Do-it-yourself open gazebo

It shows how to build an open gazebo with your own hands from wood. The design, as you can see, is solid. The main building material will be wooden beams, the volume, and the quantity will depend on the size of the structure, the author does not give figures, so you will have to select it yourself. The second required material is metal rods of two types, T-shaped and L-shaped. And you also need screws, very large screws, twice the thickness of the beams. Do not forget about the ladder, preferably a sturdy one, in this project it is the main tool. Concrete is another essential material for building your gazebo, it will be used as a base and anchor for the entire structure. Once you have drawn the drawing, you will be able to see what dimensions are needed for all the wooden parts. If you have tools, you can cut all the components yourself. This is the cheapest option. If you don't have the skills or tools, you need to find someone to do it ..

The first step is to build the base.

- Prepare the area and fill the slab of the desired size. If you want more strength, add metal reinforcement concrete.

- Next, install the wooden beams and metal supports into the concrete at a 90 degree angle.

- If there are gaps between the metal and wood parts of the supports, use tar and silicone to fill in and create a waterproof seal.

- Repeat this step for all supports. Typically four pillars are installed, but if you choose a different design, more pillars may be required.

- The next step is to place the wooden rungs on the supports, remember to measure all sides and make sure they are equal. Then secure them in place with the screws.

- The next step is to attach the side rails to the ones you installed on the posts.

- Then you need to make a triangular structure that will support the roof. The triangular shape of this part of the structure is designed to distribute weight down to the supports, which will be especially useful if you live in an area with high rainfall, especially snow.

- Use metal rods to hold the diagonal pieces securely in place. Pass the metal bar through the two pieces of wood to make sure they hold firmly in place.

- Now install the top bar where the roof will be attached. This may require the use of a rope or extra help to keep the pieces together.

- Now it's time to put in the roof supports to help support the weight. Place the support approximately every 55 cm. Fasten the supports securely with screws.

- Cover the roof with sheets of plywood, this layer must withstand a lot of weight, it must be fixed very securely.

- Then attach the waterproof layer. There are different types of roofs, you can choose whichever you prefer, but laminated tiles are a popular and effective choice.

And this is a gazebo from VIDEOCASSETS !!!

Dimensions of the structure

In most cases, two beds are placed in a greenhouse, which are separated by a path.

Beds in a greenhouse made of plastic pipes

The width of the beds is on average 0.9–1.1 m, which makes it possible to plant plants in two rows with the required spacing and provide unhindered access to them.

The width of the path must be made such that it is possible to move comfortably with a bucket and other summer cottages, including a wheelbarrow.

Correct passage width

The optimal track width is 0.7–0.8 m. In this case, the width of the structure will be 2.3–3 m.

The length of the product will depend on the needs and requirements for the location of the vegetables you plan to grow. Planting rates per 1 m2 can be seen in the table below:

| View | Roots per 1 m2 |

| Cucumbers | 2–4 |

| Peppers | 4–6 |

| Tall tomatoes | 2–4 |

| Eggplant | 2–4 |

| Undersized tomatoes | 4–6 |

| Pumpkins and zucchini | 1–2 |

Using the table, you can determine the length of the building. Usually, structures are made with a length of 4–6 m, since it is impractical to install a greenhouse of smaller dimensions, and for buildings of greater length, you will need to use materials of increased strength. Construction technology will also differ.

The height of the building should allow you to comfortably move around it. It is worth knowing that at least 50 cm of free space should remain above the landings.

Correct greenhouse height

Warm air will accumulate in this place and air exchange will take place during the ventilation process. If you plan to grow low-growing vegetables, then a height of 1.9–2 m is sufficient. For tall crops, the minimum height of the greenhouse is 2.3–2.4 m.

The frame of the tube structure forms half a circle. The width of the item is the diameter of this parameter. If the diameter is known, then the radius can also be determined. The values are used to calculate the length of the parish. This can be done using the following formula:

L = 2πR = πD, where L is the circumference, R is the radius, and D is the diameter. The number π is 3.14.

