Durability

Artificial raw materials are several times more durable than natural rattan. As a rule, the service life of technorattan interior items is at least twenty years, during which they do not lose their performance. A set of polytangled furniture is not exposed to fading under the influence of ultraviolet rays. Garden furniture is resistant to any external damage (scratches, cracks, etc.).

You can safely leave wicker chairs and a table on the open veranda without fear that the furniture set will deteriorate from frost or heavy rain. Artificial rattan retains its attractive appearance for decades in any weather. Products are not afraid of sudden temperature changes. If natural rattan furniture should never be exposed to moisture, then artificial wicker can be doused with water from a garden hose.

Metal furniture

Forged elements look lovely and can be used in any landscape design. Clear geometric lines will be a wonderful decoration for austere gardens, and graceful curls will create an amazing atmosphere in classic styles. The nobility of the metal elements will give the site the appearance of an ancient castle.

The metal is durable, even heavy loads are not afraid of it.

The disadvantages include the thermal conductivity of the material, it will become very hot under the rays of the sun, and at the slightest hint of cold it will immediately become unpleasantly icy. Although this problem can be solved by a variety of pillows and blankets.

History of creation

Surprisingly, wicker furniture is thousands of years old. Our ancestors learned to process vines tens of centuries ago. At first, such furniture could only be seen in the homes of the poor. It was considered an inexpensive and very affordable interior design option. Subsequently, the beauty of rattan was appreciated by representatives of the nobility. Craftsmen and whole factories for the production of wines and rattan products appeared.

In Russia, wicker furniture became popular thanks to Prince Golitsyn. Regularly visiting abroad, the prince appreciated the magnificent appearance of the wickerwork. Returning home, Golitsyn created a whole workshop on his estate.

Garden furniture styles

Garden furniture should match the style of the site.

- For decoration in the style of the classics, wooden tables and chairs are more suitable, and if there is a lot of greenery, then it is better to use coarser models.

- The country style is beautifully accentuated by bright chairs and fabric sun loungers. And the addition of Provence will be small wooden products made of white wood and fabric. Bright cushions on pieces of furniture will emphasize the unusual and colorful Moorish style.

- For modern styles, strict lines of stone, plastic and metal are best suited, while modern style will more accept the curls of forged products and the graceful texture of wood.

Photos of garden furniture will show all the variety of these items, help you choose the required items and place them beautifully.

The main advantages of rattan wicker furniture:

- She does not need special care to keep it in good condition, you just need to periodically wipe it with a rag;

- It can be used successfully both indoors and outdoors;

- Does not germinate like natural rattan;

- Can be dyed in any color, has different thread thickness. Fully imitates natural rattan;

- Withstands significant loads, while being lightweight.

Also rattan is very cheap and can also last a long time.

Benefits for the master:

- Simplifies the work and shortens the production time of products, it is easy to bend. In view of this, it is possible to manufacture furniture of any shape;

- Has a great length. Because of this, it is not necessary to connect individual threads.

