How to choose a joint sealant

Before proceeding to the choice of a sealant for the body, it is necessary to determine the answer to the question of what it is for. Even at the stage of body production in the factory, the manufacturer treats its surface with special compounds that are designed to protect it from minor mechanical damage and corrosion. This is especially true for various joints, grooves, welds and other transition surfaces.

The use of body sealant in repair shops (or in a garage environment) is for the same purposes. The only difference is the repair or replacement of any body part. The task of the sealant for car body seams is to protect the latter from corrosion (both liquid and electrolytic), as well as minor mechanical damage.

Based on this, it is possible to formulate the criteria that the sealant chosen for the purchase must meet. So, these include:

- Durability. The sealant should not lose its performance properties for as long as possible (ideally, the entire life of the machine).

- Elasticity. Many seams are curved rather than straight. Accordingly, the vehicle weld sealant must be elastic when cured. In addition, the body of the car during its movement constantly gives in to vibration, respectively, in such conditions, the tool should also normally perform its functions.

- High adhesion. These are the properties of a sealant that allows it to adhere to the surface on which it is applied (and, moreover, it is not always pure metal).

- Resistance to external factors. In particular, to the effects of moisture, ultraviolet radiation, technological automotive fluids (fuel, oil, brake, washer fluid, etc.), overheating and hypothermia.

- Possibility of painting. All joint sealants are divided into those that can be painted (varnish applied to them), and which cannot be painted.

The better the sealant for the treatment of welded seams will meet the listed requirements, the better will be protected both the seams themselves and the car body as a whole.

Which sealant is best?

Not every sealant can be effective and safe.

Not every sealant can be effective and safe.

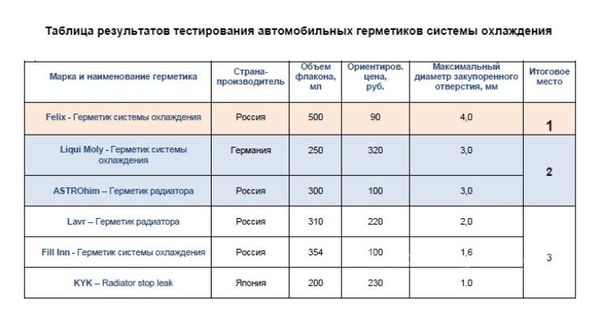

To determine the choice of sealant and decide which one is better, consider several popular examples. Not all of them work the same, they all have different prices and characteristics. Tests radiator sealants are held regularly, which is why we provide several tables with test results, key indicators and prices.

Test of sealants from the magazine Behind the wheel, as always, the results do not really coincide with real reviews

Test of sealants from the magazine Behind the wheel, as always, the results do not really coincide with real reviews

Made on a polymer basis. Visually looks like a white emulsion. Domestic manufacturer. On the market since 1996. During this time, it has proven itself well. Has a fairly low price. The reviews are mostly positive. It takes 3 to 5 minutes to tighten the breakdown. Leaves a minimum amount of deposits.

The manufacturer gives a guarantee for 36 hours of work. In practice, the term is much longer. Widespread, you can buy it at the nearest car dealership. The optimal choice due to the price-quality ratio.

Price: $ 1.3. Article: 3322.

Application:

- Stop the engine.

- Let the engine cool down to 60 degrees.

- Shake the tube several times.

- Pour into the radiator or expansion barrel (the instruction does not regulate the volume of sealant per liter of coolant).

- Start your car. Let it idle for 10-15 minutes.

Liqui Moly Kuhler Dichter 250 ml

Polymer base. Sealant from a renowned German manufacturer. Suitable for repairing micro cracks and small bruises.Mostly the manufacturer indicates the content of a water-soluble monomer and plastic chips in the composition of the product.

- Shake the product.

- Start your car.

- Turn on the stove at maximum speed.

- Fill in the solution in the ratio of 25 ml to 1 liter of coolant.

- Let it run for about 10 minutes

Hi-Gear Radiator Stop Leak

An American manufacturer gained its popularity due to high-quality de-coking of the fuel system. Specializes in additives, additives and other auto chemicals. The sealant allows you to repair fairly large damage. The reviews are mostly negative. The reasons for this are a large amount of deposits and problematic cleaning of the system.

