Options for summer cottages made of logs

Arbors chopped from logs differ from each other:

- by the type of material used;

- by form;

- by design features.

The most common is the rectangular (square) design.

When selecting the materials from which the structure is being built, it is important to take into account that the structure is constantly exposed to the negative effects of the external environment:

- sunlight;

- moisture;

- temperature drops.

Therefore, before building a gazebo from a log with your own hands, you need to purchase means to protect the material from decay and fire.

By material

In the manufacture of arbors for summer cottages from a bar, various materials are used. For the construction of supporting elements, the following are often used:

- oak;

- larch;

- cedar;

- fir;

- Pine.

In the construction of structures from a log, pine support elements are more often used. This material is resistant to moisture, so it does not rot for several years. But in comparison with other types of wood, pine is much cheaper.

For the construction of a gazebo from a 100x100 bar with your own hands, glued material is suitable. The latter consists of several boards pressed together. And due to the fact that an adhesive composition is used in the production process, a durable bar without cracks and cracks is obtained. Standard blanks are produced with a cross section:

- 100x100 mm;

- 150x150 mm.

Such a bar is used for the construction of the base and frame. For strapping, rafters and logs, you can use material with a section of 100x50 or 100x40 mm.

By form

Arbors made of wood come in the following forms:

- square (rectangular);

- round;

- 6- and 8-sided;

- oval.

In small areas, square structures are suitable. It is recommended to build structures of a similar shape if it is planned to erect a closed gazebo from a rounded log.

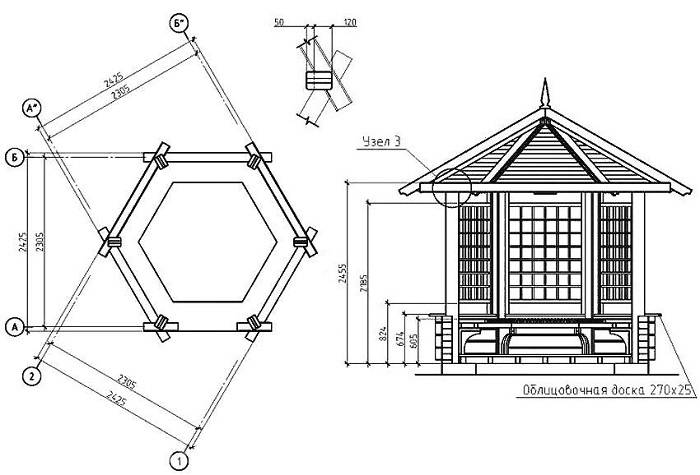

The 6- and 8-sided wooden structures are distinguished by their beautiful appearance. In addition, due to their design features, such structures take up relatively little space.

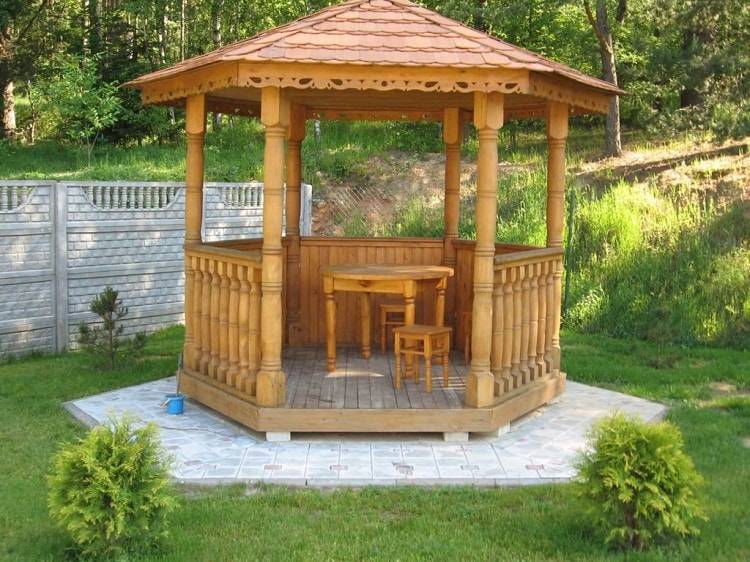

Hexagonal gazebo

Hexagonal gazebo

By construction type

There are three types of gazebos:

- Open. They are structures devoid of walls and windows. The opening of the gazebo made of wood looks like a pavilion in which air circulates freely.