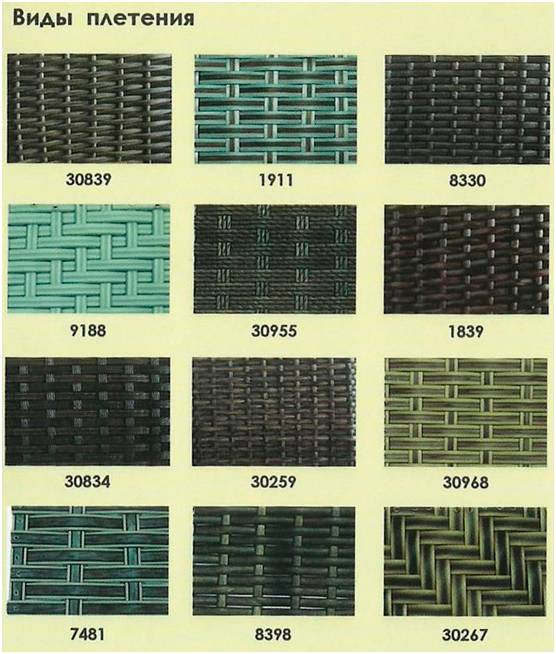

Weaving methods and patterns

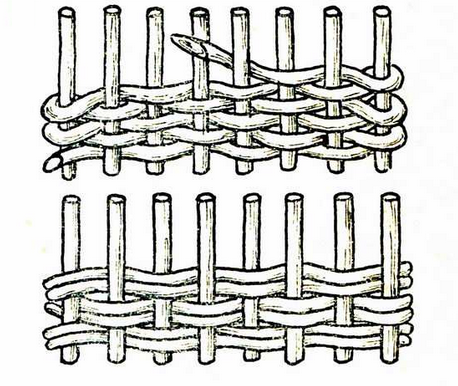

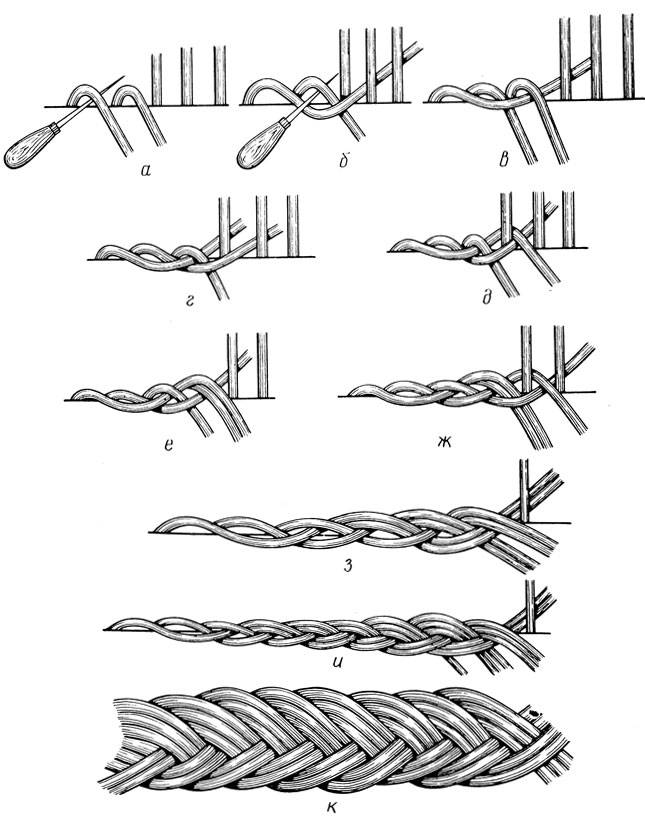

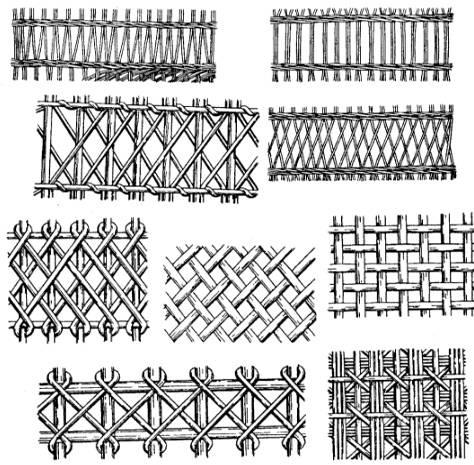

To make the finished furniture not only durable, but also beautiful, various techniques are used. It can be either a simple continuous weaving, which even beginners can handle, or decorative, with patterns and pigtails. Have each of them has its own characteristics.

Solid

Such weaving is used everywhere, it is this method that is chosen in the manufacture of loaded furniture elements: seats, sidewalls, countertops. Depending on the algorithm of actions, there are:

- Simple solid weave with continuous weaving of single strands through one rack with spiral or twist layering. The minimum level of complexity, there is no need to trace the scheme.

- Layer-by-layer weaving (several blanks of the same section are thrown over one rack). The number of rods in this scheme must match the number of racks.

- Checkered or square weaving, with a laying of two-color or one-color rods. When choosing this scheme, the number of base racks is a multiple of 4 - the first working rod in a checkerboard pattern braids 2 racks at once, the second repeats these movements. Further, the rods are sequentially bent around 2 racks from the outside and from the inside, the second - vice versa. Such weaving is simple and layered, the scheme requires attention.

