Construction of a gable roof step by step

Installation of a Mauerlat gable roof

The Mauerlat takes all the load from the roof and transfers it to the walls, so a fairly thick and strong beam is chosen as the Mauerlat. The thickness is chosen based on the thickness of the wall on which it rests. As a rule, they tend to choose the thickness of the Mauerlat bar equal to or close to the wall thickness.

It is necessary to lay the Mauerlat flush with the outer part of the wall, firmly connecting them together. To connect the Mauerlat to the wall, even at the stage of wall construction, anchor bolts or wire are laid (poured into the armored belt). If a wire is used as a fastener, then after laying the timber, it is tightly tied around with this wire and remains firmly fixed in this form. If anchor bolts were walled into the wall, through holes are pre-drilled in the Mauerlat, with which the bar is pushed onto the bolts and tightened from above with nuts with wide washers.

It is also important not to forget to lay a layer of waterproofing material in the form of a gasket between the wall and the Mauerlat. Roofing material or similar materials are usually used as waterproofing.

Read more about fixing the Mauer in this video.

Installing gable roof rafters

After the base is prepared, proceed to the assembly of the gable roof rafter system. The installation of rafters can be done in several ways: install the rafters directly on the roof or perform some structural elements on the ground, and then lift them with special equipment to the installation site. It is quite problematic to correctly put the rafters on a gable roof with your own hands without the help of a partner, so it is better to use help so as not to make a mistake and not to nullify all efforts.

To make it easier to fasten the beams, it is worth marking the attachment points on each wall and connecting the opposite walls with beams (legs), on which the racks will be installed to support the rafters. A ridge bar is installed on the racks, which is a guide for installing the rafter system. In order to connect the rafters as accurately as possible, so that the entire skeleton of the rafters is the same, use templates. This way you can avoid dips and distortions in the roof.

After installing the ridge beam, they proceed to the most critical part - the installation of rafters (already fastened together or separately)

In this case, it is important to constantly monitor the level and evenness of the installation. The rafters are fastened together, as a rule, on nails or with the help of iron staples

Common schemes for placing rafters on a gable roof and attaching them to each other are shown in the figure below.

After completing the roof frame, it is required to install auxiliary fasteners to improve the rigidity of the roof. For this, struts and middle skates are installed.

We invite you to watch a video that clearly shows the installation of rafters with your own hands for a gable roof.

Gable roof lathing

The lathing of a gable roof in the simplest case is the installation of transverse boards on the rafters for laying roofing material on it. But, as a rule, modern roofing is a more complex pie of different layers.

After installing the lathing, the roof is covered with a layer of waterproofing, the layers of which are mounted with an overlap on top of each other, and the joints are fastened with tape.

The next step is to secure the counter battens - slats fixed at an angle of 90 degrees to the main batten. This is to provide a ventilated gap in the roofing pie to get rid of moisture.

At the final stage of the installation of a gable roof, the roofing is laid, the choice of which, as mentioned at the beginning of the article, depends on both several factors, including the financial component

External work on the installation of the roof ends with the filing of the cornices and the arrangement of the gables, if they are not part of the walls. After that, they move on to interior finishing work and roof insulation, if necessary. We will talk in detail about roof insulation in the following articles.

It is worth noting that building a gable roof with your own hands is not so difficult, the main thing is to correctly calculate and follow the instructions step by step so as not to miss important points during installation.

A short video instruction on the construction of a gable roof is presented in the video:

Types of truss systems

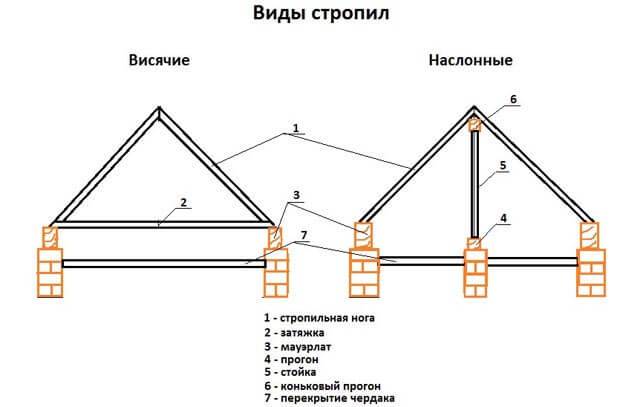

There are two options for the design of rafter systems:

- with hanging rafters;

- layered rafter system.

