Required materials and tools

Almost any building materials intended for the construction of capital structures can be used for the construction of a gazebo. However, the cheapest and easiest to handle option is natural wood, while it allows you to create a fairly aesthetic design.

From wooden materials you will need:

mounting rail;

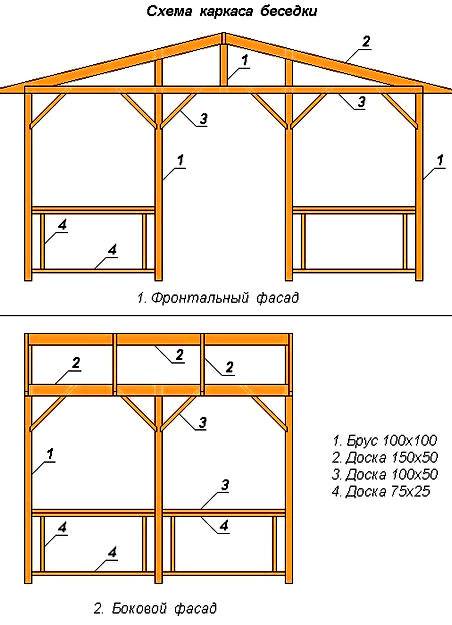

- timber 100 × 100 mm (strapping, frame and overlap);

- timber 150 × 50 mm (rafter system);

- moisture resistant polished board;

- decorative lattice railings.

In addition, you will need perforated metal corners and plates, self-tapping screws for wood, anchors, as well as reinforcement and concrete mix of at least M200. Concrete can be made either independently or purchased ready-made. You will also need roofing material or any other similar waterproofing material.

Of the tools for construction, you need the following minimum:

- hammer;

- saw on wood;

- cross screwdriver or screwdriver;

- hammer drill or hammer drill;

- shovel shovel;

- container for mixing and storing concrete mixture.

Preparatory work

A do-it-yourself gazebo is built from various materials (stone, brick, wood). The choice of material depends on the following factors:

- the load that will be applied to the structure;

- average number of vacationers;

- dimensions of the structure;

- presence or absence;

- open or closed gazebo;

- form of construction.

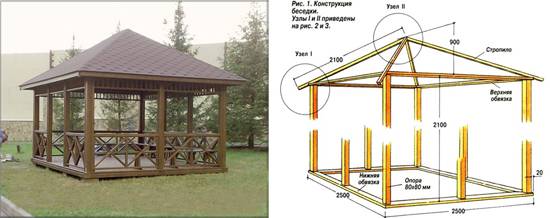

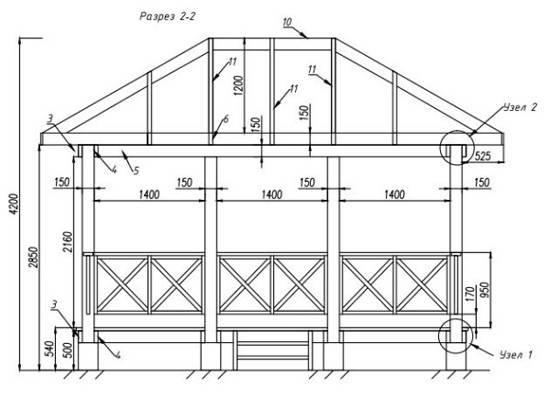

To make a rectangular two-story gazebo for summer cottages, we use wood as a basis - beams and tongue-and-groove boards. For the roof, you will need to buy metal tiles. The lower strapping is made using raw beams with a section of 120x150 mm, and the upper one is made of similar elements with a section of 100x100. Grinding bars (100x100) can be used as racks.

For the manufacture of handrails, lumber is required. We will equip the floor from a grooved board. To sheathe the ceilings, we use a wooden lining. For rafters, beams (50x150 mm) are required. We will lay the crate from edged boards. The ladder can be made independently from polished beams or bought ready-made.

