Rafters of the main ramps

It is quite difficult to calculate a hipped roof on your own. For the reason that the safety of the system will depend on this, it is preferable to entrust these works to specialists. But the construction of the roof itself can be done independently

It is important to remember that installation begins with the installation of rafter frames. To do this, you can use hanging or layered rafters, but the latter are considered more preferable.

This is due to the fact that the main load from the slope is transferred to the ridge part. Visually, the roof will look more aesthetically pleasing if the angles of inclination, as for the main slopes, are the same. For this reason, the first rafter pair must be located at a certain distance from the corner of the Mauerlat. Calculating this distance can be simple: for this, the size of the hip side is determined, from the corner to the corner of the strapping. Then the resulting figure should be divided by 2, and the existing value must be set aside from the corner on the larger side. The marked point will be the installation site of the first rafter frame. In this case, it will be possible to achieve the desired, thus, the slope will turn out with the same angles.

The main types of hipped roofs

There are no pediments (these are triangular ends of the facades of the building, bounded on the sides by two roof slopes, and at the base by a cornice) on such a roof, and the attic windows are placed in the slopes.

This roof is much more economical than a gable roof in terms of the cost of wall building materials, but the inclined ribs at the joints of the hips and frontal slopes require the installation of a very complex rafter structure and additional measurement and adjustment of the roofing material.

Slopes are often made with different levels of inclination, due to which the silhouette of a sloping roof is created.

Half-hip (Danish) design. It differs from the previous one by the presence of a pediment, which has a small hip at the top. Protection against wind loads at such a roof is provided by a ridge (the upper horizontal edge of the roof formed due to the intersection of two slopes). Most often, such a roofing device is found in regions with frequent strong winds.

Hip design. It looks like a pyramid: four triangular slopes, converging tops in one place. Such roofs do not have gables; they are erected on small buildings in the form of an equilateral polygon or square. Installation of a rafter system at such a roof is very difficult.

Complex design design

Before starting work, you will need a sketch of the future structure. It is more rational to calculate the design of the roof together with the structure itself, when a system of its fastening is installed in the walls in advance.

Before starting work, you will need a sketch of the future structure. It is more rational to calculate the design of the roof together with the structure itself, when a system of its fastening is installed in the walls in advance.

The sketch for the appearance of the roof should take into account the local characteristics of neighboring houses so that the future creation does not look pretentious. At the same time, it can have its own original design, thereby standing out against the background of similar buildings.

The simplest and cheapest option is a pitched roof with one "working" surface. This option is used for non-capital, utility rooms and annexes to the main building. For residential or presentable capital real estate, a lean-to building is unacceptable.

It is best to hand over the design of such a building to professional construction companies, which will help to create not only a beautiful appearance of the building, but also provide for the high quality and durability of the coating. Experts will help you decide on a roofing for such a roof, advise the best manufacturers at affordable prices, and also make sure that further installation is simple and quick.

Recommendations from the pros!

Bath accessories

DIY gazebo

Concrete fence

Diy potbelly stove

Do-it-yourself veranda

Screw foundation

Country toilet do it yourself

Decorative brick

Stone fence

Pouring the foundation

How to make a fence

Wicket from corrugated board

DIY fireplace

Brick fence

DIY flower beds

Forged gates

Do-it-yourself porch

Bath tub

DIY chicken coop

DIY ladder

Metal gates

Installation of lining

Installation of polycarbonate

Pump for giving

Garage arrangement

Fences for flower beds

Do-it-yourself blind area

Steam room in the bath

Railing for stairs

DIY cellar

Painting the walls

DIY press

Lattices on windows

Rolling gates

Do-it-yourself shed

Alarm for summer cottages

Benches for giving

Fence posts

Floor screed

Solid fuel boilers

DIY greenhouse

Fence installation

House insulation

Attic insulation

Insulation of the foundation

Weir on roofs

The final stage of the installation of the roof is the equipment of its drainage system. Here, additional finishing of the entire structure is possible due to parts of the slopes or tightening beams protruding beyond the dimensions of the building.