The fundamental difference between these options is the fulcrum of the rafter legs. The first option also provides for their connection at the top point, when the run (ridge) rests on them. The second option provides a more durable girder with load-bearing functions, and the rafters are fully fixed on the Mauerlat and on the ridge bar.

Both options are actively used. In practice, they differ little from each other, since the features of the implementation of a particular type directly depend on the size of the building and the design of the bearing walls. The construction of houses of medium size forces the use of structures that are more similar to the layered type, providing greater strength and rigidity of the system. Let's consider both options in more detail:

Hanging rafter system

The traditional use of hanging rafters is small houses, with a maximum distance between supports up to 6 m. This is due to the appearance of an additional load - in addition to the weight of the roof and the effect of atmospheric factors, the rafters acquire self-supporting properties. With an increase in the size of the house, the load becomes excessive and requires strengthening of the structure.

A feature of hanging rafter systems is the bursting force applied to the Mauerlat. To compensate for this pressure and protect the walls from deformation and subsequent destruction, puffs located at the bottom of the rafter legs are necessarily used. During construction, they often resort to the manufacture of so-called. rafter trusses in the shape of an isosceles triangle. They are made on the ground or assembled directly on top of the house and installed on the finished structure. This method somewhat speeds up the process of creating a roof, since elements of the same type are used, which allows you to repeat the same operations several times and get the required number of elements.

Rafter roof system

Building medium to large houses requires a strong and rigid roof system. The weight of the roof, snow and wind loads force the use of a layered type of system. It differs, first of all, in the installation technique. First, the supporting elements are installed - the Mauerlat, the bench, the racks and the girder. They have a high bearing capacity and are designed to take significant loads, therefore they are made of timber. The rafter legs are installed with support on the Mauerlat from below and on the girder in the upper part, with a large length, they are reinforced with struts.

Experts note the great reliability of the layered rafter system.When assembling, there are no ready-made parts of the structure, so all work is carried out directly on the top of the building. There is no need to lift heavy ready-made elements, only material is fed to the top. Each strip is installed separately, which allows to ensure the accuracy and tightness of the connection, to avoid poor-quality installation or errors. Compared to structures with hanging rafters, layered rafter systems significantly benefit in strength and allow you to get a better and more durable support structure. In regions with high rainfall, snowy winters, strong gusty winds, a layered rafter system for a gable roof is much preferable and reliable.

How to choose the optimal gable roof rafter design

The main selection criterion is the size and purpose of the building. Small houses that do not have a large roofing area can do with lighter supporting structures. Medium-sized buildings, large buildings must have a strong and powerful rafter system that can withstand the pressure of snow, wind, and withstand the weight of the roof. In order to decide how to make a roof correctly, it is necessary to find out the climatic features in the region, the amount of precipitation, the possibility and frequency of strong winds, heavy snowfalls, etc. These data are involved in the calculation, they are available in the SNiP tables or in the reference literature.

At the same time, one should not be too zealous and build an overly powerful rafter system for a small house. It must be remembered that power is an additional material, and therefore an increase in the weight of the structure. The optimal choice will allow you to get a sufficiently strong and lightweight system that does not overload the foundation and walls, but fully provides protection from external atmospheric manifestations.

Elements included in the roof frame

Mauerlat, as it is often called (roof foundation), is a support beam for rafters installed on the upper part of the walls of the house, evenly distributing the load on the building. In a house made of wood, the last row of the log house acts as a mauerlat.

Mauerlat is installed on brick or block walls using powerful anchors. Mauerlat is made of dried wood, treated with a protective fire-fighting and antifungal agent, with a cross-section of 100x100mm. up to 150x150 mm.

Rafter legs - installed in pairs, on both sides of the roof and fixed on the ridge, thereby forming the rafter system (roof contour).

