What is riveting

The mechanical connection of parts using a series of rivets is called a riveting, and the connection itself is a riveted seam. It is used where it is inconvenient to weld parts or where non-weldable materials are connected. Not only metals are riveted, thus they connect parts in clothes, accessories, etc. But there it is more of a finish than a loaded connection. So further we will talk about riveting in construction or home improvement. In principle, instead of riveting, you can use a screw connection, but bolts and nuts are more expensive, and their installation takes more time.

Advertisement

This is what a riveted joint looks like

If we talk about installing fences made of profiled sheet, rivets are more reliable, since they can only be removed by reaming the fasteners. When installing screws or self-tapping screws, they can be unscrewed and carried away both metal and hardware. In some cases, riveting is more convenient when installing a roof from corrugated board or metal. On the roof, the installation of screw connections is problematic and time-consuming. And with rivets, and with a good tool, you can do it in an hour or even less.

The most common use in the personal household

How are parts connected with rivets? The rivet is inserted into the prepared through hole. It has a head that rests against the material and the rod. During the riveting process, the end of the rod is flattened, changing its shape under the influence of force. Therefore, plastic metals are used for these hardware.

4 Installation of blind rivets

Usually, at the sight of rivets, the question of how to use such fasteners is not worth it - the design of the fastener is simple and straightforward.

Using blind rivets

Using blind rivets

When installing, it is important to have a special riveting tool, which greatly simplifies and speeds up the fastening process. Today, such tools are produced in fairly large quantities and models: pneumatic rivets, mechanical rivets

Or you can purchase an electric riveter. At worst, in the absence of a tool, you can use pliers.

The installation process is as follows. The drill drills a hole at the attachment point, the diameter of which is equal (by 0.1 mm less) to the diameter of the fastener. The hole depth must be equal to the cylinder length minus the rivet length. A fastener is inserted into the hole with a rod towards itself, and then the rod is pulled out with a riveting tool. Then the elements are fastened.

Views

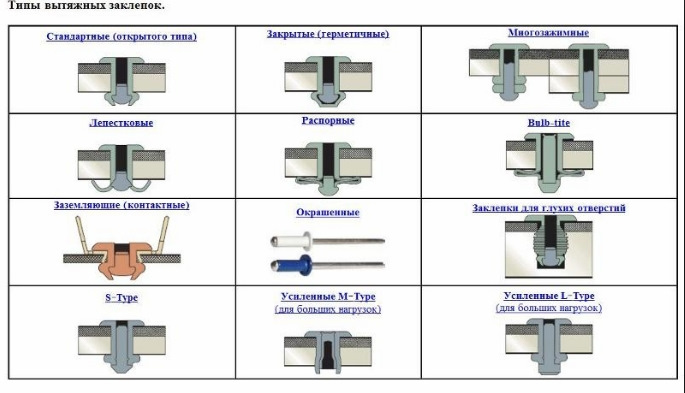

The type of hardware is selected in accordance with the requirements for the connection. Due to the fact that the modern market of fasteners presents a wide range of blind rivets, it will not be difficult to choose the right element. Depending on the performance characteristics, the hardware is divided into several types.

Combined models are considered the most common type. Hardware is capable of providing a permanent connection of particularly hard parts that are exposed to mechanical, weight and vibration loads.

- Sealed models have a rather narrow specialization and are widely used in shipbuilding industries. A feature of the design of blind models is the sealed end of the rod. Products can be made of stainless steel, copper and aluminum.

- Multi-clamp models have several riveting sections and are installed in movable structures if it is necessary to connect three or more elements.Such a section is located between two adjacent elements, and the installation is carried out using a pneumatic gun.

In addition to traditional models, there are reinforced rivet options, in the manufacture of which a more durable material with thicker walls is used.

Useful Tips

In addition to the general algorithm for performing work, each individual material has its own small subtleties of installation. So, when connecting materials of different thickness, the rivet should be installed from the thin side. This will allow the reverse head to form a thicker flattening and improve the reliability of the connection. In the absence of the possibility of such an arrangement on the side of a thin material, you can put a washer of the required diameter. Such a gasket will not allow a thin layer to be pushed through and will not allow the surface to deform.

When joining hard and soft materials, it is recommended to use hardware with a high rim, while it is better to place the reverse head on the side of the hard material. If this is not possible, then from the side of the soft layer, you can put a washer or use a petal rivet. It is better to connect fragile and thin parts with plastic blind rivets or use spacer and petal options. To obtain a smooth surface on both sides, it is recommended to use rivets equipped with countersunk heads on both sides.

To form a sealed waterproof connection, it is necessary to use closed "blind" hardware that can effectively prevent the ingress of dust and prevent the ingress of water and vapors. When installing a rivet in a hard-to-reach place, along with a rivet gun, it is necessary to use additional equipment in the form of extension nozzles to help get to the rod.

