How to calculate the amount of material

To determine the consumption of materials for creating concrete do-it-yourself tracks in the country, make a drawing of the planned path, taking into account all the features of its shape. So you can calculate its area and determine the optimal amount of everything you need.

Tip: For ease of movement, make the main road 1-1.5 meters wide. Paths leading to flower beds or beds may not be more than 50 cm wide.

Material consumption will depend on the complexity and length of the tracks, as well as the structure of the soil. If the soil is heavy and clayey, the concrete layer itself should be up to 0.7 cm. not less than 1 cm concrete layer. If it is expected that such a track will be regularly subjected to heavy weight loads, you can make this layer even larger.

For marshy soils, you will also need gravel drainage with a base of half a centimeter.

For marshy soils, you will also need gravel drainage with a base of half a centimeter.

Multiply the length, height, and width of the layers to determine the volume of consumables.

A cubic meter of sand weighs about 2.4 tons, and concrete weighs from 2.8 tons.

To calculate the parameters of the remaining components, it remains to subtract the known indicators from the total volumes.

For example, for a concrete slab with an area of 1 m2 with a thickness of 0.1 m, you need 0.1 m of sand layer. The volume of sand is 0.1 m3, weight is 240 kg.

To calculate the weight of cement required for installation work, calculate the weight of the concrete layer (280 kg) - and, subject to the creation of a concentrate and cement, water and sand in proportions of 1: 1: 4, divide this indicator by 5. That is, we need cement no more than 56 kg.

By the way, there is no need to do such calculations yourself. When buying materials, you can contact specialists who will not only recommend a good quality product, but also make the necessary calculations. But we advise you to take 5% more than the calculated volumes, since if the relief is not even enough, more material will be required to correct defects.

Preparatory stages

For successful construction, you need to choose a place for the path in advance, draw up a project, perform calculations, stock up material and tool... You need to think about the location of the structure. Based on this, the width and shape of the structure are calculated. You will need a regular sheet of paper where we will make a homemade plan. We indicate the location of buildings, important areas. We connect them with lines that will be the axes for the tracks. It is advisable to make the paths slightly curved - this way the view of the territory will look more interesting.

From the tools we will use a hammer, concrete mixer or other container for mortar, shovels, spatulas, etc. You will also need cement, sand, crushed stone, a mixture for waterproofing, components for formwork.

Design

Drawing up a work plan is an important step-by-step process in any construction. This will help not only visually present the result, but also save you from buying unnecessary resources.

Before installing a concrete path, it is necessary to draw up a plan and calculate the amount of materials

Before installing a concrete path, it is necessary to draw up a plan and calculate the amount of materials

The mortar layer is selected depending on the soil:

- for clayey - 4–6 cm;

- for sandy, light loamy - 8-10 cm;

- for a marshy one, you need a layer of gravel 5 cm thick.

You cannot do without a sand cushion. Its thickness is 12-15 cm.

As for the calculation of proportions, there is nothing complicated here. For example, we are building a track 1 m wide (W), 10 m long (D) 10 m thick, 10 cm thick (T), the bottom layer of sand (P) - 10 cm. To correctly make a sand pillow, you need to calculate the amount of sand. Let us resort to the formula WxLxL - it turns out 1 m. In total, 2200-2400 kg of sand will be needed for the underlying filling.

Concrete can be prepared at the rate of 3 parts of sand plus 1 part of crushed stone, cement, water. The composition can be different. We calculate how much concrete is needed: WxLxT. It turns out 1 m.Since approximately the weight of a cubic meter of concrete is 2800 kg, we divide this figure into 5 parts. It turns out 560 kg.

Such calculations will not give ideally accurate data, but you can roughly know how much material is needed.

