With increased power

Modified model of increased power. A comfortable handle is cut with an electric jigsaw from a piece of durable wood, cleaned with sandpaper. The rogatina is cut from a steel sheet with a diameter of 2 mm, the saddle is from a piece of sturdy leather. For stretching - medical latex catheters. All parts are connected by bolts and nuts, glued with polyester resin. To increase the power of the shot, the author uses a system of blocks of furniture wheels for the bracket. During testing, steel balls leave a through hole in thick cardboard, dents in a wooden block, break glass bottles.

A simple solution

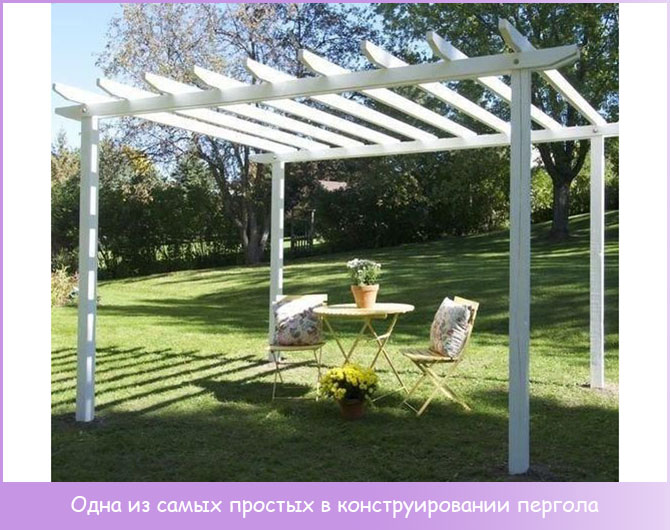

The simplest pergola for beginners is a roof in the form of crossbeams (along which ivy or liana will start up) supported by 4 beams.

Let's consider step by step how to build it yourself.

What is needed

For the construction of a pergola, pine is good, as the most inexpensive wood species. However, it must be well dried, otherwise the structure will then lead, and it is extremely difficult to level it. The table shows building materials, sizes and their quantity.

Preparatory stage

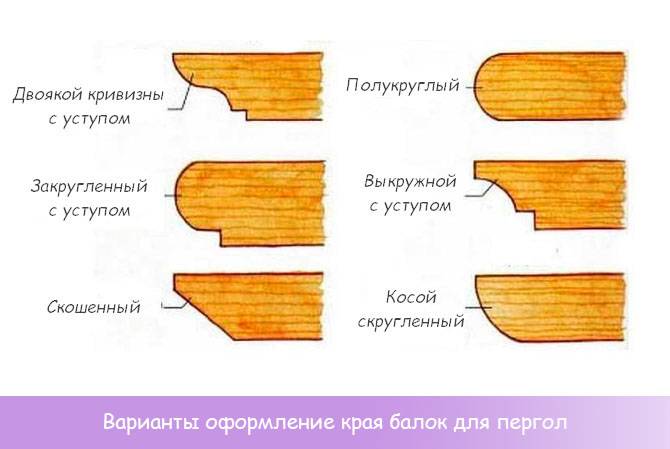

1. Cut the edges of the beams with a jigsaw (those that are indicated in the table in the amount of 9 pieces and with a section of 100x100x3000 mm).

2. On the remaining beam, which will go under the posts, make recesses for the longitudinal floor beams:

- fold 4 beams together;

- align in height;

- fasten with clamps;

- make markings: from the edge - 90 mm;

- notch depth - 25 mm;

- make multiple cuts with a hacksaw from the cutting line to the edge;

- knock down partitions with a hammer;

- process the grooves with a chisel.

Make notches on both sides of the beams.

Toner treatment

Toner is a paint specially formulated for wooden buildings. It has many advantages:

- tints (you can choose any shade);

- preserves the natural texture of wood;

- does not require the application of a fixing layer of varnish;

- gives the material such practical properties as hydrophobicity, UV resistance;

- protects from external negative influences.

