Making a garden swing: step by step instructions

Doing a garden swing yourself is an interesting and not as complicated process as it might seem. We bring to your attention a step-by-step instruction with a photo of making a swing made of wood with an A-shaped frame.

Choosing a location is the first and very important step. You cannot install a swing in a place you just like. You should choose a surface with a perfectly flat relief. This will simplify the installation process. In addition, it is better to choose a place for installation away from prying eyes. Then it will bring peace and satisfaction.

Selection of inventory and purchase of material

For a wooden structure, you will need a beam of good quality, without cracks and knots. Oak, birch, spruce or cedar are fine. For the frame base, you will need:

- cedar timber (10 * 10 cm) - 4 units. 3 running meters each (for side supports);

- cedar timber (8 * 8 cm) - 1 unit. 2.5 running meters (for the manufacture of a crossbar);

- edged board (3 * 10 * 60 cm) - 1 unit. (for side brace).

For the bench you will need additionally:

- cedar timber (4.5 * 5.6 cm) - 12 running meters;

- sheathing board (2.6 * 4.6 cm) - 18 running meters;

- pillows - for decoration (if you wish, you can make it yourself);

- suspension and fastening (chain, metal corners, suspensions, furniture bolts, various self-tapping screws).

As for the construction tool, for the manufacture of a garden swing, store the following necessary items in your inventory:

- Bulgarian.

- Plane.

- Screwdriver.

- Level.

- Electric drill.

Well the preparatory work is completed, it's time to start making a home-type swing.

Creation of side racks

Advice. The base of the side posts should be at least 0.5 m wider than the seat.

- First you need to calculate the upper corner of the rack.

- Then you need to draw out the dimensions and work with a jigsaw.

- The next step is to connect the structural parts.

- It is necessary to connect the upper parts of the beams, fastening with furniture bolts.

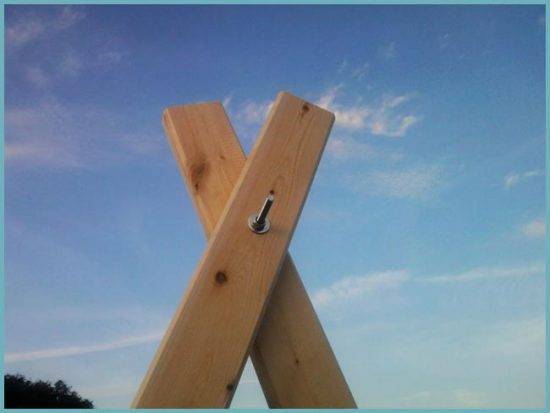

- Next, you should proceed with the side ties. Externally, the racks should resemble the letter A. Therefore, you will need to mark the bars from the height of the soil.

- Then the screeds are marked. Parts are cut and fixed with screws and corners.

Seat installation

To make a comfortable seat, you will need to make two frames with dimensions of 20 * 5 cm. And one more (back) - 20 * 6.5 cm.

- Their inner contour is fixed with stiffeners.

- Then you need to connect the back and the seat using corners and screws.

- Sheathe the seat with a special board.

Attention! Armrests can be mounted on request. Then attach the suspension to the seat by means of eye bolts.

Then attach the suspension to the seat by means of the eyebolts.

Swing installation

Almost all work has been completed and there is very little time left before your site will be decorated with an eco-friendly and comfortable swing made of wood.

- Install the bearing support on the uprights using self-tapping screws.

- Dig holes for the support posts.

- Pour crushed stone into the pits, install racks and fill everything with concrete.

- Correct the inclination of the side struts with a spirit level.

- Secure the uprights with rope ties. They should be in this state until the concrete hardens completely.

- Before installing a garden swing, the wooden structure must be varnished.

The final stage

Check the fixation of the crossbeam.

- Drill holes in the beam to hold the eyebolts.

- Install the seat.

- The swing is ready. Enjoy the fruits of your own labors!

A garden swing is a great option for relaxation in the country. It is especially pleasant when they are made by hand. It will take a little time to make them, but you can enjoy the result every day!