- Closed. It looks like a small wooden house with windows and doors. Closed structures are often used as a summer kitchen.

- Semi-closed. Such structures made of wood have 1-3 walls. Semi-closed structures are installed if there is a need to close the wind access to the inside of the structure.

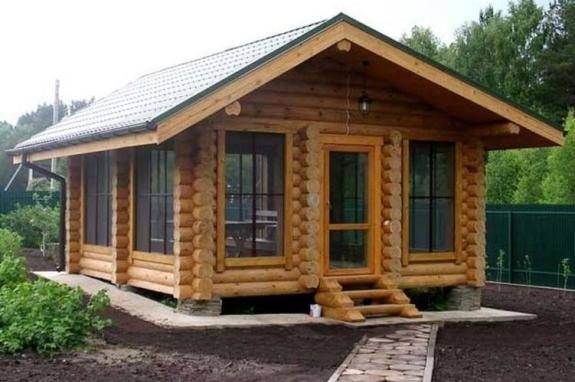

Closed log gazebo

Closed log gazebo

Regardless of the type of construction, if desired, at the summer cottage, you can build a gazebo from a log with a barbecue or barbecue. If an open structure is planned, a separate chimney is not required to organize the specified zone.

Types and types of wooden arbors

There are several types of pavilion designs, which are selected depending on the preferences of the owner, the seasonality of the use of the structure, the general style and size of the site. There are three main types of arbors:

- Open. They are a frame with a roof. The building is used only during the warm season. Curtains can be installed to protect against insects, wind, rain.

- Semi-open. Along the entire perimeter of the building, wooden gratings, fences, and small sides are installed.

- Closed. The buildings have full walls and glazed windows. With a heating system, they can be used even in the cold season.

Among the wide variety in shape and size, the following typical designs can be distinguished:

- Rectangular, square. The most practical, standard option.

- Polygonal. They are distinguished by their unusual appearance and complex installation.

- Round. They represent a classic semi-antique rotunda, often decorated with ampelous, climbing plants.

- Combined.Two-storey buildings can have sites of different shapes.

By design features, the gazebos are divided:

- With the presence of a floor. The structure has a bottom rail with a floor covering laid on it.

- No gender. Installed on a finished base, lined with paving slabs, paving stones, stone, poured with concrete.

Separately, frameless structures can be distinguished, which are a construction of a wooden bar fixed on a strip, columnar foundation. The walls are erected close to the roof from all or only from two sides. Volumetric semicircular, round versions of interconnected boards look interesting.

Roof structures for gazebos

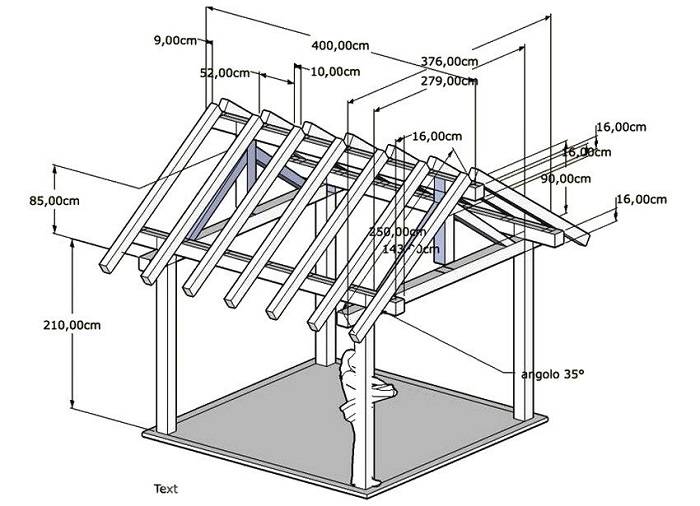

The type of roof depends on the shape and size of the gazebo itself. For do-it-yourself structures, it is better to choose simple options, in the form of a one-, two-slope roof. More complex forms will require drawing up a project, additional calculations, and special skills. Among the existing varieties, the following models can be distinguished:

- Flat. It is characterized by simple installation, but precipitation accumulates on top. In winter, it may not withstand the load exerted by the fallen snow.