Therefore, instead of ordinary paint, purchase a toner and treat the prepared timber with it in 2 layers - this will be enough for a reliable, durable coating. Algorithm of actions:

- Grind parts.

- Protonate them in one layer.

- Wait until it is completely dry.

- Protonate a second time.

- Wait until it is completely dry a second time.

Another indisputable advantage of the toner is that after 2-3 years, when the need for re-painting arises, there is no need to peel off the exfoliated pieces. All you need to do is go through the grinder and protonate it again (only once).

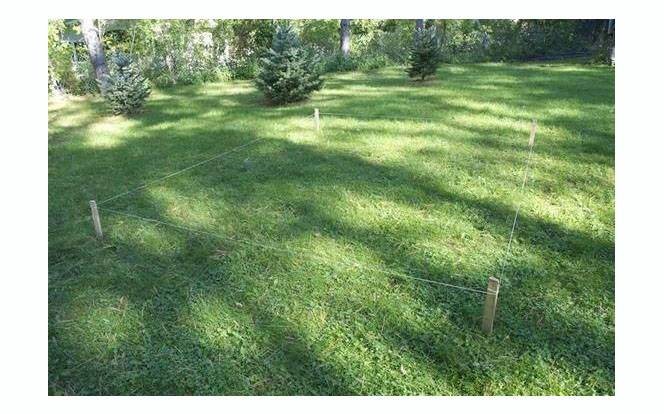

Marking on the ground

1.Use pegs and a rope to mark on the site the place where the pergola will stand. Dimensions - 2.6 x 3 m.

2. Make holes for the supports (with a shovel or drill). Depth - 1 m.

3. Place the beams in the holes so that the cuts run along the long sides of the markings. Make sure they are at the same height.

4. Fill the pits with cement mortar. Let it freeze.

Mounting

1. Longitudinal beams (those that are 4 m long) should be mounted on the recesses. Leave the edges to protrude 40 cm beyond the racks.

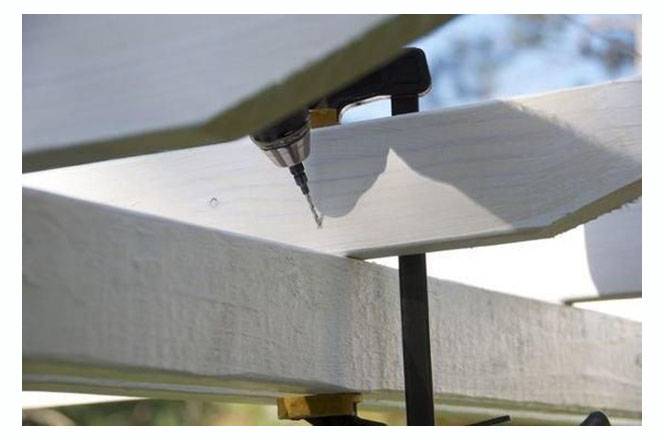

2. Drill through holes with an electric drill (they are needed for the bolts holding the beams and the rack together).

3. Fasten the construction parts with bolts and nuts.

4. Evenly spread the crossbeams along the top of the longitudinal beams, fixing with clamps and securing with self-tapping screws.

Inside you can put a table with chairs, flower pots. Place climbing plants on the ceiling and uprights - girlish grapes, garden ivy, gold hops or tropical dicentra. This design option can be draped with airy translucent fabrics.

Cob stage robot

For the first time, it is necessary to complete the plan in detail.If you can’t be aware of the design, then on the current day there are magazines and sites dedicated to the theme of the week. There you can see the butts of the unwitting ones themselves, and at the same hour the simplest alcoves for the sadibi. Planning a plan includes:

· Appropriateness;

· Altanka shape;

· Rosemir, height and so far.