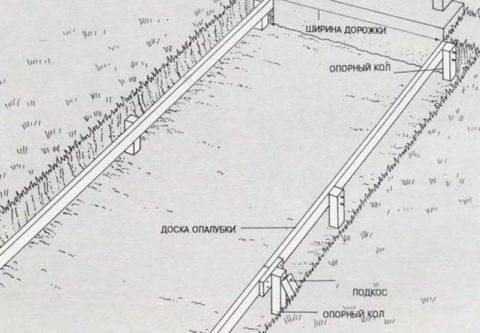

Layout and soil preparation

When the preparatory stage is completed, you can allocate territory for the track. Keep the path in mind. It is most convenient to mark the points with wooden pegs. They are driven in at an identical distance, a rope is pulled between them. The more bends in the track, the more pegs.

First you need to mark the future track, then prepare the ground

First you need to mark the future track, then prepare the ground

You can start removing the top layer of soil. We remove everything, down to the roots, as they can rot, accumulate water, and this will negatively affect the structure in winter. Suppose that the layer of "pillow" is 10 cm, cement is also 10 cm, it is desirable that the path is slightly raised. We subtract 3 cm from 20 cm.It turns out that you need to clear the soil by 17 cm.

Advantages and disadvantages of concrete walkways

Like any material, concrete has both advantages and disadvantages. The advantages of this coating include:

- strength and durability;

- low moisture absorption: even in the rainy season, water does not sink too deep into the monolith;

- easy to care for: concrete can be washed, swept, removing all dirt;

- affordable price, which will be lower than paving with natural or artificial materials;

- decorativeness of the coating: simple technologies are used to achieve different effects;

- the ability to fill a track of any configuration;

- simplicity of work and availability for independent execution;

- compatibility with any decor, plants, buildings and suitability for any style of landscape;

- the cottage with concrete paths takes on a well-groomed look.

The disadvantages include the ability to absorb water, albeit to a small extent. When moisture penetrates into concrete, it gradually collapses. Special impregnations allow protecting the top layer and making it more moisture resistant.

Decorating

Cured concrete looks inconspicuous. To freshen it up, they resort to the help of decor. This can be done in any way convenient for you.

Painting

One of the easiest ways to freshen the track is painting. To do this, you need to wait until the cementing process is completed and, using acrylic paints, turn the surface into a work of art. You can make a volumetric coloring so that the color covers not only the surface, but also penetrates inside. In this case, the dye must be added to the solution while mixing it. The color will be more abrasion resistant.

Did you know? The composition of modern concrete (based on cement) was discovered in 1844.

Using forms and stencils

You can create a concrete walkway that resembles paved paving stones. For this, a special plastic mold is used. It allows you to make any drawing. Modern stencils make it possible not to interrupt the process of creating paving stones. The form is filled with ordinary concrete mortar, after which, after 10-15 minutes, it can be moved to another area. The elapsed time is enough for the material to grab.

In this way, with a small investment of time, effort and money, you can create a path from elements that imitate expensive tiles or paving stones. Stencils, which are patterned rubber mats, are also in demand. They are applied 45 minutes after pouring the solution and the pattern is pushed through with a cardboard tube.

Stamping

Stamped concrete is a common material with decorative embossing that is applied using special stamps.This option for decorating trails is also very popular, as it requires minimal costs. You can choose a different pattern: under a brick, stones, animal skin, animal footprints or their silhouettes, plant motifs. It is applied the next day after concreting the track using a special stamp.

Imitation of limestone and mosaic installation

Paving slabs are very popular with many owners of private territories. But not everyone can use a real cobblestone in the country due to its high cost. It is possible to solve the problem with the help of concrete mortar and a special form. The final product will be slightly inferior in quality to the original, but it will cope well with the role of a footpath.

Several forms must be used, since the solution poured into them must fully grasp. This takes at least 2-3 days. The stencil must be lubricated with oil for better separation from the concrete, and each tile must be reinforced. Those who do not like boring and standard solutions can make a mosaic track.

You can create it from scrap materials:

- old plates;

- small stones or jewelry;

- glass.

You need to take a metal baking dish, preferably round, grease it with petroleum jelly. Prepare a concrete solution, put part of the decor, reinforcement in the mold. Pour half of the concrete, lay out the remnants of the mosaic and pour out the entire solution. Leave to harden.