A 2-storey wooden gazebo is assembled on a flat area. For this we use free-standing pillars or reinforced concrete strips. Since the weight of the structure being erected is small, it is possible to equip a shallow foundation. If you plan to build a gazebo with a terrace, then roofs are also produced. From the tools you will need a level, a tape measure, a concrete mixer, a grinder, buckets, a shovel.

The gazebo is actually a very useful structure. Here you can enjoy your vacation alone, arrange family gatherings, receive guests and even fry delicious kebabs. When drawing up a project for this structure, first of all, you need to decide on its shape and size.

The correct choice of these parameters will determine how harmoniously the gazebo will fit into the design of the site, as well as the ease of use of it. We will talk about the advantages of courtyard structures of a particular design later in the article.

DIY installation

In order to make a gazebo with your own hands in the country, you need to adhere to the order of the stages of work. This will allow you not to make mistakes during installation and get the expected result at the end.

Frame and floor

You need to start with the frame and floor. If the structure is wooden, then the beams for the base are also suitable. The floor will also be made of wooden planks. The base for the beams and the floor is best made of concrete. It is enough to fill in the screed several centimeters thick. It will be the best and most reliable option, and will last a long time. Before work, you need to carefully choose a place for installation, think several times before making a decision. Also, the site needs to be cleaned and leveled under the foundation pouring.In such a structure, it is not recommended to combine metal and wooden parts.

As practice shows, even if you protect a wooden base with roofing material or bitumen, when the tree comes into contact with concrete, it starts to rot over time. As a result, the subsequent destruction of the structure. Therefore, initially it is necessary to avoid this.

To accomplish this task, you should:

- concrete the profile pipe (it should be 30 centimeters higher than the concrete);

- we drill holes for screws in the pipe;

- push wooden posts into the pipe;

- we fix the column in the pipe with screws.

If the owner plans to put a small light gazebo, then it is not necessary to install a brick fence for the fence. You can get by with a fence made of Euro lining 90 cm high.This is quite enough. Fasten the lining to the longitudinal bars. This design will help to hide from the sun and wind blowing. The fences for its walls are attached to the supports with screws.

As an alternative to lining, you can use polycarbonate. It is also easy to install and resists high temperatures and wet weather. For the roof frame, it is better to use a beam of 50 × 50 centimeters. From such a beam, it is necessary to create a base on which the crate will be installed, and then the roofing material. As a roof, you can use slate, metal tiles and ondulin.

Roof installation

When designing a roof, you need to calculate it in such a way that at the end of the roof you do not need to cut the last sheet. To do this, measure the height of the roof and subtract the overlaps of the sheets on top of each other. Making a gazebo at home is easy. It is enough to pick up quality material.

For example, for slate, each sheet of which has 8 waves, the length of the arbor will be a multiple of 1 meter, and the length of the slopes is 1.75 m

Considering coating options, special attention should be paid to polycarbonate.

It has the following advantages:

- An excellent option for light arbors, as it weighs a little, but is a very durable material.

- Fences are made of polycarbonate.

- It is a lightweight translucent plastic.

- A metal profile is often used with it.

Polycarbonate is a material with good elasticity. It can be easily bent. Because of this property, it is often used when installing an arched roof. To create such, it is necessary to weld strips of steel 50 mm wide. First, they need to be installed on the support strips, and then holes are drilled to fix the sheets.

Also, gazebos are sometimes covered with metal tiles. OSB sheets are installed under it. They perfectly fulfill the role of keeping the tiles on the roof. Basically, these sheets are 10-12 millimeters thick. This material has fairly good strength and stiffness.

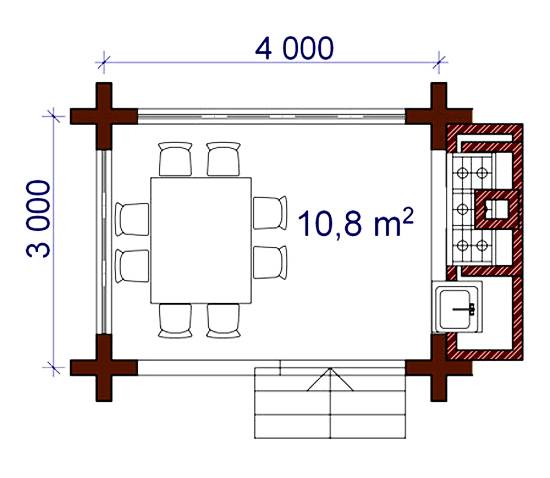

General rules for drawing up drawings

Drawing up drawings of a gazebo for a summer residence will allow you to accurately plan the location of all sorts of important structural elements - lamps, doors, windows, possibly or. In addition, accurate diagrams and sketches will help determine the amount of required building materials.

