Bench made of old boards

When there is no time to draw up drawings and detailed diagrams, but you just need to put together the most primitive design in haste, then in this case using boards as a base is the best option.

If there are good boards available, you can, of course, use them too, but old boards are also fine for making a wooden bench. For example, from old pallets.

The first step is to prepare all the blanks by sawing them off to the desired size. We collect legs from the first batch of blanks.

In this case, the hind legs are short, and the front ones are long, the back will then be attached to them.

In general, the process of making a do-it-yourself bench with a back is quite simple. It can be done literally in 1 day.

When the legs are ready, you can start making the seat and back. To do this, we glue the prepared boards in pairs. Then we process it with a plane and grind it.

We drill holes and screw the remaining parts to the legs. A garden bench with a back is ready. Since it will be on the street, it is necessary to paint or varnish it.

As you can see, using even the simplest building materials, you can make a pretty decent garden cottage furniture... And this does not require so many tools.

Why made of wood

If we dwell in more detail on the issue of the expediency of using wooden blanks for the manufacture of country furniture, then we can highlight several main advantages.

To make a wooden bench with your own hands, you do not need a lot of tools.

It is quite possible to get by with a hand hacksaw (well, or a hand circular, if any), an electric drill and a screwdriver, which can be replaced with a hammer and nails. Many summer residents have this minimal arsenal.

Wooden garden benches are quite lightweight. It will not be difficult to drag them from one place to another, if the need arises. And it is very easy to care for them.

And the most important thing is that lumber can be found without any problems in the required quantity. Old wooden pallets are one of the "donors". But, for example, rafters dismantled from the old roof are also suitable for making a bench or bench.

How easy it is to make a bench from a professional pipe with a back

The backrest does not complicate the design too much. It is only necessary to increase the number of elements and arrange them correctly.

In the proposed scheme, rectangular sidewalls are used, the lower parts of which protrude backward - for greater stability and so that the bench cannot tip over. The back has three longitudinal and three transverse elements, the seat has only two longitudinal beams. The third is located below, between the sidewalls, to increase the strength of the structure. You can move it to the level of the lower cross-members of the sidewalls, but in this case it is better to install two such beams - in front and behind.

The bench is made from a square shaped tube 30x30 mm by welding. For flooring of the seat and backrest, a dry pine board, section 20x100 mm, is used. The length can be strictly equal to the length of the bench (1500 mm), it can be increased due to lateral offset by 20 ... 100 mm on each side.

Calculation of materials:

- profile pipe - 2 pcs. 364 mm, 5 pcs. 350 mm, 4 pcs. 500 mm, 1 pc. 140 mm, 8 pcs. 1500 mm;

- board 20x100x1700 mm 5 or 6 pieces (on the back, if desired, you can install not two, but three strips).

To weld a metal bench, you must adhere to the following sequence:

- first, the sidewalls and the back are made;

- then connect the sidewalls with the longitudinal beams of the seat and an additional beam located under the seat;

- the shortened rack is welded onto the beam under the seat and the middle cross member of the seat is attached;

- connect the bottom of the bench to the back.

After the completion of welding, the seams are cleaned, polished if necessary, and the frame is painted.

In the finished frame, holes are marked and drilled for the seat and back boards, and wooden elements are attached. It is better if the tree is treated with an appropriate decorative and protective compound before being installed in place.

In more detail, the process of preparing parts (including wood) and assembly is shown in the video.

According to a similar principle, benches are assembled from a profile, presented in the diagrams below.

Here, bent elements are used instead of the lateral strips of the sidewalls.

In this version, the sidewalls are completely assembled from parts bent according to a pattern, and the back and seat frame is made of strip.

Simplified design without side members and longitudinal beams

It is advisable to use a pipe with a larger cross-section and pay special attention to the quality of welding.

Model with a wide lower cross member (left) and X-shaped sidewalls (right).

And here is a more detailed drawing of a bench for a summer residence with bent armrests, which are part of the sidewall structure.