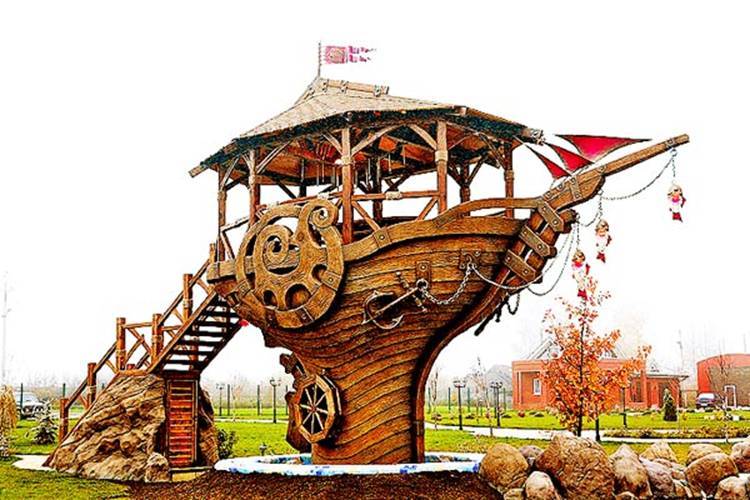

Behind the shape of the sporud can be square, round, rectangular, octahedral, hexagonal, and so far. Gentlemen of the dilyanka with creative missions and boisterous imagination can experiment by staying in the alcove at the viglyadi of the little boy Babi Yaga, the Kazak palace of a space ship. Below, the creative і unwitting butt of the altanka is pointed.

For it is possible to show the rewind in a more classic style, as if it would be seen simply and with relish.

Altanka is also recognized for its attributions. It is necessary to make an appointment from the ear itself, if you want to just read it in the same place on a new occasion, for in the Altans, a great company will have a fun hour.

It’s a very first option, you can start in such a way before the awakening of an alcove with your own hands and a table with benches.

As soon as we plan to set up for a fun hour of the company, give the pass to the great Maydan and Navis.

For quiet people, who do not find out without a barbecue in nature and Polish cuisine, an ideal option would be an altanka with a barbecue.

Wrist bracelet

An unusual piece of jewelry for a girl consists of a large braided wire - aluminum or fluffy model. On the outside, there is a large decorative stone in a metal cut.

Wire braiding is performed according to the following scheme:

Three strong metal strings (elastic) are used as a base. One of them bends in an arc, the two remaining at the ends are twisted into a ring (the figures should not be large, so as not to interfere with the girl when wearing the product).

The next step is to assemble the bracelet: two short cuts of wire are screwed to the main string with intermediate coils of large wire.

The characteristic arrangement of the three components of the bracelet: the middle of the central string remains free, since it is on it that a stone or other decoration is glued.

It is important to first measure the wrist of the future owner of the bracelet in order to model the product in size.

Metal

If you want to install a metal pergola, it is better to make it from profiled rectangular pipes or fittings.

Choice

Metal pergolas are quite diverse in their design. So it's worth starting with a choice:

- hinged, arched, semi-arched, gallery;

- dynamic and static;

- single-row and multi-row;

- decorated with forged elements and as simple as possible in decoration.

You should choose a model not only taking into account its beauty and functionality, but also from the point of view of its ease of installation, because you have to do everything yourself.

Sketch

The construction of a metal pergola begins with a sketch. It requires much more precision than wooden construction. It is easy to saw wood, remove excess, make another notch or fill in unnecessary. All this is difficult to do with metal.

Manufacturing process

Start with making a frame

It is important here that the profiles and steel arches lay on top of the arch evenly. First, the appearance of the structure depends on it.

Secondly, the plants will then grow along it, too, in the same way. If you are new to metalworking, it is easier to choose a rectangular roof mounted pergola first. All structural elements are cut with a grinder in exact accordance with the sketch. Then they are connected by a welding machine.

After that, you can proceed to the foundation:

- At the points of support, dig holes 80 cm deep.

- Cover them with sand by 20 cm and tamp them.

- Clean the support posts from rust, treat with an anti-corrosion compound.

- Weld corners to them from above and below, so that later on to facilitate the installation of the arch.