- Rope weaving is chosen when it is necessary to strengthen individual strips or walls. When implementing this scheme, at least 2 rods of different lengths are used, enveloping the base racks on both sides.

The opinion that all solid schemes have a low level of complexity is erroneous. With rope weaving, the number of rods and the options for their direction are not limited by anything, and when entering colored blanks, the work becomes more complicated. But without mastering them, it makes no sense to start more complex patterns.

Simple

Simple Layered

Layered Checkers

Checkers Rope

Rope

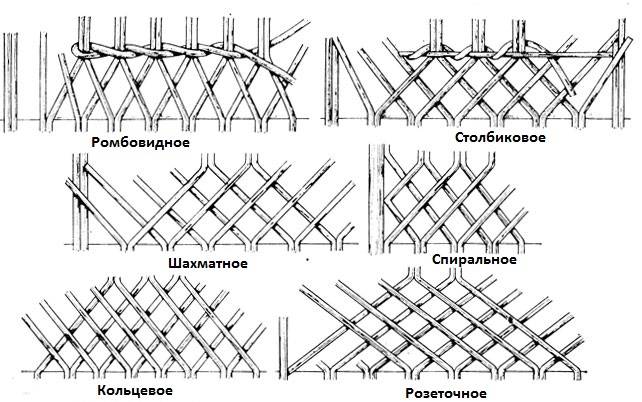

Openwork

This weaving method is used to decorate furniture, giving it lightness and airiness. The openwork method requires perseverance and high concentration of attention. This group includes open cell circuits, including:

- Diamond-shaped weave, starting and ending with rope. To implement this scheme, the first, second and third rods are deflected at an angle, the fourth is applied to the first base. After that, the racks are pulled together by the tops of the rods and reinforced with a rope scheme. Then the process is repeated.

- Weaving with a bookmark of columns, reinforced horizontally with pigtails.

- Chessboard - alternation of rods with different colors, textures and the laying of even intervals.

- Weaving with the establishment of symmetrical and asymmetrical rosettes, rings or spirals. When implementing these schemes, the bases of 3 rods are smoothly bent and fixed on different racks.

- "Star of David" is a complex, but spectacular-looking openwork weaving, with a combination of several methods.

Special tapes are used to fix the rods. Separate rows are reinforced with a rope pattern of two rods. In addition to complexity, the disadvantage of openwork patterns is the loss of strength of wicker furniture.

For edge finishing

To make the edge of the product look neat, it is finished with a fold. To do this, three, four or more stripes are connected and simply intertwined. If it is necessary to lay strong decorative racks for furniture, the edges of the rods are bent into a pigtail. This is a rather complicated method. To make such a weaving of three rods, you need to put sticks under the first and second. Bend the blanks to the right, after which the first rod goes around the second through the awl. Further, the same rod must be wound between the third and fourth, press it down with the third curved one.

This method is used for almost any furniture design. But beginners do not immediately succeed in hiding the edges of the workpiece beautifully. Therefore, they are better suited to a simple bend with a crease with the hiding of the rods on the back side.

The general requirements of the technology for the manufacture of wicker furniture include the need for an even distribution of rods or strengthening of individual openwork patterns. With high density requirements, the workpieces are adjusted to each other with a wooden mallet, any defects are eliminated immediately. Docking or splicing of individual rods, if possible, is performed on the reverse side; to simplify the creasing process, measures are taken to increase the elasticity of the rods (wetting with water, punching with fingers).

Bending

Bending

What materials are used for weaving furniture

In our region, willow vine is traditionally used for weaving, in tropical latitudes - stalks of rattan palm (calamus). The vine is an affordable raw material, but harvesting it with your own hands is a rather laborious process. Wicker furniture is less strong and durable than rattan furniture. Natural rattan, like the vine, is harvested and subjected to multi-stage processing - the stems are cleaned of bark, sorted by thickness, processed with steam, acquire elasticity and straighten. After this treatment, thick stems can be bent, giving the shape required for the frame elements, and dried. For weaving, thin stems and bark are used, they are cut into fragments of the desired length. It will not work to prepare natural rattan with your own hands - it does not grow here, and the purchase of prepared raw materials, taking into account the costs of transportation, will be very expensive.

