Painting a garden path: how to paint concrete

The inexpressive gray color of concrete is often not very popular with the owners of summer cottages. Therefore, many craftsmen paint the concrete surface in order to get the desired color for their garden path. There are several ways to paint concrete, and now we are going to tell you about them.

So, concrete can be painted by adding pigment to the solution at the mixing stage. This method is very popular because it has many advantages. The painted concrete solution will not lose its color even after a long time, will not wear off and will not fade in the sun. The only drawback of such coloring is that it will take a lot of pigment to get a deep and rich color, and at a cost it will come out pretty decent. This method is used in the production of paving slabs, curbs, monolithic blocks, which accordingly increases the price of the product, and increases the quality and durability. For coloring in this way on the construction market there is a wide range of pigments - in the form of powder, microcapsules, emulsion or paste.

Another popular way is to paint the finished concrete product. Most often, a deep-penetrating compound with a pigment is used for painting concrete. Such staining occurs according to the type of wood processing with protective impregnations. The composition penetrates deep into the concrete and the pigment is retained for a longer time and does not wear off. As a base for the pigment, you can use a colorless base for facade paints, penetrating varnishes, etc.

You can also simply paint the concrete surface with nitro, alkyd or acrylic paint.

Masters do not advise using oil paint when painting concrete, as it clogs pores and the concrete does not "breathe".

Having carefully studied all the methods of painting concrete with our own hands, we came to the conclusion that the first method is durable, but expensive, and the second is affordable, but will not last long.

Features of laying paths with paving slabs in the country

There are a large number of construction companies that are engaged in laying paving slabs. Prices for work depend on the popularity of the company, the complexity of the composition, the technique used and other similar parameters. The price tag also differs depending on the region, as well as the city.

Today it is quite possible to find private traders who are ready to inexpensively lay paving slabs for paths in the country. The price per square meter of work performed by them starts from 200 rubles. Anyone who has some skills in the production of construction work can independently perform the laying of tiles on the paths of their garden.

A beautiful combination of paving slabs with natural pebbles

A beautiful combination of paving slabs with natural pebbles

To carry out the work, you must have a tool: a shovel, a level, a grinder, a drill with a nozzle for mixing a solution or a concrete mixer for large volumes. The work is carried out in the following order:

- Marking is made on the ground. This takes into account all the unevenness of the landscape. If necessary, steps are immediately planned for large differences in elevation.

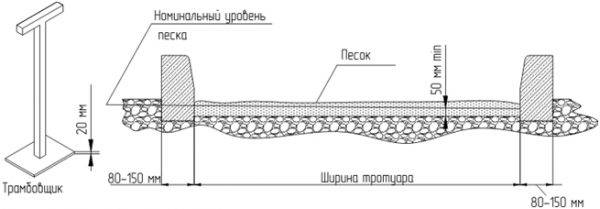

- A recess is dug up to 15 cm deep and of the required width, after which it is tamped.

- Borders are arranged, if they are needed.

- It is backfilled with sand or sand-cement mixture and compacted.

- Tiles are laid.

- Seams are rubbed.

Relaxation area with pool and fireplace

Relaxation area with pool and fireplace

It should be noted that for the device of curved paths, tiles of an arbitrary shape are more suitable.

Helpful advice! Those who wish to drastically reduce the cost of arranging tracks can purchase special molds for self-casting of coating details. Then the price per square meter of laying paving slabs on your site will decrease.

The patio with paving slabs looks nice and cozy

The patio with paving slabs looks nice and cozy

Stylistic varieties of creating garden paths from tiles

To create a unique look for your site, the paths on it must be planned and made in accordance with a previously developed design. The very scheme of laying the tiles is also of great importance. The tiles can be installed in a checkerboard pattern or herringbone pattern. It is possible in a chaotic manner, if you need to achieve maximum harmony with nature. This scheme is suitable for country style.