- Insert the supports into the holes, align, secure with retaining boards.

- Pour with a mixture of concrete and gravel.

If you intend to rest under a metal arched pergola, you can fill the entire foundation with concrete, and make a wooden flooring on top. This will allow you to put country furniture there.

48 hours after pouring the foundation and supporting pillars, a frame can be attached to them, which was made according to the sketch at the very beginning. For strength, corner lintels are used.

After the arched frame is installed, all structural elements are primed and covered with protective and decorative paint. It remains only to plant climbing plants along the supports, decorate the pergola with hanging flower pots.

Our article will help you choose plants for a pergola: Perennial flowers for the garden.

Brooch made of copper wire for a backpack

It is best to start your creative activity with flat crafts - volumetric products require a certain skill from the master.

To make an original butterfly brooch you will need:

- Dense plywood template.

- Several push pins.

- Copper or chenille wire.

- Nippers.

If desired, the master can add decorative elements (beads, bugles or cut for a brooch). The work continues according to the scheme:

- A butterfly figure is drawn on a plywood blank according to the selected model.

- Push pins are placed along the main points of the figure.

- The buttons begin to wind the wire, creating the outline of the butterfly.

- The finished contour is removed from the buttons.

- Next, they begin to form the internal parts: each part is made separately.

- The attachment of parts is done by carefully screwing the part to the frame elements.

Finish the work with decoration. This can be original twisting of a wire, decoration with beads or a large bead, cutting or stretching of a decorative mesh.

How to build a metal pergola for a summer residence (with photo)

Traditional pergolas are most often made of wood, and to ensure their strength, parts of a sufficiently large section are used, which often spoils the appearance of the site, and also increases wind loads.

The way out can be the manufacture of a structure from metal parts: The proposed pergola from metal is welded by hand from reinforcing rods and an iron strip. Structurally, the pergola consists of uprights, fixed with anchor bolts on concrete bases, and arc-shaped trusses. In this case, only one end of each truss rests on the rack, and the second is fixed with a flange on the brick wall of the house using dowels and wood grouse screws. The flange is a 4mm steel plate measuring 150x285mm with 10mm holes. The trusses are attached to the uprights with bent steel strip brackets and bolts with nuts.

To build a metal pergola with your own hands, you will need the following materials:

- 17 reinforcing bars 16 mm and 6 m long;

- 28 belts 120 x 120 mm from a strip 4 x 20 mm;

- 68 rings 0100 mm from a strip of 2 x 20 mm;

- 30mm staples from 3 x 30mm strip;

- 8 flanges 150 x 150 x 4 mm;

- 2 flanges 285 x 150 x 4 mm;

- 4 anchor bolts М16х200mm;

- 4 nuts М16 with washers;

- M6 bolts with nuts;

- wood grouse screws 10 x 100 mm.

Each post is welded from four 016 rebars mm with belts 120 x 120mm welded from steel strip. The lower end of the post has a flange with a 16.5 mm center hole for anchoring to a concrete base. The upper ends of the struts are widened.

Conductors in the form of rectangular plates with 016.5 mm holes, into which the bars of the rack are threaded, will help to weld the pergola racks. The steel belt of the rack is fixed with clamps next to the conductor, and then welded to the reinforcing bars. After welding the next belt, the conductor is moved further to the place of the next joint.Conductors can be cut, for example, from flat slate. It is not worth using plywood conductors - they will catch fire very quickly.

The trusses also consist of four bent reinforcing bars welded together with rings and spacers. To facilitate the bending of the reinforcing bar along its entire length, at the points of attachment of the rings, cuts are made with a depth of 4 mm with a step of 300 mm. Bend the bar in a vice by hand, using a hammer if necessary. Rings 100 mm bent from steel strip 20 mm wide.

The side of the pergola truss is welded, focusing on a cardboard template drawn in a 1: 1 scale. The parts are fixed with heavy blanks and clamps, and gaskets made of non-combustible material are placed between the cardboard and the place to be welded. To weld other identical parts of the pergola, you can use the first welded part as a template.

