ceiling covering, OSB or plywood is covered.

- This is followed by a waterproofing film.

- A frame is constructed from beams, in which mineral wool, foam or other type of insulation is placed.

- At the end, the structure made of beams is covered with a film, on top of which the lining is hammered.

Third way

- The third method is the easiest. Frameless insulation is made only with solid material.

- Styrofoam sheets are fixed to the ceiling itself without any specially equipped structures.

- Next, a construction mesh is placed on the ceiling, which is covered with putty.

Methods and methods of insulation

Insulation methods are recommended to be considered for each type of structure - separately.

Do-it-yourself insulation of the veranda from the inside looks more attractive: you can work in any weather, both in winter and in summer. And this method is more suitable for a veranda due to the peculiarity of the construction (there is no attic).

Before starting work, preparation is carried out, the walls are freed from the finishing material, and the cracks are filled. A vapor barrier film is attached to the finished wall (using a stapler).

A crate is installed on the film, the step is determined depending on the width of the insulation material. In this case, we are talking about mineral wool. Such material is often used for internal work, but it without fail requires covering with insulating film from 2 sides (as shown in the photo). It must be remembered that the dew point is transferred to the insulation, closer to the wall. After laying the insulation, it is covered with a film

It is important that the crate is thicker than the insulation, so that when the film is attached, it does not touch the insulation. The next step will be to fix the finish (gypsum board, or plywood, finishing rail)

Insulating the veranda outside is also an option, but it has its own characteristics. The fact is that when using this option, it becomes impossible to dock the wall insulation with the roof. It turns out a gap that will certainly affect the quality. On a veranda insulated in this way, the upper corner will freeze. Or you have to remove the roof, which is not advisable if there is no intention to change it. With the floor, it will not work either, since the distance under the floor is usually not great.

Warming the veranda with foam plastic attracts the fact that it is a fairly simple method, and does not require additional insulation with a film. Before starting work, you need to decide on the finishing material. In this case, the choice is large. It can be gypsum board, facing strip, plywood and plastering.

Considering that the material requires protection from direct exposure to fire, due to its properties, gypsum board and plaster are the most suitable type of finishing. Initially, there is a difference in the conduct of work for different types of finishes. For gypsum board, you will need a crate, which must be arranged depending on the width of the gypsum board sheets. For plastering, you need a mesh for reinforcement.

In the case of choosing plaster, the lathing is not required. Styrofoam sheets are attached to the wall with self-tapping screws, which should have a large cap. There are 5 self-tapping screws for each sheet, 4 of them in the corners and one in the center (how to correctly place the screws is clearly visible in the video).

Perhaps there will be gaps between the sheets, they are filled with polyurethane foam. Excess after drying is cut off with a knife. After the foam is attached, the mesh is attached to it with a stapler and plaster is applied to the mesh. This method is suitable both for further surface painting and for wallpapering. It is recommended to insulate both the floor and the ceiling at once. This will create a "cocoon" that will achieve the desired result.

The sequence of thermal insulation of the veranda - step by step diagram

Step 1: insulate the floor

It is easier to lay the insulating layer directly on the floor, subject to the mechanical strength of the base. The cracks in the floor are preliminarily covered with epoxy resin or a mixture of sawdust with PVA glue - then, when solidified, even the "musical" floorboards will become a monolith. But! Epoxy hardens quickly, almost instantly, so you need to work with it confidently and quickly. A mixture of PVA glue with fine sawdust hardens for a long time, almost a day. This gives time to calmly process all the cracks, but the floor insulation itself is postponed the next day.

The base is ready and strong - we lay a roll of moisture-resistant insulation on the floor and shoot it with a stapler in increments of no more than 10-15 cm (the thicker the insulation, the more often the fasteners). We punch in the corners with nails with wide flat caps, carefully glue the seams with tape. Lay linoleum or laminate on top. The direction of the flooring of the topcoat must necessarily be perpendicular to the insulating layer - so plan in advance how you will lay the laminate or lay the linoleum on the new insulation.

If desired, a "double floor" system is installed - logs are laid on the insulation and a full-fledged covering is assembled from new floorboards or solid boards. But such repairs are quite expensive and significantly reduce the height of the room. In addition, you will have to redo the doorways and the doors themselves to the veranda.

Step 2: insulate the walls

If the walls are made of boards, then they are carefully removed and the insulation of the plank veranda is carried out along the "wrong side" of the facade. Then the old boards can be put in place, putty and wallpaper pasted, MDF panels, wall plastic, etc. can be mounted, depending on design preferences and repair budget. Often the kitchen is taken out to the insulated veranda - then tiles or PVC panels for the kitchen are used in the decoration of the walls.