The fastening of the drainage gutters is carried out on site, taking into account their slope to the drainage vertical pipes. It should be noted that such designs are extremely important for any type of home. So, the spillways not only provide dryness to the foundation of the house, but also allow avoiding the formation of ice and freezing in the winter season.

With the help of a simple installation of weirs, you can not only protect your house from dampness, but also significantly increase its service life.

Do-it-yourself hipped roof

The hip (hipped) roof gives the house a sophisticated look. The special design of the roof allows you to additionally protect the structure itself, its walls from moisture. Therefore, the construction of a roof with four slopes is optimal for regions with high rainfall and strong winds.

Stages of building a hipped roof

The first stage in the construction of a roof is to determine the purpose of the roof (covers the attic floor, attic, etc.), the choice of roof material (depending on this, a list of materials for construction will be determined), taking into account the atmospheric conditions of the place where the roof will be used (wind, rain , snow).

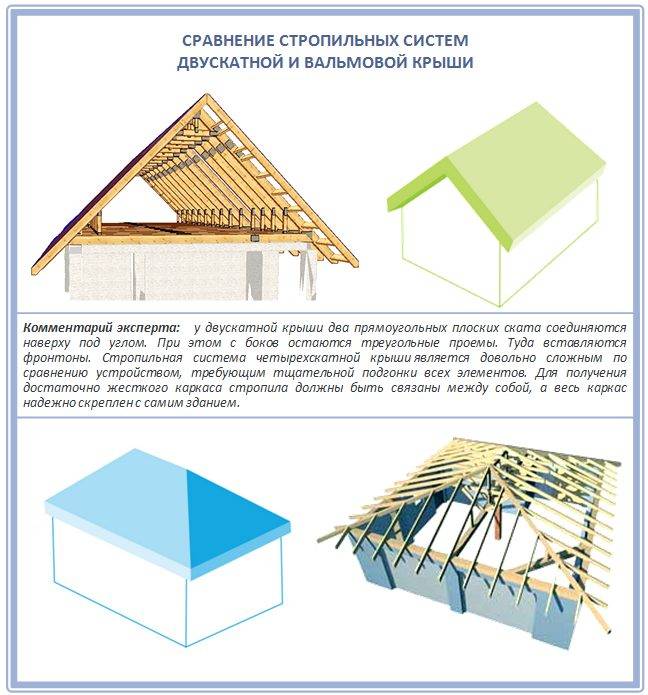

Choosing a hip roof will make the structure more resistant to rain and make it more durable (the rafter system is more reliable). The main difference between this type of roof and a gable roof is that it has two triangular roof slopes instead of side gables.

When choosing the angle of inclination of the slopes, one should take into account the level of precipitation and wind characteristics of the terrain. With low and medium average annual precipitation, it is recommended to choose an angle in the range of 4-40 degrees. With heavy snowfalls and lingering rains, the recommended optimal slope angle of the slopes is within 40-60 degrees.

The roofing material can be: roll roofing, shingles or metal shingles.

Depending on all of the above nuances, the thickness and other parameters of the wooden component of the hipped roof will be selected.

The end result of the first stage is the creation of a scheme for the future roof, on the basis of which the construction will be carried out.

We will describe the further technology of how to make a hipped roof with our own hands.