The pitch of their installation is usually in the range of 0.6-1.2 m, and depends on the type of roofing material used. The heavier the roof is, the smaller the pitch is used. The rafters are made of dry edged boards of conifers, with a thickness of 50 mm. For the safety and durability of the structure, it is also necessary to use special impregnations for wood.

The ridge of the roof is horizontal, the upper line of the connection of the rafter legs to each other. Its height at the beginning and at the end in relation to the upper points of the walls should not differ. You can measure this using the hydro level.

- Racks - vertically installed supports for the rafter system. Depending on the width, the racks can be installed both just under the ridge beam, and additionally in the interval from the ridge to the eaves. Supports are made of edged board or timber.

- Fillets - these elements of the rafter system are required to extend the rafter legs when they are too short and there is no way to make the overhang of the required length. They are attached to the bottom of the rafters by overlapping boards of a smaller section and fastening them to each other with a nail.

- Girders are a horizontal bar that holds the legs of the rafters together. Fastened from the inside at the base of the ridge, or in the center of the rafter legs.

- Tightening - a bar fixed from below that connects the rafter legs, preventing them from diverging.

- Lezhen - a support bar lying horizontally on the load-bearing wall inside the log house, on which stands are installed that support the rafter system.Material - timber with a section of 100x100mm. up to 150x150 mm ..

- Braces and struts - additional supports for the rafter legs, which give the structure additional stability, are attached to a brace or a bed.

- Sheathing - a structure made of bars or boards, necessary for laying the roof, is attached perpendicular to the rafter legs, the step depends on the type of roof. For flexible shingles, plywood sheets are used, laid on the rafters with a solid carpet.

Do-it-yourself gable roof - elements of the rafter system The presence of the above components in the roof structure depends on its type and size. There are two options for installing the rafter system on a gable roof: layered and suspended. In the first version, the rafters are attached: at the bottom to the Mauerlat, at the top to the ridge beam. The ridge must be supported by either an inner wall or vertical posts.

The hanging rafters at the top rest on each other, and at the bottom to the tightening or floor beams. In houses built of wood, the fastening of the rafters to the Mauerlat is made sliding, this will avoid breaking the roof frame when the house shrinks.

Varieties of gable roof

People say: "the roof is a house", that is, it means not only the shape, but also the reliability of the structure, which has a long list of advantages:

- Variety of options for the roof scheme and architectural forms of the roof;

- Simple calculations and cost-effectiveness of the roof;

- Natural runoff of atmospheric precipitation;

- Simple roof geometries ensure low water accumulation and roof leakage;

- Large usable attic area, it is possible to make an attic;

- Good maintainability, high strength, durability and wear resistance of the roof of two slopes.

The three most common gable roof options are:

- Symmetrical gable roof: This is the most popular solution due to its absolute reliability and simplicity of execution. Symmetrical slopes evenly distribute all the loads on the Mauerlat and the walls of the house. The choice of roofing material does not depend on the type and thickness of the insulation layer. The load-bearing loads can be easily increased by making the rafter system from a thicker bar, jibs and spacers can be attached anywhere. A negative factor - a full-fledged attic in such an attic will not work - or there will be low sloping walls with many "dead" zones, or a small but rectangular room;

- Asymmetrical roof of two slopes: Different angles of slope of the slopes reduce the usable area of the attic, but you can make a full-fledged living space on one side. Due to the different angles of the roof slope, the load on the load-bearing walls and the foundation of the house is distributed unevenly, which requires recalculation of the load capacity of the base and the load-bearing walls of the house, recalculation of the types of materials and their quantity, as well as changes in the methods of insulation, waterproofing and finishing;

- Asymmetrical gable roof with internal or external slope: Allows the construction of living spaces without regard to the roof structure. The disadvantages are the same as in the paragraph above.

Mauerlat fasteners

The frame structure made of rafters is fixed to the floor beams. However, in this case, the load on the rafter structure is distributed at the points of attachment of the beams. This approach when installing a roof structure is possible for small and light buildings. Mauerlat is needed to evenly distribute the load of the roof in the upper part of the walls. Mauerlat is mounted parallel to the ridge of the future roof. This is how the main frame is made. A wooden beam with a section of 150x150, 100x100 or 100x150 mm is used for the manufacture of a Mauerlat.