- Shed. In fact, this is the same flat roof, only located at a slight angle. The bottom should be on the leeward side.

- Gable. The most popular option for rectangular arbors. Has an attractive, neat look.

- Four-slope (hip). Consists of two trapezoidal and two triangular planes.

- Tent. All rays are represented by the same isosceles triangles.

- Round (domed). The most difficult option. Consists of curved elements of the same shape.

- Multi-slope. A complicated design with several skates and planes of different structure.

From metal and wood: how to make a gazebo with your own hands?

If you decide to build a metal structure, then it is better to use a profile pipe, the wall thickness of which should be at least 2 mm. This is because round pipes are more difficult to cook.

If you intend to use a roof made of lightweight material: flexible tiles, corrugated sheet or slate, then a profile with a cross section of 50X50 cm is suitable for the racks.And in the case of tiles, it is recommended to use a pipe with a cross section of 75X75 cm. As lintels, you can use a metal profile whose cross section is not exceeds 50X50 cm.

The selected site must be cleaned of debris and grass so that it does not rot under the floor. Then dig a hole, cover it with a layer of sand. The pipes can be installed directly into the ground.

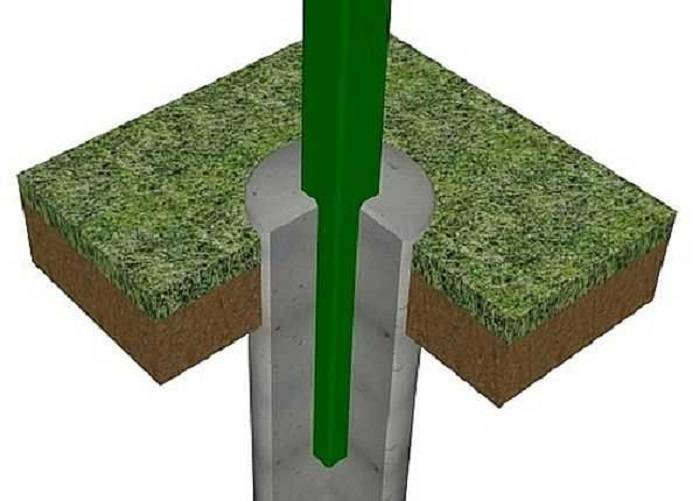

With the help of a drill, make shallow pits, about 90 cm. Pipes are inserted into them and covered with rubble or construction waste, after which everything is carefully rammed. The rack must be filled with cement mortar.

Vertical posts should be checked with a plumb line.

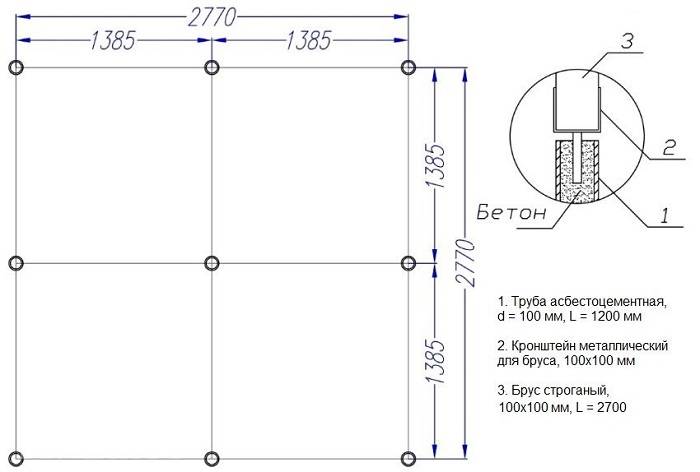

If it is necessary to slightly raise the structure, then it is recommended to use foundation blocks. Then place them all over the area, as shown in the image below.

At the next stage, the lower strapping is made, for this, pipes with a cross section of 50X50 mm are laid on concrete blocks. The coals are cooked by the apparatus. A profile with a cross section of 40X20 mm is suitable for jumpers, boards will be laid on them.

The profile must be primed, especially at the joints. The height of the posts should be just over two meters. To strengthen them, the jibs should be welded.