How do-it-yourself gazebos are made (drawing, photo)

There are rules for drawing up drawings with your own hands, which should be followed:

- First of all, you need to measure the place on the site designated for. The dimensions of the structure in the drawing should not exceed its area.

- Next, a sketch is drawn.

A sketch of a building made of wood or its 3D model clearly shows how it will look in the end

- Then they draw the frontal and profile projections of the structure, indicating the dimensions. For complex structures with barbecue or massive furniture, you will also need to attach a plan (projection from above) to the set of drawings.

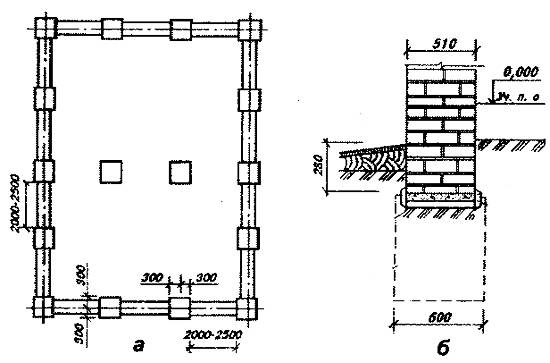

- Further, a separate foundation diagram is drawn, which may be.

Columnar foundation diagram

- After that, walls and large elements (barbecue, table, etc.) are drawn. At the same stage, the location of the windows and doors should be noted.

- Then, on the finished drawing, the dimensions of all elements of the frame and sheathing are noted.

Drawing of the frame of a summer building with the indicated dimensions

- The next step is to draw up a roof diagram with dimensions and angles.

- The locations of the lamps and the wiring diagram are noted.

- If necessary, a brazier is drawn with a foundation and a chimney (oven, barbecue).

- Next, you will need to "arrange" furniture on the plan.

The plan should be applied, including furniture.

In the event that it is planned to build a closed structure, it is imperative to indicate the location of all ventilation holes.

Do-it-yourself beautiful gazebo made of wood

Simple rectangular structure with a gable roof and beautifully designed side walls. The gazebo is assembled from ready-made forms, all the details of the project were made to order according to the personal drawings of the author. The third photo shows the modules made in the workshop. The structure is installed on a red brick point foundation. See the step-by-step photos for the assembly procedure. Due to the unevenness of the terrain, the gazebo is slightly raised, the stairs apparently were not included in the author's plans, so a temporary version was made.

Construction of a hexagonal arbor

Construction of a hexagonal arbor

A hexagonal garden gazebo always looks very elegant and is a decoration of any site. During its construction, the accuracy of calculations is very important, because errors at any of the stages will significantly affect the final result. You need to start with a drawing of the future building, which will allow you to correctly mark the site and calculate the amount of materials.

Sectional diagram of a hexagonal arbor

For construction you will need:

- cement mortar;

- brick or cinder block for pillars;

- wooden beams with a section of 150x150 mm;

- planed timber 100x100 mm;

- edged board 50x100 mm;

- roofing material;

- floor boards;

- self-tapping screws;

- primer;

- wood varnish;

- screwdriver;

- jigsaw;

- building level;

-

roof covering.

Step 1. Markup

To mark the site, you will need two wooden slats and a rope about 2 meters long. The selected area is leveled, freed from vegetation and stones, a rail is driven into the ground in the middle and tied with a rope. The other end of the rope is tied to another rail and, using such a homemade compass, a circle is drawn with a radius of 1.75 m. The resulting circle is divided into 6 equal parts and beacons are placed on the marking line. Support posts for the gazebo will be located here.

