Basic properties

Two-component polyurethanes have good strength characteristics, are resistant to harmful effects, corrosive environments, high temperatures, etc.

These qualities make it possible to use such mixtures in many areas, in particular, for the manufacture of various varnishes, paints, adhesives, and sealants.

In addition, after mixing the components, the mixture has good fluidity, which makes it possible to manufacture various parts from liquid two-component polyurethane by casting: for example, bushings for mechanisms. We will consider precisely the injection molded two-component polyurethane.

The properties of two-component polyurethanes are determined by the original components. In this case, the composition of both the base and the isocyanate hardener is important. Also, the properties of injection molded polyurethane can be adjusted by various additives - dyes, fillers, and so on.

Some polyurethanes can replace rubber because of their high elasticity. There are also polyurethanes that are capable of restoring their original shape with minor mechanical damage, which makes them especially valuable in industry.

What it is?

Polyurethane (abbreviated as PU) is a polymer that stands out for its elasticity and durability. Polyurethane products are widely used in the industrial market due to a wide range of strength properties. These materials are gradually replacing rubber products, since they can be used in an aggressive environment, under significant dynamic loads and in a wider operating temperature range, which varies from -60 ° C to + 110 ° C.

Two-component polyurethane (liquid injection molding plastic) deserves special attention. It is a system of 2 liquid-like components - a liquid resin and a hardener. You just need to purchase 2 components and mix them to get a ready-made elastic mass for creating matrices, stucco moldings and more.

Applications

Two-component injection molding polyurethanes are practiced for a wide variety of applications, from casting gears to creating jewelry.

Particularly significant areas of use for this material are as follows:

- refrigeration equipment (cold and thermal insulation of commercial refrigeration equipment and household refrigerators, freezers, warehouses and food storage facilities);

- transport refrigeration equipment (cold and thermal insulation of automobile refrigeration units, isothermal railway cars);

- construction of quickly erected civil and industrial facilities (thermal insulating properties and the ability to withstand the load of rigid polyurethanes in the structure of sandwich panels);

- construction and overhaul of residential buildings, private houses, mansions (insulation of external walls, insulation of elements of roofing structures, openings of windows, doors, and so on);

- industrial civil construction (external insulation and protection of the roof from moisture by a rigid polyurethane spray method);

- pipelines (thermal insulation of oil pipelines, heat insulation of pipes of a low-temperature environment at chemical enterprises by pouring under a casing installed in advance);

- heating networks of cities, villages and so on (thermal insulation by means of rigid polyurethane hot water pipes during new installation or during overhaul using various technological methods: spraying and pouring);

- electrical and radio engineering (imparting wind resistance to various electrical devices, waterproofing contacts with good dielectric characteristics of rigid structural polyurethanes);

- automotive industry (molded interior design elements of a car based on thermoplastic, semi-rigid, elastic, integral polyurethanes);

- furniture production (creation of upholstered furniture using foam rubber (elastic polyurethane foam), decorative and body components made of hard PU, varnishes, coatings, adhesives, etc.);

- textile industry (manufacture of leatherette, polyurethane foam composite fabrics, etc.);

- the aviation industry and the construction of wagons (products from flexible polyurethane foam with high fire resistance, made by molding, noise and heat insulation based on specialized types of PU);

- machine-building industry (products from thermoplastic and specialized brands of polyurethane foams).

The properties of 2-component PU make it possible to use them for the production of varnishes, paints, adhesives. Such paints and varnishes and adhesives are stable to atmospheric influences, hold tightly and for a long time.

Liquid elastic 2-component polyurethane is also in demand for creating molds for castings, for example, for casting from concrete, polyester resins, wax, gypsum, and so on.

Polyurethanes are also used in medicine - they are used to make removable dentures. In addition, you can create all kinds of jewelry from PU.

In some areas, products made from PU are superior in a number of characteristics even over steel.

At the same time, the simplicity of creating these products makes it possible to create both miniature components weighing no more than a gram and bulky castings of 500 kilograms or more.

In total, 4 directions of using 2-component PU mixtures can be distinguished:

- strong and rigid products, where PU replaces steel and other alloys;

- elastic products - high plasticity of polymers and their flexibility are required here;

- products resistant to aggression - high stability of PU to aggressive substances or to abrasive influences;

- products that absorb mechanical energy through high viscosity.

Criterias of choice

When choosing molding polyurethane, it is necessary to remember: the maximum temperature that it can withstand is 110 C. It is used for resins and low-melting metals. But its strength and resistance to abrasion makes it indispensable when working with gypsum, cement, concrete, alabaster. All these materials do not give a temperature higher than 80 C during the hardening process:

- for plaster casting in order to obtain an artificial stone, filled polyurethane of the "Advaform" 300 brand is used;

- when working with concrete for paving slabs, bricks, the most suitable brand is "Advaform" 40;

- to obtain decorative ornaments, a compound of the Advaform brand 50 was developed for 3D panels;

- "Advaform" 70 and "Advaform" 80 are used for casting large-sized products.