The middle harness should be about one meter high. For this, a pipe with a cross section of 40X20 mm is used. For stiffening, it is recommended to fix the vertical posts as shown in the image below.

The middle harness should be about one meter high. For this, a pipe with a cross section of 40X20 mm is used. For stiffening, it is recommended to fix the vertical posts as shown in the image below.

If bitumen shingles are used as a roof, then the roof rafters must be made of a wooden bar with a section of 75X40 mm.The lathing can be made from wooden lining. In the upper part, the rafters are attached with self-tapping screws.

Fix the board in the middle, and nail a beam to it, on which the rafter system will rest.

The image below shows how to fix wooden jibs from a bar with a section of 75X40 mm.

After that, you need to spread the shingles.

For the floor, a board with a section of 70X40 mm is used, and for the walls a board of 70X20 mm.

In this way, you can build a structure using two types of material in a few days. For the installation of the structure, you need to have experience with the welding machine, and at the other stages, difficulties should not arise.

What material can be used to build a gazebo in one day

The gazebo at the summer cottage was created in order to provide a comfortable rest and pleasant pastime. Such designs are of varying complexity and can be made from various materials.

The simplest option available to every gardener is a lightweight gazebo without a foundation, which can be built in one day using special tools. For its manufacture, you can use wood, metal or polycarbonate. The choice of material depends on the general design of your site, financial capabilities and the purpose of the structure.

Wood

For the construction of a gazebo made of wood, you can use almost any beam. Such a structure most often does not have a foundation, and its basis is bricks, small concrete blocks or paving slabs. They must be evenly distributed around the perimeter of the future gazebo.

Important! To prevent the wooden beams from cracking during installation, it is recommended to pre-drill holes in them. So, you can easily tighten the screws and protect the structure from premature damage .. The great advantage of this material is its availability and ease of use

To increase the service life of the structure, it is recommended to cover all wooden elements with protective agents. The natural texture of wood will give the structure a primeval beauty and charm. Such a gazebo will organically fit into any exterior and emphasize the charm of the surrounding nature.

The big advantage of this material is its availability and ease of use. To increase the service life of the structure, it is recommended to cover all wooden elements with protective agents. The natural texture of wood will give the structure a primeval beauty and charm. Such a gazebo will organically fit into any exterior and emphasize the charm of the surrounding nature.

Metal

Metal structures with forged elements are able to give the site elegance, sophistication and create an effect of lightness. In general, such gazebos are quite durable and reliable, but they have a number of disadvantages.

This material corrodes over time, and keeping the structure in good condition is always quite problematic and costly.

It is also important to note that not everyone is able to install such a gazebo alone. This, at a minimum, requires welding skills, additional equipment and a team of assistants.

Polycarbonate

This material is gaining popularity among gardeners who want to create a spectacular and stylish place to relax on their site. In operation, polycarbonate is quite lightweight and maneuverable, but such a structure will not last long. This is due to the limited service life of the material: it dries out under the influence of direct sunlight and cracks.

Find out how to design a recreation area on your site.

Also, for laying polycarbonate, you will need special knowledge, because if improperly installed, water will get into the joints. As a result, condensation forms, which leads to rapid wear.But, in general, subject to all the rules, such gazebos look quite stylish and will become a real decoration of your site.

Arbor made of wood only (wooden) - instructions and drawings

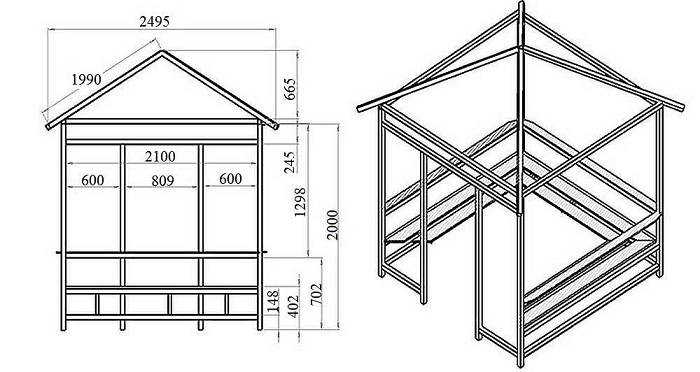

Wood structures can be very different. If you first decided to build a structure, then it is better to choose the simplest shape - square. The drawings of such a gazebo are quite simple, so everyone can figure them out.