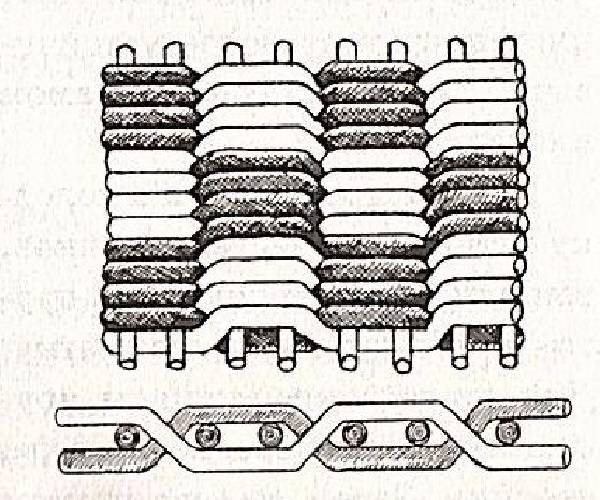

Natural rattan has a synthetic counterpart - polirotan or technoratan. It is made by extruding a soft polymer through holes of different diameters and cross-sections. The material has many modifications:

- a flat strip with a textured surface, a ribbed surface, imitation of bark is possible;

- tape, braid with a smooth surface;

- round or oval cord;

- crescent-shaped cord;

- rattan bar.

Artificial rattan is more popular in comparison with natural software for a number of reasons:

- the price is significantly more affordable;

- the flexibility and elasticity of synthetic rattan is superior to its natural counterpart;

- environmental friendliness and safety is not inferior to natural raw materials, does not have a specific smell characteristic of some polymers;

- polirotanga is more durable, furniture made of it can withstand significant loads without deformation;

- furniture turns out to be moisture-resistant and frost-resistant, not afraid of changes in temperature and humidity conditions;

- furniture is unpretentious to care, it can be cleaned from dirt using various detergents;

- rattan ribbons and cords are available in any length, which allows you to weave furniture without joints;

- raw materials are completely ready for work;

- a large selection of modifications of various shapes, colors and textures allow you to create attractive furniture that will fit into any interior.

For lightweight furniture that will be used in humid environments, such as in a bathroom or outdoors, it is better to use a plastic or aluminum frame rather than a wooden frame. If the furniture will be exposed to significant loads, a metal or wood frame is preferable.

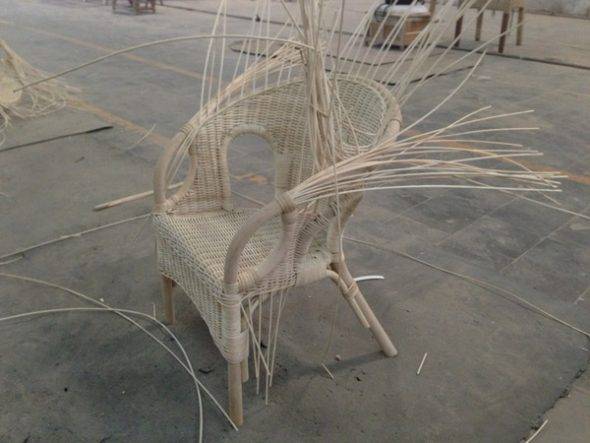

Sofa manufacturing technology

A master class of this process for beginners is presented step by step below. The procedure does not have any specific difficulties, therefore it can be performed even by people who do not have complex skills.

The following actions are performed in advance:

the material used for work is selected, and most often artificial or natural rattan is bought for this, since these elements have an affordable cost and are easy to use;

it is important to check that the purchased rods do not have any defects, and if natural materials are purchased, it is advisable to sand them to ensure that smooth surfaces are obtained;

it is determined what dimensions and other parameters the future sofa will have;

it is advisable to make a special scheme for the future design, according to which all work will be performed;

the method of weaving is determined, and since a beginner acts as a master, standard single weaving, which does not require experience or special skills, will be optimal for him.

