How to build?

Making each type with your own hands is quite possible, stock up on the necessary literature and patience.

The first step in a tile installation is to prepare a groove in the soil for future installation. The dimensions and depth in this case are not fixed by anyone (although there are recommended dimensions - up to 500 mm), the developer must independently select the optimal characteristics.

The next stage is filling the pit with rubble (up to 10-15 cm) and tamping. You can fill in the finished solution after waterproofing the structure with roofing material. The composition of the filling in this case is 1/3/5 (cement, sand, crushed stone). Often this type is installed on the basement floors of small buildings.

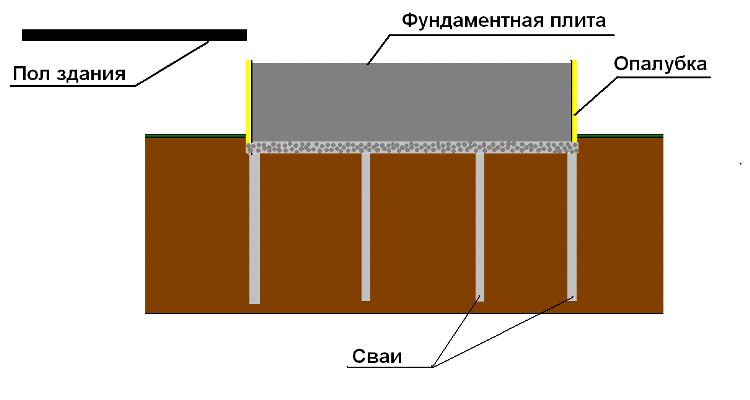

Pile foundation or foundation on screw piles - no less reliable and easy to install type. For it, you will need to dig holes in the corners of the proposed slab (while the diameter must remain at a level of at least 20 cm). The pits are pre-filled with moistened sand and gravel (from 10 to 15 cm) - it is necessary to do it for ease of tamping.

The preparation of the formwork for the further pouring of concrete requires the installation of a roofing felt sheet and an armored belt. After ramming, pouring and coating the piles, the latter are mounted with each other and serve as bases for reinforced concrete or concrete slabs. As already mentioned, there is a type of pile foundation without excavation.

An in-depth view is more difficult in design and installation. There is a sequential installation plan here.

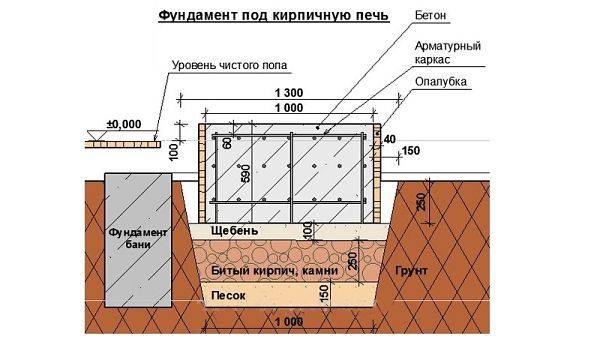

- Make sure that the pit you dug is 10-15 centimeters larger than the dimensions of the stove itself. This figure must be observed on each side of the pit. Depth characteristics in this case are not fixed, everyone follows different rules, but most often it does not exceed one and a half meters.

- The next step is to compact and tamp the bottom of the excavated pit. For this, rubble can be used (pre-moistened or not - it's up to you). After compacting the bottom of the pit, the thickness of the crushed stone should not fall below 15 cm.

- For a tighter compaction, the developer can use a sandy loam layer up to 30 cm thick, the latter moistened with a small amount of water for greater compaction. When the sand layer is dry, you need to add another layer of rubble on top of it. This time - already up to 20 cm.

- The next important step is to make wooden formwork. The inner surface can be pre-lubricated with bitumen, so you will provide waterproofing to your structure.

- Further installation of the buried view is similar to the installation of a pile foundation, however, the formed space from the walls of the soil to the foundation in this case is covered with sand.

The shallow type is represented by three separate types: columnar, monolithic slab, lattice. Each of these types has its own installation features.