Making a swing with your own hands

Step-by-step construction instructions can be considered using the example of the simplest swing made of wood:

- Before starting work, it is necessary to prepare 4 beams with a length of 3 meters, and make two structures of them in the shape of the letter L. The angle of connection of the bars is 50 degrees.

- It is imperative to make flat surfaces for the supporting structures.

- On the border of the lower and middle third of the length of the supports, wooden puffs are made, two on each side.

- The resulting supports are connected with a crossbar made of strong material (oak beams can be used).

- The "legs" of the frame are dug into the ground to a depth of 60 cm.

- The bench itself is made according to the principle of an ordinary bench with a high back.

- Eye bolts of sufficient size and strength are mounted in the crossbars of the back and armrests. The same bolts are attached to the upper crossbar.

- The bench is hung on a thick strong chain and attached to the upper beam.

The final stage of construction work is the decorative finishing of the swing: painting, opening with varnish, forming a pattern (if you have woodcarving skills).

Construction type

The choice is small - stationary swing, collapsible or suspended. It is unlikely that a tree left on the site in the winter will last long. From the point of view of practicality and reasonable economy on materials, it is advisable to dwell on the second or third option.

Naturally, we are not talking about the complete dismantling of some types of collapsible swings. Every year at the end of the season, no one will take the same supports out of the ground in order to do everything anew in the spring. But it is not out of place to think about the possibility of partial disassembly of the structure.

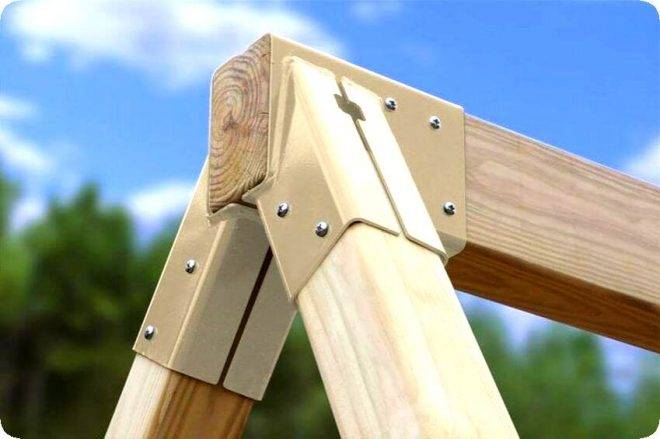

In this regard, one should competently decide on the fasteners and methods of connecting the component parts. The fact that nails are definitely not suitable for assembling a mobile structure is understandable. Staples to strengthen it as well. The best choice is metal plates (corners) and self-tapping screws, bolts.

Swing for a summer residence with your own hands

Simple designs of a swing can be completely done with your own hands. There are the simplest models, which will not be difficult to design, even without having the skills to work with wood or metal. If you have a special tool, you can tackle more serious structures. Next, we suggest that you familiarize yourself with some of the options.