Learn how to attach a gazebo to your home with your own hands.

Most read

B-B-Q brick

Alcove with barbecue

Concrete paths

Land improvement

Choosing a hedge trimmer

Geogrid

Guzmania

Ornamental grass

Decorative flower beds

Decorative fence

Children's slide

Garden design

Firewood for summer cottages

Mesh fence

Winter Garden

Ideas for giving

Flower bed of stones

Flower beds from perennials

Lianas for the garden

Polycarbonate awnings

Site lighting

DIY greenhouse

DIY sandbox

Car platform

Retaining wall

Facade lighting

Swing gates

Garden arch

Garden fountains

Snow shovel

Brick tandoor

Topiary in the garden

Thuja western

Plot 15 ares

Figurines for the garden

Coniferous plants

Photos of beautifully executed concrete paths in the country

Original examples of concrete paths are presented in the photo selection. Using designer tiles, they create gardens in fashionable English and French styles. The simplest option for arranging a path with a fancy approach will turn into a bright accent of design. Combining concrete with other types of coatings will help to give a narrow alley a modern look. Experiments, flight of imagination, individuality are in trend.

Classic garden with concrete tile paths

The Mediterranean style will be complemented by a concrete path, if you add pebbles, fragments of shells, broken glass to it, which will shine under the rays of the sun.

To create a beautiful mosaic decor, you have to be patient.

Original forms are welcome. Using soft formwork, they create paths with wavy edges, denticles, and asymmetry. Such a composition is much more elegant than classic paving stones.

Tiles in soft formwork are poured right on the spot, after the mortar has set, the form is moved and the pouring is repeated again

For the manufacture of tiles, old kitchen utensils and ready-made stencils are used as a mold. The resulting coatings are not inferior in strength to store counterparts.

Which cement is best for paths

With the right choice of material, a concrete walkway will last for many years. Experienced builders recommend choosing cement of at least M500. It must be combined with sand in a 1: 3 ratio. The final consistency should resemble sour cream in density.

Important! When building a walkway, it is not recommended to add a lot of water, since the more there is, the lower the final quality of the concrete.

How to correctly calculate the weight of building materials

Cement, sand and water are all you need to create paths

But before erecting them, it is important to correctly calculate the weight of the final product so that the soil can withstand it. If the ground is heavy, then the concrete layer should be 60 mm

For sandy unstable soil, about 100 mm is needed.

When the width and length of the canvas reach 2 m, and the thickness is 2 cm, then 30 cm of a special layer must be laid under it. To find out the required amount of sand, you need to multiply the parameters of the track by the weight of the building material (taken from the reference book). The weight of the cement is also determined. To find out the volume of concrete, you need to divide the specific gravity by five (this will be part of the cement, the rest is sand).

What to make tracks from

Track coverage can be hard or loose. The following materials are used to create a hard coating:

Concrete. Concrete walkways are more than just plain gray tape. In addition to the fact that there are dyes and, if desired, you can decorate it. There are also molds for pouring in place. It turns out homemade paving slabs. Another option is to pour small concrete slabs of the required size on your own, then put them on a bedding. For examples of design, see the photo.

Flagstone. This is a natural stone that has been cut into plates. It is laid on a prepared base (more on this later), the gaps are filled with backfill. It turns out beautifully, reliably, non-slip. No wonder it is stone limestone paths so love landscape designers.

Brick. Ordinary ceramic bricks are a beautiful material, but not for paths. It absorbs moisture, if it then freezes wet, it is torn to pieces. If you are going to make a path from broken bricks, then it is more or less normal to walk along it only for a couple of years. Then you have to redo it. The resulting cracks will need to be covered with coarse sand or fine gravel. Clinker bricks will serve much longer on the track, but this option cannot be called low-cost: the cost of one piece is from several tens of rubles.

Wood. Such a seemingly unsuitable material, but with proper processing, it can serve for a long time. Moreover, many do-it-yourself wood paths can be classified as low-cost. For example, they came up with the idea of using hemp and tree cuts as curbs or coverings. They also make a flooring from well-processed boards - better terraced, but if not, it will work from the old floor as well.