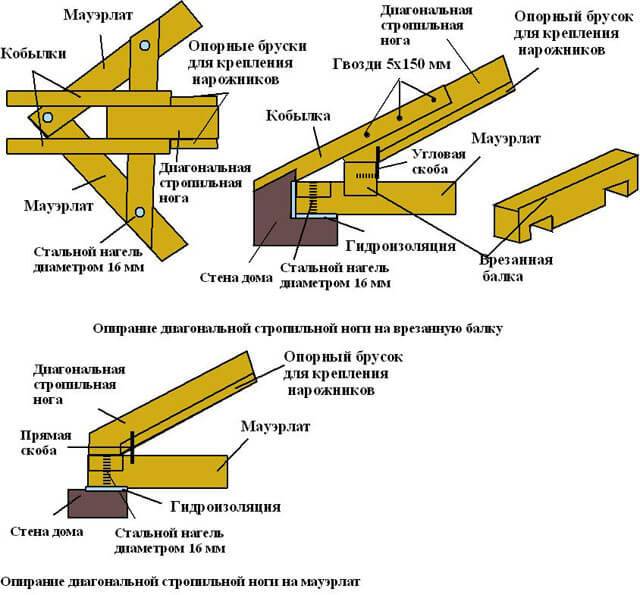

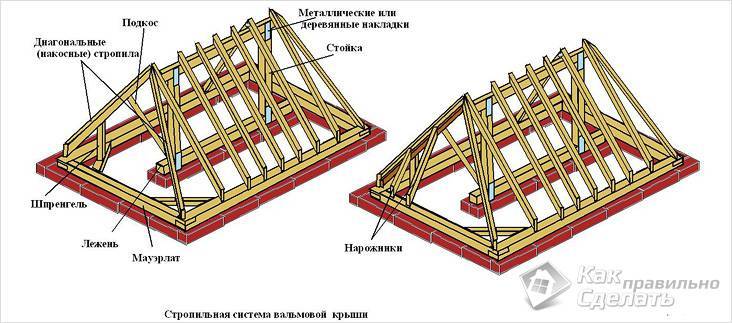

The second stage is to build the base for the roof. The base is used to evenly distribute the load from the roof to the load-bearing walls. The construction of a hipped roof assumes a base that you can build on your own - a wooden Mauerlat and beds. Waterproofing is required under the base to extend the life of the roof.A Mauerlat is placed on the hydro-barrier along the outer contour of the building (the size of this bar varies, either 100x150 mm, or 50x150 mm.).

Legs - a bar located in the plane of the base of the rafter system at the same distance from the two side Mauerlats. It serves as a supporting element for struts and struts, therefore it is laid on load-bearing partitions (see drawings of a hipped roof). Large roof structures can provide several beds.

The third stage is the direct installation of the roof frame (base, rafters, lathing).

The construction of a roof in a house with or without existing ceilings is structurally different (in this case, there is no need to lay the floor beams on which the supports will be installed).

The installation of the racks (vertical supports of the roof frame) should be approached with special care. The installation angle (90 degrees) must be precisely maintained. At the slightest deviation, further deformation of the roof is possible. The step of mounting the racks is up to two meters.

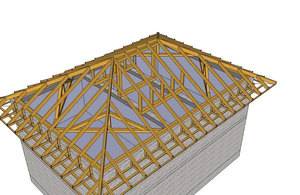

The device of the hipped roof of the house consists of four planes (slopes). Two trapezoidal and two triangular. Trapezoidal rafters will be formed by side rafters, hip (triangular rafters) - by slant (diagonal) rafters.

The support of the rafters at the top of the frame is carried out into the ridge beam (girder). This bar goes on top of the vertical posts (groove connection with the posts is possible). The distance between the rafters is from 50 to 150 cm (according to the roof plan). The recommended width of the rafter board is 150 mm.

The frame is fastened using corners and steel plates with self-tapping screws (nails). To strengthen the resulting structure, diagonal supports, struts, wind beams are used. They increase the load capacity of the system.

Waterproofing is laid on top of the rafters. Then a counter-lattice is made (bars that are attached to the rafters over the waterproofing). It is needed to create a ventilation duct between the roofing material, lathing and waterproofing. This will allow moisture to be removed quickly and efficiently. Next, the lathing is performed - the horizontal boards are attached from the bottom to the very top to the counter-lattice (see the diagram of the hipped roof device).