Log bench

The site can be decorated in any style, but almost everyone leaves the standard approaches to solving the problem. Everyone wants to have something of their own. But not everyone knows what is new, it is an improved old one. As a variant of the new, but somewhat improved old one, this is a variant of using a log as a bench. As a seat, you can use a large diameter log, sawn lengthwise. A log of a smaller diameter, also sawn lengthwise, is used as a backrest. Or a smaller trunk, but cut closer to the edge. Narrow lengths of logs are used as legs.

The legs and seats are connected with metal pins. For the pins, holes of a slightly smaller diameter are drilled. The pins must be firmly inserted into the holes. In this case, half of the pin is hammered by blows to the pin, and the other half is driven by blows to the tree. As a rule, they do not hit the tree itself, since traces of the hammer may remain, but with the help of a wooden guide. Such a connection must be reliable, although there are many mounting options.

In the photo, just above, you can see another option, in the style of "ethno". Its organization is associated with the presence of a stone, although this option is quite feasible in the presence of a log. A fairly thick log is used as a seat, and a part of a large-diameter log is used as legs. In one and the other part of the deck, grooves are cut out for the seat. An ax or grinder is used as a tool. Alternatively, you can use a chainsaw. These are not the post-Soviet "Friendship" or "Urals", which have significant weight, and they, perhaps, are convenient to roll pines in Siberia. If you take into service the "Calm" chainsaw, then with its help you can make not such works of art.

It is really possible to make a table from logs, which is simply necessary in the country. In the photo you can see the results of such actions. The table top is made of planks, and the rest of the ensemble is made of logs of different diameters.

The next bench, built in this style, has a completely original design. Here, the legs and armrests are made of twigs of various thicknesses, and the seat is made of processed, high-quality unedged boards.

Another bench is made in the same style. The only difference is that the boards and branches have opposite directions. The result is a completely different look. As for the execution, there is no special skill required. The more careless the end result, the more valuable it is. In any case, this is how others perceive this approach. Most likely, people are tired of imaginary perfection and they prefer handicraft and primitivism.

Alternatively, you can organize a rest area and install a bench around the tree.

It is not at all difficult if you install a swing and a gazebo next to it. Above the bench itself, it is better to build an arch-like pergola. For a good rest, only a pond, a fountain or a waterfall are not enough.

Making country benches from wood with your own hands in ethno style

Ethno and rustic style design trends are often used in interior design. A country house, cottage or summer cottage is a great place to create an eco-friendly and natural corner suitable for family vacations. This design can be continued in the garden. To do this, it is enough to make a do-it-yourself bench with a back from logs (Fig. 1) and other natural materials.

Helpful advice! For the construction of the structure, you can use logs with or without bark. To process the material or leave it in its original form - it depends on your wishes and the design of the site.

Benches made of logs are distinguished by their originality and environmental friendliness

Do-it-yourself technology for making a country bench from a log

To form a seat, it is enough to saw the tree trunk lengthwise. This can be done exactly in the middle (in the diameter zone) or by moving the saw closer to the edge (in the middle diameter zone). The backrest is made from a thinner tree trunk, or you can cut it closer to the edge. As a result, this element should be thinner and lighter than the seat part.

Legs can be made from the remains of a log. They are connected to the seat part using metal pins. This is done like this:

- In the parts to be connected, holes are made for the pins in the appropriate places. The diameter of the holes should be slightly smaller than the diameter of the fastener.

- The pin is driven into one of the holes at about the middle of its length.

- On top of the free edge of the pin, the second connected part is pushed on and also hammered. In this case, the blows do not fall on the pin, but on the wood.

Ethno and rustic styles are great for decorating a personal plot

The fasteners are hammered in with a sledgehammer or hammer. Since wood is a fairly soft material in structure, hammer blows can damage the surface. To avoid this, you need to place an unnecessary board under the tool.

The pins ensure a secure connection of all parts. To strengthen the fixation, 2-3 pins can be installed.