Step 2. Making a columnar foundation

In place of the beacons, holes are dug 0.5 m deep and rectangular. River sand is poured onto the bottom with a layer of 10-15 cm, then a layer of coarse gravel of the same thickness. A 70 cm long steel bar is driven in in the middle of the hole, after which everything is poured with cement mortar. A brick is laid on top in 3-4 rows with obligatory dressing. The rebar should be centered on the masonry. In the same way, lay out the remaining 5 supports and allow the solution to dry well.

Step 3. Installation of the base of the gazebo

Making the foundation

Measure the distance between adjacent posts and cut the beams according to measurements. You should get 6 beams of the same length and thickness. To securely connect the supports to each other, cuts are made at the ends in half the thickness of the tree. After that, the lumber is primed and dried, and then laid on poles in the form of a hexagon. Pieces of roofing material must be laid between the beams and pillars of the foundation.

Gazebo construction

When the beams of the lower harness are fixed, lags are attached inside the hexagon.The central joist is placed exactly in the center of the structure, horizontally aligned and fixed to the beams using metal plates and bolts. Next, 2 logs are mounted perpendicular to the central one, and all the rest are inserted at an angle, for which small cuts are made at the ends of the boards on both sides. In conclusion, the logs are strengthened with jumpers from a bar and sheathed with boards.

Step 4. Erection of walls

Hexagonal gazebo made of wood

The frame of the gazebo is made of 6 beams 100x100 mm of the same length. Each beam is installed on one of the corners of the base and fixed with anchor bolts. Be sure to check the verticality of the support posts so that the structure is not skewed. Along the upper edge, a strapping of thick boards is mounted, and at a height of 70-90 cm from the floor, the racks are connected with horizontal jumpers from a bar, leaving the entrance free.

The walls can be made in several versions, depending on the materials available. You can close the gazebo up to half with sheets of waterproof plywood, sheathe it with boards, fix wooden figured lattices on the jumpers between the posts. You can make two or three walls blank, and decorate the rest with forged elements.

Step 5. Roof installation

Roof fabrication on the ground

When the walls are ready, proceed to the installation of the roof rafters. Planks 50x100 mm are taken as rafters; for convenience, the assembly is carried out on the ground. Since there is no central post in the gazebo, it is quite difficult to neatly connect the rafters. To simplify this process, a hexagon cut from a bar will help, each side of which will correspond to the thickness of the rafters. The ends of the boards are cut at an angle and fastened with nails to the hexagon; and on the inside of the strapping, grooves are cut out for installing rafters. After that, the structure is sheathed with boards in a circle, leaving small gaps, lifted up and fixed with bolts. Now all that remains is to lay the roofing material.

Gazebo furniture

Prices for various types of fasteners for rafters

Fasteners for rafters

How to build?

Foundation

You can build a lightweight structure with one floor on a flat surface and not attach it to the base, but for a two-story gazebo, you will need to build a foundation

... When installing the frame structure, vertical posts should be installed. The ideal option for such a structure would be to use a point foundation.

... The cost of such work is relatively low, moreover, you will need to spend a minimum amount of time on them.

The optimal cross-section of the foundation supports is 0.4x0.4 m (or so). It is recommended to choose solid blocks or bricks to create the base.

.

Monolithic pillars

Foundation supports can also be monolithic. The design will have increased strength, but this option is more expensive. You can pour the foundation directly into the ground (if the walls of the hole are strictly vertical, and it itself has the correct geometry). The pillars are brought to the surface by 0.2 m, no more

... However, for greater reliability, many people prefer to use formwork.

- Dig a hole about 0.3 m deep. The formwork box will need to be installed around the perimeter of the cut. Then take polyethylene and cover the hole and formwork with it. It will prevent the penetration of ground moisture and will prevent the liquid from leaving the concrete.

- The reinforcement cage must be lowered into the post. Formwork should be made immediately for each support. The concrete will have to harden to a certain extent. It is necessary to wait for solidification, and this is one of the disadvantages of this method.