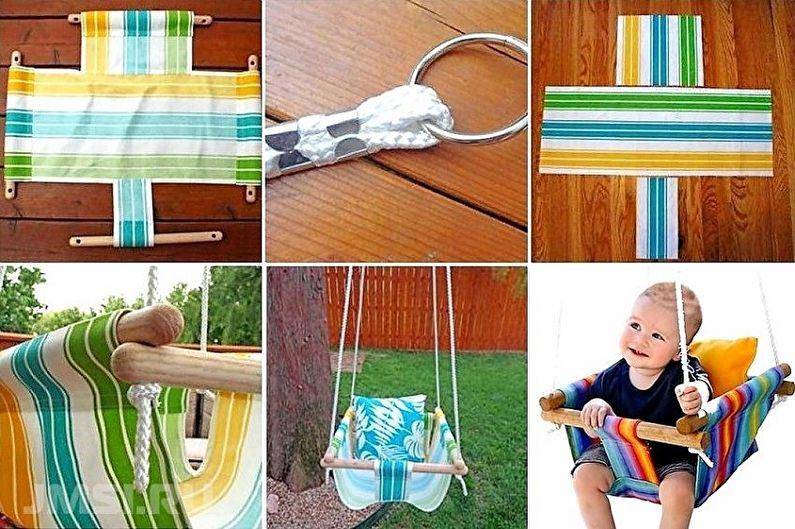

Hanging swing for a summer residence with your own hands

The easiest way to make a swing with your own hands is to make a suspended structure, which will be designed primarily for children. First you need to prepare a place, level the site. Then two holes for the posts are dug, their depth should be about a meter in order to ensure good stability. The prepared pillars are buried and the crossbar is fixed on them. Next, you need strong ropes or chains to hold the seat. For the manufacture of the seat, durable natural wood is used. The board must be thoroughly cleaned, it can be painted, varnished or covered with cloth.

If you doubt the reliability of the U-shaped support, you can make an X-shaped one - then you need four identical pillars, fastened in pairs, as shown in the photo. Sometimes the swing is simply attached to a sturdy branch of a massive tree.

For a seat, you can use not only a wooden plate, often tires from cars are used for this. Fancy original figures can be cut out of them. You can also make a seat from fabric and slats for the smallest, use the base of a wicker chair (without legs) or the most common small pallet.

Garden swing made of metal

If you have welding equipment, you can make a simple but very reliable swing from metal. Most often, support pillars are made from a metal pipe with a diameter of about 5 cm.They are welded in pairs, and a crossbar of the same diameter is welded on top.

The support can be installed in the ground, fixed with cement mortar, or additionally welded on the lower base, which will ensure their stability and balance on any level surface. Such a swing can be freely moved to the desired location.

The seat can be metal, but it is more practical to make it from wooden planks that do not heat up in the sun; an elegant vine seat is an excellent option. Strong chains or metal slats will act as holders. It also does not hurt to equip a canopy that protects from sunlight and precipitation.

Garden swing made of wood

Wooden beams are much more pliable in processing, which makes it possible to make a wide variety of designs on their own

Here it is important to correctly draw up the initial drawing and take a responsible approach to the choice of material. A pine bar is quite suitable for the manufacture, you will also need power tools, a jigsaw, a plane, a grinder, etc.

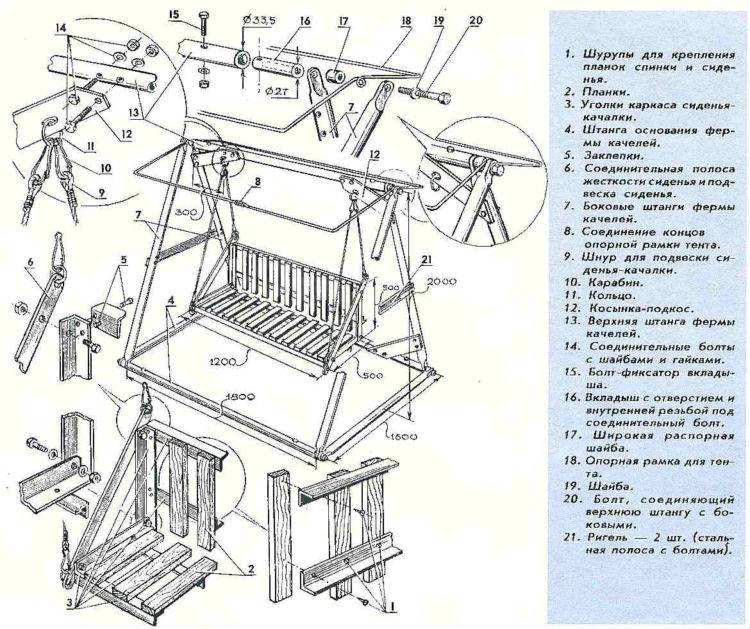

Wooden parts are cut according to the drawing and sanded. First of all, you have to sweat over the seat structure. First, a frame is assembled from three corner elements, to which the transverse rails of the seat and backrest are then attached (you can equip the structure with armrests).