- Columnar is a cheaper option and is presented in the form of several vertical supports, immersed in the prepared soil by no more than 30%. The approximate distance between the supports should be 2 meters.

- A monolithic slab is more suitable for installing a foundation on soils without soil subsidence. But this type is applicable to lighter buildings, as it is subject to the influence of external factors - mechanical damage and others. Hydro- and heat-insulating elements can be brought under the finished monolithic slab - in order to avoid freezing in the winter season.

- The lattice type is perhaps one of the simplest types of non-buried foundation. Making it involves mounting a large number of slabs with fittings. This will save your resources when pouring. In addition, the lattice type is more resistant to breakage.In case of breakage or formation of cracks in certain parts of the foundation, the risk of transmission of damage to another part of it is reduced.

Foundation laying calculations

To calculate the size and thickness of the foundation, take into account the total weight of the stove

To calculate the size and thickness of the foundation, take into account the total weight of the stove

In order to correctly calculate the characteristics of the future foundation, you will need to decide on its estimated dimensions. The latter depends on the weight of the sauna stove and its dimensions. When arranging a standard brick stove, a value of about 8 tons is taken for the average indicator of the mass of not dried masonry, after drying it decreases by about half. At the same time, the option is not excluded when the monolith expands over the area it occupies (for the chimney). This approach to the formation of the base avoids uneven shrinkage of the two components of the brick structure.

The depth of placement depends on the following factors:

- characteristics of the soil in a given area (its heaving, for example);

- the freezing point characteristic of these places;

- the indicator of the deepening of the foundation of the main building;

- depth of groundwater flow.

It is important to take into account the stage in which the construction of a residential building is at the time of the construction of the foundation for a brick stove. On sandy soils, it is laid at a depth of about 80 cm. When the variant of heaving unstable soils is calculated, the desired indicator is selected taking into account the freezing point of the soil.

Basic rules for laying the foundation

Whatever version of the foundation for the furnace you choose, and whatever size you decide to implement, there are a number of basic rules that you should not ignore:

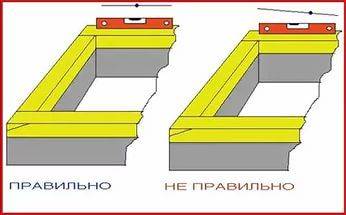

The foundation for the stove must be made independent, in no way connected with the foundation of the whole house. Why? The fact is that during operation, the house may shrink slightly. When lowering, he should not pull the stove with him, as this can lead to its deformation, deterioration of traction and violation of technical properties.

The foundation for the furnace is separated from the general

In some cases, you can partially combine two bases by connecting them with one wall.

- If both foundations (for the house and for the stove) are located close to each other, sand backfill with a thickness of 50 mm must be made between them.

- If the foundation for the common house is tape, then the base for the furnace should in no case come into contact with this foundation with the walls.

- When choosing a place for a stove and, accordingly, a foundation, one should not only rely on wishes, but also on factors such as: the location of doors, windows and roof beams. The location of the chimney should be taken into account so that the pipe does not fall into the ceilings and beams during the construction of the stove.

- When calculating the size and depth of the foundation, be sure to take into account the severity of the floors and the weight of the stove together with the chimney.

The dimensions of the foundation are influenced not only by the dimensions of the furnace, but also by the density of the soil on which it is being erected. The main load in the stove is usually created by the chimney, therefore, when designing the stove, it is necessary to carry it closer to the center of the base. This will help to avoid asymmetric loading and premature, improper shrinkage of the oven.

Sometimes, when designing a very large and massive stove with a stone chimney, stove-makers make a separate base for the chimney.

Also, the choice of foundation depends on the material of the furnace. For a metal structure and a stone one, it will be different in depth, the entire mass of a brick oven is at least 400-500 kg, while a metal oven weighs about 150 kg.

How to calculate the weight of a stone oven

In principle, for a small metal stove, you can separately and not equip the foundation, especially if it is being built in a house that stands on a tiled monolithic base.