The last step is the installation of the roofing material. Installation is carried out depending on the parameters of the material. An example of metal tile installation.

Thus, the installation of a hipped roof is a rather laborious process that requires a careful approach. For a deeper understanding of the building, you should view photo and video materials.

Main elements

It is important to know the basic elements of a hipped roof. The frame or framing structure is designed to support the roofing materials, thus keeping the building watertight

Rafters are the structural elements of the roof that support the sheathing. Usually they are perpendicular to the wall, they never touch it.

Roof pitch refers to the amount of roof lift compared to the horizontal roof pitch, called pitch. As a rule, it consists of 12 units. If the roof rises 4 units in length of twelve, the height is 4: 12. In degrees, this figure is 18.43. The wrap-around sheets are small, overlapping roofing blocks with vertical stepped joints. They are made from wood, asphalt, slate, clay, concrete, metal or other materials.

Assembly and installation of hip rafter legs

Using the stretched lace from the ridge to the center of the slope, measure the lower angle γ and calculate the opposite angle δ = 90º-γ. As well as with diagonal parts, templates are made for cuts on the upper and lower heel of the element so that it fits snugly between the diagonal rafters. Having made the central hip rafter, it must be installed in the appropriate place.

The rigidity of the structure and reliable fastening of the shortest legs is ensured by installing short stems between the cornice and corner stems.

At the next stage, templates for women are made:

- A piece of board is sawn off at an angle δ and tried on at the junction with the diagonal leg.

- Distinguish the extra areas, then saw them off. You will need this template to create all the cuffs that will be installed on one side of the hip. For the other half, the cut on the blanks will need to be done from the opposite side.

- The lower heel of the wives is cut according to a template sawn off at an angle γ. Such a blank is suitable for creating the bottom joints on all wives.

The production of handcuffs is carried out taking into account the estimated length of the elements and according to the manufactured templates. They will fill the hips and main slopes. The installation of these parts is carried out so that the joints of the mats with the knuckles from opposite sides do not converge in one place, that is, they are staggered. Fasteners for connecting the rafters with diagonal rafters are corners, and with outriggers and floor beams - toothed plates or corners - to whom it is more convenient.

The construction of a roof with a hipped-roof type of frame is carried out using the same technologies as with a hip. The only difference is the absence of a ridge in hipped roofs. In this case, the installation of the rafter system of the hipped roof begins with the joining of the diagonal rafters, and then the rafters. If hanging rafters are used, the installation of the central truss is carried out first.

Thus, a detailed study of the features of the construction of hipped roofs will allow you to start creating a frame structure with knowledge.

Hip roof classification

Differences in the shape of buildings, as well as the requirements for functionality and practicality of traditional hip roofing, have contributed to many variations. If you do not consider the most exotic of them, then there are several main types of hipped roofs.

- Traditional hip roof, the side slopes of which reach the level of the cornice. For the construction of its main surfaces, straight rafters are used, and the ribs of the hips form bars extending from the ends of the ridge. The well-developed design and distribution of the weight of the roof over an increased area allows not only placing the overhangs on the same line, but also increasing their overhang. Thanks to this, the facade of the building is reliably protected from rain, even with strong gusts of wind.

- The hipped roof can be installed on a house that is square in plan. A feature of this design is the slopes of the same configuration. Their edges converge at one point, and their hips are in the form of isosceles triangles.

- Half-hip roofs got their name from the shortened hips. In contrast to the traditional roof, their length decreases 1.5–3 times in comparison with the dimensions of the main slopes.

- The Danish half-hip roof has a small gable under the ridge and a short hip on the eaves side. This design allows the installation of ventilation and lighting elements directly into the vertical end of the roof, thereby eliminating the need to install roof windows.

- The semi-hip Dutch roof has a vertical pediment that divides the hip into two short ramps. The rafter system "Dutch", although it has increased complexity, but it allows you to make the attic more spacious and practical. In addition, this design is excellent for the installation of vertical glazing in the attic.