The next step will be the formation of L-shaped racks. To do this, you need to cut special grooves at an angle. The design must be supplemented with a lower bar for reliability.

Using clutches, carabiners and chains, the seat must be attached to the base. Ready-made swings can be painted, opened with stain, varnish, or a canopy made of fabric or polycarbonate.

Frame fabrication and installation

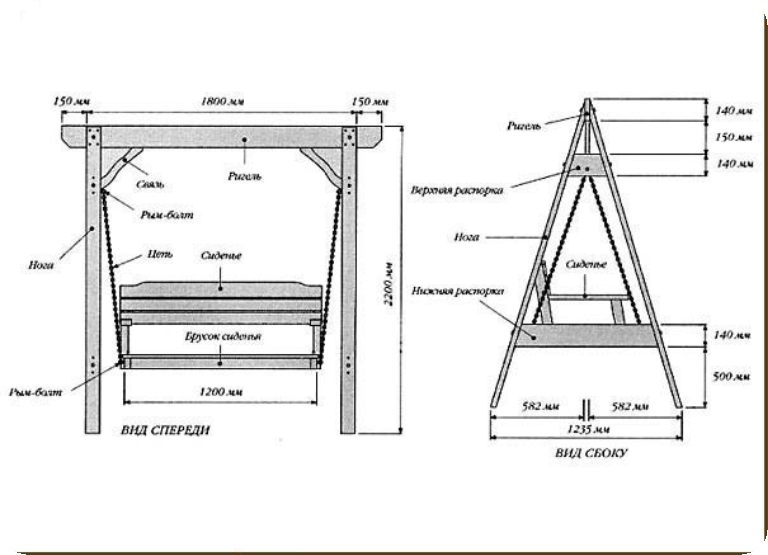

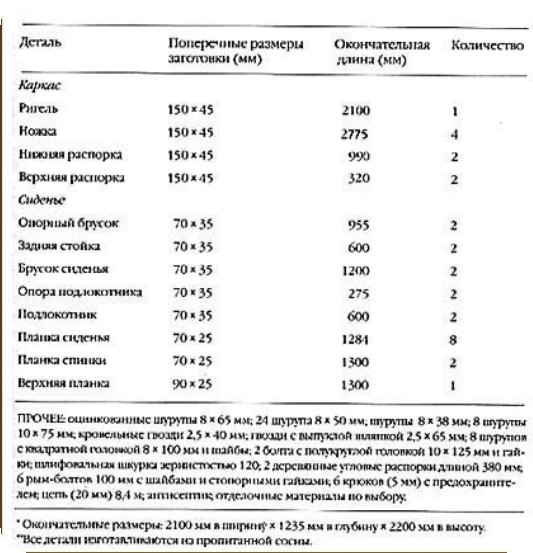

To design the main part of the swing, you need to buy and deliver building materials in advance. This will require wood with transverse dimensions of 150x45 mm of the following length:

- 2100 mm - 1 board (for the transom).

- 2775 mm - 3 boards (for legs).

- 320 mm - 2 spacer boards at the top of the base.

- 990 mm - 2 spacer boards at the bottom of the base.