The density of the soil and the degree of its freezing play an important role in determining the size of the foundation.The climate in Russia is accompanied by rather severe winters practically throughout its entire territory. Therefore, the foundation for the furnace should be laid to the entire depth of soil freezing.

The type of soil is also of great importance.

Soil types

It is of three types:

- clay;

- sandy loam;

- loam.

In places where a large number of rivers, reservoirs, lakes prevail, as a rule, sedimentary types of soil are found. Here, it is better to entrust the construction of the foundation for the furnace and the house to professionals, so the calculations of the point of passage of the waters should be carried out.

In Central Russia, a very common type of soil is loam, which is a mixture of sand and clay. It is clay that predominates in it, therefore such soil is less plastic.

Loam

Erection of a foundation on such soil is usually associated with hassle and additional problems, since in a dry state the loam is crumbly, with the onset of frost it begins to "heave", and with a large amount of sediment it becomes viscous.

Clay soil

Therefore, in this case, the depth of laying the foundation for the furnace must be made above the freezing point.

But in forest areas, on the contrary, it is necessary to lay the foundation for the stove below the freezing point of the soil and equip the base on a sand cushion 60-90 cm thick.

One of the most reliable types of soil for building a foundation is gravel and rocky, but, unfortunately, sometimes you have to build a house and a stove on an unstable one. Competent construction of a reliable foundation will help neutralize this fact.

How to choose and prepare a place?

The type and size of the foundation are determined by the size of the barbecue area, which, in turn, depend on the size of the stove, the number of people, the direction of the winds and other factors. If you plan to create a gazebo, inside which a brick oven, work and dining tables will be located, then the foundation corresponds to the contours of this gazebo with reinforcement at the place where the furnace was laid. Let's consider the most difficult option:

- The site is selected based on the requirements for distance from wooden buildings and the prevailing wind direction.

- The plot is planned, the top fertile layer of the earth is removed.

- The cushion is added from ASG.

- Adding a layer of river sand.

- Formwork construction, inside which the reinforcement cage is knitted.

- Pouring the slab foundation, holding for the complete hardening of concrete.

Backfill is required to create a water-permeable layer that will absorb rain or melt water. This option is good in the presence of heaving soils that have seasonal movements due to changes in the level of soil water. The slab foundation seems to "float" on the surface of unstable soil.

When using a pile (pile-screw) base, the platform hangs above the ground, which contributes to drying and greater durability of the material. The piles are tied with a bearing belt - a grillage, which serves as a support for a concrete platform. The absence of contact with the soil, excluding capillary suction of moisture, the support of piles on dense layers of soil makes the option quite successful, especially since no basement is usually required.

A strip foundation is a trench with a formwork and a reinforcing cage placed inside, into which concrete is poured. The trench must be deeper than the level of freezing of the soil, otherwise the tape can break or break during seasonal movements. This condition can be overly difficult for a small furnace, but for large structures the method is good and quite economical.

The final choice of the foundation is made after examining the condition of the soil, deciding on the size and design of the site and the furnace itself and financial capabilities.

Tools and materials for the construction of the foundation

The first thing to do before starting construction work is to stock up on the necessary set of tools.

Work will have to be carried out not only excavation, but also carpentry, so prepare the following tools:

- Bayonet shovel (needed to dig out the main pit).

- Shovel (it is convenient to prepare a sand-cement mortar).

- Hammer.

- Hacksaw or saw.

- Sieve for sifting cement (mesh size 1 * 1 mm).

- Sieve for sifting sand (mesh size 2 * 2 mm).

- A bucket for water (for preparing a cement-sand mortar).

- A metal trough in which we will prepare the solution.

- Building level.

- Roulette and pencil.

- Stapler.

- Concrete mixer.

Of the materials you will need:

- Boards (for the manufacture of formwork).

- Polyethylene (for formwork waterproofing).

- Sand.

- Cement.

- Gravel.

- Reinforcing mesh or rods.

We begin to fill the foundation for a brick oven with our own hands

The foundation for a brick oven

Step 1. Marking for foundation and pit

-

After you have decided on the location of the future furnace, you need to correctly calculate its dimensions, based on the power. It depends on the area of the room, the number of doors, window, etc.