Grass sprouted in the gaps between the tiles enhances the beauty of the sidewalk paths

Grass sprouted in the gaps between the tiles enhances the beauty of the sidewalk paths

I would especially like to note the possibility of decorating the space around various small architectural forms or objects of the garden landscape. The area surrounding a small pond, paved with paving slabs, in combination with pebbles, will look very natural and attractive.

Paths with patterned tiles, passing through alleys and arches of green bushes and flowers, will add fabulousness to the surrounding space. The tiled area around the house will keep it clean and tidy. This is clearly seen in the photo of paving slabs for paths in the country.

The price for the work depends on the choice of this or that style of design. Laying paving slabs with various artistic delights is a creative business that requires an integrated development of a landscape design project. Therefore, the cost of such work can amount to thousands of rubles.

An original combination of different types of paving slabs and natural pebbles

An original combination of different types of paving slabs and natural pebbles

Helpful advice! One of the artistic tricks when laying tiles is to deliberately leave gaps between parts. This allows the grass to sprout, creating an original style.

When implementing a project for the construction of garden paths from paving slabs, you should show your maximum imagination and be guided by the general rules for choosing a tile and laying it

Review of prices for tiles and their installation

The cost of a tile, as mentioned above, can depend on many factors. Below we take a look at popular tile options with prices.

A simple domestically produced tile can cost about 300-500 rubles per square meter. Foreign options will cost more, but not much, it is quite possible to keep within the same 500-600 rubles / m². The upper limit for elite paving slabs is about 1,500 rubles.

The price for laying the tiles depends on the nature of the additional work. So laying tiles on a base of crushed stone and sand will cost you about 1000 rubles per square meter, but installing tiles on a concrete base is 200-300 rubles more expensive. There is also a difference for laying curbs - from 300 to 600 rubles on average, depending on the parameters of the curb stone. The cheapest way (about 500-700 rubles) will be laying tiles on a ready-made base.

An economical option can be the independent production of products using a mold for paving slabs.

Correctly and beautifully laid paving slabs will delight you for many years

Correctly and beautifully laid paving slabs will delight you for many years

Making a mold for garden tiles

The shape for the tracks is necessary to solve several problems at once when creating an economical, but functional and durable section for movement:

- acceleration of the process of making a track according to pre-planned and executed templates;

- saving on material and using a strictly fixed volume of filling;

- the ability to independently regulate the parameters of the thickness of the coating in order to create the most convenient pedestrian or parking area, as well as recreation areas;

- using a form with the desired configuration allows you to create tracks not one tile at a time, but rather large sections, which reduces the work time;

- the embodiment of an original and individual design that will harmonize perfectly with the surroundings.

Thus, the road area will fully meet all the requirements for landscape design. The sidewalk on the site can be colored, monochromatic, rubber or concrete. You can make a mold for the plates yourself in different ways.

To make durable and high-quality forms for creating a track on a personal plot with your own hands, it is advisable not only to use your imagination, but also to pay attention to the recommendations of specialists:

- The wood form is the simplest and most affordable option. Depending on which tile size is needed, four wooden blocks are hammered into a frame, and the bottom can be made of sheet plywood. After pouring, the tile surface is painted with ceramics, gravel or pebbles.

- The sheet metal mold is practical and durable. This option is most often made of galvanized iron, cut into strips of a given height, fastened in any convenient way. This is a great opportunity to make a garden path with imitation of natural stone of various sizes and shapes.

- No less popular is the form of steel sheet, which should be cut into strips 50 mm wide and bent according to the intended design. Then it is required to decompose the resulting parts and weld their adjacent surfaces.

Geotextiles in the construction of the base for the walkway - should it be used?

Currently, in the construction of garden paths from paving slabs, geotextiles are increasingly used - a material used in agriculture, medicine, furniture production, and construction. The main functions of geotextiles are filtration, separation, drainage and protection against mechanical damage.