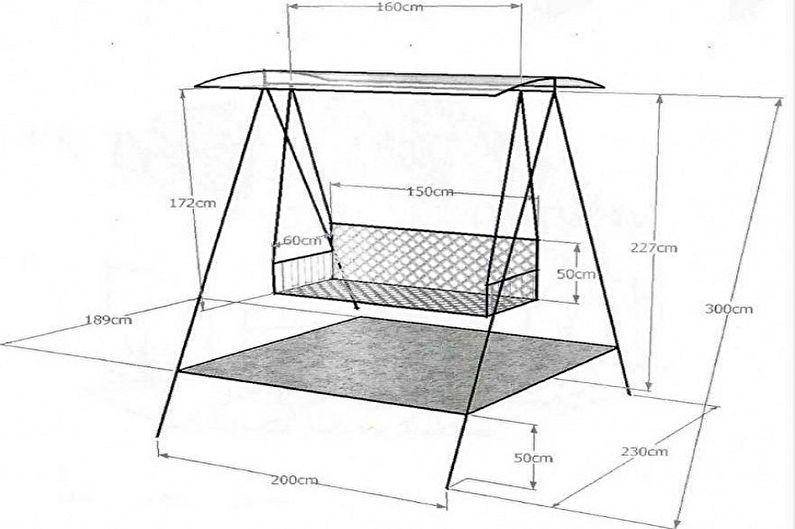

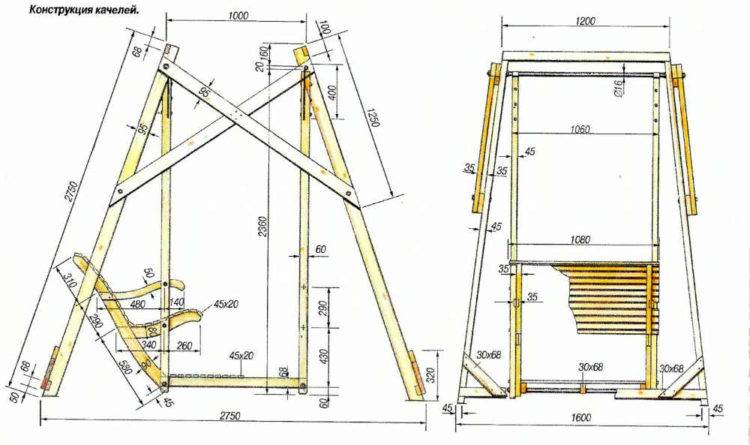

Below is a drawing of the classic A-type frame.

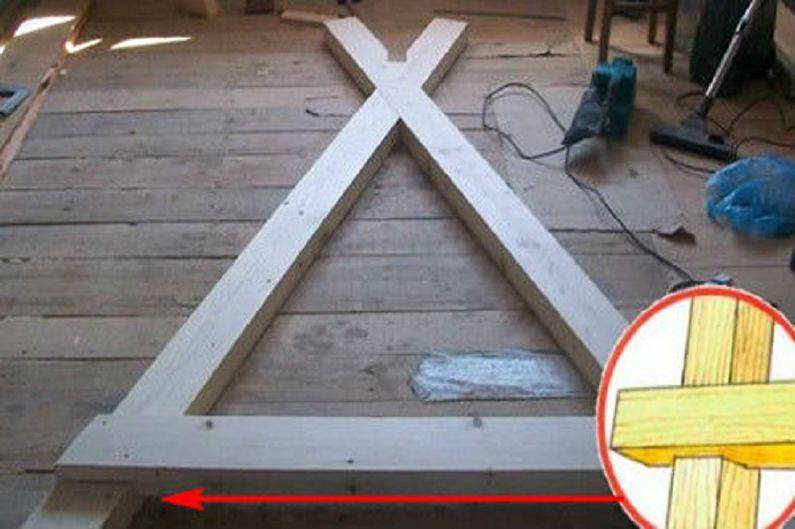

When trimming parts of the base yourself, you can use the following scheme for diluting and leveling the legs.

After preparing and cutting the materials, it is necessary to connect the legs with the spacers and the crossbar with screws. Fasteners are carried out in the places indicated in the diagram.

The lower part of the structure is dug into the ground for half a meter. This will keep the bottom brace flat on the ground.

The base crossbar must be strictly horizontal to the surface. This can be checked with a bubble level. If everything was done correctly, and the swing was installed on a flat prepared surface, then there will be no problems. Otherwise, you need to align the swing by deepening one of the parts.

Important! Since some of the legs will be in the ground or concrete base, it is necessary to treat these parts with bitumen mastic. This will extend the life of the swing, reducing the effect of moisture on the tree .. Preparing materials and assembling a swing with your own hands from a tree will be quite simple, having at hand drawings and a photo of the desired model

The video below provides a detailed explanation of the basic principles of assembling a swing.