As shown in the photo, for a metal pergola, prepared structures before installation are cleaned of rust, scale, primed, and then painted:

To check the horizontal position of the trusses fixed on the pergola racks, a long even bar or metal profile will help, which is placed in the plane of the mounted structure, and a building level is placed on top.

The pergola posts with flanges welded to the base are fastened using concreted M16 anchor bolts and nuts. The trusses are fixed to the racks using steel brackets and M6 bolts with nuts. The truss is attached to the wall with a wall flange using dowels and wood grouse screws.

Watch the video "Do-it-yourself pergola" to get a better idea of how such a building is being erected:

Budivnitstvo altanka for dacha with your own hands

How can you open the summer cottage with your own hands? In the Internet, as it was said earlier, it is a simple design and an armchair for altans. If you are not aware of the fact that you can independently complete a vlasny project, it is recommended to speed up projects of quiet alcoves, as you know in a framing.

Armchair of construction "altanka with trees" and with sizes

Otzhe, the stem of the gazebo project will be stored in decilkoh stages. For the cob, it is necessary to open the ear canal, on the side of the working chair. Schemes and often allow at the stage of planning the design, development of the design in new possessions and furnishings. As long as in the altans of the communal services, if there is a light, then the system of supply will start. Read the recommendations to allow the correct preparation of the project.

Scheme of open design

So, the list of signs for the type of altanka is open or closed. Then - the thoughtful style of the summer cottage altar, which is guilty of being brought back to the old days in the village. Awesome materials will start, like being victorious in robots. Nareshty, on the day it is necessary to see a place for the altanka. All guilty considerations are clearly seen in the armchair and taken out of the window at the seat. If the altanka is for dacha matime zakrytiy type, then it is necessary to open the ventilation system. For massive gazebos, the type of foundation starts:

- stricter,

- hundred parts,

- pіdstava z slabs.

Now you can go to the description of constructive universities. Here we can make the installation of windows, doors and descent. Dahu scheme - the center of the robot. The technology of the construction of the skin constructive elements of the summer cottage will start around the corner, which is shown in the project. Having come the hour for the wiring, electricity and water supply. The plan is to see the installation of furniture, possession, lighting. It is necessary, of course, that not all robots, nuances, like the next vrahuvati, are putting together the project of the altanka with their own hands.

Photo of the rectangular project of the buduvnytstva altanka for the dacha

In order to re-establish the project, it will be more exact to be broken up of the awakening materials, and it will be easier to carry out the awakening itself. Naygolovnishe, it is practical to avoid pardons. The construction is of a kind and dovgovic.

Tips before starting work

A common mistake newbie builders make is to get down to work without preparing. This is fraught with lengthy rework and wasted material.

Let's designate a few points that are important to consider even before purchasing materials:

- Explore the ground. Soil analysis will allow you to make a decision about the foundation for your future gazebo, as well as about the need for it in general. And also about the materials. If it is sandy soil, the foundation needs to be worked on. If it is densely trampled black soil - if desired, the floor can be partially "bare";

- Submit the drawing in advance. Even if you are not strong in the art of drawing, present at least a rough plan of your future structure on a piece of paper. Designate with a separate list what exactly the gazebo will include: do you want to build a brazier or a smokehouse into the gazebo, or it will just be benches and a table.

- Stay on track. In addition to the previous point - having thought everything in advance, do not deviate from the plan. This will help you not to "mess up" with the dimensions, save on materials (buying extra boards or tiles will be more expensive than buying everything in bulk), keep within the allotted time (the faster you do everything, the more likely your gazebo will not fall under the rain, etc.) .NS.).

Sometimes a solid foundation is required!

We also advise you to provide yourself with the necessary safety equipment: a dust mask and construction goggles will help protect yourself from wood chips and other troubles.