First you need to choose a suitable place, as well as decide on the appearance. After that, create drawings of the structure or use ready-made solutions. On the diagram, it is imperative to indicate all dimensions, the shape of the structure, the entry point and other parameters. If it is planned to build benches and a table into the structure, then they must also be indicated in the sketch.

You also need to prepare a separate drawing of the roof and foundation, with its specification. In addition, you need to take into account the consumption of wood processing products. In the diagram, it is necessary to indicate the supply of water, as well as the electrical wiring and installation locations of lighting devices, if they are expected to be present.

If you doubt that you can prepare a sketch yourself, then you can use the services of professionals.

It is recommended to buy consumables with a margin, since in the process of work, some of them may be damaged, and it is also possible that some parts will be defective.

You need to understand that the construction of a structure is a laborious process, so you need to stock up on time and patience. It is recommended to strictly adhere to the prepared project. Provided that all stages of construction are consistently completed, the gazebo can be made with your own hands in a couple of days. To do this, you need to purchase all materials in advance and prepare the necessary tools.

Foundation

After you decide on the place of the future structure, you need to clean it of debris and, if necessary, level it.

The next step is to make the markup by driving in wedges in the corners, between which to pull the lace.

If you want to build a small gazebo, then a columnar or strip foundation is best suited, since the square structure will be lightweight.

To prepare the base, it is necessary to dig a pit, the depth of which does not exceed 80 cm. Then fill it with a 5-cm layer, and then a 10-cm layer of cement mortar.

When the mixture hardens, you need to install vertical racks, which are temporarily fixed with special jibs. First, you need to place small metal pipes of the same size in the pit, pour concrete into them, and then fix the anchor. After about two days, the racks are attached.

Construction floor

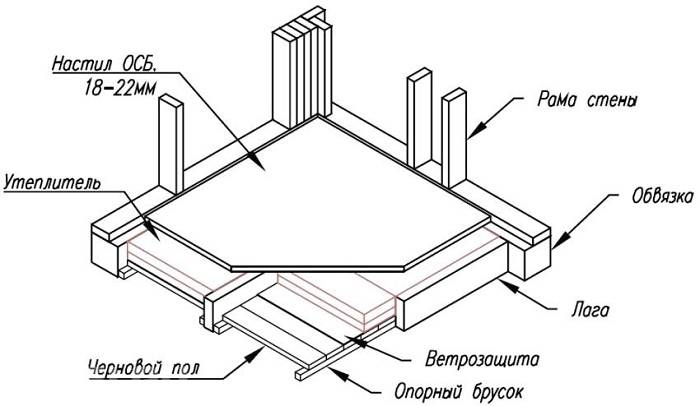

At the next stage, using a 50X150 bar to make the strapping, I will lower the racks. Then logs are laid out with a step of 45 cm, which are attached with a horizontal strapping to the bar with special corners.

To fasten the upper harness, you need to install intermediate posts, which are fixed to the logs using ordinary nails

It is important to note that the racks must be strictly vertical. They are also needed so that the structure can withstand the weight of the roof.

As a floor covering, it is recommended to use an edged board, which must be pre-treated with special agents in order to increase its service life. The material is fastened on both sides. It is best to use self-tapping screws, as nails can split the board.

The next step is to make the top harness. To do this, you need to prepare a beam with a section of 10X10 cm. The image below clearly shows an example of how to do this.

Roof

Since the structure is square, it is recommended to make a hipped roof.For manufacturing, you need to prepare inclined rafters from beams and fasten them with nails. One edge of the brace must be fixed to the rafter legs, and the other to the horizontal strapping.

The roof is covered with an edged board and fastened with self-tapping screws. Some experts recommend using plywood. Flexible shingles can be used as a covering.

At the final stage, all wooden elements need to be covered with a double layer of varnish. This completes the construction of the square gazebo. If necessary, you can arrange furniture indoors for a more comfortable stay.