The scheme of a walking path for a garden using geotextiles. 1. Curb 2. Curb foundation 3. Initial soil 4. Sand drainage layer - 10 cm. 5. Geotextile 6. Crushed stone layer - 10 cm (fractions 20-40) 7. Leveling sand layer - 5 cm 8. Paving slabs

Many people mistakenly believe that the use of geotextiles when laying paving slabs, first of all, is made in order to exclude the germination of weeds on the path, but seeds that have flown from outside into the inter-tile joints germinate on the path. Common causes of deformation of garden or house paths are soil erosion or heaving. To prevent this, like nothing else, geotextiles are most suitable. Its use has many benefits.

By separating one layer of soil from another, geotextiles do not allow mutual penetration of one soil into another. There is no mixing of crushed stone and, for example, clay, since there is no high concentrated load. For example, in Germany, the use of reinforced geotextiles is an integral stage in the construction of highways, as it increases the service life of the asphalt pavement up to ten times. The use of geotextiles is especially recommended for the construction of paths on clay, water-saturated and peaty soils.

Advice: instead of geotextiles, it is possible to use old linoleum, always with holes punched in it with a certain frequency over its entire surface.

DIY concrete garden path in the form of steps

The terrain for the future path is not always flat - often there are lowlands and hills on the site, which significantly complicate landscape design solutions. Khoyaevs of this house faced such a problem - the path to the garage on their site was located just on the slope. For several years they suffered, slipping in the mud, but then they came up with an ingenious solution! They made a path of concrete and wood with their own hands in the form of steps.

In this detailed master class, they told how they made a concrete path to the house with their own hands.It turned out to be quite simple, and only the materials available and a little effort were required to create the track.

This path is perfect for anyone who has a house located in a hilly area. This landscape move perfectly solves the problem of gentle slopes and sloping paths.

The author advises using metal brackets to connect wooden blocks, the more the better. This will provide a secure fit and improve the durability of the track. In addition, it is better to drill holes in wood and insert iron rods into them - such reinforcement will make your track very durable!

DIY concrete path in the form of paving slabs

Many homeowners like paving slabs, but the opportunity to purchase real paving stones is not always available. A concrete solution comes to the rescue, which, with the help of a form, turns into whatever the master wants. Such a track will be slightly inferior in quality to store tiles, because vibropressing is used there. But for walking paths in the garden, this option is great!

A form for creating a concrete walkway with imitation of sidewalk can be purchased at any store. It is worth noting that the mold in this case must dry out, so it is better to purchase a large number of molds at once in order to improve performance.

The author advises to grease the form with oil and fill it only halfway before filling it. Then put reinforcement (a piece of iron, rod or mesh) in the concrete and add the rest of the mortar.

It is better to remove the resulting plate from the mold only after 2-3 days. In general, concrete dries completely within 28 days.

This imitation of the sidewalk will appeal to everyone who does not like simple solutions on their site!

Stage 1 - Layout of paving slabs - schemes, patterns, drawings

To create a beautiful tile path, you need to make the right sketch. A drawing or scheme for laying paving slabs will help not only visualize the project, but also calculate the required amount of material.

The choice of laying scheme is influenced by the shape (geometry) of the tiles (see photo) and the planned layout design.

Options for paving slabs

Considerable room for maneuver is created by the use of rectangular paving slabs with standard dimensions of 100x200 mm, such as "paving stones" or "brick". They provide the greatest number of styling options.

Traditional options for laying paving slabs:

1. Geometric styling. It can be represented by colored canvases or illusions.

Patterns for laying paving slabs

Patterns for laying paving slabs Patterns for laying paving slabs

2. Illusions 3D - paving slabs with 3D effect. Laying tiles with a pattern that creates a three-dimensional stereoscopic (three-dimensional) image is a clever technology of optical illusion.

Paving slabs with 3D effect

3. Chaotic laying of paving slabs, an example of which is provided below, does not have a scheme in the classical sense. It involves laying out the tiles in an artistic mess. If the tile is monochromatic, then the size of the tiles varies during the layout, if it is multi-colored - the colors.

Chaotic laying of paving slabs

4. The artistic layout of paving slabs, the photo of which is provided below, gives an idea of the variety of different laying options. The complexity of the drawing is determined by the skill or perseverance of the master.