Late activation of the agent is also noted, up to half an hour. In such a situation, it is most likely that the coolant will not be able to be saved. The positive side is the longest lifespan among competitors - about 90 hours. The composition forms a strong shell, lasts a long time.

Price: For 444ml $ 6.7, 325ml asks for $ 50. Article: HG9029 - 444 ml, HG9025 - 325 ml.

Application:

- Shut off, let the engine cool down.

- Drain off 2-3 liters of coolant.

- Shake the can thoroughly.

- Pour the compound into the radiator or into its upper branch pipe (15ml per 1 liter of coolant).

- Let the engine cool completely, then start.

- Warm up for 5-7 minutes.

- Then muffle again.

Wait 10-15 minutes.

Cooling system pump after treatment with Felix sealant

Cooling system pump after treatment with Felix sealant

Popular rubber sealants

It was noted above that the variety of these funds is great. This opens up great opportunities for choosing a composition, taking into account the nature of the task at hand.

The construction / hardware stores receive imported and domestic sealants. It is recommended to choose the product that has passed the technical control and meets the current norms and standards (there must be a corresponding mark on the package).

To make the selection of a rubber sealant as easy and fast as possible, we provide a useful overview of leading manufacturers and well-known products.

Rubber Roof Sealant Tytan

The products of this brand are well known and loved in our country, as it has proven itself well. Tytan creates a reliable waterproof connection that can withstand ambient temperatures ranging from –55 to +100 degrees Celsius.

Resistance to fungi and mold is an important feature of this composition. This allows you not to be afraid of the development of microorganisms in hard-to-reach places (joints between tiles, cracks between the bathroom and the wall). The sealant is indispensable for processing:

- roof ridge;

- roof windows;

- sewer hatches;

- gutters;

- stormwater systems;

- ventilation.

For ease of use, Tytan rubber sealant is available in 310 ml tubes. It is curious that the product is able to withstand up to four freezing cycles, while maintaining its consumer qualities.

This sealant should be applied at a positive air temperature. The curing rate is approximately 2 mm per day.

Penosil Premium All Weather Sealant

The main advantage of this sealant is its excellent adhesion to the surface combined with a viscous consistency. The product does not drain even from vertical panels and partitions, adhering to them and hardening gradually.

Penosil sealant is indispensable when working with brick / masonry, monolithic concrete surfaces, glass, wood and metal. In addition, he is not so aggressive towards plastic. Complete hardening occurs 20 minutes after removal from the cartridge.

Like the previous composition, this sealant is resistant to mold. An important difference is application even at a temperature of -5 degrees Celsius, which expands the possibilities for using the product.

Body 920

Thick consistency, stability on the surface, protection against cracking - these are the main advantages of Body 920 one-component rubber sealant.It is non-corrosive to plastic, has good adhesion to metal parts and perfectly adheres / seals joint seams.

Due to its availability, this composition is actively used in the treatment of air conditioning systems. It is used in the construction of small ships made of metal and wood, as well as for the sealing of sea containers and the processing of automotive body parts.

Rubber sealant MasterTeks Liquid rubber

This tool is good because it is suitable for work in any season and regardless of weather conditions. Based on butyl acetate and synthetic rubber, this sealant is used to restore roof coverings and protect rafter systems from the damaging effects of moisture.

The composition has a narrower operating temperature range (from –40 to +90 degrees Celsius), but it can be applied even at 10 degrees below zero. Liquid rubber is excellent for working in rooms with high humidity and is very often used to seal building facades.

TechnoNIKOL No. 45

Another equally popular butyl rubber sealant that has become famous for:

- cold curing;

- low gas permeability;

- elasticity of the seam;

- application at a temperature of –20 degrees Celsius.

This sealant has a neutral white color and is well suited for overpainting. It is durable. Complete drying occurs one hour after application. For ease of use, the product is available in buckets weighing up to 16 kg.