- Usually, the formwork is removed one week after pouring. Installation can be continued in about two weeks.

Fastening

If the foundation is monolithic, then special nodes can be provided to secure the columns made of wood. If you have embedded a rod in the foundation, make a hole in the vertical bar and push it onto the support. After that, you only need to take care of the additional fastening.

Additionally, the frame can be secured using pins made of wood, struts, brackets or steel corners

... When installing vertical elements, you need to constantly check whether they are evenly located.

For structures with one floor, one pillar is usually enough, but for two-story structures, it is recommended to install 2-3 racks in the corners

... This will make the gazebo as stable as possible. The distance between the vertical elements depends on what dimensions the gazebo has, as well as on the type of construction.

The height of the vertical posts varies. You can install a vertical element along the entire height of the structure: it will be a solid column. This is a rather difficult option for doing construction work with your own hands. You can choose another way: as if build up the vertical elements of the 2nd floor to the racks of the 1st

.

Having installed and secured the pillars of the 1st floor, begin to mount the floor beams, which should be located between the floors. They are held in place by a transverse harness. You will also need to take care of additional fastening. Craftsmen use a variety of methods that allow you to reliably connect different elements. This, for example, the use of hidden spikes that do not allow the beams to move.

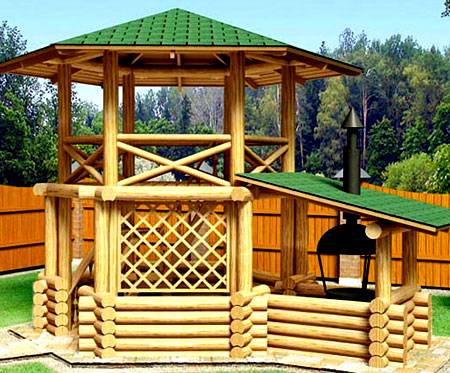

A two-story gazebo in the country is a comfortable and functional place for outdoor recreation. Such a building is being built taking into account the number of people in the family and the area of the land plot.

The project of a two-story wooden gazebo with barbecue and barbecue

For a two-story gazebo, the following advantages are characteristic:

- Multifunctionality - this design is large, so it can be divided into several zones. Experts advise to divide the space of the gazebo into two floors into a summer and winter zone. Separately, you can make a children's corner.

- Aesthetics - such buildings adorn the cottage.

- Saving space - in a small area, you can build such a spacious structure as a two-story gazebo with an open terrace.

- A complete rest - the structure in question will allow all family members to enjoy the sunrise and sunset.

It is being built according to a preliminary prepared project. You can use ready-made ones or prepare projects yourself. First, you need to decide on the functionality and the season of use (all year round or in the summer) of the building.

Projects of REALLY LARGE gazebos 6 by 6

From a bar

For a large building - a thick bar. It is impossible to put "weaving" for free, you will have to use a section of 150 by 150 mm.

With barbecue

I saw an interesting solution from the patio, that is, a small area next to the gazebo. The building itself turns out to be small, but due to the site it expands to just 36 squares.

From a log

Many trees will have to be filled up to make such a gazebo, oh, a lot ... During construction, the cheapest log of natural moisture is used, otherwise the cost of the structure will be prohibitive.

You can save on material by increasing the number of entrances to the gazebo. As a standard, there are two of them, and so you can implement four.

Small openings can be made in the walls to use less logs. In the future, they can be covered with polycarbonate or simply left as they are.

Made of metal

Large metal buildings are expensive. Due to the scale, it is impossible to use a thin profile pipe, otherwise the whole structure will sooner or later bend and collapse.For safety reasons, it is recommended to use wrought iron, since a lot of solutions have already been implemented.

The cost of such a turnkey gazebo will be estimated at hundreds of thousands of rubles. Do you need such a recreation facility? The owner is a master, take your pick.

More options

Large gazebos are diverse in terms of shapes and designs. In some cases there is a utility block, sometimes a stove complex, somewhere in front of the entrance. There is something to diversify the building, in contrast to small buildings.