You can also watch a video on this topic:

Types of wooden arbors

Modern gazebos can differ from each other in many aspects. Some people prefer to install simple square closed-type buildings on their site, which serve as a platform for rest and meeting with guests. Such designs are hidden from strangers, which is very convenient if you want to communicate face to face. Others turn the gazebos into real works of art, highlighting the decorativeness, rather than the practicality of the design. The end result depends primarily on the drawing as well as the materials chosen.

By form and design

In modern landscape design, of which garden gazebos are a part, various types and forms of this structure are distinguished. It can be open or closed (depending on the amount of wood covering), and also often differs in the number of corners

Increasingly, summer residents are paying attention to the original hexagonal or octagonal options, moving away from the usual square gazebos. Round designs are also popular.

With the right blueprint and materials, creating each of them won't be a problem.

Separately, there is a belvedere, which is a summer-type building, necessarily installed on a hill or hill. The view of such a gazebo is always circular. Pergolas are mounted next to pools and other reservoirs - open-type multi-tiered frame structures.

Did you know? The first gazebos began to be made back in Ancient Egypt in 2000 BC. NS. At that time, this was the advantage of the pharaohs, who decorated them with marble, gold and various precious stones.

By material

The main advantages of wooden buildings in the country are their strength, durability, as well as environmental friendliness, which is extremely important in the conditions of modern life. Since the installation does not imply anything complicated, structures of various shapes and sizes can be produced.

Wood also has its drawbacks, for example, it is not resistant to fire, moisture, and insects. You can eliminate these disadvantages by treating the board with special means. You can use various types of wood to create a gazebo: oak, cedar, beech, etc.

The main types of materials used should be considered:

- Profiled timber - this material has a high strength, which makes it possible to use it in the construction of baths, arbors and other outbuildings. The second advantage is that over time it does not change in appearance (does not rot, does not warp). The shrinkage percentage after the completion of the construction process is very low. Due to the high rate of heat preservation, it is recommended to use a profiled beam when building closed-type gazebos. For the manufacture of profiled timber, mainly such species as oak, pine, linden, eucalyptus are used. The latter material has a rather pleasant specific smell.

- A block house is a lumber that is used primarily for sheathing a finished frame. It has a semicircular shape, therefore, in its finished form, such a structure is somewhat reminiscent of a real rural log house. Such a structure is assembled quite simply, and also has excellent thermal insulation characteristics, so it will be possible to gather for tea in such a room even in cold windy weather.

- Grooved board - this material is no different from a block house in terms of technical indicators, but it has a different appearance. Such wood does not have a semicircular cut, but is absolutely flat. The material is fastened to the frame using spikes and grooves located on the sides of the board.

- Carved board - ordinary wood can be easily turned into a real work of art if it falls into the hands of a master. Gazebos with various patterns look very beautiful and even fabulous, especially if they are then painted or opened with a dark varnish. Carved railings or shutters look very original. But you should not waste your time on this, since beautiful and intricate patterns are beyond the power of beginners. Better to order individual items from a professional.

Whatever material you choose to create a homemade wooden gazebo, you should definitely complete the processing of raw materials. This guarantees the durability of the structure and its resistance to water or insects. For this, parts of the holiday cottage are impregnated with a wood preservative, then primed and the next day covered with persistent facade paint or varnished. Some experts recommend simply waxing the surface, which will take longer, but will also create a thick, protective layer.

Advantages and disadvantages of wooden arbors

Before building a gazebo on his site, each owner takes into account all the advantages and disadvantages of the materials used in construction, giving preference to the most suitable ones. It is no coincidence that the majority opt for wooden structures. This is due to their merits, namely:

- relatively low cost of raw materials;

- the wood is environmentally friendly, has a natural pattern;

- does not heat up under the sun;

- allows you to build any non-standard structures in one or even several floors;

- compatibility with any stylistic design;

- long service life;

- the ability to combine with other building materials;

- the tree is easily processed;

- installation work can be done by hand, with minimal construction skills.

They are not devoid of structure and weaknesses, which are expressed in the following:

- when erecting a barbecue, it is necessary to follow safety rules, since wood is highly flammable;

- raw materials are subject to decay, poorly tolerates moisture, temperature changes;

- is a good food source for various pests.