- The sloping hipped roof has several slopes of different sizes on one slope. Thanks to their different slopes, it is possible to increase the volume of the roof space. Although the broken structure cannot be called simple, houses with such a roof are very common.The reason for the popularity is the ability to equip additional living rooms on the upper tier. For this reason, a roof with broken slopes is often called an attic.

There are also more complex structures of many hips, as well as those in which a hipped roof is combined with other types of roofing systems. The design and installation of such a roof requires many years of experience and knowledge, therefore it is better to entrust the construction of a tricky roof to specialists.

Installation of a hipped roof

The assembly of the rafter system must be performed in a strictly defined order. This is necessary in order to correctly install and secure all structural elements of the roof.

- To redistribute the load that the roofing structure, wind and precipitation exert on the walls, a Mauerlat is laid on the outer walls. In individual construction, for these purposes, a bar with a cross section of at least 100x150 mm is used. Anchor pins are used to fasten the longitudinal beams of the structure. They must be laid in the upper rows of masonry even at the stage of wall construction. Mauerlat waterproofing is performed using two layers of roofing material, which is laid on top of the load-bearing walls.

- If it is necessary to install vertical supports, planks are laid on the supporting walls. For horizontal alignment of the elements of the rafter system, wooden linings are used. In the future, this will greatly simplify the installation of racks and purlins. If the capital partitions are not provided for by the building plan, then the vertical supports are mounted on the floor beams. To do this, they are reinforced by splicing two boards of 50x200 mm or using one beam of 100x200 mm.

- Expose the support posts. To align them, use a plumb line or a laser level, after which temporary supports are installed. Metal corners and plates are used to attach the vertical support to a bed or a horizontal beam.

- Girders are laid on top of the racks. Traditional hip roofing requires the installation of one run, which, in fact, forms the ridge. Hip structures require the installation of four girders. As with the installation of racks, fastening is performed using metal corners and self-tapping screws.

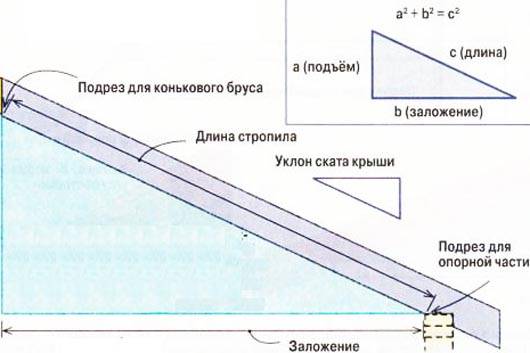

- Preparing the rafters. The side rafter legs of simple gable roofs are mounted in the same way as the layered legs on a gable roof. First you need to make a template. To do this, from the side of the extreme support, a board of the same width as the rafters is applied to the ridge. Its thickness should not exceed 25 mm - the template should be light. On this board, a cut is noted, which is necessary for reliable support and an accurate fit of the rafter leg to the ridge bar, as well as a cutout corresponding to the place where it joins with the Mauerlat. The marked places are cut out and then used to quickly prepare the rafter legs.

- When applying the manufactured sample to the purlin, it is necessary to check whether an exact fit of the rafter is necessary. If there are gaps, the cuts in the rafters are performed taking into account the amendments. After all the supporting legs are ready, they are set in 50–150 cm increments and attached to the Mauerlat and the ridge. Brackets are best suited for installation, but you can also take powerful metal corners.

- As already mentioned, diagonal rafters are made from spliced boards or a bar of an increased section. For their installation, you will also need a template, which is prepared in full accordance with the method described above. Since the rafters with one side adjoin the corner of the Mauerlat, and the other rest on the racks, the cut is performed at an angle of 45 ° to the plane.