Ethno style in country benches with a backrest with your own hands: additional ideas

In the ethno style, you can create a design with a non-standard performance. A highlight can be, for example, making a bench using curved branches of different diameters. Before assembling the product, these branches are processed and sanded. In other words, the bark is removed from them, and then the surface is sanded with sandpaper. An unedged board must be used to assemble the seat. It is handled in a similar way.

Note! All elements of this structure have rounded shapes, and the seat boards are facing forward. If your summer cottage has a wicker fence, you can use the same design option with some changes.

Short seat boards can be replaced with long ones by placing them lengthwise. The back is formed according to the principle of weaving from branches of medium thickness, which bend well

If your summer cottage has a wicker fence, you can use the same design option with some changes. Short seat boards can be replaced with long ones by placing them lengthwise. The back is formed according to the principle of weaving from branches of medium thickness, which bend well.

You don't need to have any special skills to make a wicker back. You may succeed not a very neat result, but this is not necessary. The back should be simple and unobtrusive, rough weaving will only increase its decorative properties.The branches can be placed tightly or, conversely, you can leave gaps between them so that your bench "breathes".

Location

The first problem that needs to be solved is choosing a place for the shop. It affects the material of construction. For example, for an old garden with large branchy trees, wood products are suitable, for a small area that is not heavily planted trees and shrubs, small openwork designs are recommended.

If you search the net for examples of photos of benches in the country, you can see that they are often a constituent element of gazebos, verandas and summer grounds. If you plan to do something like this, then make sure that all the details are in the general style.

Choose a place for the bench so that a pleasant view opens up from it. It is unlikely that you will want to admire the neighbors' fence or the walls of the barn.

It is desirable that the bench is located in the shade. It is placed under the crowns of large trees or under awnings. Remember that it acts as a place to rest and relax.

You can put benches next to the beds. There are several advantages to this. Firstly, the owners of the site will be able to monitor the growth of the crop. Secondly, the shop is suitable for taking a break from physical labor (digging, watering, harvesting) for a few minutes.

Do not forget about decorative ornaments. Did you make a simple shop with your own hands? Place flowering shrubs around it. Flower beds are also suitable for decoration. They are placed on a raised platform or a special platform made of bricks, tiles or logs is created.

DIY soft bench

The X-legs are an extremely versatile piece that can be used for extra fit wherever you need, because they are lightweight and flexible. An upholstered bench can be placed separately against a wall or under a table when not in use, grouped around a coffee table or at the foot of a bed. The possibilities are almost endless.

To have a visual idea, take an old piece of cardboard and sketch out the finished part, then you can make sure your corners are cut correctly. Note that the corners shown here will work for these dimensions, giving you finished X-legs that are 43 cm in width and height. You can change the length of the bench from one leg X to the other without changing the angles, but any change in the width or height of the bench will change the angles required for proper assembly.

You need to cut the parts like this:

- Planks 1 1/2 "(38 mm) x 3/4" (19 mm) - cut one end at a 50º angle. Measure 9 1/2 "(244 mm) from the pointed side and cut the other end at a 9 ° angle. Repeat this process eight times to make eight equally cut pieces of wood.

- Planks 1 1/2 "(38 mm) x 3/4" (19 mm) - cut one end at a 50º angle. Measure 19 inches (480 mm) from the pointed end and cut the other end 50 degrees. Repeat this process four times to make four identical pieces.

- Planks 1 1/2 "(38 mm) x 3/4" (19 mm) - cut one end at right angles. Measure 17 inches (432 mm) and cut the other end at a right angle. Repeat this process twice.

- Block 1 1/2 "(38 mm) x 1 1/2" (38 mm) cut one end at a right angle. Measure 14 inches (355 mm) and cut the other end at a right angle. You only need one such detail.

- You will also need a sheet of 2mm plywood cut into a 17 "(432mm) square, 100mm foam cut into a 17" (432mm) square, at least 30 1/2 "(780mm) batting and fabric the same size. Glue, impregnation, upholstery nails and staples, wood screws. You will need a total of four planks that are 1 1/2 "(38 mm) x 3/4" (19 mm) thick and 182 cm long.