For example, if you plan to make a greenhouse with a height of 200 cm, then with the correct arc, the width should be 400 cm.In this case, the diameter of the circle is 400 cm, and the radius is 200 cm.

Accordingly, the length of the district: L = 2 x 3.14 x 2000 = 12560 mm. Only half of the circle is needed, so the arc length is calculated like this: 12560/2 = 6280 mm.

The arc consists of 2 tubes and a cross, so the obtained value must be divided again: 6280/2 = 3140 mm. This will be the size of the pipe.

Next, you need to determine the shape of the structure.

Instructions for construction in the country or in a personal plot

The simplest and wisest solution is to build a tent with a wooden frame. The construction of a temporary wooden building is a multi-stage work:

-

On the territory where it is planned to put the tent, markings are made according to the dimensions of the future structure. In those places that will later become the corners of the tent, with the help of a brace, they create pits with a depth of half a meter;

- Bars, boards and rafters are treated with a primer and painted in the desired color. The dried up beams are immersed in the grooves made in the ground and covered with soil, which must be tamped;

-

Bars are attached to the installed supports in a horizontal position, that is, they create an upper harness. The rafters are fixed to the resulting structure with self-tapping screws, which will become the basis for fastening the tarpaulin or other material;

- Cover the walls and roof of the tent with a thick waterproof cloth. At the entrance to the tent, a mosquito net can be pulled onto the supports.

You will have to act differently if you decide to make a tent with metal supports. Its construction involves the following stages:

- The site for the construction of the tent is leveled and cleared. In the places where the construction supports will be located, 4 concrete slabs are laid, which will become a kind of base. A hole is drilled in the center of each stone block;

-

Metal rods are installed in the holes made by the drill. The upper edges of these supports are connected with wire, creating arcs;

- A waterproof fabric is pulled over the wire and fixed by tying it with a string at the points of alignment with the arcs of the frame. The material laid on top of the wire is straightened, giving the structure a complete look;

-

To avoid slipping of the fabric, additional ties are sewn on the inside of the material. They should be located in the areas of contact between the fabric and the frame;

- Between the third and fourth pillars, it is not a waterproof tarpaulin or raincoat that is pulled, but a mosquito net.

Options for plastic structures

Plastic is a rather broad concept. When erecting gazebos, the following can be used:

- Polyvinyl chloride (PVC) is a very popular, but least suitable material for the construction of street structures. The thing is that it does not have the required strength. Therefore, PVC buildings often break or deform. In addition, when heated in the sun, this material emits toxic substances and smells unpleasant. The indisputable advantages of polyvinyl chloride include ease of handling and ease of cutting, thanks to which PVC can be used to create designs of any unusual shapes. Plus, during the production process, the material is painted in a wide variety of shades, resulting in exclusive structures of any shape and various colors.

- Polypropylene is a matte plastic with an opaque structure. This material is more environmentally friendly than PVC (no harmful emissions). However, it can only be operated on the street in a limited mode. This is due to the fact that polypropylene also does not have sufficient strength. But from it it is quite successfully possible to make collapsible structures, especially on a metal basis. This type of construction does not require the arrangement of the foundation and is quite mobile (if necessary, it can be moved from place to place without any problems).

- Polycarbonate is the most successful version of a summer cottage made of plastic. This material has excellent performance characteristics: strength, transparency, resistance to external influences. In addition, polycarbonate gazebos, photos of which confirm their original appearance, fit perfectly into any landscape design. Such structures are classified as capital and require the arrangement of the foundation or, at least, careful preparation of the site and filling it with cement.

- Acrylic, polyurethane, thermosetting plastic are other types of plastic. However, they are not used as a basis for the construction of street buildings. Most often, these types are used only as an addition to other materials.

As practice shows, it is best to combine various materials when building a gazebo: make a frame from stronger and harder ones, and patterned fences and a roof from softer ones.