After completing all the preparatory steps, you can proceed to the direct process of creating a sofa.

Rattan

Rattan

Required tools

Required tools

Seat frame

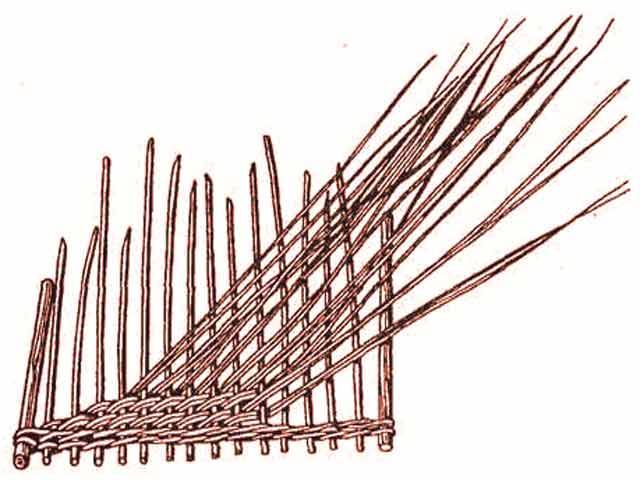

Initially, the frame is made. Some wicker furniture can be made without it, but not a sofa, since quite significant loads will certainly affect it during operation.

The frame can be made of wood or metal. It should completely repeat the shape and size of the future seat

It is important to use materials for it, coated with special protective agents that prevent the process of corrosion or decay. Self-tapping screws or other fasteners can be used to connect individual parts. The resulting frame is braided with the selected rods, for which you can use different weaving technologies

Wooden frame

Wooden frame

The frame is gradually braided with rattan

The frame is gradually braided with rattan

Legs and back

Three or four legs can be selected. Their height can also be different, and for this, the height and other dimensions of people who are the main users of the received sofa are estimated. Their optimal height is considered to be 40 cm. They are fixed to the seat with self-tapping screws, and the distance between them should be the same.

To create the backrest, a metal rod or a wooden stick is prepared. In length, this element should be slightly larger than the seat. It is fixed to the rear legs with self-tapping screws. The resulting structure is covered with braided elements that are connected to each other securely and tightly.

Work is best done on a stand

Work is best done on a stand

We give rigidity

A sofa made of wicker elements must be reliable, for which, in the process of its manufacture, it is imperative to give it rigidity. For this, the following actions are performed:

- identical wooden sticks are attached between the side legs with self-tapping screws;

- they must be at the same height;

- to connect the rear legs, two sticks are also used, and they are fixed diagonally;

- the rod of the selected material is folded into an arc, after which it is fixed to the left side of the back, and its ends are attached to two legs, and the upper arc is connected to the back;

- the same work is done on the other side of the back;

- another rod is taken, having a large size, which also folds into an arc;

- its ends are fixed to the front legs with small nails, and the upper part is attached to the seat.

How to carry out the work correctly

Particular attention should be paid to the processing of corners.

Armrests

Assembling the structure

At the end of the work, the structure is assembled. For this, all elements are securely and firmly connected to each other using suitable fastening elements.

If the fasteners are not too reliable, then it is allowed to strengthen them with a high-quality adhesive solution. The made structure is processed with special protective compounds, after which you can start decorating it.

Novelty and comfort - rattan furniture for summer cottages

Not so long ago, furniture in summer cottages could only be represented by tables and benches made of durable varieties of wood. Nowadays, designs made of natural or artificial rattan are becoming more and more popular. Such products are aesthetic, reliable and original. Sizes and shapes are very different, which allows the furniture to be used on any type of landscape.

According to its design features, rattan furniture is divided into several categories. Hanging beds, armchairs, hammocks are referred to as hanging products.Models that can be rearranged at any time represent the category of portable furniture. A reliable and durable frame is equipped with stationary structures installed at a specific location. You can combine products, decorating the interior with the help of competent placement and installation of furniture from different categories.

Style

Wicker outdoor items made using artificial rattan are presented in many forms. All products differ in size, shape, color and style in which they are made.