It will be quite simple to prepare materials and assemble a swing with your own hands from a tree, having at hand the drawings and a photo of the desired model. The video below provides a detailed explanation of the basic principles of assembling a swing.

Varieties of swing

In modern design, practicality is the main rule. Therefore, in the photo of plots equipped by professionals, you can often see a garden swing.

Such devices are divided into two main types:

- pendulum;

- balancing.

The balance swing is the simplest. But they are intended primarily for children.

Pendulum designs are more versatile. They are most often used as a substitute for boring benches, since swings are also suitable for adults.

Similar designs are also divided according to their main characteristics. First of all, the classification is carried out in relation to the material of manufacture of the product, it can be wood, vine, metal, plastic, textiles.

According to the method of attachment, the swing is divided into suspended and free-standing structures. Products also differ in design style (traditional, modern, beach), or overall dimensions.

Features of creating a wooden swing for a summer residence: characteristics and types of structures

Three main materials are most often used to create a garden swing. This list includes wood, plastic and metal. Undoubtedly, each of these materials has its own advantages and disadvantages. But when it comes to do-it-yourself garden swing drawings, you will not find more practical and convenient raw materials than wood.

A wooden swing has only one drawback, which concerns the operation of any products made of wood. Such structures without the use of appropriate protective measures can be severely affected by the influence of negative environmental factors.

Original garden swing with a soft mattress

These factors include the impact:

- rain;

- snow;

- direct sunlight;

- fungi and mold;

- insects;

- sharp temperature changes;

- decay processes.

You can make a variety of swings with your own hands and translate your own ideas into reality

You can make a variety of swings with your own hands and translate your own ideas into reality

Helpful advice! To prevent premature damage to the wood, it is enough to install the structure under a canopy or pull an awning over it. Thanks to this, you will protect the swing from the harmful effects of rain and sun. Special protective agents and antiseptic compounds solve the problem of parasites, fungi, decay processes and moisture.

The advantages of creating a wooden garden swing with your own hands

The wood has excellent technical and operational characteristics. Thanks to the properties of this material, you can create a truly comfortable and beautiful design.

The wicker swing in the form of spheres is roomy and comfortable enough

The wicker swing in the form of spheres is roomy and comfortable enough

Features of do-it-yourself garden swing made of wood:

- environmental friendliness. Since wood belongs to materials of natural origin, products made from it are completely safe for human health;

- external aesthetics. The structures are able to fit into any landscape and garden design, since the main part of the environment is made up of natural materials (stone, wood) and vegetation. Compared to metal products, wooden structures are significantly aesthetically pleasing and can support the exterior of any country house;

Pillows and blankets will make the swing softer and more comfortable

Pillows and blankets will make the swing softer and more comfortable

- security. Due to its softness, wood is easy to work with and use, it can reduce the number of injuries. This advantage is most advantageous if you intend to carry out the construction of a children's swing;

- simple installation system. Anyone with the simplest skills in construction and handling wood can be engaged in the construction of a swing;

A canopy over the swing will protect you from the scorching rays of the sun in summer

A canopy over the swing will protect you from the scorching rays of the sun in summer

versatility. This type of material lends itself quite easily to various types of processing (grinding, cutting, cutting).Thanks to this, any of the do-it-yourself garden swing made of wood, the photo of which you most like, can be done by you yourself without involving specialists in this process. The wood allows the construction of a single-seat type or swing with a large capacity, made in the form of sofas

Adults also do not mind to relax and unwind, swaying imposingly on a swing

Adults also do not mind to relax and unwind, swaying imposingly on a swing

Note! Material procurement costs are not high. In addition to this, creating products yourself, you save on the services of craftsmen

Buy ready-made swing

This option is easier, since it does not require any construction skills and creative work from the owners of the garden plot. The future owners of the swing will only need to choose a model and external design, as well as assess their financial capabilities.