Artistic laying of paving slabs

Why is a pavement covering necessary?

There are several reasons for the high-quality arrangement of the tracks with this or that coating. Most of them are well known to the owners of the sites, but nevertheless they should be re-designated.

Correctly equipped aisles between the beds in the garden solve several important problems at once.

- The first reason is that the paths are constantly overgrown with weeds that sprout into the beds or shed seeds that fall on the territory of cultivated plants. All this ultimately turns into an endless struggle for the harvest.

- If you completely remove the weeds, but then leave the soil open, then in rainy weather it will be impossible to approach the beds without wearing rubber boots, which will then have to be cleaned for a long time from the moist soil adhering to them. Otherwise, the soil adhering to the shoes will spread to the rest of the covered areas of the yard, and then will certainly fall into the living quarters of the house.

- In addition, strips of uncovered land completely cleared of weeds contribute to very rapid evaporation of moisture from the beds. Therefore, the consumption of water for irrigation increases significantly.

- Another reason to equip the paths between the rows is to get the absolute maximum comfort of working in the garden, and as a result - a significant increase in the productivity of this noble work.

- A garden with neatly decorated paths always looks more aesthetically pleasing than with ordinary earthen or densely overgrown weeds.

All of the above negative points in no way improve the mood, since even having vegetables, berries or herbs “at hand”, it is quite difficult to collect them from the garden both during the rain and for quite a long time after it. Therefore, you will have to wait until the soil is dry and slippery and sticky.

In a word, high-quality paths between the beds should be the goal of any self-respecting gardener.

Concrete curbs for paths

Concrete curbs are universal: they can be used to protect not only garden paths, but also beds, tree trunks. A framing of any shape and size can be made from fresh mortar.

There are a lot of design solutions for decorating the edge of the track with a concrete curb. There are even special devices that allow you to independently make the top of the curb curly, for example, semicircular.

If you have never worked with concrete or are not confident in your abilities, then you can use the help of specialists.

A curb made of pieces of concrete is suitable for framing grass paths

However, you can use not only a fresh solution, but also frozen pieces of this material, laying them around the perimeter on geotextiles, which will not give a chance to weeds and prevent soil subsidence. Hosts planted along the path will look especially good against the background of such a border.

Materials for the manufacture of paving slabs

Paving stones and paving slabs have long been made of natural stone - granite, basalt, sandstone and others. Today, artificial materials are more common: concrete, plastic, rubber.

Paving slabs are most often made from decorative concrete - a cement-sand mixture with the addition of dyes and plasticizers. Three different technologies are used for production: vibration casting, vibration pressing, hyper pressing.

Vibration casting. Plastic molds with concrete mixture are placed on a vibrating table for several minutes. Thanks to vibration, water bubbles are removed from the mixture, the concrete is compacted, becoming more durable and frost-resistant.

Vibrated concrete tiles

When "cement milk" forms on the surface of the solution, the molds are removed and left for 2-3 days in a closed room with certain values of temperature and humidity.

After this, the products can be laid, but carefully, since the concrete will gain final strength only after a month.

The method of vibrocasting is widely used in the manufacture of paving slabs by hand, as well as in the production of artificial stone such as "granite", "ultra-concrete" and others.

Vibrocompression is used in industrial automated production. The concrete mix is compacted in press molds under pressure, and the press vibrates continuously. The result is a product that is ready to be laid.

Types by production method

Hyper pressing is also an industrial high-performance method. The semi-dry mix is compacted without vibration under the very high pressure of a hydraulic press.

Hand-made lovers make concrete tiles for garden paths on their own. For this, all kinds of plastic forms are sold, and the vibrating table is easy to make at home, based, for example, on an engine from an old washing machine.

You can make a molding tool yourself from wood, plaster, silicone, or use cheap food containers. It is advisable to treat the finished products with a water repellent agent to make the concrete water-repellent.