A crate made of wooden slats is nailed (shot) onto brick or concrete walls. Bars are selected with a section from 25x25 to 40x40 mm. Polyfoam can be tightly inserted into the formed openings (then they are made wide and deep, according to its dimensions) and glued along the end. In general, when working with polystyrene, it is easier to assemble a mounting crate, based on the size of its sheets, than vice versa - to saw hard material along an already installed grid.

Thermal insulation in rolls is stitched (nailed) to the slats, the seams are glued with tape. If it is used without foam, then the mounting rails are chosen thin, along the length of the fastening nails, in order to save the space of the veranda. If necessary, you can combine the installation of foam and roll insulation on the same crate.

Step 3: We insulate the ceiling

The procedure will require waterproofing work, any ceiling is affected by atmospheric precipitation. Even if the roof is good, there is no escaping moisture condensation, accidental leaks, etc. First, the ceiling lining is removed and a hydro-barrier is mounted - a special roofing film with fine perforations, the seams of the film are carefully glued with metal-sprayed tape. Further work is similar to the wall installation of the insulation material, with the exception of safety measures. When insulating the ceiling, it is necessary to use protective goggles, as there is a risk of eye injury when fixing the insulation with nails, shedding small chips, etc.

Large-scale work on arranging a warm veranda

When insulating a veranda, one cannot do only with insulating the walls. We have to work with the floor, and with the ceiling, and with the windows, and with the door.

We start with windows

Any insulation starts with windows. Usually the veranda has a very large glazing area. If the windows are old, the frames are dry and do not keep heat well, the windows will have to be replaced completely

It doesn't matter if the new windows are wood, plastic or aluminum

All these types are able to retain heat inside the veranda, as long as there are no cracks in them. In an unheated veranda, you can make single-glazed windows, but if you plan to heat it, you will have to spend money on double-glazed windows.

The veranda has a large glazing area, so the windows must be of high quality

Working with walls

At this stage, you need to decide on the insulation. The industry produces enough types, almost any will fit for warming the veranda. However, in addition to the advantages, each material has disadvantages, which will also have to be taken into account.

The main thing that you need to pay attention to is fire safety, since the veranda is a light construction, moreover, a summer kitchen is often placed on it. We list the main types of insulation

Warm veranda is comfortable and cozy at any time of the year

Insulation sheets are attached to the walls with dowels with large-diameter caps. To prevent the hats from going into the insulation, put thin wooden plates on top of the insulation at the attachment point. The cracks in the joints of the insulation must be "blown out" with polyurethane foam. A bar is stuffed on top of the insulation, to which a decorating material, for example, a lining, is attached.

We continue to work: floor and ceiling

Ideal if you can make a concrete screed. If not, at least cover the plank floor with linoleum or carpet. It will be more effective to make a double floor: a rough floor from an unedged board is laid on the logs, any insulation is put on top, then a finishing floor, leaving a gap between it and the insulation of 1-2 centimeters.

Isn't it a pity to give such a corner "to be devoured" by the winter frosts?

Use any available insulation, such as mineral wool. Glass wool is undesirable, since it absorbs water well and at the same time becomes very heavy.

A layer of waterproofing is made between the insulation and the roofing material. If this is not done, you will end up with a damp and ineffective insulation. Compared with industrial heaters, it is ineffective to use expanded clay, soil, sawdust for roof insulation.

Heating thin film (thickness 0.4 mm) - an infrared film heater that converts electrical energy into heat: like the sun's rays, such a film heats not air, but objects in the area of their action

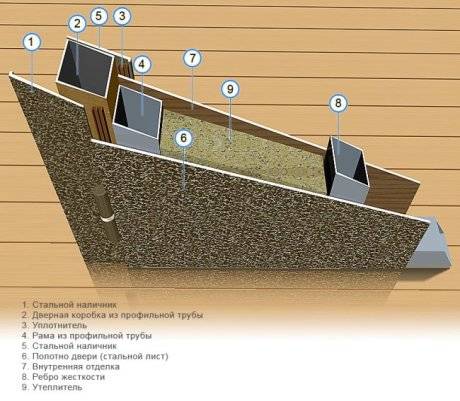

We insulate the doors

First of all, you need to insulate the door frame so that a draft does not penetrate into the cracks. The easiest way to do this is to glue the seal around its perimeter. A self-adhesive tubular rubber seal is suitable. If the door frame is rotten, then it will have to be replaced.

The door leaf can be insulated by covering it with batting or other soft insulation. Remove the fabric from the hinges and lay it horizontally.

First, make protruding rollers around the perimeter from the outside, which will become an additional barrier to drafts. Then attach the insulation to the entire door leaf, nailing it down with nails or a furniture stapler. Top can be upholstered with dermantine.

Insulation of the veranda greatly expands the possibilities of its use.