There are different ways of attaching the Mauerlat to the wall

- For installation, special metal pins are used, which are embedded in a metal beam (it is poured along the entire length of the wall). The fastening step in this case is up to 120 cm. The fasteners are staggered. In this case, the thread of the M12 studs is selected. The element can protrude up to 30 mm above the concrete. The height of the Mauerlat bar can be exceeded, taking into account the waterproofing layer of roofing material.Holes must be drilled in the wooden beam through which the material is attached (attracted) to the beam (with nuts and washers).

- If you plan to install a gable roof with an area of less than 250 sq. m, then the studs, with the help of which the Mauerlat is attached to the wall, are laid into the walls themselves even during construction. To ensure greater strength and reliability, the future wooden frame is fastened with studs walled up to a sufficient depth (more than in a concrete beam).

- The wire rod, which is built into the brickwork, allows the installation of the Mauerlat. This method is good in that a small area is taken into account when installing the roof.

An important part of the roof structure - the pediment - is an extension of the wall with roof slopes. On the gable roof, pediments are erected in the form of a triangle. Installation of the rafter system in this case involves the installation of extreme farms, which will serve as their frame. For the competent construction of the frame, the verticality of structures with the same height must be checked. From above, the gables are attached to the ridge (run), then the remaining elements of the rafter structure are installed.

The installation of the rafter system is carried out on the lathing with a step designed for the installation of a certain roofing material (dimensions, degree of rigidity, installation method are taken into account). For flexible materials (bituminous tiles, PVC foil, rolled bitumen roofing material), a smooth, continuous layer is made. Roof insulation is a mandatory stage in the construction of a structure, since you need to take care of minimizing possible heat loss. It can be sheet material that is laid on the frame with a certain step based on calculations.

Types of rafters

Before you put the rafters, you need to find out about their design features and decide on the installation option.

There are two types of rafters: layered and hanging.

Hanging rafters - these are inclined beams mounted on supports with different heights. The support can be the outer walls of the house (in the case of a pitched roof) or both interior and exterior walls (in the case of a gable roof). Rafter legs do not have to be laid in the same plane opposite the slopes. They can be mounted alternately on a ridge girder. The alternating laying of the rafters in the ridge area makes it possible to create a rafter truss. For this purpose, all the details of the hanging rafter systems are connected together into a single rigid structure.

A wooden roof truss must be laid on two extreme supports. Due to the fact that there is no internal support, the rafter legs rest against each other in the ridge connection, which creates a fairly strong horizontal pressure. If the technology of the rafter system was not followed correctly, then too much load may be transferred to the walls, sufficient to destroy them.

To prevent this from happening, experts recommend making a tightening belt at the bottom of the truss. Its purpose is to extinguish the emerging order.

Stages of the construction of the rafter system

can be roughly divided into several stages. If we assume that the box of the house is already ready, then at the first stage you need to make a foundation on which the rafter system will rely. A beam can be in the form of such a support. Its cross-section is, as a rule, 10x10 cm. The beams are laid on the waterproofing. Roofing material can act as a waterproofing material.

The second step is to make racks. They are installed on a beam or on an upper crown. A beam with a section of 10x10 cm is used as racks.When installing racks, it should be remembered that the maximum distance between them should not be more than 2 m.An optimal distance is 90 cm.The construction of such a rafter system entails high costs, but it is more reliable.

The racks should be made strictly vertical. A plumb line or level will help with this. In the future, it is these elements that will become the frame of the walls of the attic room. In addition, the racks must be in the same plane so that the wall is not only vertical, but also flat along its entire length.

Racks to the beam should be fastened with metal brackets or using a spike connection. In order for the struts to remain in an upright position during the entire process, they are reinforced from below with slopes, which have floor beams at their base.

The third step is to make a cross bar. A beam of 10x10 cm is used. It is attached to two opposite and opposite risers at the top points. You can fix it in any convenient way. At the end of such work, a structure is obtained, which is called a rafter frame. Actually, this frame will determine the dimensions of the attic, that is, its width, length and height.

The next step is to make a Mauerlat. This roof element is a beam that is. Mauerlat can be made from a board with a thickness of 40 mm. A similar size can be used.