Plastic. There are tiles for garden paths made of plastic - polyethylene or polypropylene. It has a square shape and a system of locks that is attached to one another. It can be laid directly on top of the lawn or previously trodden in the country or on a section of paths. This option is fast and cheap. It can definitely be called "Low Cost". It is better, of course, to make a dump of rubble and sand according to the rules, and put plastic elements on top. This is already a little longer and more expensive. There is also an immodest, but very beautiful version of plastic tiles for paths. There is also "garden parquet". These are slabs or boards made of wood-polymer composite - WPC (they are in the photo, they look exactly like parquet). This material has appeared relatively recently. It looks and feels like wood, but in fact it is a mixture of wood flour and polymer. These are very beautiful coatings, but their cost is by no means modest. Although not fabulous.

Pebbles. These are rounded natural stones that can be found on the banks of rivers or lakes. Flatter stones are more suitable for making paths. There are different shades of gray, black, white, sometimes you can find burgundy. From these stones, laid close to one another, mosaic paths of amazing beauty are obtained. But this is an occupation for the diligent and persistent.Those who lack patience can find large flat boulders or large pebbles and place them in the sand. It is not that luxurious, but no less reliable. You can do the same with granite or other similar stones.

It is important that at least one face is relatively flat. Put this flat part up, bury the rest

The work is not easy, but it will be possible not only to walk, but also to ride along the path.

Materials at hand. Country paths are made from old tires and bottles.

There are also paths with a poured surface: gravel or crushed stone. Their peculiarity is that with a small layer of 2-3 cm and with sufficient compaction, it is convenient to walk on them. If the layer is slightly larger, bumps are formed when walking, and such walking is tiring. Therefore, as you have seen in many photographs, gravel and crushed stone are used as backfill, in which rigid elements from other materials are laid. If done correctly, it is convenient: gravel conducts water well and puddles do not form. Those who do not like gray can be advised to paint it: many designers do this when organizing rockeries.

An example of a gravel track

DIY garden path: concrete as a base

Quite often, under such a concept as garden paths made of concrete, they mean nothing more than just a concrete base, which is subsequently lined with paving slabs. The technology is quite widespread and, most importantly, reliable - if, of course, the right approach to its implementation is taken. Among all its advantages (reliability and durability), one can separately highlight such a moment as the possibility of phased manufacturing - first, a concrete base is poured, which, after hardening, can already be safely used for walking, and then, perhaps even after several years, this base can be will be faced with stone or paving slabs.

You yourself understand that the reliability and durability of such a garden path primarily depends on the concrete base, and in particular, on the quality of its manufacture. You should familiarize yourself with this point in more detail.

- Marking and removing excess soil. In fact, to begin with, you will have to dig future paths - before pouring concrete, you need to perform certain preparations, for which you need to arrange a deepening in the ground. If we talk about the technical aspects of this stage, then two things are important here - this is the direction and width of future tracks (I think you yourself will decide on them), as well as the depth, which is at least 200mm.

- Preparation of a concrete path. In fact, this is a bedding, which in professional construction jargon is called drainage. It provides effective removal of excess moisture from concrete, which prevents cracking in the winter. This drainage consists of two parts, or rather layers: the bottom layer is sand, poured in a layer of at least 50 mm, and the second layer is fine crushed stone, poured in the same layer. Before filling, the bottom of the grooves must be tamped - the filling itself is also tamped.

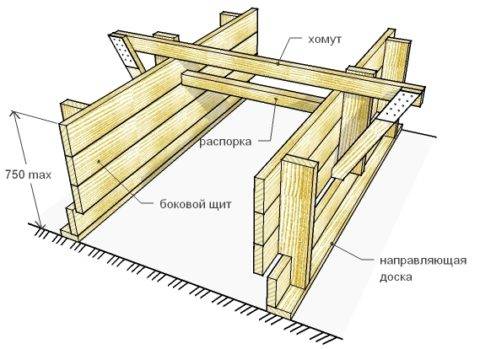

-

Next, a formwork is installed that matches the shape of the tracks. Ask why is it needed? In principle, you can do without it, but in such a situation you will need to dig a depression with very flat sides. In addition, the formwork is also needed in order to subsequently be able to correctly install the curbs - like concrete, they must be above the drainage. If the concrete base of the walkway is planned to be used as a topcoat, then even curbs can be used as formwork, the installation of which is carried out using cement mortar.