The given sealants have passed technical control and a number of tests, and most importantly, have been tested in practice. These funds are available not only for professional builders, but also for ordinary consumers, which is reflected in the growth of their popularity.

Advice

To make a really high-quality repair, you should follow some advice on working with a sealant.

When choosing a liquid, you should carefully read its properties. Only knowing the composition of the solution and its purpose, it is possible to eliminate the leak, repair cracks, and obtain a durable connection. You only need to use the sealant that is suitable for this type of piping system.

Different sealants can act with different coolants, this must be taken into account when making a choice

Some are intended for a heating system, inside which there is water, others operate in pipes filled with other liquids, for example, antifreeze, saline or anti-corrosion solutions.

Make sure the surface is clean and dry before starting work.

Before pouring liquid sealant inside the heating system, the amount of liquid that is planned to be filled must first be drained from the system.

Special attention should be paid to whether the product is resistant to high or low temperatures.

After applying the liquid, it is better to immediately remove all excess from the surface. The solution hardens very quickly, therefore, over time, its elimination will be almost impossible.

If a malfunction is detected in the heating system, before filling in the sealant, it is worth making sure that the expansion tank or boiler is working correctly. In the event of a malfunction, a decrease in pressure may occur, which can be mistaken for the formation of leaks in pipes, joints, and the boiler heat exchanger.

The solution begins to act on about 3-4 days. It is possible to determine that it gave a positive effect when the sound of water droplets inside the system disappears, the floor becomes dry, moisture will not form, the pressure inside the pipe will stabilize and will not decrease.

If the pipes are made with the addition of aluminum, a week after pouring sealant into them, the liquid must be drained, and the pipeline must be flushed.

When working with liquid sealant, remember all safety rules

It is a chemical that must be handled with care. If the solution gets on the skin or eyes, it is necessary to immediately rinse the damaged area with plenty of water.

If the liquid gets inside the body, you need to drink a lot of water, rinse your mouth and call an ambulance.

The sealant should not be stored near acid.

In order to dispose of the liquid sealant, no special conditions need to be observed.

If it is not possible to buy a sealant, you can try using mustard powder to fix the leak instead. To do this, pour it into the expansion tank and wait a few hours. During this time, the leak should stop.

For information on how to choose a liquid sealant, see the next video.

Colors

The adhesive-based sealant has gained considerable popularity among users and thus has caused the need to expand its advantages both in composition and in color. It must be remembered that sealant adhesives do not stain, there are ready-made colored goods that you can buy. Black, white, gray and brown shades are most commonly purchased. But there are also extraordinary colors such as silver and gold.

Adhesive sealant can be presented in such tones as:

- transparent glue is used when installing furniture and plumbing to avoid moisture ingress;

- a color tone is necessary for working with building materials already with a certain piment;

- white is intended for plastic balconies and windows;

- black tone is often used in cars;

- the colorless version is considered universal, with no restrictions in its use.

Packaging and dispenser

Now let's move on to the packaging features, since the safety of the composition and the convenience of its application will directly depend on the packaging of the sealant. As a rule, sealants are sold in special tubes made of aluminum or plastic, which contain 45-95 grams of the drug. Also, for the tube, many manufacturers provide a cap-cap equipped with a dispenser.

The presence of a dispenser allows you to apply the strictly required amount of the composition, and this can be done carefully. Also, the product does not dry out after the tube has been opened. Before re-use, it will be enough to remove the remains of dried sealant from the dispenser with a thin pin or in another way, after which the product and dispenser are again ready for use.

Tubes of increased volume can be considered as another packaging option. Often in this form, professional formulations are realized, which are squeezed out of the container and applied using a special pistol.

In such a packaging, sealant is purchased only if it is necessary for frequent use. In other words, for the repair of one car, the purchase of a large tube of the product itself and a pistol for it will be costly and impractical, while for a service station (taking into account the work put on the stream) it makes no sense to buy a small tube.

Silotherm EP-71

One-component silicone heat-resistant sealant

One-component silicone flame retardant neutral sealant Silotherm EP-71 is a material based on a silicone elastomer with increased reliability.