Plastic is a rather broad concept. When erecting gazebos, the following can be used:

- Polycarbonate is the most successful version of a summer cottage made of plastic. This material has excellent performance characteristics: strength, transparency, resistance to external influences. In addition, polycarbonate gazebos, photos of which confirm their original appearance, fit perfectly into any landscape design. Such structures are classified as capital and require the arrangement of the foundation or, at least, careful preparation of the site and filling it with cement.

- Acrylic, polyurethane, thermosetting plastic are other types of plastic. However, they are not used as a basis for the construction of street buildings. Most often, these types are used only as an addition to other materials.

As practice shows, it is best to combine various materials when building a gazebo: make a frame from stronger and harder ones, and patterned fences and a roof from softer ones.

Functions and structure of the tent

A tent is a small building with walls or a frame located under a canopy. As a rule, it is installed for a short period and, if necessary, can be moved from one place to another. Most often, a tent is installed in a recreation area - where the barbecue is located, or on the side of the house from where a beautiful view opens.Sometimes it is mounted next to the pool so that you can take shelter in the shade after swimming. Thanks to the removable side walls, it can be fully or partially open and closed from the desired side, so that no draft is created.

The tent is a temporary structure that can be disassembled or moved to another location.

Types of tents

With an independent project development, you can design a tent of almost any design and shape. It all depends on how you represent it, and on the materials that are available. There are four main types of tents:

- tourist - small in size, easily carried in a backpack. It is mounted from a frame and guy wires that pull the awning and make the structure stable even in windy weather;

- folding - lightweight construction, consisting of racks and an upper canopy, without side rails. Most often used as a hiding place during a picnic;

- gazebo-tent - a structure similar to the gazebo, with side walls made of fabric or mosquito nets, attached to the upper horizontal part of the frame;

- tent-pavilion - a mobile structure used during festive events: weddings, festivities, etc. Decorated with various types of fabrics, can be of various sizes and shapes.

Using tents for various events

Depending on the purpose, tents can be decorated in different ways - from multi-layered and luxurious to the simplest ones that do not attract attention.

Table: advantages and disadvantages of a tent in comparison with a gazebo

While the tent and the gazebo have similar functions, there are a number of differences. And if you are faced with a choice, to build a gazebo or build a tent, you should compare some of their characteristics.

| Tent | Alcove |

| Mobile structure that can be moved on site and stored for the winter | Robust, permanent design, installed for a long time |

| Installation does not take much time and does not require special skills | Installation will require special equipment and accurate calculations. |

| Lightweight and relatively short-lived | The building is designed for a long time, has a lot of weight |

| Does not require large financial investments, since it can be assembled from scrap materials | For construction, you will need high-quality wood, which has a high cost. |

| Thanks to the awning, it protects from heat and rain, and with a mosquito net - from mosquitoes and other insects | Good weather protection, but no insect protection |

| For installation, just select a flat area and level it | Foundation fill will be required |

| All materials can be selected independently, at your discretion | Requires precise selection of building materials |

| Deaf side walls are afraid of strong wind, therefore additional strengthening of the tent is required | Wind resistant design |

What plastic is used to make gazebos

Several types of plastic are used in the production of arbors:

- Polyvinyl chloride is the most inexpensive of all options, but the least suitable for making gazebos. PVC structures are not very strong, they can deform and even break. This type of plastic can release toxic substances on contact with direct sunlight. Products of the most complex shape are obtained from PVC, it is easily cut and glued.

- Polypropylene is a matte, opaque plastic that, unlike PVC, is considered non-toxic. Gazebos made of polypropylene are environmentally friendly, but not durable enough. Polypropylene is most suitable for the manufacture of prefabricated buildings on a metal frame.The portable gazebo is easy to install in a new location and does not require the installation of a foundation.

- Polycarbonate is an expensive and fairly durable plastic. Polycarbonate constructions are attractive and stylish due to its light transmission. In addition, this type of plastic keeps its shape well, this allows you to make curvilinear buildings from it. Polycarbonate is used for the construction of gazebos with a frame made of shaped pipes, and for large-scale gazebos with a frame and metal strapping. Such a building needs a full-fledged foundation.

