What color and thickness of polycarbonate is best for a greenhouse?

Polycarbonate is a plastic that has almost completely replaced glass in horticulture. It is popular with greenhouse growers. This material is known for its economy and high quality characteristics. It is stronger, more practical and cheaper than glass, but at the same time much more durable than the familiar film greenhouses. Polycarbonates are used in various fields, but the most common area of its use is in gardening. For the manufacture of greenhouses, it is simply irreplaceable.

Content:

- Types and features of polycarbonate

- The choice of polycarbonate for the greenhouse

- Polycarbonate color and its meaning

- Advantages and disadvantages of polycarbonate greenhouses

Types and features of polycarbonate

Polycarbonate is a synthetic material, a plastic that is often used in various fields. Headlights, lenses, discs, etc. are made of polycarbonates. Due to its flexibility and plasticity, this material is often used for the construction of garden greenhouses. A thin film has long outlived its usefulness, because it does not hold heat well, and glass is too fragile, expensive and not heat-resistant enough.

Polycarbonate is the best option for a greenhouse.

Before constructing a building, it is necessary to solve many questions: what type of material to buy, what color of polycarbonate is better to choose for a greenhouse, what size, etc. The main task of the greenhouse is to create optimal conditions for plants: temperature, lighting, humidity.

Polycarbonate allows you to keep warm, transmits light, and also has a low weight, that is, there is no need for a bulky frame.

There are several types of polycarbonate, depending on its thickness:

- 4 mm. This is the most common variety, which is most often used for the construction of garden greenhouses. The material is quite lightweight, durable, thin, but practical and inexpensive. The downside is the fact that the four is not designed for high winds and hurricanes.

- 6 mm. Despite the small difference in thickness, this polycarbonate is significantly stronger. It protects from wind and hail better, but has a higher cost. Choosing a six is worth it if a durable collapsible building is planned.

- 8 and 10 mm. Polycarbonate of this thickness is very durable, but it is not often used for greenhouses. This is due to the fact that its bend is large enough, that is, it will be impossible to decorate small structures with such sheets.

Also distinguish between monolithic and cellular polycarbonate. They differ in structure. For a cellular one it is cellular, and for a monolithic one - cast. The structure affects the main characteristics of the material, for example, thermal conductivity. Due to the fact that cellular polycarbonate has air inside the cells, it better retains heat inside the room. Monolithic polycarbonate looks more like thick glass, and it costs much more than a cellular one.

The choice of polycarbonate for the greenhouse

Before building a greenhouse not on your site, you need to think about what material is needed, in what quantity, where it will be located, whether it will be a prefab, etc.As a rule, greenhouses are built for more than one year. For convenience, collapsible structures are made that can be quickly disassembled and removed into the house when the heat comes.

When choosing polycarbonate, the following criteria must be considered:

- Structure. As mentioned above, there are monolithic and cellular polycarbonate. In the case of greenhouses, the honeycomb option is more practical. It is several times cheaper, easier to cut, retains heat well and transmits light. The monolithic version of polycarbonate is more shock-resistant, which is not always required when building greenhouses in garden plots.

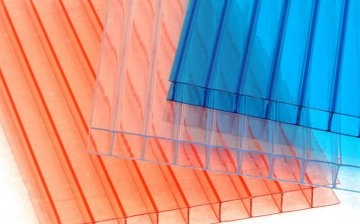

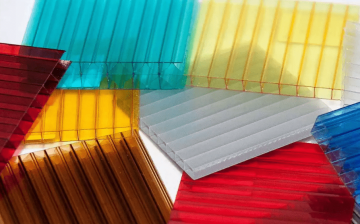

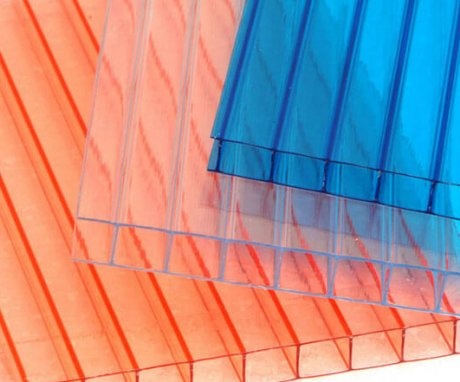

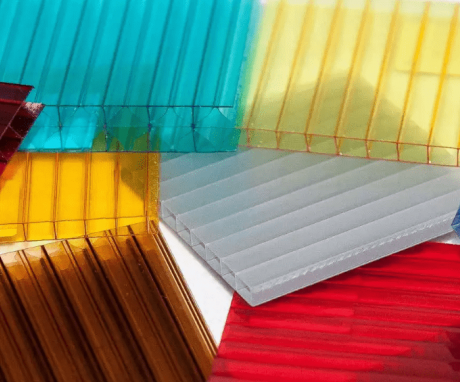

- Colour. Polycarbonate is a synthetic material and comes in a wide variety of colors. You can choose the usual transparent version or any other shade you want.