Corner wooden bench

See how to transform a regular balcony into a cozy outdoor seating area that can accommodate 4 to 5 people. Having so many chairs on such a small balcony would be cumbersome, so instead, it is better to make a corner wooden bench with a large stand that acts as a backrest and railing.To keep things simple, use this simple design. Given the basic tools and materials, this project will only take a couple of hours to complete. See below for step-by-step photos, which show the highlights of the assembly and drawings of the bench.

Simple bench with backrest

Another simple project is shown in Fig. 2. To make a do-it-yourself bench with a back, you will need 2 pieces of logs about 25 cm long, boards for the back and seat and 5x5 cm bars for the back uprights. If you want the seat to be a little higher, you can take 4 segments logs or beams and lay them on top of each other, fastening with dowels.

Making a bench is very simple. So that there are no nuts and heads from nails on the surface of the product, fasten the parts with dowels and glue. The back can be screwed on with self-tapping screws from the seamy side so that they do not drill through the board.

To make dowels, you need wooden rounded rods (a thin handle for a garden tool will do). Drill 2 holes with a diameter equal to the dowel thickness in the log. Focusing on their location, make reciprocal grooves in the underside of the seat. The work must be done very carefully so that during assembly it is not necessary to adjust the parts of the bench. For more information on making a bench with a back, see this video:

Grease a piece of wood for the dowel with glue and insert it into the hole on the log so that a small fragment remains outside. Its length should be equal to the depth of the recess drilled in the seat (fig. 3). Lubricate the dowels with wood glue and place a board on them. Do the same with another piece of log.

Cut the bars to the desired length for the back uprights. Fasten with self-tapping screws to the ends of the logs. Drill 2 holes in the upper part for attaching the backrest. The distance between the holes should be less than the width of the board. Screw the self-tapping screws through the holes into the board. The finished bench can be painted or varnished.

How to choose a place to install a country bench

Before you start making your own bench, you need to be very careful about where to place it. This issue is worth tackling because a bench is not only an object for the convenience of rest, but also a place where a sufficient amount of time will be spent, and therefore the view and atmosphere should be suitable. In addition, a lot in its design and installation process will depend on the selected site for installing a garden bench, as well as its type.

Examples of the arrangement of garden benches from the side of the design solution.

| A garden bench made of wood combined with framed forging.

A bench made of logs with a stone base. |

It will harmoniously fit into a garden where trees with large crowns and various fluffy shrubs grow. |

Bench romantic style, openwork |

A garden of young trees or a vineyard is good for placement. |

Miniature bench, painted white |

Ideally, it will be in contrast with a dense hedge of rich green color. A pond, flowering flower beds, or just in a secluded corner decorated with flowers would also be a good option for such a shop. |

Retro bench made of "old" wood |

It can create a very mysterious atmosphere together with curved trunks located nearby old trees, near which flowers of various types are planted. |

Bench combined with decor items |

A very popular place to place a bench is a veranda or gazebo. In this case, a do-it-yourself garden bench should be made in a similar style with the already existing decor items and the veranda or gazebo itself. |

Combined benches and table |

Such a design will be good on a small spacious plot of land, which can be decorated with floral vegetation, it can also be located next to the house or under a shed. |

In addition to the listed options, you can install a bench in a place where children usually spend their leisure time, which will allow you to be next to them when they play. A place to rest will be especially well organized if there is a lonely tree on the site with a spreading crown, setting a bench directly under it.

In addition, you can organize a shed near the house, under which you can put a garden bench. It will be a good resting place even in rainy weather. There is another option simply to determine the place of the bench on the ridges where the crop is grown - it will be convenient for rest between work in the garden.

There are a lot of options and ideas for implementation that a do-it-yourself garden bench made with your own hands can allow. It is quite simple to come up with a decorative composition with her participation, for example, it looks good on elevations, decorated with boulders or shrubs, and a bench that harmoniously merges in a flower bed is also pleasing to the eye.