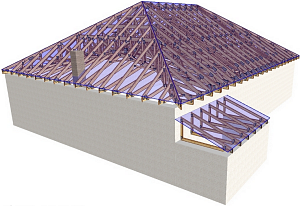

- In the intervals between the rafters, the beads are attached. Their step corresponds to the distance between the rafters, and the diagonal legs and the Mauerlat are the support points. The load experienced by the rafters cannot be compared with the weight that falls on the rafters, so the first ones can be built from boards with a thickness of 30-50 mm.To speed up the installation, you will need a template with cuts on the side of the diagonal rafters and Mauerlat, but the cutouts on the half of the rafters must be made in mirror image.

- If necessary, filly are fastened to the rafters and the rafters. The ends of the rafter elements are cut along the cord.

- Strengthen the slant and side rafters. In the first case, vertical sprengels are used, and in the second, struts installed at an angle of 45 °. They are supported on benches or beams.

- After the rafter system is assembled, a roofing pie is installed on top of it.

How to correctly calculate the loads on the rafter system

There are two types of loads on the rafter system: permanent and temporary.

There are two types of loads on the rafter system: permanent and temporary.

Constants include the weight of the battens, insulation, insulation materials, roofing.

Temporary loads include the weight of the snow layer on the roof of people and equipment.

The technology of roof erection in accordance with SNiP takes 180 kg per square meter as an average value. But in the case of the formation of a snow bag in one of the sections, the figure increases to 400 kg per square meter. The load of the snow layer can be ignored only if the slope of the slopes is more than 60 degrees.

The intensity of wind loads should also be taken into account, but they are much less than the load of the snow layer. The average can be in the range of 35 kg per square meter. Wind load can be ignored if the slope of the slopes does not exceed 30 degrees.

Additional loads can also be placed on the rafters. Suspended structures attached to the rafters, water heating tanks, and ventilation chambers fixed in the attic are used as such.

When designing a rafter system, two calculations must be made.

The first is to assess the degree of structural strength. It is necessary to ensure that the structure will withstand the pressure exerted on it.

The second calculation is done to assess the degree of deformation of structural elements. For example, the deflection of the rafters of attic roofs should be less than 1/250 of its length.

For the manufacture of the rafter system, a rectangular bar is used. This shape allows the rafters to withstand the maximum load possible for a particular case. Alternatively, 5x15 and 5x20 cm boards are used.

Paired options are used if necessary.

The optimal choice for creating a rafter system is coniferous wood: larch or pine, the moisture content of which does not exceed 18-22%. Another important point: the lumber should be free of knots, other irregularities, defects.

Elements made of metal can also act as supports for the most loaded ridge girders, and the girders located between them are filled with wooden supports.

Combined structures are distinguished by a high level of strength and make it possible to create non-thrust-layered rafters.

The design and calculation of the rafter system must be carried out as carefully as possible to ensure the reliability and strength of the structure.