Gazebos are most often made from several types of plastic. The frame is made of plastic, which is harder and more durable. A fencing and a roof of a structure made of soft or transparent plastic are attached to the frame.

For giving, plastic gazebos would be a good option. They are easily assembled from individual elements; if desired, the gazebo can be disassembled and assembled elsewhere. Another advantage will be that after the end of the summer season, the gazebo can be disassembled and stored in the shed. Plastic does not need painting or additional maintenance, which saves you time and money.

Plastic gazebos can be pure white, or they can imitate the texture and color of wood.

$

The price of a plastic gazebo is

The photo shows a plastic gazebo.

The main advantages of metal arbors

It is worth noting that a gazebo made of a profile pipe, in addition to the ease of construction, has other important advantages.

- It weighs a little - if the soil on the site is dense enough and does not move depending on the season, then the foundation may not be required at all - instead, the structure can be piled on bricks / stones. If the gazebo is small, then, if necessary, it will generally be possible to transfer it to another place. As a last resort, you can build a columnar foundation, which is much less expensive than a strip type.

- This design is fireproof, which cannot be said about arbors made of wood. Therefore, inside without problems, you can place, for example, a brazier. In this case, even if a fire occurs, it will not damage the structure in any way.

The metal gazebo is very durable, it can withstand seasonal soil movements without any problems. The frame holds its shape much better than those made of wood or brick.

Finally, all connections are as accurate and geometrically correct as possible. Although, even in case of inaccuracies, they can be easily eliminated.

Of course, such gazebos also have their disadvantages. So, thermal insulation here is practically zero. For this reason, such gazebos are made open, that is, more for summer use. Of course, the structure can be sheathed with something (say, clapboard), but it will still remain uncomfortable and cold. In addition, the frame needs permanent maintenance. The anti-corrosion coating will have to be regularly updated, otherwise the frame will come into contact with wet soil and, as a result, will begin to rust.

Step-by-step instructions for building a tent with a mosquito net

-

We mark the boundaries for installing the tent and prepare the site for installation. We preliminary designate the place for installing the tent, driving in pegs in the corners, and with the help of a stretched cord we designate its sides. We prepare the site by removing the soil and making a cushion of sand and granulate.

- We proceed to the installation of the support posts. In the places where the supports for the tent will be located, using a brace or a garden drill, we make holes about 70 cm deep.In the prepared pits, we install support pillars strictly vertically with the help of a building level.Their lower part, which will be in the ground, must be pre-wrapped with roofing material or painted with oil paint to prevent rotting.

The ground around the pillars can be tamped, but for reliability it is better to fill it with concrete. If the tent will have a pitched roof, then the rear pillars should be 30 cm shorter than the front ones, so that the water can drain freely from it. If a cone-shaped roof is planned, then in the center one more pillar can be concreted, which will be at least 50 cm higher than the side ones.

-

We mount the top harness. The fastening of the transverse strips is carried out only after the side supports have completely dried. For this, metal plates or special corners are used.

- After the formation of the upper harness, we proceed to the formation of the roof. To do this, we attach additional strips, placing them crosswise or in another way, provided for in the drawing.

-

We additionally attach the rafters to the upper part of the supports for strength. The top awning will be mounted on them.

-

We stretch the top awning and attach the side walls to the finished frame. For this we use special ties or Velcro fasteners. In the daytime, you can only use an awning - it is quite enough to shelter from the sun.

If necessary, side panels made of fabric can be attached to the top of the frame. They are attached to the transverse strips of the frame from three sides. From the side of the entrance to the tent, you can hang a mosquito net. It is very convenient if it consists of two parts and is equipped with special magnets or a zipper.

Mounting options for the tent in the ground and on the asphalt

When setting up a prefab tent on the ground, you need to use additional safety cables.