- The next step, which provides for solving the question of how to make a garden path out of concrete correctly, is reinforcement. For these purposes, a metal mesh with a cell of 50 by 50 mm or 100 by 100 mm is used, made of wire with a minimum thickness of 2 mm. The mesh is simply laid on the crushed stone - of course, it must first be adjusted to the size of the track.

-

Concreting.There are only a few nuances here: firstly, this is the concrete itself for garden paths, the proportions of which you need to know, and, secondly, it is a flat fill plane, which can only be achieved with the help of lighthouses. As for the correct preparation of the solution, the composition of concrete for garden paths is not much different from standard concrete. The only point is the proportions that provide for a slightly larger amount of cement - in particular, concrete used on the street has the following composition: three parts of cement, two parts of sand and three parts of crushed stone - water to "taste", but concrete should not be too runny. All this is poured into the formwork, after which it is carefully leveled with the rule - the thickness of the concrete layer should not be less than 100 mm.

And the last, so to speak, the final stage of concreting garden paths is the control of the process of concrete hardening

It is very important that this process is carried out slowly. To reduce the rate of evaporation of water from concrete, after the initial solidification, it must be thoroughly moistened with water and covered with polyethylene

After drying, the concrete can be revetted with tiles, paving stones, stone, or you can simply operate the paths as they are, painting them for beauty.

Marking aisles on a site - how to make beautiful

Before you design, you should determine what types of tracks and how many of them should be on the site. Household facilities are intended for access to objects located around the house: a barn, a woodshed, a bathhouse. Walking places are for utilitarian purposes, they are needed as decorative elements.

When planning a site, it is necessary to calculate the required number of tracks

The strongest and most durable should be the paths you walk on most often. First of all, this is the path from the gate to the house.

Paths and paths add picturesque notes and serve to visually adjust the territory. Short stretches divide the garden into smaller pieces, making the plot appear smaller. The winding paths, on the contrary, will create the impression of spaciousness.

Two or three operative passages are enough, the rest have a decorative function.

Any garden path should be practical, without puddles, bumps. In the garden drawing, during landscape design, zones of high humidity are marked

It is important to make the correct slope so that rain and melt water leaves faster, provide drainage in an area with a high groundwater table

When there are too many tracks, they divide the area into small fragments, and it looks much smaller than it actually is.

Long track visually enlarges the area

Paths between flower beds, beds are made of separate, unconnected fragments, so that you can easily dismantle the coverings, replace damaged tiles with new ones.

The path of individual tiles can be easily moved to another place if necessary

Strong coverings are necessary for heavy loads, in places of constant movement of people. On small paths, it is advisable to lay coatings of small thickness.

The winding paths with hedges create intrigue, creating the illusion of a long journey and spaciousness.

Monolithic track

Below you will find instructions on how to make the surface in question yourself in the country. The composition of the solution includes a base of sand and gravel mixture and, reinforced with reinforcement, a cement-sand layer with crushed stone.

How to pour concrete on the street

How to pour concrete on the street

Tools and materials

To carry out the work, you will need the following materials:

- Building cement with markings from M400 and more;

Cement

Cement

- Building sand;

Sand

Sand

- Mesh and wire;

Low carbon wire for reinforcement

Low carbon wire for reinforcement

Reinforcement mesh

Reinforcement mesh

- Waterproofing additives;

Waterproofing mixture

Waterproofing mixture

- Formwork boards;

Formwork boards

Formwork boards

- Pegs, spacers, bars.