What to look for when buying a garden swing:

- Frame color. It is worth giving preference to darker tones, since dirt and dust are not so noticeable on such shades.

- The presence of a cover for a garden swing. They try to clean portable structures for the entire winter period, and a durable cover will protect against dust settling, moisture and pests.

- Maximum permissible support load.

- The strength of the seat to the frame.

- The material of the frame and the seat itself.

- Package contents: it is worth knowing in advance if there are swings and pillows, covers and auxiliary elements in one set.

A large selection of garden swings, different in texture, shape and color, is presented in the largest construction hypermarket - Leroy Merlin.

Recommendations for the parameters of wooden blanks

This is not a strict standard, but the given data will facilitate the process of selecting the required size of wood for the swing.

For the swing to stand firmly, compaction alone is clearly not enough. Alternatively, the installation of a support frame from a bar. It is not difficult to fix the entire structure on it, given that it is made of wood. And there will be no problems with dismantling.

If the timber is properly impregnated (for example, by using engine oil), then it will be in good condition for several years. And for the winter, the frame can also be removed from the garden area.

The article provides comprehensive information on the peculiarities of making a swing from a tree. Everything else - dimensions, shapes, drawings - is at the discretion of the master. But the author does not consider it correct to impose in the literal sense of the word a certain model of a garden swing.

Good luck, DIY lovers!

Place of installation

If you walk through the territory of the garden partnership, then you will not find areas that are absolutely identical in layout. Naturally, each owner himself is guided by the dimensions of the swing that are acceptable for his giving. It is hardly worth "looking back" when drawing up a diagram at typical drawings, since a huge advantage of making something with your own hands is the possibility of independent design.

That is, the swing is made in such a way that, on the one hand, they do not become an obstacle, on the other hand, they are fully consistent with their purpose.

Determining their size is easy if you remember what scaling is. Therefore, you can take any drawing you like as the initial one, and even remaking it for your site is not a problem.

Since we are considering the issue of making it from wood, it should be borne in mind that it deteriorates quite intensively in the sun. Cracks that cover all the parts of the swing will lead to the fact that after a short time you will have to deal with either its partial repair, or a complete restoration associated with the dismantling of the elements

For metal structures, this is not so important, but for installing a swing made of wood, it is advisable to choose a shaded place.Or one that is illuminated by direct rays for only a small part of the day

It is quite wrong to think that a canopy (canopy, awning) mounted above the "hanging board" will save you from the sun. If we are talking about who uses the swing - yes; a shadow will be provided for him. But what about wooden supports, a beam-crossbar, which will begin to dry out rather quickly? All this should also be taken into account, unless, of course, the swing is made for short-term use.

It is unnecessary to talk about such criteria for choosing a place as distance from the fence, trees, walls of the garden house - these are elementary things. You need to think not only about the convenience of using the swing, but also about safety. Especially if they are mainly used by children.

Materials and tools for manufacturing

The choice of material depends on the design and type of structure. Homemade swings are made from boards, beams, euro pallets, logs. The latter must be used strong, rather solid. Coniferous types of wood, such as pine, larch, are well suited.

A set of necessary tools:

- chainsaw;

- electric jigsaw;

- plane;

- drills with a drill;

- screwdriver;

- ring screws;

- hammer;

- eye bolts.

The ends of the logs to be buried must be protected from rotting, for example by tar. Chains or strong ropes with a metal core are used as a suspension. Not only great seats are made from planks. With proper skill, it will turn out to create a full-fledged A-frame from a double canvas, which will ensure good strength and reliability of the structure. The seat can be in the form of a bench, an armchair, a sofa with armrests. In addition to the standard set of hammers, nails, a screwdriver, you will also need emery. A varnish to protect the wood from destruction will make it safer and smoother to the touch.

The swing from the bar is stable, and the fit of the parts is easier due to its correct shape. For manufacturing, either cylindrical or non-cylindrical building material is used. A standard section of 40 x 70 mm will allow you to create a version with good load-bearing capacity and a sofa seat. The material must be sanded, treated with fungicidal and antiseptic solutions. The basic set of tools is supplemented with metal staples, rigging fasteners, chains.