How to make a simple wooden bench with a backrest with your own hands

How to make a simple wooden bench with a backrest with your own hands

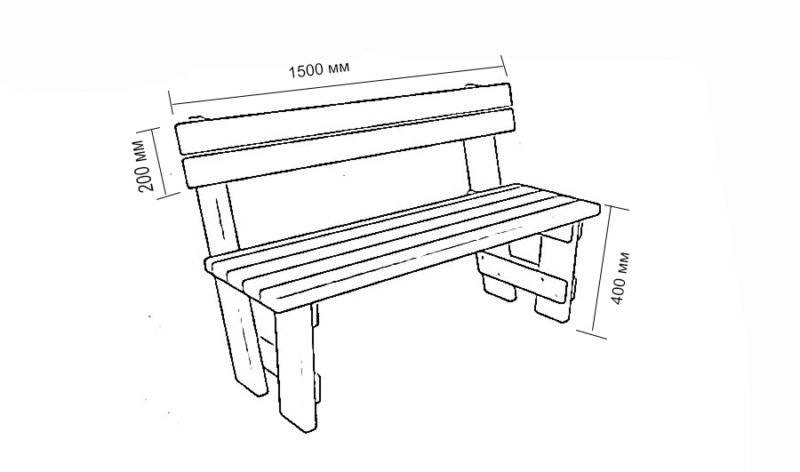

Bench design

The length of the seat and backrest will be 1500 mm. This furniture can comfortably accommodate three people at once. Seat height 450 mm, backrest height 900 mm. It is advisable to position the back at an angle of 18-20 degrees. The seat width is 400 mm.

Material and tools for making a garden bench made of wood

- Wooden boards 1500 x 150 mm, 35-40 mm thick. Three blanks for the seat and two for the back.

- Workpieces that function as legs and holders for the backrest - 900 x 150 mm, 35-40 mm thick.

- Blanks for the front legs of the bench - 360 x 150 mm, 35-40 mm thick.

- Beams 40 x 40 mm will be used to reinforce the bench structure.

- Self-tapping screws.

- Electric jigsaw for cutting boards.

- Electric planer for sanding the surface of boards and processing chamfers.

- Screwdriver.

- Sandpaper.

- Varnish and primer.

Manufacturing of a wooden structure

Bench drawing

Step 1. Boards for making a bench can be purchased immediately in size, if they are not available for sale, the wood will have to be cut into blanks using a jigsaw or a miter saw.

After the wood has been cut to the desired length, it must be carefully processed. The blanks for the back and seat must be sanded. All ends of the boards also need to be processed with an electric plane, it is desirable to give them a rounded shape.

Step 2. The long back legs of the bench, which additionally serve as a frame for the back, must be set to the correct angle of inclination. To do this, you need to apply markings on two wooden blanks with a length of 900 mm.

The first is the height of the bench - 400 mm. This piece of board does not need processing. Starting from the segment, you need to make a cut of 20 degrees along the entire remaining length of the board, which forms the angle of inclination of the back of the bench. The cuts on the two back legs should be the same both in height and angle. Otherwise, the bench will be skewed.

Step 3. Legs are assembled first in the design of the bench. The distance between the front and rear legs is 280 mm. The legs are connected with a bar, which is cut to the full width of the bench - 500 mm. It is advisable to make a double strapping - top and bottom.

Step 4. After the two sides of the bench are assembled, you can connect them together with boards designed for sitting. Boards are screwed with self-tapping screws to the upper strapping beams. It is desirable that between the wooden blanks there are gaps of equal size - 1-2 cm. These gaps promote air circulation and moisture removal.

Step 5. Strengthening the bench structure. For garden furniture to be stable and durable, it is advisable to strengthen its structure. For these purposes, you need to make the lower strapping along the legs with the help of beams. Two pieces, 1500 mm long, are screwed to the front and back legs of the bench. If there is not enough lumber, you can use one cross member, which is attached to the lower rails of the strapping.

Step 6. Mounting the back of the bench.The bench is almost ready, the final touch remains - the fastening of two boards that serve as a backrest. It is recommended to fix the first plank at a distance of 200 mm from the seat. The second is at a distance of 380 mm from the seat.