Installation of the Mauerlat is carried out to the rafter frame along the entire length of each slope. It not only serves as a support for the rafters, but also serves to give greater rigidity to all rafter frames, fastening them together, as well as to transfer the load that the rafter system exerts on the walls.

To protect the Mauerlat from getting wet, a waterproofing layer is placed under it. Since the Mauerlat gives rigidity to the entire rafter system, for its greater stability, it is also fastened with annealed copper wire. A thickness of 3-4 mm will be sufficient for the wire.

When the base for the rafters is ready, you can start installing it. To do everything right, you need to apply the markings. On the Mauerlats, markings are applied on both sides, which shows the step of installing the rafter legs. As already mentioned, the optimal step will be a distance from 90 to 120 cm.First of all, you need to do the extreme pair. It is installed so that the upper point of contact of the two rafters is projected exactly in the middle between the two corresponding risers. Moreover, this point should not go beyond the line of the pediment.

As a material for the rafters, you can use beams 10 * 15, while they need to be installed on the edge. You can also use a board 50 mm thick and 15 cm wide, but it must be straight and free from knots.

After installing the extreme pair of rafter legs, proceed to the installation of the second extreme pair. Further, a twine is pulled between them, which will indicate the plane of the slope, thereby simplifying the installation of the remaining pairs of rafter legs.

After the entire rafter system is installed with your own hands, all pairs should be connected to each other at the highest point, that is, near the ridge itself. This can be done by nailing boards to them.

It should be noted that with a rafter length of more than 8 m, a ridge beam is installed on top, which will serve as a support for the rafter pairs.

Mauerlat installation

If the calculation is completed, and the materials are purchased, you can install the Mauerlat, and then create the lathing. Mauerlat is a kind of foundation for the future roof. Only this structure is not made of concrete, as the foundation for a house, but of pine logs.

Softwood is an ideal material for this, strong and light enough to distribute the weight of the roof evenly around the perimeter of the supporting elements of the house. It is placed along the roof slopes, between the rafter leg and the top of the wall.

For greater safety of the Mauerlat and its long service life, a layer of waterproofing is laid between it and the wall, which is most often a roofing material. Depending on the material from which the house is being built, the installation of the Mauerlat is performed using various methods.

DIY construction involves checking the reliability of the connection. If we are talking about a wooden house, fasteners can be made using pins or bars, in a brick one - they use metal wire, reinforcement, in buildings made of foam blocks, gas silicate - a concrete screed.

Sequence of work

If there were step-by-step instructions on how to build a gable roof, it would start with how to attach the rafters. Hanging ones should be assembled in advance using metal corners and bolts. The first to carry out the installation of the extreme structures, and only then located inside.

To create a layered system, you must first establish a bench on which the supports will be installed. The assembly can be considered complete after fixing all the rafter legs as shown in the drawing. If their length is not enough to create an overhang, it is increased by attaching the fillies.

The next stage is the installation of the lathing. Since its purpose is purely practical, the simplest, cheapest material is used, for example, an unedged board or even a croaker. However, you should not neglect the removal of bark from the surface of the tree, this simple operation will increase its service life. Depending on what is planned to cover the roof of the house, there are two types of lathing:

- Solid. It is used in cases when the choice fell on soft types of roofs that are experiencing a new wave of popularity, in particular ondulin. Since by themselves they do not hold forms, they need a rigid support in order to avoid possible deformations from their own gravity or the weight of the precipitation.

- Lattice. In this case, the board is not laid in a continuous layer, but at intervals, the pitch of which is chosen depending on the material used for the coating. More often, such a scheme is used to create a lathing for metal tiles, slate, corrugated board.

The final stage of work and subsequent operation

The construction ends with the laying of roofing material. It will be difficult to paint the installation of each material step by step, of which there are a lot on the construction market.

Therefore, you will have to limit yourself to general recommendations: strictly adhere to the instructions of the manufacturers, do not forget about the need to overlap between the sheets (rolls) in order to avoid leaks, work carefully, trying not to damage the material.

The gable roof construction guarantees:

- Excellent resistance to wind gusts;

- Light snow removal from the slopes;

- Protection from rain and cold;

- Durability and reliability.