This will increase the rigidity of the structure and extend its service life. Stretchers are installed using special pegs 15–20 cm long, which are driven into the ground along the perimeter of the tent.

Stretch marks are used to strengthen the structure against gusts of wind.

If the tent is to be mounted on asphalt, additional metal rods are used. To strengthen them, special holes are drilled, rods are inserted into them, which are then poured with concrete mortar. After the concrete will harden, stretch marks are attached to the rods.

Video: dome gazebo

Tent construction works do not take much time and make you feel like a designer. If necessary, tents of different colors and sizes can be used with the same frame, which will allow the structure to look different every season. And the work on decorating the tent for a special occasion will bring pleasure to family and friends.

Types and methods of assembly

In addition to different shapes - rectangular, hexagonal, octagonal, round - the metal frame can be installed in two different ways:

The vertical pipes of the frame are concreted into the ground. The rest of the structure is then attached to these racks. With this method, the presence of a foundation is not provided. In principle, having made the lower strapping at some distance from the ground, you can lay the floor, but most often with this method of making an iron gazebo, the site is concreted or paving slabs are laid out.

Wells are drilled under the metal racks, a pipe is inserted, the empty space is covered with rubble. The pipe is exposed evenly, the crushed stone is rammed, then poured with liquid concrete

First do shallow columnar or strip foundation, sometimes a monolithic slab is poured, the site is laid out with tiles, etc. The frame is constructed separately and fixed after at least the lower harness and racks are ready. If the foundation is columnar or strip, the pipe is placed on it and connected in place: only a crane can lift the finished structure.

This is a gazebo made of a profile pipe on posts

Which is the best way? It depends on which side you look at. If from the side of fastening reliability, it is better - the first: the racks are walled up. Also, this option is more economical: there is no bottom piping and there are no costs for making a foundation. But such a structure, if it is without a floor, is only a summer gazebo.For a closed winter one, you need a floor.

A gazebo on a foundation is better from the point of view that it initially assumes the presence of a floor. In addition, the elevation, even if it is small, protects against splash and dirt from entering.

Assembly methods

Traditionally, metal is joined by welding. It is fast and reliable. But in the case of a summer cottage, a collapsible design may be needed. After all, leaving a large amount of iron for the winter in an unguarded dacha is very unsafe. In the sense that it can easily be stolen. In this case, the modules are welded, which are then bolted together. As a rule, such collapsible metal arbors are a frame to which an awning is attached, or another similar quickly mounted or dismantled fence and an equally light roof.

For a prefabricated metal gazebo, frames are separately cooked for each side, then assembled with bolts

The frame in collapsible arbors is broken along the edges. If it is quadrangular, four separate circuits are boiled with all the necessary jumpers. There are six of them in hexagons, etc.

Plastic construction options

PVC pipes are flexible materials with high lightness. It makes it possible to build a gazebo of any shape, sometimes even fancy. The arc structure of structures is widespread. It is used as a base for a PVC structure, it is also used for pergolas, awnings. The roof can be pitched or two. Ideas for future construction can be taken from the photographs. At first, the building is depicted in the form of sketches from several angles. Diagrams should also display dimension marks. The design takes into account the material for the roof, walls, dimensions and approximate price. It is better to think over everything in advance, this is necessary in order to avoid mistakes during construction.

Note! Acrylic and polyurethane are used to create additional parts in all types of structures.

PVC pipe is a common material for the construction of street structures. But it breaks down easily and can smell unpleasant under the sun. PVC is easy to cut into pieces and form a structure out of them. This material can be painted in any color, which also contributes to its distribution. If the budget is very limited, then the use of PVC is justified, since you can keep within a very small amount.

Polypropylene is a matte plastic:

- It is not transparent, it is produced in different colors.

- The material itself is relatively environmentally friendly, because it does not emit harmful substances when heated.

- It is fragile, therefore it is used only to create parts, in combination with metal parts.

- The polypropylene version of the gazebo is easy to disassemble and move if necessary.