- On the ground, we draw the required size of the furnace. The foundation should be 15-20 cm larger than the heating structure. Make markings and set pegs that will mark the boundaries of the pit under the foundation pit.

-

Use a bayonet shovel to dig a hole 70-100 cm deep, depending on the density of the soil and the climatic zone (see above).

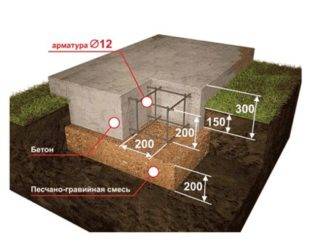

- At the bottom of the trench we lay a sand cushion 10-15 cm thick. Tamp it tightly with a shovel and pour a layer of medium-grain gravel to a height of 30 cm. Pour a bucket of water onto the surface of the crushed-stone cushion and tamp it tightly.

Step 2. Formwork installation and reinforcement

- We proceed to the construction of board formwork. For formwork, in principle, any old boards or plywood that is on the farm are suitable. This does not affect the technical properties of the foundation in any way.

-

The formwork is a wooden box, which, for reliability, is fastened at the corners with metal corners. Connect the boards to each other with nails.

-

We lower the finished formwork to the bottom of the pit.

-

After the pillow is firmly compacted, it is necessary to waterproof the base. To do this, we measure the size of the pit on polyethylene, cut it out and attach the polyethylene to the walls along the perimeter of the formwork using a construction stapler.

- Reinforcement of the foundation is necessary in order to give rigidity to the entire structure. We will reinforce with steel rods with a cross section of 12 mm, which must be connected to each other by welding in the form of a frame or a metal wire with a cross section of 0.8 mm.

- Finishing work on the construction of the foundation is the joining of the floor to the foundation. It is better to do this by laying an even row of bricks.

Step 3. Preparing the concrete mixture for pouring the foundation

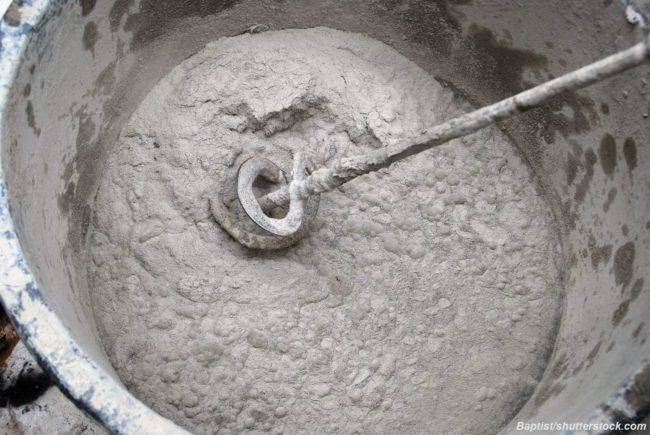

We prepare a mixture of the following proportion: for 4 parts of sand we take 1 part of cement + 3 parts of crushed stone of the middle fraction.

Concrete mixer

Stir the dry mixture well with a bayonet shovel and add water. We mix the mortar well with a concrete mixer. In consistency, it should resemble thick sour cream.

Preparing a concrete solution

We fill a part of the pit with this mixture, not reaching the level of the base floor by 8 cm. These works must be done within 24 hours. The concrete solution must be complete and not lay down in layers.

Fill and wait 2 weeks

After you fill the entire pit with concrete, you need to check the horizontal level of the coating with the building level. After the solution has completely dried, it will be more difficult to correct your errors.

we check the horizontal level of the foundation with a building level

Cover the foundation with a layer of polyethylene or roofing material and leave for 2 weeks until completely dry.

We remove the upper part of the formwork only after complete drying, beating the boards with a hammer. Pour crushed stone with sand into the resulting gap and tamp well.

Furnace foundation design: general recommendations

There are several requirements for the base for the oven. And two of them can be distinguished as the most important:

- It must be durable and reliable.

- Even seasonal movements of the soil should not affect its structure in any way.