Site selection and site equipment

The choice of a place where the future metal gazebo will be located for a summer residence is an equally important aspect in construction. The gazebo should be located in an advantageous place so that there is a beautiful view and there are no drafts. For example, if you have a small pond on the site, then the gazebo is best built on the shore. It should be visible from everywhere. It will not only be a place to have a good time. The gazebo should decorate the entire territory of the site.

After the location is selected, you can start preparing the site. The place must be leveled and all the grass removed. Usually, a plan is prepared in advance. But if there is no plan, then you can follow your own intuition. Building a gazebo made of metal is not difficult and does not require special education. Even a person far from construction can cope with this matter.

As soon as the site is prepared, you should start applying the markings. This will require wire or thread. Then you can dig holes that are not too deep, in which the support pillars are placed.

The height of the posts is calculated from the total size of the gazebo. To make the structure stable, the pillars can be placed at a closer distance. Usually, heels are also attached to the supports.

Materials for the gazebo - what to choose

Most of the frames of the gazebos are made of either wood or metal. In rare cases, PVC is used. By the way, PVC is the only one of the listed materials that does not need additional processing.

Polyvinyl chloride is not susceptible to mold, fungi, and is immune to temperature extremes. But leaning your hands in the gazebo on PVC poles is far from the best idea. Even thick PVC pipes are not particularly durable. It is also better not to lean the furniture in the gazebo on the walls.

Wooden and metal structural elements need to be processed. You can do this with a tree - either saturate it with biosecurity a couple of times and calm down on that (a cheap and angry option), or protect the wood with an acrylic compound like "Ecolax" or polyurethane "Pinotex". From an aesthetic point of view, the second option is much more attractive.

The metal is treated with a rust converter before priming.Then it is strongly recommended to protect it with a primer, for example, GF-024 of domestic production has proven itself well. After that, the metal is treated with enamel, from domestic good inexpensive PF-115 enamel.

Advanced version of the wooden pergola

Those who know a lot about carpentry are able to make a more complex structure with their own hands. For example, with a pitched roof. Moreover, you can not completely cover it with the material, but leave it for ivy and vines. If you want a more reliable shelter from the same rain, then you should make a full-fledged cover.

Blueprints

A drawing is already required here, since you will be building a more complex structure than was described above. The problem is that it is difficult to find a ready-made scheme for your garden and adjust the dimensions of the same building materials to it. The figure may indicate one area, and you have a completely different one. What are the options for action in such cases:

- using mathematical calculations, change the dimensions indicated on the ready-made scheme, taking into account the area of your site and the initial parameters of your building material (this can be done either yourself or ordered by the designer);

- independently draw up a drawing, using an approximate version only as a sample;

- do not look for any other sketches, drawings and diagrams - initially draw up your own, reflecting in it your vision of the pergola;

- use very convenient 3D computer programs, specially created for the independent compilation of such drawings: you drive in the required dimensions, and it gives out a ready-made result, which can be adjusted at each stage of construction.

The last option is the most accurate and convenient, although often such programs can only be downloaded for a fee and you need to understand at least a little bit of computer graphics.

Here is one of the blueprints for a wooden pergola that you can use for DIY construction:

Materials (edit)

The following materials are used for the roof of the pergola:

- roofing material;

- decorative types of tiles;

- metal sheets;

- slate;

- polymer building materials;

- ondulin;

- profiled sheet.

When buying wood for construction, be sure to keep in mind that it must be:

- all - from one batch, otherwise different quality will affect the decorative properties of the structure;

- without damage, deformation, chips, cracks and fungal infections;

- one color.

The quality of building materials will determine the functionality and decorative appearance of the pergola. After purchasing them, the wood must be treated with special solutions if you want the structure to stand as long as possible. Fire retardant and antifungal impregnations:

- protect against aggressive weather conditions (rain, frost, heat);

- prevent corrosion of wood by moisture, fungus, pests;

- retain their decorative appearance;

- reduce the risk of fire.

Such compositions are applied to the tree in 2-3 layers, but each time you need to wait for complete absorption and drying. The final stage will be processing with a stain or special varnish, which will give the material a beautiful shade and preserve its natural structure.