Polycarbonate is transparent, durable, resistant to sunlight and high temperature. Structures from this material can be given any look and used in different landscapes. It is considered the best of the listed materials for the construction of plastic arbors. Structures from this profile require a capital approach to construction, including pouring the foundation. A polycarbonate gazebo looks expensive.

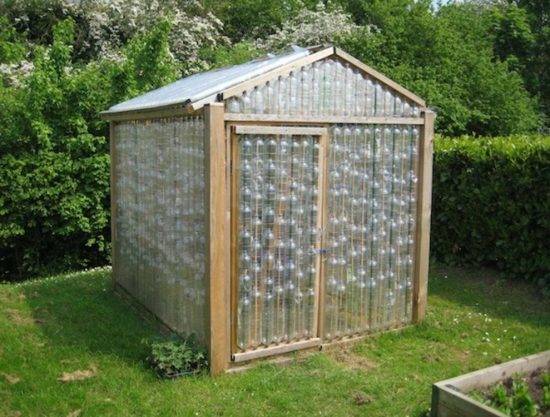

Gazebo made of plastic bottles

They can be quite original. For example: a gazebo with plastic bottles. The use of plastic bottles in everyday life helps to preserve the environment, and this material can be used for gazebos.

Of course, it will not work to decorate the structure exclusively from such materials, but you can apply them in the design of the walls. In addition, pots or custom decorations can be made from bottles. It will take quite a long time to collect bottles for such a project, since it will take a lot of them.

Before use, the container must be washed and removed from the remnants of labels. It is usually sufficient to simply soak the bottles in salted water for several hours.If a complex design is assumed, then it is also necessary to provide a metal frame.

Plastic windows

A gazebo made of plastic windows is an unusual design that is built to order according to your own standards. It looks like a wardrobe, a wall-mounted window panel can be moved to the side. The roof is made of durable material, often shingles. Such buildings:

- durable;

- transparent;

- have a high price because they are considered to be of high quality.

It is possible to use plastic boxes for ennobling gazebos. You can plant flowers in them for an interesting decor option. The veranda can also be ennobled with these boxes. You can also use plastic pipes to assemble gazebo furniture. This will complement the overall look and is suitable to usefully spend the material remaining after construction.

Design features of gazebos made of shaped pipes

As you might guess from the name, the main consumable material that will be used in this case are profile pipes, which, in turn, can have either a square or rectangular cross-section. In many respects, such a material is significantly superior to other types of rolled products (for example, round pipes, rods or corners) and is better suited for the construction of all kinds of metal structures, especially if they are made with our own hands.

Due to the special shape of the section, the professional pipes provide the following important parameters.

- The load will be distributed as evenly as possible, and not only over the pipes themselves, but also over the elements that are connected to them.

- The construction process itself will be as fast and simple as possible.

- The structure will turn out to be quite strong, although it will not weigh very much (the fact is that such pipes are hollow inside).

- The gazebo will be more beautiful and attractive than if other types of metal were used.

- Finally, attachment points with other parts can be easily and conveniently adjusted from either side. But this cannot be said about the same pipes with circular cross section.

It is also worth noting that shaped pipes are a truly versatile material. They can be used not only for load-bearing structural elements (roof beams, for example), but also for all others (even decorative ones - tables, benches, etc.). For the manufacture of the gazebo, you can use only the metal profile itself, as well as the material that can be used for the roof (for example, cellular polycarbonate). And to ensure the attractiveness and ultimate lightness of the entire structure, you can, as shown in the illustrations, use pipes of different sections.

For the gazebo, in particular, for its support pillars, it is preferable to use a square metal profile. As for the rectangular one, it is also suitable, but it is better to use it for battens, fences and other elements that are not subject to significant mechanical stress.

In addition, during the construction process, you will need skills in working with electric tools - an electric drill and a grinder. It is also advisable that you know how to work at least a little with a welding machine. Thus, you will be able to make welds in the places where it is needed. Agree, the fastening made with a bolt and nut does not look as neat and attractive as that made with a welding machine.