For information on how to make a polyurethane mold with your own hands, see the next video.

Components for manufacturing

To get a polyurethane form, you need to have all the components of the technological process at hand:

- two-component injection molding compound;

- natural stone or its high-quality imitation;

- material for the frame box - chipboard, MDF, plywood;

- screwdriver, screws, spatula, liter capacity;

- mixer and kitchen scales;

- divider and sanitary silicone.

Preparation method.

- Tiles of stone are laid out on a sheet of MDF or plywood, installed strictly horizontally. A gap of 1-1.5 cm is left between each tile, the edges of the mold and the central dividing part should be thicker, at least 3 cm.Having chosen the most suitable location of the prototypes, each tile must be glued to the base using silicone for this.

- After that, it is necessary to make the formwork. Its height should be several centimeters higher than the stone tile. The formwork is attached to the base with self-tapping screws and the joints are sealed with silicone to prevent leakage of liquid polyurethane. The surface is exposed and checked with a level. After the silicone hardens, lubrication is required - all surfaces are covered from the inside with a separator, after crystallization it forms the thinnest film.

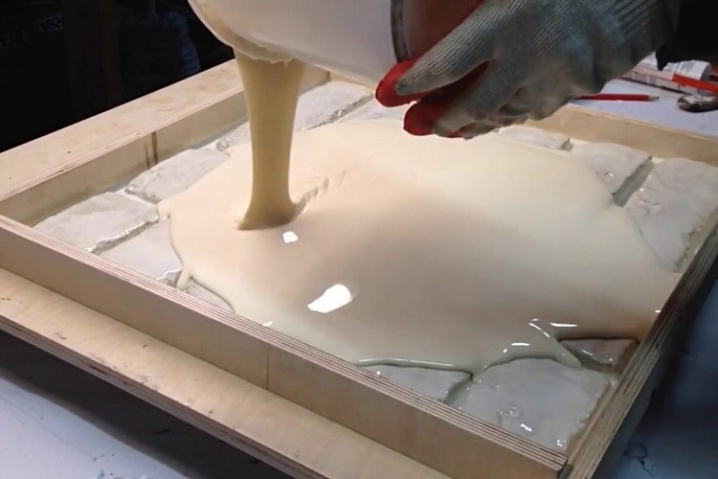

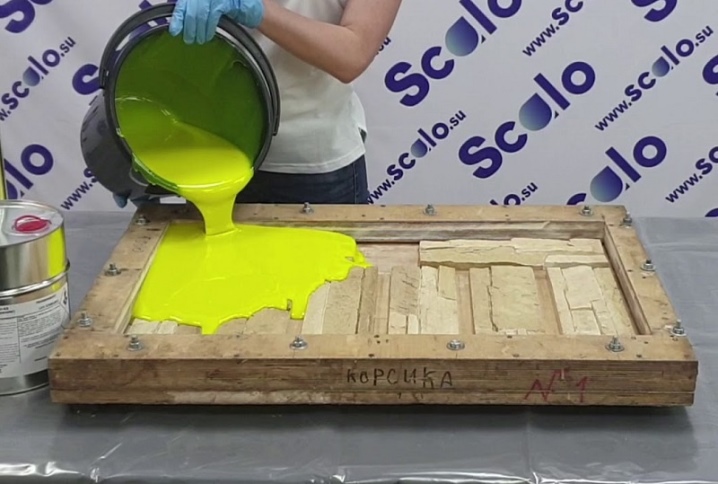

- The two-component injection molding polyurethane is mixed in equal proportions, weighing each component. The resulting mixture is carefully brought to a homogeneous mass with a mixer in a previously prepared container and poured into the formwork. According to the technology, it is required to carry out vacuum processing, but at home very few people can afford it, so the craftsmen have adapted to do without it. Moreover, the surface of the stone has a complex relief, and a small dissemination of bubbles will remain invisible.

- It is most correct to pour the resulting mass into the corner of the formwork - when it spreads, it will densely fill all the voids, and simultaneously squeeze out the air. After that, the polyurethane is left for a day, during which the mass hardens and turns into a finished form. Then the formwork is disassembled, if required, cut with a knife polyurethane or silicone and separate the form from the prototype. Well-glued tiles should remain on the surface of the substrate. If this did not happen, and the tile remained in shape, it is necessary to squeeze it out, perhaps carefully trim it.

How to use?

Polyurethane elastomer belongs to the category of materials that can be processed without much effort. Polyurethanes do not have the same qualities, and this is intensively practiced in many areas of the national economy. So, some matter can be elastic, the second - rigid and semi-rigid. The processing of polyurethanes is carried out using such methods.