The use of pegs, spacers and bars

The use of pegs, spacers and bars

Of the tools you will need:

- Shovels - bayonet and shovel;

Shovels

Shovels

- Capacity;

Capacity

Capacity

- Ironer;

Ironer

Ironer

- Small spatulas;

Putty knife

Putty knife

- Sand ramming device;

Tamping device

Tamping device

- Formwork hammer.

Hammer

Hammer

Main steps

The device of a monolithic structure includes several stages:

- First, you need to decide on the design and location by completing sketch sketches;

Sketch drawing of the site with the designation of the location

Sketch drawing of the site with the designation of the location

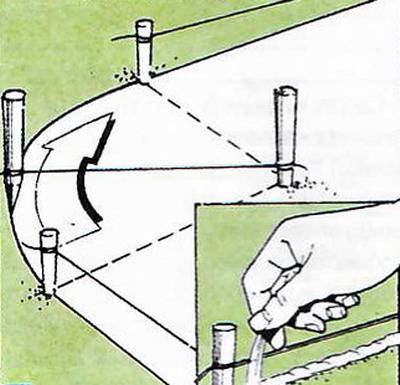

- Then, on the territory of the land plot, markings are arranged in the place where the track will be located. Given the size and configuration, they fix its location with pegs and a cord.

Nylon cord secured on pegs

Nylon cord secured on pegs

Where the coating will be rounded, additional pegs are driven in;

Turning clearance

Turning clearance

- Prepare the soil;

At this stage, they are determined with the height of the bedding and the location relative to the ground level. At the same stage, the top layer of soil with plants and their roots is removed so that they do not cause the destruction of the concrete structure in the future.

Destruction of concrete by plants

Destruction of concrete by plants

The soil is removed to a depth that can accommodate four layers - 10 cm each of sand and gravel, another 5 cm layer of sand and a solution of 7 cm.

Excavation

Excavation

- The formwork is mounted by fixing the boards to the pegs;

Formwork

Formwork

Dividing the formwork into fragments

Dividing the formwork into fragments

Coverage scheme

Coverage scheme

The outer side of the formwork should rest against the side inner edge of the trench, or vice versa, the boards can be attached to the pegs using self-tapping screws. To create expansion joints, transverse boards are installed every 50 - 60 cm, which should not be higher than the longitudinal formwork boards.

- The device of a sand cushion is necessary for timely natural drainage. As a result of this, the solution will not be destroyed from the inside by the expansion of moisture;

How to fill concrete paths in the country

How to fill concrete paths in the country

When filling sand, it is necessary to tamp it - to form an even dense layer without voids.

To build a high-quality foundation, first lay crushed stone, or crushed stone with sand, geotextile material, and then another small leveling layer of sand - about 5 cm.

- Reinforcement is laid.

Reinforcing mesh

Reinforcing mesh

First, polyethylene is placed on the sand cushion to ensure high-quality hardening of concrete, thanks to which the cement milk cannot go into the ground.

Film

Film

Reinforcement process

Reinforcement process

- The solution is mixed in a ratio of one to three, where for 1 portion of cement there are 3 portions of sand;

Mixing solution

Mixing solution

Using a shovel, the solution is laid and distributed over the trench.

Laying mortar

Laying mortar

Then, using a trowel or a level, the mixture is leveled.

Alignment

Alignment

Using a float or wide spatula, the surface can be perfectly smooth.

Smoothing

Smoothing

How to prepare a solution with your own hands

When preparing porous concrete on your own, it is important to observe not only the proportions, but also the sequence of adding components to the solution. First, in a concrete mixer, you need to combine the sand and crushed stone, then add cement to the resulting mixture and only at the final stage the liquid is supplied

Another important point to keep in mind is temperature conditions.

However, too much heat can also be a problem. During the preparation process, the mortar should not warm up to a temperature above + 30 ° C, therefore, if the work is carried out in the summer, it is advisable to install a concrete mixer in the shade and arrange an afternoon siesta, transferring the bulk of construction manipulations to the morning and evening hours.

Advantages and Disadvantages of Drainage Concrete

The use of drainage concrete for laying garden paths has a number of undeniable advantages.