- Thickness. Thickness affects the cost of the material, its strength and other important characteristics. The best option is a thickness of 6 mm. Such polycarbonate will be strong enough, wind-resistant, but not too expensive.

- Price. The cost of material in the manufacture of a greenhouse plays an important role. Many gardeners cannot afford an expensive greenhouse, especially if a large area has to be covered. Polycarbonate in this case is a suitable material, as it is relatively inexpensive. However, strong savings in material can negatively affect the quality of the building.

- Thermal conductivity. It depends largely on the structure and thickness. The thicker, the better the material keeps heat.

- Durability. Unfortunately, polycarbonate cannot be classified as a durable material, so manufacturers are trying to apply protective layers that will protect it from harmful radiation. The presence and quantity of these layers must be taken into account when purchasing.

You also need to consider impact resistance, light transmission and other characteristics. Monolithic polycarbonate, externally close to glass, has a higher light transmission than cellular polycarbonate.

Polycarbonate color and its meaning

Many people think that the color of polycarbonate only affects the design. You can make a bright, beautiful greenhouse to please the eye. However, this is not quite true. Light, penetrating through the material, enters the plants, facilitating the process of photosynthesis. Experts believe that color can influence the course of this process, therefore, the choice of polycarbonate color for a greenhouse must be approached very responsibly.

Polycarbonate is produced in the form of sheets of several shades:

- Transparent. This is the best option for a greenhouse. Transparent polycarbonate allows about 90% of the sun's rays to pass through. This lighting allows plants to grow and bloom normally. Lighting is created that is as close to natural as possible.

- Green. Green polycarbonate transmits no more than 40% of the sun's rays. This option is suitable for those plants that do not require a lot of light and prefer partial shade. It is believed that green polycarbonate protects plants very well from exposure to ultraviolet radiation and direct sunlight.

- Blue. It is believed that blue and cyan colors improve photosynthesis, so even with insufficient permeability, blue polycarbonate can be used to build garden greenhouses.

- Red. It is a translucent polycarbonate material that is often used to cover gazebos and various awnings. It is not used as often for greenhouses, although experts have proven that it is the red and orange colors that contribute to good photosynthesis and rapid plant growth.

- Yellow. Yellow polycarbonate allows up to 45% of sunlight to pass through. It looks beautiful and bright, while not interfering with the process of photosynthesis. For plants that need a lot of natural light, this greenhouse option needs to be supplemented with lamps or other artificial light sources.

In addition to transparent there is polycarbonate in the “ice” shade.It looks like transparent, but has a light dove bloom. Its ability to transmit light is also quite high, so you can buy it safely. Please note that it is necessary to buy polycarbonate with a UV protective coating for the greenhouse. This will protect both the plants and the material itself from rapid wear.

Advantages and disadvantages of polycarbonate greenhouses

Polycarbonate is used not only in the construction of greenhouses in gardens and vegetable gardens. This material is widely used in various fields of construction. The reasons for the popularity of polycarbonate are its main advantages:

- Little weight. Due to its low specific weight, polycarbonate is easy to use in construction. It does not require a complex frame structure. You can even cope with the installation of such a greenhouse alone.

- Affordable price. The cost of polycarbonate is low, but it depends on the thickness, size of sheets, manufacturer, and the presence of protective coatings.

- Practicality. Polycarbonate is very practical to use. He is not afraid of light, winds, humidity, easy to clean and wipe. On average, the service life of polycarbonate, if used correctly, can reach 20 years.

- Insulation. The material has high noise and sound insulation properties. For a greenhouse, these qualities do not always matter.

- Safety. Polycarbonate is not fire hazardous and does not form sharp fragments upon impact. It is quite shockproof and difficult to damage. But even with a strong impact, polycarbonate does not form sharp parts that can cause injury.

There are not many disadvantages of this material. This includes the fact that polycarbonate is still amenable to combustion and begins to melt under the influence of high temperatures. The price is not high, but at the same time it is still higher than that of the film. However, in this case, other characteristics should also be taken into account, for example, practicality. A greenhouse made of film will not stand for long.

Polycarbonate does not require special care or special cleaning agents. It can be easily washed with soap and water, by other means, but it is worth avoiding its contact with ammonia, which negatively affects the structure of the material.

More information can be found in the video:

We bought a roll of matte white polycarbonate for the greenhouse, I think this is a very good option, although matte is not dense, but somewhat transparent. They decided not to take it at all transparent.

And what if the greenhouse is covered with "soft windows", then what will such a greenhouse be like? Will it cope with its functions? I think this is better than normal film, but polycarbonate looks stronger.