In this case, it is very important to take into account what kind of soil on the site where the bathhouse is being built: black soil, sandy, clayey soil, or we are talking about a wetland

The following readings indicate how deep the foundation should be for a brick oven in a bath. The type of soil is taken:

- sandy - 50 cm;

- rocky - 25-30 cm;

- clayey - 70-80 cm;

- wet soil - 100 cm

Separately, it is worth considering this option if there is bulk soil on the site. In this case, the foundation must be built taking into account both the depth of its freezing and the level of dense intact soil.

What can be the basis if the stove in the bath is no more than 700 kg? In this case, you can proceed as follows:

- on top of the finished floor, you need to lay out a clay solution;

- then the asbestos sheet is laid;

- then you need to put a sheet of metal (you can use roofing iron);

- only now can the oven be installed.

In this case, it will be possible to achieve a double goal. Firstly, all fire safety standards will be observed. And secondly, the thermal insulation readings of the floor will increase, i.e. the heat from the stove will not go under the floor.

The base for any oven can be the same, even if its weight does not exceed 200 kg. But nevertheless, experienced builders note that such an arrangement cannot be called 100% reliable, therefore it is advised not to do this if the floor in the bath is wooden. It is better to remove the wood flooring at the place where the stove will be installed and make the brickwork. But in any case, a pillow of sand and gravel is required under the bottom.

Foundations for a furnace on piles

If you decide to arrange a shallow foundation, you will need a pile foundation for the main stove. This can be done as follows.

The vegetation layer is removed to a depth of 200 - 250 mm.

Foundation on piles

- With the help of a drill, holes are made with a depth of 1000 mm, while a 200 mm diameter will be quite enough. A layer of rubble is poured onto the bottom of the wells and compacted. The location of the piles should be such that your foundation rests on them.

- Liners of the corresponding diameter are rolled up from roofing material and inserted into the wells. You can fill in the solution.

You can act differently. If you have at your disposal asbestos or polyethylene pipes of the appropriate diameter, after the crushed stone is poured into the bottom of the wells, pipes are inserted there. Of course, the pipes will need to be aligned at the same level. Approximately 7-10 days after pouring the piles, the foundation itself can be poured.

Varieties of foundation for the furnace

The climatic features of the area, the condition and structure of the soil, limit the options for the execution of the base that distributes the load. The main types of foundations are divided into:

- A concrete slab laid on a leveled surface. Used for light stoves and barbecue in case they are built on the ground. The total number of bricks of a building placed on such a foundation should not exceed 500 pieces. In the case of a more massive building, the following foundations are selected from this list.

- Reinforced concrete is the most common. The depth begins below the freezing point of the soil, so the value differs depending on the region.

- Foam concrete.Rubble stone is laid out in the prepared foundation pit in layers. It is poured with concrete mortar. A layer of stone - fill, repeated up to the specified height. Allows to reduce the consumption of mortar, it is economically beneficial in areas where there is rubble stone. In other regions, it is not profitable.

- The foundation on the piles is shallow. Reinforced concrete slab, laid on supports, is suitable for areas rich in groundwater.

Before starting work, when marking the location of the foundation for a brick oven, add 50-100 mm to the dimensions of the base in each direction. This will ensure that the correct support is always wider than the structure to be held. Plus, it will eliminate the influence of ground displacements in the future.

Advice

As you can see, making the necessary foundation for the stove is a complex, but necessary process for the good operation of any heating system. There are a few simple, summarizing points that, if used correctly, you will competently organize any stove in your home.

- Define the parameters of your territory. These are: environmental conditions, possible mechanical damage, calculate the load and pressure from the stove. Conduct an in-depth analytical calculation - from your financial capabilities to measuring the level of groundwater. The more accurate the data, the easier it will be to choose the right type of foundation, and the less hassle it will bring you to operate it.

- Everyone has their own financial capabilities, but try not to save on equipment, solutions and mechanisms for high-quality filling. Remember, the price equals the quality, and the higher it is, the more chances that your installation will last a long time and will only bring you satisfaction and joy.