Sequence of work

Mauerlat and rafters

Mauerlat and rafters

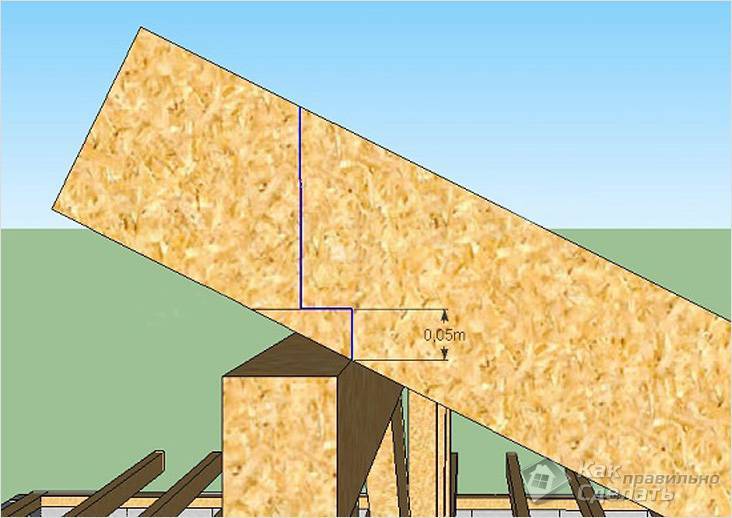

Roof installation begins with fixing the supporting base - Mauerlat. This is a bar with a section of 150 × 150 mm, which is laid along the perimeter of the walls. Its horizontal placement is controlled by the level. The beam should not be on the edge of the wall, you need to leave a distance of 5–7 cm. The Mauerlat is fastened to studs embedded in the masonry, which are tightened with nuts. This beam allows you to connect the rafter system and the walls of the house into a common structure.

For the installation of the racks, you will need a floor or floor beams. These elements are made of 100 × 200 mm beams or double planks. All supports are installed strictly vertically and are attached to the bed with a metal corner or plate. For a hip roof, the racks are installed in one line, a ridge girder is attached to them. When erecting a hipped roof type, the supports are placed diagonally, equal distances are laid from the corner. As a result, they form a rectangle on which the purlins fit. Fastening is done with corners.

Description of the structure of the hip roof

Description of the structure of the hip roof

The side rafters are installed after pattern processing. A thin board is taken as a workpiece, applied to the girder and the gash is noted. The second end rests against the Mauerlat and the lower gash is outlined. The required number of rafters is prepared according to the template and installed with the selected fastening step, it can be from 60 cm to 1 meter. With the girder and the base, the connection is made with staples or self-tapping screws.

Washed down the rafters

Washed down the rafters

Oblique rafters with a ridge run form the angle of inclination of the slopes. These rafters are located diagonally and carry additional load, so they use double boards. The rafters are washed down according to a template, their length takes into account the overhang of 50 cm. In the upper part, the rafters are connected with a crossbar to give strength. When installing a hipped roof, the rafters are connected in the ridge knot with the help of puffs. The rafters are installed at an angle of 90 degrees and are certainly connected to the walls with wire clamps.

Hip pattern

Hip pattern

Short rafters or rafters are attached to the diagonal rafters. They are of different lengths, but must be parallel to each other. Narodniks, together with ordinary rafters, form side slopes. For the tent model, the installation of the cribs and the fastening of racks, struts and trusses is also the final stage of construction.

Construction of a hipped roof

Construction of a hipped roof

To relieve the load from the diagonal rafters, trusses are installed under them. These are vertical supports that rest on the beds. The side rafters are secured with struts. One of the horses of the board rests on the bed, and the second is cut off at 45 degrees and attached to the rafter leg.

Calculations of the structure of a hipped roof

Installation of a roof of this form is impossible to implement if there is no project for its construction.

The procedure for calculating a hipped roof correctly is known only to employees of specialized design organizations. In the technical documentation prepared by specialists, there are drawings of the truss structure, its main joints, a diagram of the roofing "pie" and other elements for arranging the roof.

When calculating strength indicators, it is taken into account that constant (among which the weight of the roof itself) and temporary loads are on the rafter system. The latter factors include precipitation, strong winds, and the weight of people inspecting or repairing the roof. The weight of the roof is determined by multiplying the specific gravity of each material used by the surface area of the slopes. To do this, you need to know how to calculate the roof area of a house.

First of all, for the roof, the angle of inclination of the roof is calculated, based on the climatic characteristics of a particular region. The average value of this indicator is from 5 to 60 degrees. If heavy rainfall is observed in the area where the house is located, experts strongly recommend building hipped roofs with an angle of inclination ranging from 45 to 60 degrees. According to SNiP, the snow load for central Russia is 180 kg / m² if the slope is no more than 60 degrees. With an increase in the angle of inclination, the amount of material for creating a roof increases, and, accordingly, the cost of its construction increases significantly.