Step 7. Finish the garden furniture. To protect wood from environmental influences, it is advisable to use deep impregnation and varnish. The impregnation will protect the bench from moisture, mold, insect pests.

The varnish will give the furniture a beautiful and elegant look. To give the wood shine, you need to thoroughly polish the material, and varnish the blanks several times.

Original benches made of wood

In the event that you consider yourself a creative person, by looking at the photo of benches for a summer residence, you will definitely find the option you need.

With an abundance of greenery, large flower beds, you can go for a little trick. It is necessary to combine the flower beds with a board. By stuffing several long boards on the wall (when the bench is located near the wall), you will make a back.

For self-production, it is worth picking up ready-made flower beds and purchasing a polished board. An alternative option is half of the log.

The seat can be secured with a metal corner. Use self-tapping screws, bolts for secure attachment to the tree. Dowels are suitable for fixing to concrete.

Functional features and types

When arranging a personal plot, the owners usually first plan the location of the beds, arrange paths, install gazebos

Also, much attention is paid to flower beds, lawns and flower beds. And only at the final stage they think about purchasing garden furniture

The range of garden furniture in stores is extensive

When choosing, you should pay attention to:

- main characteristics (dimensions, weight, complexity of installation, assembly);

- material (wood, plastic, metal);

- functionality.

If we talk about functionality, the benches can be roughly divided into 2 categories:

- standard models that can only be used for their intended purpose;

- transforming benches (can be folded out, turning into a table), swings, folding models.

A good option for giving are hanging swing benches with a back. Sold in a variety of materials, shapes and designs. It is better to buy models with an awning, and if you make such a swing with your own hands, build a canopy made of thick fabric, for example, tarpaulin, which will protect from the sun and rain. You can also make a "roof" of cellular polycarbonate - practical and reliable.

Stationary benches are also popular with dacha owners (you can find out how to do it from step-by-step photos). Concrete is usually used as a base, less often brick. They are reliable, maintenance-free, resistant to humidity and temperature extremes, but take up a lot of space. Therefore, this is the easiest way - for large areas.

Also read: Summer kitchen with terrace under the same roof

Foldable - Compact and mobile benches come in handy if the garden area is used as a weekend getaway. If necessary, the benches can be quickly expanded, and in the absence of the owners, stored in the garage or house. For the frame, metal or wood is usually used.

How to make a do-it-yourself plank bench

Check out five pictures of how to make a simple wooden plank bench.

If you can find several planks that you need to pre-cut in the workshop, then you probably won't even need a saw. Start assembling the bench on a flat surface. You can press the pieces against the wall so they are well aligned. Make sure the screws are not too long to go through the boards. Fix the parts as shown in the pictures, that's all.

Street bench with drawer

At first glance, this bench may look like a complex project. But take a closer look, and you will understand that there is simply no simpler design. It is just a box of four frames with legs. The panels, which are fixed to the frames, are plywood covered with waterproof fabric.

Covering the seat with foam and fabric is something that even a beginner can do. If necessary, you can easily resize the bench to suit your needs; choose a fabric to blend in with other garden furniture; paint the tree to match your terrace or color to match your home design.

Time to make an outdoor bench with a drawer: you can do it over the weekend

The bench is made of 1 × 4 pine planks. Using rot-resistant wood like cedar or teak will more than double the cost of lumber

Pine planks are not that expensive, but attention must be paid to quality in order to assemble the knot-free sections for the visible parts of the bench. You can use the remnants of the planks (G) that form the floor inside the structure

The padded seat and panels are cut from a single 3/8 ”BC plywood.

For the project, you will need a table saw, jigsaw, sander, and drill. Router bit and chamfer as required. You will also need a pocket hole clamp to assemble the frames.