- Explore other resources, electronic and written, with quality foundation installation information. You should understand that someone who is knowledgeable is armed for emergencies. And experience is not only a matter of theory, but also of practice.

The process of building a furnace from laying the foundation, see below.

Foundation calculation with an example

The choice of the base for the furnace directly depends on the total weight of the structure, for this you first need to calculate it by calculating the amount of bricks and cement mortar used. Usually 1 cubic meter of brickwork weighs 1350 kilograms - keep this in mind.

If the total weight of the heating system exceeds 750 kilograms, then a high-quality foundation will require a strong and durable foundation, with a deep type of foundation made of rubble or concrete stone. With a lower weight of the structure, a base made of roofing iron, asbestos sheets and even ordinary wood may be suitable.

When making calculations for the foundation of a brick stove, take into account the type of soil on the site. On soft, swampy and easily sinking wet ground, the foundation should have a height of at least 150 centimeters, while on dry ground, the foundation may have a depth of only 70 centimeters.

Let's give an example of calculations:

We decided to install a brick oven, made of 0.8 cubic meters of brick and using cement mortar with a total weight of 70 kg. We will carry out the installation on dry black earth soil, with large stones under the base for the stability of the foundation. First, let's calculate the total weight of the structure:

1350 * 0.8 = 1080kg

We add 70 kg and we get the total weight of the heating system - 1150 kg. Since our soil is quite hard, but the furnace has a large mass, we will install a foundation with a depth of 1 meter - this will be enough for long-term stability.

If the foundation for a brick stove is laid before the walls are erected, then before installing it you need to determine where the heating system will be installed - it will not be possible to change the decisions, so think before starting the construction of the base where exactly you will have the stove.

Furnace foundation height

There are three options:

- below floor level;

- on the same level;

- above.

Questions can only arise about why the base of the stove should be made below the final level of the floor. The answer has two parts:

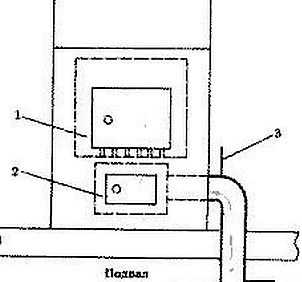

- So that combustion air is taken from the underground.Then the stove, if there is a desire, can be heated from the steam room, and not from the rest room or dressing room: oxygen in the room is not burned out, as it “stretches” from the underground. Only in the foundation should there be ventilation holes to ensure the flow of air.

- To keep the floor warm. Despite the increased circulation in the subfloor, the floors warm up quickly with this arrangement of the stove. Then there will be no problems with the cold floor, whether it be wooden or concrete.

Also, as a bonus, with this arrangement, there is no problem with drying the floor. Only this is true only with properly made drainage and waterproofing of the floor.

Everything will work if the blower is below the level of the finished floor. If the foundation is made at the same level with the floor or higher, and the air intake must be organized from the underground, the metal stove is modernized (in the photo, the option on the right). A thick-walled metal pipe with a gate is welded into the sidewall. The damper regulates the level of air supply and the intensity of combustion

Just note that if the integrity of the oven is violated, it is removed from the warranty (if any)

A more detailed image of the oven limiter

A more detailed image of the oven limiter

In the same way - by welding the pipe - problems with the combustion of an already installed furnace are solved. Problems arise from lack of oxygen. And it is provoked by current technologies: to reduce heat loss and heating costs we make houses and saunas - thermoses. If you forget to make ventilation or make it insufficiently effective, then the stove burns badly. Here, however, there is an option that does not require making changes to the furnace: the pipe coming from the ventilation hole in the foundation is taken out in the area of the blower. Sometimes it is enough to bring it under the boards, sometimes it is necessary to bring it flush with the floor or slightly higher. Not the best and most aesthetic option, but the stove will burn normally.

Please note that if the foundation of the stove is close to the base of the bath (house), it is necessary to make them incoherent. This means that they should not touch each other.

There should be a gap of at least 5 mm between them for an iron stove and 50 cm for a brick one. In the case of an iron stove, the gap can be filled with a layer of heat insulator (basalt cardboard).