All designs in accordance with the device can be:

- frameless, characterized by the absence of a basic structure, and to create such furniture, the most durable rattan is used, which has a significant thickness;

- stick, in which strong and reliable sticks are used as a basis;

- frame, called in another way type-setting, and here tubes made of wood, metal or plastic are used to create a frame, namely, rattan weaving is made between them.

The most reliable and durable are frame objects, therefore, even with significant mechanical loads and influences, they keep their original shape. The variety of furniture models is due to the use of different weaving technologies. The most commonly used technology is chess, and you can implement the whole process even with your own hands in the absence of experience and specific skills, since the process is not considered difficult. Openwork weaving provides a truly unique and unique result.

Items are produced in numerous colors and styles, but most often a set is chosen in any one stylistic direction:

- a classic that is considered always relevant, and in this case the designs are distinguished by unusual and intricate shapes, as well as light colors, and they are written out in any exterior due to their versatility;

- high-tech, and products in this style fit perfectly into modern summer cottages, where people are constantly using various innovations and the latest inventions, and the colors of the furniture are usually metallic;

- modern, which is usually preferred by many young people, and it involves the use of various attractive interior items, so the furniture is distinguished by its sophistication and originality, but has straightforward forms and high functionality.

The most relevant are wicker products, in which there is an aluminum frame, which is their basis, since it guarantees a long service life of such furniture, even with constant negative influences.

Peculiarities

One of the main requirements for garden furniture is thermal and moisture resistance. The products will have to be outdoors for a long time: wicker tables and chairs are taken out into the street at the beginning of the season and brought into the room in late autumn. The material and fasteners must withstand dry air, heat, ultraviolet radiation, and dampness.

The second requirement is strength, resistance to mechanical stress. Nobody will take good care of garden benches and chairs. They are often rearranged, moved from place to place, while dropped, scratched

An important property of garden furniture is UV resistance. It can get very hot in the summer cottage.

The sun emits not only heat, but also ultraviolet light, which is harmful to many materials. These rays affect objects in the most destructive way. After a long time on the street, any thing loses its original color, fading.

Lightness and compact dimensions are indispensable qualities for garden furniture.The braided product cannot be disassembled to translate or carry, so it should be small. In the garden, chairs, armchairs, sofas often have to be rearranged from place to place. Good rattan furniture can be carried even alone. This mobility is provided by lightweight materials.

Environmental friendliness is a requirement for any furniture, not only for garden furniture. Safe materials are those that, during production, do not harm nature, and during operation do not emit harmful fumes. Traditionally, natural bases are considered the most environmentally friendly: stone, metal, wood. However, good artificial raw materials such as polirotang, for example, are not inferior to them.

An indispensable requirement for street products is aesthetics. Beautiful garden furniture is just as pleasing to the eye as a well-designed flower bed. An unattractive environment causes discomfort, overshadows the joy of being in nature.

Required tools

How to make wicker furniture? This process is not considered too difficult, but first you need to prepare for it so that all the tools and materials are at hand. To do this, you must certainly have in stock:

- hammer and screws;

- high-quality glue designed for fixing different materials;

- direct weaving material, which can be represented by different rods.

In addition to preparing the materials, you should decide what kind of weaving will be used:

- single, in which you need to work with only one rod;

- combined, using several rods at once, but this technique is considered quite complicated, therefore it is suitable only for experienced craftsmen;

- openwork, allowing you to get really unique and unique in appearance designs, however, such work will take a lot of time, and it is also considered quite difficult.

Openwork

Openwork

Single

Single

It is necessary to ensure in advance the strong fastening of all the components of one piece of furniture, otherwise it will not last too long. Connections of individual elements can be detachable or permanent. In the first case, any structure can be disassembled if necessary, and then reassembled, but this method is not used too often. The most optimal is the one-piece connection technique, which ensures the strength of the resulting structure.

Final processing

The final stage of processing wicker furniture includes identifying and / or eliminating defects. If necessary, the uneven distribution of the rods is corrected, the supports are leveled, sharp ends are cut off, all irregularities are smoothed out with fine-grained abrasives.

Additional processing steps:

- Whitening. Treatment with lime, hydrogen peroxide or sulfur gas is carried out at the request of the owner, the bleached furniture is covered with transparent varnish or tinted.