- These include:

- ease of use - no puddles due to the high porosity of the material and the preservation of a given shape due to its strength;

- environmental friendliness, including due to a significant reduction in the load on the soil and the drainage system of the site (compared to ordinary concrete);

- neat and decorative appearance;

- durability - since moisture passes through the material without lingering inside it, the main reason for the destruction of monolithic structures is excluded, namely, alternate freezing and melting of water in the winter, creating microcracks in the structure and gradually expanding them;

- low cost;

- ease of manufacture.

If we talk about the shortcomings of the material, then there are few of them. Porous concrete is not suitable for those summer residents who are not lucky enough to live in regions with an overly changeable climate. For all its uniqueness, eco-concrete is still concrete, therefore, from frequent temperature jumps from freezing to melting, the paths will sooner or later begin to collapse, so for such conditions it is better to use the already mentioned geotextiles or other modern polymeric materials.

Did you know? In the United States, a significant proportion of roads are not made of asphalt, but of special concrete, which makes this structure much more durable and, in addition, less destructive for vehicles moving along it.

There are many ways to make the suburban path easy and even "removable", that is, provide for the possibility, if necessary, to change the location and direction of the route

If concrete is chosen as the material (it does not matter whether it is ordinary or porous), you need to think over the plan in advance and very carefully, since it will be difficult to break this kind of structure

Finally, the appearance of a concrete path may seem too gloomy to some (in comparison, for example, with an elegant path lined with saw cuts of large trees), and the use of paving slabs as the top layer is costly, time consuming and expensive. However, such a drawback should still be attributed to subjective, because, as you know, you cannot please every taste.

Did you know? Many consider concrete to be the achievement of modern technical progress, but in reality this invention has its roots in hoary antiquity. So, it was the mixture of sand, gravel, cement and water that was used by the Egyptians in the construction of the famous pyramids, which ensured the perfect correctness of the shape and the amazing durability of the buildings.

Garden paths made of moisture-permeable concrete can be an excellent solution to the problem for many summer residents. Of course, it is quite difficult to implement such a task with your own hands, especially on your own - the technological process will require high precision and great physical effort. But the finished result will permanently solve the problem of slapping in puddles and getting stuck in the mud, which invariably turns into any garden or flower bed after heavy rain.

Concrete garden paths: decorative molding

It is with the help of this technology that it is quite easy and simple to make decorative garden paths - its essence lies in the use of special forms. Surely many of you have met similar products on the Internet and wondered if they are so effective? Surprisingly, yes - moreover, they are not only effective, but also easy to use. Instead of paying for the work of specialists in the manufacture of paths in the garden, you simply buy these forms and slowly, slowly, as they say, for your own pleasure create your own masterpiece in the garden or on the local area. You can add your idea of this approach to the issue of making garden paths by watching this video.

The device of such tracks is carried out according to the following technology.

- As in the first option, preparation is done to begin with - everything is the same. First, a deepening is made, then backfilling with sand and gravel - then, respectively, the installation of curbs and reinforcement.From this point on, the differences begin.

- Instead of concrete, a clean cement-sand mortar without crushed stone is used here. Or rather, not even a solution, but a gartsovka - a thick solution.

- One or more forms are installed on the future pavement at once, which are filled with cement with a trowel or spatula - it must be carefully pressed into the form, thereby filling all its corners. Excess solution is removed.

-

After half an hour, the solution loses moisture and cools down a little - the forms can be removed and rearranged further, repeating the operation to fill them with the solution.

In principle, this is all technology - you must admit that it painfully resembles a child's game of pasochki. After the path is dry, it can be painted with concrete impregnation. Also, the coloring of the track can be done at the stage of preparing the solution by adding a special dye to it. In most cases such forms imitate the laying of natural stone, between which there are seams - they can be filled either with grout or simply cement, or with seeds of lawn grass mixed with sand or soil. After the vegetation sprouts, your paths will take on a very interesting look - such a lawn needs to be periodically mowed and repotted from time to time.