What material to choose: useful tips

For the manufacture of wooden structures for a personal plot, pine, oak, birch boards or logs are usually used, as well as pear, hornbeam and durable larch. Almost any tree is easy to process, has excellent decorative qualities, and also aesthetically fits into the suburban landscape. The main advantage of wood is its beautiful aesthetic appearance. But meanwhile, it negatively tolerates sunlight, high humidity and low temperatures (severe frosts). Therefore, it is best to install wooden benches in closed gazebos, on terraces covered with awnings, or to make them portable (collapsible) so that they can be removed to a closed room (pantry, basement, closet) for the winter.

- In the manufacture of stationary benches, combined materials are usually used, such as wood and iron, wood and building bricks or concrete, wood and stone. The seat and backrest are usually made of wooden planks or beams, and the supporting parts are made of other materials that can withstand various weather conditions and temperature fluctuations well.

- Metal benches are not very popular among the owners of country houses and summer cottages, who themselves make garden furniture for their home. They prefer to use wood that is easier to work and handle. The fact is that it is not very easy to work with metal and often you need to have a welding machine for this, as well as be able to work with it correctly.

- Therefore, mainly only the supporting parts are made from a metal profile, and the seat and backrest can be made of wood.

- In addition to metal legs, benches (supports) can be stone, brick, concrete, etc. Cast iron and concrete supports are considered the heaviest, therefore they are rarely used in the manufacture of benches for a country house or dacha with their own hands.

- Stone supports are too expensive and heavy, so they can only be seen on the territory of large country houses and cottages of people with good income.

- The wooden supports of the benches would seem to be the most optimal - they are beautiful, lightweight and can be used to make decorative carved legs. But the big disadvantage of such structures is the fact that in an open area in the rain, snow and sun, they will quickly become unusable.

- The tree needs special care, as it is damaged by various parasites, mold and fungi, and it also swells quickly under the influence of moisture and begins to rot.

Steel supports will be the most competent choice for making a bench with a wooden seat and back to place it on the territory of a summer cottage or a country house. Such a bench will serve you for at least 15 years, and it will not need to be removed during snow or rain.

Stone bench

Stone benches can even look like an armchair and they will be an excellent solution, because this is a natural material that will perfectly fit into the overall picture.

However, compared to previous materials, this one has a number of disadvantages, and the first of them is the lack of comfort, that is, sitting on such wonderful furniture is harsh, and the stone absorbs too much cold, which can greatly affect human health.

But you can use comfortable, thick, warm pillows, which will give such a bench even more solidity and originality.

The stone bench is installed once and for all in view of its severity, but it looks as if it has always been there.

Bench options

- A bench made of logs that blends well with the surrounding nature. It consists of half a log used for a seat, and two short round logs that are legs.

- A beautiful wooden bench with a back and armrests, reminiscent of a sofa. Curved and cut elements make it look more attractive, while the knots and unevenness left behind give the design a natural look.

- Bench made of wood and metal. The base of the structure is metal. The wooden parts of the seat and back are fixed to it. The thin metal parts make it look light.

- The bench is of a simple, classic shape. It is made of rather wide wooden planks. This width allows you to comfortably sit on the bench. The armrests complement the design.

- An original bench made of wood with curly details. This option is well suited for a plot with a natural, rural design. Carved legs and armrests, curly back - all this gives the product originality.

- A bench with an interesting backrest. Curved parts gradually tilt back, creating a unique design. The seat is slightly curved but has a more traditional look.

- The complex is made of wood - a table with two benches. The design looks traditional thanks to the material used. The original solution is to fasten all the components into a single structure.

- The bench is made of solid logs. A single piece has been cut out of it, combining the back and seat. Legs are attached below. The log is required rather large.

- Bench with storage box for toys. Outwardly, it looks like an ordinary wooden sofa bench, but under the seat it has a drawer into which you can put various things.

- A comfortable bench made of wood with a simple shape. The base is made in the form of a rectangular box. The back is also simple with a straight shape. The seat has soft cushions for added comfort.

- A wooden bench located around a tree. It is made as if it consists of four benches, each with one armrest. The composition looks attractive and comfortable.

- A simple bench made of wide boards. It looks solid, but its dimensions are somewhat obscured by the gaps between the boards and the light blue color in which it is painted.