Insulation of the veranda will make it suitable for year-round comfortable rest. There is no need to put a heater on it, except on the coldest days of winter. And if you still have to do this, then a few hours will be enough, and the air temperature will allow you to be on the veranda without outerwear.

We put heat protection for the walls

The walls have a large area of contact with the street, so we will consider how to insulate the veranda with our own hands from the outside and from the inside. Outside, insulation is performed if the wall material looks unpresentable. Those. it can be blocks, an old tree, etc.

a) For wooden walls:

- We close up all the cracks in the building.

- We fill the tree with a vertical crate of beams with a step of up to half a meter. It is better to measure the width of the insulation and fill it exactly to its size. Then all the slabs will fit snugly against the crate.

- We insert mineral wool between the beams, securing the dowel-umbrellas.

- On top we fix the waterproofing film with a stapler.

- We decorate with clapboard or siding.

After laying the mineral wool, it is necessary to attach a waterproofing film to the crate with a stapler

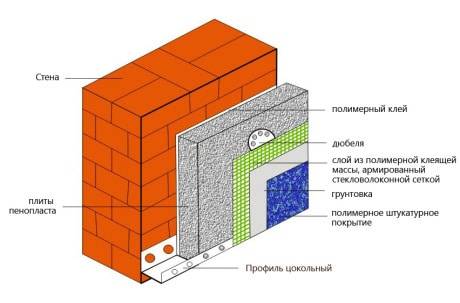

b) For block walls:

- We glue the polystyrene foam plates on the walls with a special adhesive, additionally strengthening the dowel-umbrellas.

- We coat the same glue on the top of the slabs and fix the reinforcing mesh on them.

- After drying, we cover the walls with decorative plaster.

- We paint.

Choose an adhesive specially for laying polystyrene foam boards

All layers of the insulation cake are hidden under decorative plaster.

If the outside of the veranda looks aesthetically pleasing, and you do not want to change its appearance, then you can carry out internal insulation. But, before insulating the veranda from the inside, it is necessary to carefully seal all the cracks (in a wooden building).

Work progress:

- Stuff the crate.

- They fix a waterproofing film with a stapler, which will not let moisture from the street into the insulation.

- A metal frame is mounted from profiles, on which drywall is then fixed.

- The frame is filled with mineral wool.

- Cover the insulation with a vapor barrier film.

- Plasterboard is mounted.

- Apply a topcoat (putty, paint).

The distance between the metal profiles must match the width of the insulation sheets

How to insulate the veranda - materials

With the existing variety of thermal insulation materials,

the choice is still difficult. However, among the well-recommended

myself:

1. Penofol

Flexible foil insulation Penofol can be

used as an independent thermal insulation material or in combination with

other types of insulation.

The material is environmentally friendly, thin, low

vapor permeability, easy to install and fireproof. Among the cons: softness,

small thickness.

2. Styrofoam

Tough, lightweight material that does not change

properties for the period of operation. Easily mounted as a frame or

frameless way. Disadvantages: interest for rodents and flammability.

Note. Warming the veranda with foam removes

the owner from the installation of a hydro and vapor barrier, because the foam has practically

zero indicators of hygroscopicity and vapor permeability.

3. Expanded polystyrene

Possesses all the advantages of polystyrene, and is also very

durable, easy to cut. Cons: low sound insulation, collapses at high

temperature (more than 100 ° C), does not burn, but self-extinguishing does not occur.

4. Mineral wool

Flexible (soft) insulation with low

thermal conductivity, non-flammable, strong in compression (for dense species) and tear,

provides excellent sound insulation, resistant to temperature deformation.

Mineral wool is resistant to chemical and biological

activity. Cons: needs a frame, loses density over time

(caking), which means that the thermal insulation properties are reduced.

6. Polyurethane foam (PPU)

Insulation polyurethane foam is available in three varieties:

- Dense (hard, rigid) panels

- Flexible (soft) plates

- Inflatable (sprayable)

Among the advantages: low weight, ease of installation and application,

resistance to chemical and biological activity. Cons: expensive, spoils

from mechanical stress, prone to aging when exposed to ultraviolet radiation.

Note. Low vapor permeability of polyurethane foam in slabs

will lead to the accumulation of moisture and destruction of wall surfaces or elements

constructions.

7. Flax, tow, moss

Materials designed to perform

warming of a veranda from a bar and a log, without disturbing the appearance of the structure.

Linen, tow, moss - absolutely environmentally friendly, but difficult to

installation. In addition, they are a welcome prey for birds that use

materials for building their nests.

Note.Insulation with these insulators is best done on

stage of construction of the veranda.

8. Synthetic insulation for construction

Polymer insulation allows you to eliminate the disadvantages,

inherent in natural materials. For example, building a veranda using technology

warm house.