Step by step algorithm

Depending on the size of the building, choose which foundation you will build for it. If the construction involves massive building material, it is better to spend time on tape. With a low weight, block is enough. If these are just planks, metal screw piles will do.

Algorithm of actions:

- Level the site.

- Remove the sod.

- Dig a recess of the required size, depending on the type of foundation chosen.

Frame and straps:

- Lay the grillage over the foundation to evenly distribute the weight of the structure on the base. Here you will need logs (minimum diameter 22 cm) or large section beams (20x20).

- Place the bottom crown on the grillage.

- Lay a waterproofing layer between it and the base (roofing material can be an alternative).

- Install pillars (bars) on the constructed lower harness.

- Fasten the supports with pins (as an option - corners, screw fasteners).

- Connect the pillars with crossbars from above and below (if necessary).

Next, walls or side beams are erected, if the drawing suggests them. According to the scheme that was proposed above, an open pergola will be built, without them.

Floor:

- Lay a roughing board over the grillage (minimum thickness 20 mm).

- Secure with screws or nails.

- Cover it with wood (thickness - at least 10 mm), which must be pre-treated with special solutions (for example, yacht varnish). The type of installation is better to use a thorn-groove.

Roof:

- Mount the rafter system (the thickness of the boards directly depends on the mass of the entire roof) on the upper strapping.

- Lay the crate.

- Secure the details.

- If the roof is of a closed type, lay the selected material on the rafters (tiles, ondulin, etc.).

Preparation of the foundation for the construction of a tent in the country

The base for the tent can be any, depending on the type of structure, its weight and other characteristics. There are certain rules:

- For a metal frame or sturdy plastic pipe racks, place 4 concrete slabs with holes in the center at the corners of the selected site. These discs will serve as the foundation of the structure. Then metal or plastic pipes that make up the frame of the tent will be inserted into these holes.

- For a stationary or collapsible tent, the base can be made from ordinary paving slabs. It is easy to lay, it has a high degree of strength and is resistant to mechanical stress. Even if you build a collapsible structure, the base will remain, and the next season it will be possible to put the tent back in its original place.

- Natural stone is perfect for making a base. It can be laid on top of the cement mortar. As well as tiles, stone is a durable and reliable version of the "floor" for a tent.

- The base can be made of wood, but unlike stone and tiles, it should not be laid on the ground, since this material is subject to various harmful influences (rotting, attack of bark beetles, mold growth). Therefore, it is better to lay such a flooring on concrete or metal supports.

-

If the racks are to be dug into the ground, then you can purchase an inexpensive lawn covering that will act as a "floor" for the tent. Artificial grass can be rolled up and cleaned for the winter.

How and what to fix the tent on different surfaces

Depending on the type of tent and the material of the frame, there are several ways to fasten the structure:

- A tent with wooden supports can be installed on the ground in several ways: by concreting the posts, on a columnar or strip foundation, on a base made of a similar material. You can also just bury the racks in the ground, which can be tamped well.

- The metal frame supports can be driven deep into the ground. The tent will be strong and stable due to its lightweight construction.

- If you plan to install the structure on an asphalt surface, then special "heels" can be welded to the legs of the metal frame, which will serve as additional supports. You can also install the tent on paving slabs, stone surfaces, etc. For a more secure attachment of the heel, you can nail it with special dowels or anchors to the asphalt surface.

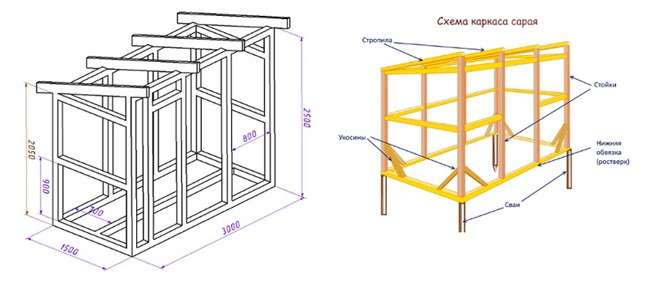

Erecting a barn frame step by step: detailed instructions

The frame is a structure of racks, a bar of the upper and lower strapping, jumpers, inclined jibs. Installation can be done in 2 ways:

- connecting all the elements in series;

- using the "platform" method, fastening the parts into large-sized sections on the horizontal surface of the subfloor.