- Extrusion is a method for the production of polymer products, in which the melted material that has received the necessary preparation is pressed through a specialized device - an extruder.

- Casting - here the melted mass is injected into the casting matrix by means of pressure and cooled. In this way, polyurethane moldings are made.

- Pressing is a technology for the production of products from thermosetting plastics. In this case, solid materials are converted into a liquid viscous state. Then the mass is poured into the mold and by means of pressure they make it more dense. This product, while cooling down, gradually acquires the characteristics of a high-strength solid, for example, a polyurethane beam.

- Pouring method on standard equipment.

Also, polyurethane blanks are machined on turning equipment. The part is created by acting on a rotating workpiece with various cutters.

By means of such solutions, it is possible to manufacture reinforced sheets, laminated, porous products. And this is a variety of blocks, building profiles, plastic wrap, plates, fiber and so on. PU can be the basis for both colored and transparent products.

Creating polyurethane matrices on your own

Strong and elastic PU is a material popular among folk craftsmen, from which matrices are created for casting a variety of products: decorative stone, pavement tiles, paving stones, gypsum figurines and other products. Injection molding PU is the main material due to its unique characteristics and availability.

Specificity of the material

The creation of polyurethane matrices at home involves the use of liquid 2-component compositions of different types, and which PU to use depends on the purpose of casting:

- to create matrices for lightweight products (for example, toys);

- to create finishing stone, tiles;

- for forms for heavy large objects.

Preparation

Before starting work, you need to purchase polyurethane for filling matrices. Two-component formulations are sold in 2 buckets and must be fluid and liquid when opened.

You also need to buy:

- originals of products from which the cast will be released;

- trimming MDF or laminated chipboard and self-tapping screws for formwork;

- specialized lubricating anti-adhesive mixtures;

- a clean container for mixing ingredients;

- compounding device (electric drill attachment, mixer);

- silicone based sealant.

Then the formwork is assembled - a box in the form of a rectangle with a size sufficient to accommodate the required number of models.

Form making

Primary models are laid on the bottom of the formwork at a distance of at least 1 cm between themselves

To prevent the samples from slipping, carefully fix them with a sealant. Right before casting, the skeleton is set to the building level.

Inside, the formwork and models are covered with an anti-adhesive mixture, and while it is absorbed, a working composition is made. The components are poured into a clean container in the required ratio (based on the preferred material) and thoroughly mixed until a homogeneous mass is created.

To create the molds, polyurethane is poured carefully into one place, allowing the material itself to expel excess air. Models must be covered with a polymerization mass by 2-2.5 centimeters

You can learn about what can be made from liquid polyurethane in the video below.

Application of injection molded polyurethane

Two-component injection molded polyurethanes are used for a variety of purposes, from casting gears of mechanisms to making jewelry.

Good performance properties of parts made of such materials allow them to be used in rather difficult conditions. These parts are chemically resistant, have good hardness and toughness. They can be:

- various shafts, gears, pulleys - due to good strength characteristics and high wear resistance, these parts serve for a long time and with high quality;

- wheels for loaders and trolleys: these wheels are stronger than rubber ones and can work even with serious tread damage;

- rollers - for example, guide and support rollers for conveyors and conveyor belts;

- toothed transmission belts, tracks and tracks - they are stronger than rubber and last longer;

- sealing elements, shock absorbers, etc. - due to the higher strength and resistance to wear, replacing rubber parts with polyurethane is quite expedient. In this case, the elasticity of the part remains at the same level;

- couplings, bushings, bearing parts;

- various protective coatings;

- pipelines - excellent chemical resistance together with mechanical strength makes it possible to manufacture both one-piece pipeline elements and protect pipelines from the outside or from the inside.

The properties of two-component polyurethanes allow them to be used for the manufacture of paints and varnishes and adhesives. Such varnishes, paints and adhesives are resistant to weathering, hold for a long time and firmly.

Also popular is liquid elastic two-component polyurethane for making molds for further castings, for example, for casting from plaster, wax, polyester resins, concrete, etc.

Polyurethanes are also used in medicine - they are used to make removable dentures. You can also make various jewelry from polyurethanes.

Even self-leveling floors can be made from polyurethane - such floors are highly wear-resistant and durable.

In some areas, parts made of polyurethane are even superior to steel in a number of parameters.

At the same time, the ease of manufacturing such parts makes it possible to manufacture both miniature complex parts weighing up to a gram and massive castings of 500 or more kilograms.

In general, four areas of application of two-component polyurethane mixtures can be distinguished:

- rigid and durable parts, where polyurethanes replace steel and other metals;

- elastic parts - high elasticity of polymers and their elasticity are in demand here;

- parts resistant to aggressive influences - high resistance of polyurethanes to aggressive substances or to abrasive influences;

- parts that absorb mechanical energy due to high internal friction.

In practice, a complex of directions is often used, since several valuable qualities are required from many parts at the same time.