Ideas and their implementation

What to build from

Like any other building, a two-story gazebo can be built from wood, metal, brick or blocks.

The simplest option is an open terrace on the second floor. At the same time, there is no need to install a roof, it is enough just to make sure that the interfloor overlap is airtight, and the floor of the upper floor is moisture resistant.

The second most difficult element of a two-story arbor is a staircase. But even this task can be simplified by making it not inside, but outside. That is, you can go up to the second floor directly from the street. Otherwise, the construction of a gazebo in two tiers will not be too different from the traditional one.

Spacious gazebo on two floors

It is easier and cheaper to use timber for construction. In any case, this is not metal that needs to be cooked, and not heavy brickwork, for which you need a solid foundation (see DIY foundation for a gazebo: choose the right one and do it). So, we will take as a basis a wooden frame gazebo, similar to the one we see in the photo above. What is needed for this?

| Construction phase | Basic materials |

| For the foundation | Under the condition of a normal geological situation, a columnar foundation is sufficient on the site for a frame gazebo. To do this, you can use: clay brick, lightweight concrete blocks, or make the pillars monolithic, pouring them with formwork directly into the ground. |

| Vertical posts and harness | It is better to use glued laminated timber with a section of 150 * 150 mm for the installation of bearing racks. It is better to tie the lower perimeter and interfloor part with lumber of the same section and you can use a cheaper planed beam. For strapping the gazebo along the upper belt, you can take a beam of a smaller section: 100 * 150 mm. |

| Beam floor | The floor beams are mounted from the same material as the upper strapping: 100 * 150 mm. |

| Rafters and other roof elements | The dimensions of the elements of the rafter system (see Rafters for the gazebo: set according to the rules) depend on the structure of the roof. If these are ordinary rafters, then they take a board of 50 * 150 mm, in the structure of the hip roof there are also nipple rafters, which should be twice as thick. A metal tile or ondulin is ideal as a roofing material. |

| Filling fences | At least one floor (second) in such a gazebo must be fenced. For the installation of parapets, 100 * 75 mm bars are perfect. If you want to make decorative trellises (trellises), you will need 20 * 40 mm slats. |

Finally

To get acquainted with the technology for assembling such gazebos, it is recommended to watch the video in this article to make the work easier. A visual demonstration of the process will help clarify some points ().

The gazebo is considered the most attractive place in the suburban area

Therefore, when preparing for construction, you need to pay attention to its location, color and size. It is strongly not recommended to start building a gazebo without a finished project.

The simplest arbor made of wood is suitable for giving. The project of a gazebo, for example made of bricks, will be more complicated and will require the development of not only the above-ground part, but also the foundation.

But brick gazebos can be used all year round, they perfectly protect from cold and wind. The project of brick arbors often involves the construction of a hearth: barbecue or fireplace. For the design of brick gazebos, it is recommended to involve specialists in order to ensure the required quality of work.

Building material such as foam concrete is gaining popularity for construction. Gazebos made of foam blocks are frost-resistant, heat-insulated and at the same time fire-resistant.

The low weight of such buildings allows you to do without a foundation. Structures made of foam blocks are distinguished by the speed and quality of construction. Foam concrete blocks allow you to diversify the gazebo with different decorative elements. The project of a gazebo made of foam blocks is economically profitable due to the low cost of the material and environmentally friendly, because foam concrete in its properties is close to wooden buildings.

Many summer residents like a gazebo with a kitchen. Designing such a gazebo has its own distinctive features. The gazebo can be conditionally divided into two functional areas:

- kitchen;

- guest area.

These zones should be clearly worked out in the project, it is also worth thinking about the drainage system. Today it will not be difficult to connect the gazebo to electricity and heating. As for the guest area, it should be equipped with a dining table and chairs.

Many firms provide a turnkey gazebo design and construction service. You can buy ready-made projects. Prices for projects for gazebos depend on the complexity of the gazebo and the originality of the design. For example, a project of a gazebo with barbecue household blocks 9 x 5.6 meters will cost 12,000 rubles.

Photo-project of a two-story gazebo