Silotherm EP-71 is a more advanced analogue of the Iceberg 701 fire-resistant sealant.

The initial consistency of the sealant is thixotropic, which makes it possible to use the fire-resistant sealant Silotherm EP-71 on vertical surfaces. The use of sealant Silotherm EP-71 can be carried out both manually and with the help of specialized pneumatic pistols.

Sealant Silotherm EP-71 is repairable, which provides for the possibility of restoration in case of mechanical and other damage.

Silotherm EP-71 neutral fire retardant sealant photo.

Application

One-component silicone fire-resistant neutral sealant Silotherm EP-71 is an effective barrier against water, smoke, gas, pressure and fire.

Sealant Silotherm EP-71 is manufactured in three standard versions:

performed by Silotherm EP-71 (trade mark S-200K) used for: - Sealing and sealing joints in building structures; execution of universal cable penetrations of passive fire protection systems SPO-E; - Sealing of cable products (sealing of cable terminations EK, EU couplings, EA connecting systems) - Cable termination, connecting and transition couplings EK and EC; local sealing of various types of cavities, joints, expansion joints with a given fire resistance limit; - Fire-, smoke-, water-proof cable seals in pipes of small diameter and cable entries into junction boxes; - Fire-resistant sealing, sealing and fixing of doors and glass units.

performed by SILOTERM EP-71M used for: - Execution of fire-resistant electrical insulating coatings, as well as anticorrosive coatings of construction materials and assemblies;

performed by SILOTERM EP-71 kNS used for: - For bonding dissimilar materials where an elastic flame retardant connection is required.

Silotherm EP-71 meets the requirements:

- TU 2257 - 003 - 33680530 - 2003 “Silicone fire-resistant neutral sealant Silotherm EP-71”;

- “Special conditions for the supply of equipment, instruments, materials and products for nuclear power facilities”;

- NPB 237-97 * “Building structures. Test methods for fire resistance of cable penetrations and sealed cable glands ”;

- SNiP 21-01-97 * “Fire safety of buildings and structures”.

Main technical characteristics of Silotherm EP-71

| 1. Appearance of the finished composition | Homogeneous vulcanization elastomer |

| 2. Color after vulcanization | Homogeneous - white or red * |

| 3. Density | 1.3 ± 0.1 g / cm 3 |

| 4. Time of skin formation | ≤ 5 hours * |

| 5. Drying time in the depth of the layer | 5-7 mm / day * |

| 6. Hardness Shore A | ≥ 30 units |

| 7. Fire resistance in assembly joints | EI 60 |

| 8. Working temperature | from -50 to + 270 ° С |

| 9. Resistance, not less | 1.35 x 10 12 Ohm / cm |

| 10. Service life | > 40 years |

| 11. Elongation | > 350 % |

Note: * the parameter can be changed at the suggestion of the Customer.

Special technical characteristics of the compound Silotherm EP-71

One-component silicone fire-resistant neutral sealant Silotherm EP-71 has a number of unique properties:

- Moisture resistance - the sealant can be used in conditions of 100% humidity;

- Radiation resistance - permissible integral dose of radiation - 1.25x10 8 Rad;

- The formation of a vulcanite crust in a fire or the effect of coking, in which the outer side of the sealant, which is affected by the fire, turns into a durable vulcanite composition that prevents the passage of smoke and fire;

- The effect of auto-sealing in case of a fire, in which, due to the special properties of the sealant Silotherm EP-71, the partition or assembly seam retains its integrity during the entire time of exposure to the fire;

- Qualification for special operating conditions at nuclear power plants;

- High electrical insulating properties;

- Explosion proof.

Production and supply of sealant Silotherm EP-71

The entire production cycle of Seloterma EP-71 sealant, such as: order preparation, supply of components, incoming control, technological preparation, production, is carried out according to the ISO-9001 quality assurance system.

Sealant Silotherm EP-71 is supplied in cartridges or folium tubes. The guaranteed shelf life of the material is 12 months from the date of manufacture.

All necessary certificates are available.