- Priming and painting. To paint wickerwork, aerosol sprays are used, applied to a clean, dry and, if possible, varnished vine covered with a thin even layer. If necessary, the process is repeated, hard-to-reach areas of wicker furniture are painted with a thin brush.

- Varnishing. Preference is given to water-based polyurethane varnishes, applied in 2-3 layers and reliably protecting wicker furniture from external influences.

- Drying the painted product in a well-ventilated, shaded area.

To improve resistance to moisture, scratches and fading, wickerwork can be further processed. For example, soaking a rattan in a liquid glass solution, opening flexible twigs of a vine with wax compounds. But in general, protection from 1 layer of drying oil and 2-3 varnish is considered sufficient. Proper care helps to extend the life of wicker furniture. It involves cleaning from dust with a soft cloth, a vacuum brush or a vacuum cleaner, using a damp blanket (the furniture is covered with it for 12-24 hours) when the air is excessively dry, drying after being soaked.

Priming and painting

Priming and painting Whitening

Whitening Varnishing

Varnishing Drying

Drying

Rattan furniture

Rattan garden furniture is the choice of real aesthetes, as well as people who are not afraid of difficulties. Elegantly wicker, very beautiful and respectable furniture will help make the site a real recreation area. Besides, it is very comfortable.

However, beauty requires sacrifice: rattan furniture is the most capricious and unpredictable lady. She will quickly become a victim of rains, sun rays, temperature changes. An elegant braid can deform from overuse.

Such furniture will require constant shelter from rain, keeping in a warm room, careful cleaning, periodic renewal of varnish on the surface of wicker products.

The cost of such products will also not be an advantage of this type of country furniture.

How to choose the right rattan garden furniture?

Unusual pieces of furniture can decorate any venue. Eco-style adherents consider such a design an ideal option. Garden furniture must comply with the overall design concept of the site, be attractive and practical. You can choose individual items that will become the highlight of the exterior, or select whole headsets for the local area.

The main qualities of the original products are considered strength, aesthetics, durability. Ease of use and durability of finished rattan products are no less important. When choosing exotic elements for a summer cottage, it is worth considering some rules and features:

Structures should not have sharp corners, dangerous parts and protruding stems.

The frame is made of aluminum or steel, this is checked with a magnet upon purchase.

Weaving should be of high quality, dense.

The presence of special impregnation from exposure to UV rays is important so that the furniture does not become fragile and does not crack.

A protective coating must be applied to the surface to prolong the service life.

Stylish rattan furniture can successfully fit into any suburban interior. Such products can be placed on the veranda, and, if necessary, taken out into the street. The plasticity of the material allows the production of chairs, armchairs, tables of different shapes, creating a unique atmosphere at the summer cottage.

If you have a small budget, you can choose furniture with straight lines, square, without unnecessary decor. This will not only make the site stylish, but also significantly save your own finances.

If you have a small budget, you can choose furniture with straight lines, square, without unnecessary decor. This will not only make the site stylish, but also significantly save your own finances.

Modern design solutions allow you to combine rattan with wood, glass, metal, plastic. A versatile approach to manufacturing provides the ability to produce a wide variety of models, for every taste and budget.

Modern design solutions allow you to combine rattan with wood, glass, metal, plastic. A versatile approach to manufacturing provides the ability to produce a wide variety of models, for every taste and budget.

How to determine the quality of rattan

The seller must have quality certificates for raw materials and dyes used in production. It is not at all necessary that artificial rattan will be delivered to you straight from the warehouse, it is often made to order, of the desired color and texture. The production technology is standardized according to ISO 4892.

There is a five-point scale for assessing the aging of the polyrotang (ISO 4892). The material has a better quality with a score of 5. The cheaper species age faster and will have a lower score.

For high-quality artificial rattan, commercial grades of plastics are used, which are mainly based on polyethylene and special additives to impart great elasticity and strength to the material. Rehau, Viro, Hularo - these raw materials are the guarantors of the polirotang quality. Raw materials are expensive, which means that wicker products from it cannot be cheap. Such polirotang is guaranteed to be resistant to mold, severe weather conditions, hot sun and will withstand temperatures from -60 ° C frost to + 70 ° C heat.