Paving slabs

Recently, a new type of paving slabs has appeared on the market - polymer sand. It is made from a mixture of sand (75%) and granular polymers (polyethylene, polypropylene, polystyrene) with the addition of dyes. Manufacturers claim the following advantages over concrete:

- great strength, wear resistance, durability;

- resistance to aggressive environments, oil, gasoline;

- low water absorption;

- frost resistance - withstands at least 500 freeze / thaw cycles;

- reliable adhesion to shoes on wet surfaces;

- light weight.

Safe rubber cover

The disadvantages include thermal expansion in the heat, therefore, when laying with your own hands, it is necessary to maintain inter-tile distances of 5-8 mm.

Rubber tiles are made from crushed car tires and polymer glue. Its main feature is elasticity. It is non-slippery and non-traumatic coating, therefore it is used in playgrounds, on terraces, around swimming pools.

Installing the curb

A border is a necessary structural element that performs several functions at once. First of all, it separates the area of the soda lane from the lawn. In addition, the curb helps to maintain the integrity of the structure. The appearance of the curb is selected depending on the decor of the tiles and the personal preferences of the owners of the site.

To install the curb with your own hands, you will need to dig a trench along the edges of the path. Its depth should be slightly deeper than the height of the curb. Then, a layer of sand approximately 5 cm thick should be poured onto the bottom of the channel. When installing each product, it is worth observing a slight slope so that the upper line of its edge is parallel to the tile. After installing the element, you need to tap it with a mallet.

The distance between the extreme line of the track and the curb should not be too great. A distance of 5-7 mm is considered ideal. This gap is filled with sand. The material must be carefully tamped. Thus, the curbstone is installed.

Metal curb for walkway

Metal curbs are ideal for paths with soft surfaces (gravel, wood mulch), which prevent small components of the loose layer from scattering over the site. In addition, this fence, driven to a certain depth into the ground, prevents the growth of plant roots in the soil.

The metal curb is a strip of steel, aluminum or copper. It is much easier to install than concrete. And although such a fence looks rather modest, it performs its function of dividing territories impeccably. And for the decoration of areas with strict geometry, a metal border is excellent, therefore it is widely used by landscape designers.

However, metal curbs can be replaced with cheaper plastic ones, which are durable and easy to install.They can be installed along the perimeter of tracks with any coating.

Excess soil excavation

After clearing the territory of the track and laying out its coordinates on the ground, we proceed to the removal of soil. The first question is how deep to dig? The distance between the plane of the track (stretched string) and the lower level of the soil to be removed consists of: the carrier layer (crushed stone) - about 15 cm, the leveling layer (sand) - 3-5 cm, and the tile itself.

For information: in this case (with a tile thickness of 7 cm) this distance is 25 - 27 cm. Do not forget that the top mark is a string, and from it we measure 25 cm deep.

When removing soil, use both a bayonet and a shovel. Part of the removed soil will later go to sprinkling of the curbstone from the outside, part to the layout of the area, and part to be removed from the site.

At the end of excavation to the desired depth, it will not be superfluous to walk over the entire surface of the bed of the track with a rammer (the most affordable option is a wide log with a cross handle).

Do-it-yourself paving slabs made of concrete master class

Paving slabs are the most popular option for a garden path. However, paving slabs are not the cheapest pleasure, so many craftsmen prefer to find an alternative to an expensive option. The author of this master class found such a method and made the paving slabs on his own.

You don't need to be a builder with a lot of experience to make such a tile. The author of this step-by-step instruction described all the stages of work in great detail, so there will be no problems with creating this track. So, to create paving slabs you will need:

- tile molds (30 * 30 * 3)

- cement М500

- sand

- gravel

- mold oil

With the help of detailed step-by-step instructions, we fill the molds and leave them to dry. The master, to improve the quality of the tiles, made a vibrating table with his own hands. Such devices are used in industrial production, and make the tile much stronger and stronger. In the same way as for tiles, the author advises to make curbs so that the look of your garden path is harmonious and complete.

With the help of simple devices and precise instructions, concrete paving slabs are easy to make at home. After making the tiles, they are laid according to the standard scheme, on a sand cushion.