Suspended structures made of Euro pallets are an economical way to create a cozy resting place. It is enough to choose a wooden pallet, process it, cover it with a mattress, blanket, pillows and hang it on ropes from the ceiling of the gazebo or shed. It turns out the country version of the swing bed. You can complicate the process a little by adding low sidewalls, a headboard, or transform the pallet into a small sofa on suspension chains.

To create, you will need such auxiliary materials and tools as:

- hammer;

- spanners;

- metal corners;

- wood drills;

- electric jigsaw.

After determining the dimensions, choosing the design and materials for the future swing, you need to pick up a drawing or create it yourself. It must be carefully worked out: mistakes that crept into calculations made in a hurry lead to negative consequences. Safety must come first.

Log

Log

Beams

Beams

Euro pallets

Euro pallets

Instruments

Instruments

Types of swing for giving

A swing at a summer cottage can perform different functions, give joy to children and adults. Depending on the size of the site, you can install several structures designed for different age categories, or one large one for the whole family.

Garden swing for a relaxing stay

In this case, we will talk about outdoor swings designed for outdoor recreation with family or friendly get-togethers. Such designs are often designed for several people, but there are options for single seats for those who like to be alone with themselves.

Structurally, outdoor swings are two support posts with a crossbar, to which the seat is attached using suspensions (chains, ropes, metal slats). The seat, as a rule, has a back and armrests, is made of wood, metal. Today it can be whole hanging chairs or sofas, equipped with soft upholstery and decorative pillows.

It is recommended to purchase or make a garden outdoor swing with a canopy that will protect from heat and rain.

Swing for outdoor activities

At the summer cottage, in addition to work and relaxation, you can find time for a more fun pastime. This is especially true for families with children who cannot sit still in search of adventure. It's no secret that adults often want to immerse themselves in childhood.

Models for outdoor activities are designed for more powerful swing, which gives great pleasure to the little ones. Such designs have existed for decades, the materials of seats and fasteners have improved over the years, but the principle of operation remains the same. The simplest outdoor swing is easy to make yourself using a simple board and ropes.

Wood species

Since the swing is made for installation in the garden, its durability is largely determined by the material's resistance to external factors. First of all - dampness. Any "do-it-yourself" technology assumes reasonable economy, therefore, we can only talk about inexpensive and available breeds on the territory of the country. It is advisable to choose only conifers. The presence of resin in their structure is already a definite guarantee against wood decay.

It makes no sense to buy cheaper spruce due to the insufficient strength of the material. Perhaps this breed is good for constructing something that is static. For example, a garden bench. Swings, on the other hand, which are subject to significant dynamic loads, require stronger wood. Hence, pine or larch. The latter breed is even better, because over time, getting wet, it acquires additional strength.

DIY construction of a wooden swing for a summer residence: drawings and selection of materials

Dimension table for creating blanks:

| Detail in construction | Dimensions of the transverse part of the workpiece, cm | Final length, cm | Required number of blanks, pcs. |

| Frame part of the structure | |||

| Spacer (top) | 4.5x14 | 23 | 2 |

| Spacer (bottom) | 4.5x14 | 96 | 2 |

| Leg | 4.5x9 | 198,7 | 4 |

| Rigel | 4.5x14 | 210 | 1 |

| Seat details | |||

| Rear pillar | 3.5x7 | 60 | 2 |

| Bar (support) | 3.5x7 | 95,5 | 2 |

| Bar (for seat) | 3.5x7 | 120 | 2 |

| Armrest | 3.5x7 | 60 | 2 |

| Backrest plank | 2.5x7 | 130 | 2 |

| Armrest support | 3.5x7 | 27,5 | 2 |

| Seat strip | 2.5x7 | 128,4 | 8 |

| Upper bar | 2.5x9 | 130 | 1 |

In addition, to connect the above blanks together into a single structure, you will need fasteners with different parameters.