How to properly insulate the veranda

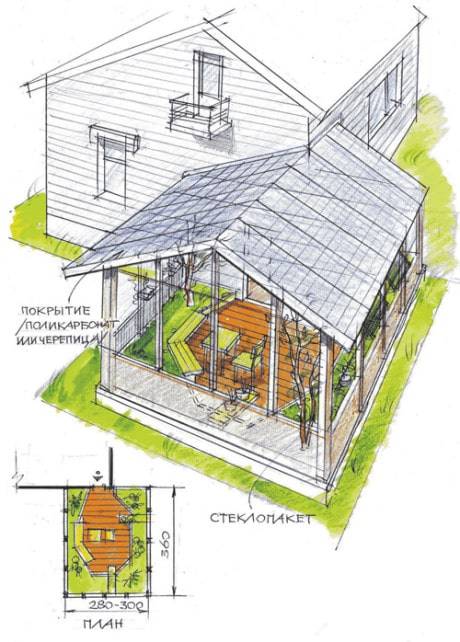

A veranda is a room attached to a house, open or glazed. It is most often a place of rest, but it can also be used for various household needs. Thoughts on how to insulate a veranda sooner or later come to every homeowner.

Relaxing on the veranda is pleasant, because on the one hand, you feel close to nature and breathe fresh air, and on the other hand, you are in a comfortable, almost homely environment. Summer rest on the veranda is wonderful - the breeze flies into the open windows, and the ceiling saves from the burning sun rays.

It is no less pleasant to be here in autumn, when the rain is drumming on the roof, and you can, wrapped in a blanket, snooze in a rocking chair. But now winter comes. And how nice it would be to sit on a frosty fresh day on the veranda bathed in the bright winter sun, admire the snow-covered landscapes!

But the wind sweeps snow in the cracks, drafts instantly blow out heat from the veranda, and the heater becomes useless. Then the question arises about the insulation of the veranda.

How to insulate a veranda outside

Pros and cons of external insulation

External thermal insulation allows you to preserve the interior of the terrace and update the exterior design of the house. This form of insulation has several advantages:

- All dirty work is done outdoors.

- The area of the veranda is preserved.

- The freezing point is carried out beyond the outer boundary of the walls.

- The whole structure resembles a thermos: in winter it keeps warm in the room, in summer it is cool.

The disadvantages include the complexity of the reconstruction in bad weather.

To carry out work on the insulation of the veranda, no permits are required, therefore, having decided on the thermal insulation materials, they begin the process. It is advisable to engage in thermal insulation of the room outside during the warm season.

Ceiling insulation

If the veranda and the house have a common roof and attic, then it will not be difficult to insulate the ceiling. The most convenient way is to fill the cells of the frame with heat-insulating material.

What material should you use? A low budget option: roofing material is spread overlapping or the sheets are joined and glued, and a layer of expanded clay is poured on top or slabs of mineral wool are laid. If possible, it is better to use foil-coated penofol, which keeps heat well and does not allow moisture to pass through.

Ceiling insulation scheme from the attic side

Ceiling insulation scheme from the attic side

Wall cladding with thermal insulation material

The easiest way is to revet the walls with sandwich panels, in which mineral wool, expanded polystyrene or polyurethane foam are used as insulation. The main plus of such insulation is the combination of thermal insulation with external decoration, and you can choose almost any version of the outer layer: metal, PVC, and so on. Choosing decorative log or siding sandwich panels completely changes the exterior of the house.

Thermal insulation with panels of expanded polystyrene, polyurethane foam or mineral wool is performed in two ways:

- If the veranda is insulated in a wooden house, then first a crate is stuffed onto the walls. The pitch corresponds to the size of the panels used. Then the insulation is attached with special dowels ("umbrellas"), on top of which the waterproofing layer is fixed with a stapler. Insulated walls are faced with siding, planking, clapboard or any other finishing material - the choice is huge.

- Heat-insulating panels are fixed to brick or concrete walls with mounting glue.Then the reinforcing mesh is attached, plastered and painted, or a suitable facing material is used.

Brick wall insulation scheme outside

Brick wall insulation scheme outside

Insulation of windows and doors

Ideally, it is advisable to install a ready-made entrance door with the provided thermal insulation (for a private house). If it is not possible to change the door, then the old one should be insulated. To do this, foam rubber (you can get by with a blanket) is fixed with a stapler or glue, then leatherette is attached with furniture nails. A seal is laid around the perimeter of the door.

Thermal insulation is provided in ready-made entrance doors for private houses

Thermal insulation is provided in ready-made entrance doors for private houses

The story is the same with windows. It is optimal to replace old windows with double-glazed windows. If this option is not feasible for any reason, they are insulated from the outside with ordinary plastic wrap. To do this, the slats are stuffed onto the frame, and the film is already attached to them with a stapler.