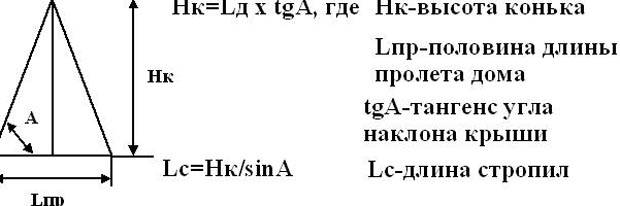

When the slope of the slopes is known, it is required to know the height of the roofing ridge.To do this, the value equal to half the span of the house is multiplied by the tabular coefficient that corresponds to this angle. For example, for an angle of 25 degrees, the coefficient is 0.47, and for 30 degrees - 0.59, so if the house is 10 meters wide, then the ridge height will be 2.35 and 2.95 meters.

Then calculations are made regarding the length of the rafters and their recommended section. Such a parameter as the cross-section of the rafters depends on the angle of inclination of the roof and the loads applied. The safety factor of the elements of the truss structure cannot be less than the coefficient 1.4. When determining the dimensions of the roof - its height, width and length, the angle of the building is taken into account. Before calculating the area of a four-slope roof, you need to know the area of each of the roof slopes, which, as mentioned earlier, can be in the shape of a triangle or trapezoid. Since it is sometimes very difficult to calculate the roof area without a diagram, we recommend doing this according to a pre-drawn up project.

Hip roof erection technology

The rafter system of a hip hipped roof differs from the hip rafter system.

The rafter system of a hip hipped roof differs from the hip rafter system.

The main distinguishing feature of the hipped roof type is the absence of a ridge girder, since the slopes are connected along the line of diagonal rafters, which converge at one point. To increase the reliability of the structure, a stand is installed in the center, which takes some of the weight.

In some cases, the installation of the rack is not possible, so other methods are used. For example, a hanging rafter system can be used. In this case, there is a need for additional modules (puffs, racks) to improve the reliability of the structure.

The main rafters are mounted from the top of the system to the edges of the walls. At the same time, they need to install wives. Diagonal rafters are best strengthened by using a bar. When the timber is not used, the rafters should be cut into diagonal rafters or cut to fit their plane.

These methods are an excellent option for the construction of roofs of small private houses, but they cannot be used for the construction of heavy floors, since they do not provide sufficient strength.

In the case of overlapping using monolithic technology, you can use a bench, which should be laid on a double layer of waterproofing under the racks.

Comparison

Now let's summarize and compare these two roof systems in terms of basic indicators:

- Resistant to weathering. The best in terms of resistance to wind and snow loads is considered to be a 4-pitched roof. It is more durable and can withstand extreme loads with ease. But its high heat transfer does not allow these systems to be used in northern latitudes without additional insulation.

- Design. Gable structures are decorated with attic and dormer windows, weather vane and platbands, balconies and windows in the pediment. We can say that this is a classic of the architecture of private houses. But the 4-pitched systems are made more laconic, since the abundance of details and elements looks ridiculous on them. The four-slope structures are the standard of European brevity. Such a house looks more solid and respectable, it is easier to sell it. However, multi-pitched gable roofs can provide him with good competition.

- Nuances of design. If you decide to order a turnkey house, then it is worth staying on a hipped roof or hip roof, since they are the indicator of the balance of the project and require a reasonably organized local area. Gable roofs are more suitable for regions with an abundance of rainfall, since only they provide protection of the space in front of the house from snow and water.

- Finance. The cost of masonry walls in houses with a hipped roof will be lower, but the cost of roof structures will increase. That is why the statement that a 2-pitched system will cost less is erroneous if we take into account the total estimated cost of a residential building.

It is also worth remembering that the weight from the roof in the four-slope system is distributed more evenly, but during construction and design it will be necessary to hire professional craftsmen. For gable roofs, the consumption of roofing material is less due to the small amount of waste, which cannot be said about the four-pitched variety.