Manufacturing process: step by step instructions

In order for the manufacturing process to take place without unforeseen interruptions, it is necessary to take into account the recommendations of experienced craftsmen, who suggest organizing it in a specific order:

- Prepare the structure chosen as a base, wood or metal. It can be made by hand, but you can also use a ready-made one.

- To make it convenient to work, install the guides on the base and fix them with self-tapping screws, a stapler or bolts.

- Level the surface of the frame by cutting off the protruding rods with scissors.

- The next step is weaving on the frame. Its type is chosen according to your taste and depending on the selected raw material.

| Weaving type | Peculiarities |

|

Simple |

Differs in ease of implementation. Perfect for those who are just learning to work with rattan. |

|

Rope |

Produces a tight weave with a twisted rope pattern. You can start working with this type after mastering a simple one. |

| Three rods | A more complex type of work that requires skill and allows you to ensure the strength and stability of the product. |

| Four rods | It is done in two ways. At the first, the drawing looks the same from the outside and inside. The second is a string; with its help, weak strips of other types of weaving are fixed or separated. |

| Openwork (simple and complex) | A variety of thin weaving with open cells. Intricate openwork is similar to lace patterns. Simple openwork is rhombuses, posts, rosettes, spirals, rings, and also checkerboard. |

- Excess material is removed after completion of the work, the ends are “masked” on the finished product.

The material provides ample opportunities for the implementation of design ideas.

To make the product even, durable and neat, when weaving, it is necessary to constantly check how the rows of rattan "fit".

Nuances of choice

Weaving furniture from artificial rattan or buying ready-made products oblige you to understand the differences between brands of polirotan. The fiber is made from primary HDPE granules (low pressure polyethylene), polyurethane and polyvinyl chloride (hereinafter PVC). Each material gives the final product its own characteristics that must be taken into account if you decide to buy fiber and weave interior or decor items.

| Polirotang type | Material characteristics |

| Polyethylene |

|

| Polyurethane | Elastic material, resistant to cracking. Best for furniture that will be heavily used. Mold and UV resistant. During processing, polyurethane loses its properties, therefore it is unsuitable as recyclable materials. |

| PVC rattan | For the manufacture, polyvinyl chloride is used in combination with additives that provide elasticity to the material. Of all the species, this artificial rattan is the least suitable for wintering in low temperatures. In addition, with strong UV exposure, it can also be damaged. Such furniture must be removed or protected with covers. |

Carefully study the characteristics of the material before placing an order. Otherwise, you risk getting not at all what is required. We remind you: high-quality polyrotang has a rating of 5 on the material aging scale!

It is necessary to choose a polirotang based on the quality characteristics of the furniture of interest. Will it be used often or from time to time

The cost of faux wicker furniture can vary widely, so it's important to understand how much you are willing to spend and whether you need it. It makes no sense to give large sums if you come to the dacha only on weekends, exclusively in summer

But if you take furniture into a house where you live permanently with the whole family, you just need to think about the quality of materials.

Who might be interested in a set of furniture made of polyrotang? First of all, these are the owners of country houses and summer cottages.Such furniture will allow you to decorate terraces or living rooms with high quality, creating a characteristic light flavor. Artificial rattan goes well not only with textiles, but also with leather, glass, metal. It can even be seen in offices where stylish headsets adorn reception areas and meeting rooms.

The second on the list, of course, are the owners of cafes, restaurants and other entertainment establishments who need a high-quality interior that can withstand heavy use. In this sense, artificial rattan is the best way to invest in an interior. Visitors like this kind of environment, which means it will attract customers. Openwork hanging chairs, furniture such as papasan and mamasan - large sizes, which allow an adult to accommodate with a child, look especially impressive. A set of wicker sun loungers by the pool will transform your summer cottage into a tropical beach. And also, artificial rattan is used to decorate counters in stores - this is a very spectacular and at the same time furniture that meets sanitary requirements.

Technorattan furniture is even becoming a business item. Not only sale, but customization or production of the rattan itself. Now they are engaged not only abroad, there are domestic firms working on high-quality raw materials.