For the frame, a timber of 150x100 mm and a dry planed board of 150x50 m are harvested. All lumber must be treated with antiseptics and fire retardants.

Fasteners - galvanized screws, nails, bolts, linings, staples. Additionally, you can use wood glue.

Do-it-yourself frame shed according to step-by-step instructions is mounted in the following order:

- A bar of the lower strapping is laid on the waterproofing layer along the foundation. Secure with anchors, studs or bolts.

- Mount the floor joists.

- Starting from the corner, the racks are installed with a step of 60 cm, they are fastened at the top with a strapping bar.

- The openings are reinforced with boards laid on the edge.

- Strengthen the frame with jibs made of boards or perforated steel strip with a tie-in into the lower and upper horizontal bar.

- The structure is sheathed with finishing materials, windows and doors are installed.

- If necessary, they arrange wooden floors or a concrete screed on the ground, carry out communications, and carry out interior decoration.

If OSB or multilayer plywood is used for cladding a frame shed with their own hands, jibs are not required, since rigid sheets give stability to the frame. The facing slabs must be staggered with the long side parallel to the foundation.

Erection of a classic building

Before starting construction, it is necessary to prepare the site for the pergola, clearing it of weeds and shrubs that can damage the structure. The construction of a building includes the following stages:

- The soil must be leveled and two foundation trenches 30–40 cm deep and slightly wider than the pillars must be made.

- Then fill the trenches with gravel and fill them with concrete. To give the structure additional stability, a low wall can be laid out above the surface of the trench.

- Before installation in the trench, the support pillars must be prepared in this way: treat the base of the wooden bar with molten bitumen, then wrap the base of the support pillar with roofing felt and dry thoroughly.

Create a cozy atmosphere on your site

Create a cozy atmosphere on your site

- Then we mount the arch from the crossbeams. First, we install the crossbeams that connect the pillars of one side. After that, we lay the peppered beams that connect the two walls into a classic pergola.

- After completion of the work, the support posts and crossbars must be polished and treated with insect repellent and varnish.

Drawings and diagrams of sheds

The barn is a capital structure, therefore the drawing is the basic basis for both the calculation of materials and for further construction

When drawing up, it is important to take into account, in addition to your wishes, the sizes of blocks, sheets, measured products, so that during the construction there are as few scraps and waste as possible

The drawing needs to be drawn up in several projections, preferably all 4 facades, if there are any differences. Indicate the dimensions of the building along the axes, the height, dimensions of the opening, the thickness of the walls. Indicates the layout of the main structural elements and other technical details. You can use the scheme from the Internet, and then work it out in detail.

The layout can be quite simple. If there are premises for various purposes under the same roof, they need to be delimited by partitions. It is advisable to arrange at least one window

This is especially important for raising animals, since sunlight has a beneficial effect on their behavior.

Examples of drawings:

Rabbit materials

Traditionally, coniferous wood is used for the independent production of rabbitries.

According to the drawings developed by you, it is necessary to make a specification of the blanks.Each blank must be signed with a pencil and a separate place must be found.

The bearing racks of the rabbitry frame are made from a three-meter bar with a section of 70 x 70 millimeters. For roofing, you can use steel profiled flooring, slate, roofing material.

For exterior walls and partitions, use twenty-five millimeter thick edged boards, plywood or wood waste panels. In queen cells, the floor is made from edged boards.

In enclosures for young animals, the floor is made of galvanized steel mesh with a mesh size of 25 x 25 millimeters. Insulate the nests of the mother liquor outside with a layer of foam or mineral wool.