Specifications

Liquid sealant is used to eliminate leaks in heating systems, gaps and joints between pipes, radiators and boilers.This composition is polymeric and is characterized by the ability to self-seal and is suitable for sealing gaps both from the inside and outside of the system.

Due to this feature, the use of a liquid product for sealing allows solving the following tasks:

- sealing gaps that are inaccessible for visual perception;

- elimination of cracks in hard-to-reach places where it is impossible to use a clamp or soldering;

- elimination of leaks in the underfloor heating system without dismantling the walls and the floor itself, flooring;

- sealing pipes with a hidden installation system.

Types of joint sealants

Any joint sealant for a car has a reliable composition, otherwise it will not be able to provide the proper level of sealing of the joints. And yet, the materials are not the same in terms of the base, therefore they differ in properties and characteristics.

Acrylic based mixtures

Acrylic sealants are prepared on the basis of polymer compositions. They have good adhesion to the surface, but with strong vibration or shock loads, they can peel off due to the medium elasticity. It is best to use such products for porous materials and stable knots, seams. Any acrylic sealant can be painted, varnished.

Anaerobic sealants

These products are easy to distinguish from the rest: they have a liquid texture, which is why they got the name "liquid pad". The sealant is distributed inside cavities and the smallest cracks, and hardens only after contact with oxygen stops. Usually, anaerobic compounds are used to repair small areas, otherwise there is a risk of insufficiently strong seams. Most often, the compositions are used by professionals, because they must be applied correctly and strictly follow the instructions.

Silicone sealants

They are considered the best option for home repair of metal products. Such sealants are easy to apply, harden quickly, retain their strength and elasticity for a long time. Silicone is impervious to moisture even at elevated pressure, not afraid of temperature extremes. With significant air humidity, it hardens very quickly - in 10-15 minutes. Usually the products are applied from a tube with a long nozzle. They can fill irregularities up to 6 mm deep.

Polyurethane compounds

These sealants are the most popular on the market, available in a huge range. They are sprayed, pasty for brush application. Distinctive features of polyurethane sealants are:

- ease of use;

- lack of spreading from vertical bases;

- high flexibility, elasticity, heat resistance, moisture resistance;

- withstanding high mechanical loads.

Bituminous mixtures

Presented in the form of compositions based on bitumen with the addition of modifiers, fillers, adhesion accelerators. It looks like a dark paste. They do not require careful surface preparation, they are suitable for most materials, including any metal. Can be used in humid environments and tolerates direct contact with water well.

Basic requirements for compositions

The sealant can be used for polypropylene, bimetallic, and other pipes of the heating system

But before buying, it is important to clarify that its characteristics correspond to one or another pipe material, because plastic compounds are not suitable for metal networks. You can get acquainted with such information on the packaging, which always indicates the exact data on the composition, properties

In addition, the sealant must meet the following requirements:

- Resistance to adverse factors. The water in the pipes is under pressure and hot. Therefore, the product must necessarily be moisture resistant, not reacting to temperature extremes, the action of an aggressive chemical environment. If the sealant is used in steam systems, it must be high temperature (heat resistant).

- Long service life.The operating time of the entire CO depends on this factor. If the sealant is reliable, the system will last for at least 5-10 years. The cost of such funds is usually quite high.

- Elasticity. Leakage sealants after hardening must remain plastic. So they will easily, without destruction and detachment, tolerate the expansion and contraction of the base material, which inevitably occurs during temperature extremes.

Glue or seal?

Got the difference? Can you replace one with another? Perhaps under certain intended conditions. There are cases when liquid nails are used for sealing: window and door frames, plumbing, seams are insulated, cracks are closed, cracks are filled, and tiles are placed on the sealant.

Consider the quality of performance in this situation. According to the technology, liquid nails are applied in thin strips or pointwise, irrationality will greatly affect expensive materials. Drying, the glue forms hardness, it is destroyed at the slightest shear. The sealant is applied with a long seam on flat surfaces, dries, shrinks, becomes elastic, plastic. The influencing factor on the choice of liquid nails is played by the strength of the adhesion, the drying time, the exact composition, and the sealant is intended for use in a phased manner.