In addition, when installing hardware, it should be borne in mind that the distance from the axis of the element to the edge of the parts to be joined must be greater than or equal to two diameters of the head. The connection of loose materials must be accompanied by the installation of an additional sleeve, into which the rivet will be installed. When joining pipes with flat surfaces, it is not recommended to pass hardware through the pipe. The connection will be stronger if only one side of the tube is involved in the docking.

Thus, blind rivets are a universal fastening element. They allow you to form a strong and reliable connection in hard-to-reach areas. Also, the parts easily bond surfaces with limited access from the back side.

A detailed story about the use of blind rivets is in the video below.

Let’s block ads! (Why?)

Mounting

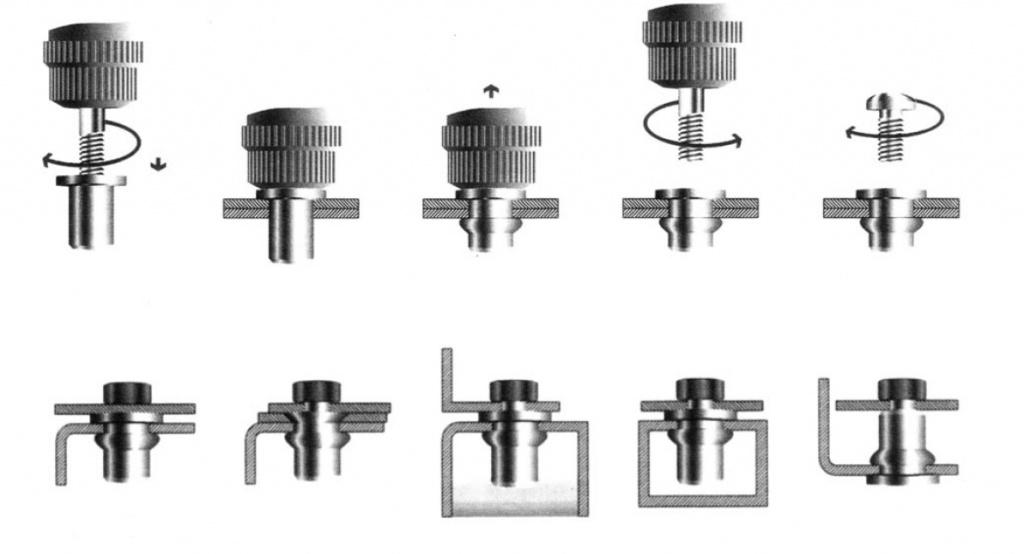

Installation of blind rivets is so simple that it is not difficult even for beginners.

A prerequisite for installation is only the availability of a riveting tool and adherence to the sequence of work.

- The first step will be to mark the front side of the top of the parts to be joined. The distance between two adjacent rivets should not be less than five diameters of their heads.

- Drilling holes should be carried out with a small allowance.

- Deburring is performed on both sides of each part. If access to the closed side is restricted, deburring on the closed side is negligible.

- The installation of the blind rivet must be done in such a way that the shank is on the face side.

- The gripping of the rod with the rivet and the work with the pneumatic gun must be done smoothly and with sufficient force at the same time.

- The remaining part of the rod, if necessary, is cut off or cut off with nippers. In the case of an inaccurately executed break of the rod, it is allowed to file the head with a file.

Manufacturing materials

A wide variety of materials are used as a raw material for blind rivets. This allows the use of hardware in almost all types of repair and construction work.For the manufacture of rivets, a number of materials are used, each of which has its own strengths and weaknesses and determines the place of installation of future products.

Aluminum

Its anodized or varnished modification is often used. Aluminum rivets are lightweight and low cost, however, in terms of strength, they are somewhat inferior to steel models. Products are used for bonding light metals, plastics and are widely used in electrical engineering.

Stainless steel

Also used in several modifications. So, grade A-2 is considered one of the most resistant to rust and is used for mounting parts when performing outdoor work. While A-4 has no equal in acid resistance and is widely used in chemical industries.

Cink Steel

Possesses high anti-corrosion properties and provides a reliable connection. However, if one of the connected elements is mobile, the galvanized parts wear out quickly.

Copper alloys

They are widely used in the production of rivets. The most popular is Monel, an alloy composed of 30% copper and 70% nickel. Sometimes bronze is used as a rod in copper models. The disadvantage of copper elements is their high cost and the risk of a green coating during oxidation.

Polyamide

They are used for making rivets used in light industry and for sewing clothes. The material is not particularly durable, but it can be painted in any color and looks good on products.

Optimally, all rivet elements should be made of the same material. Otherwise, the risk of galvanic processes increases, during which the more active metal destroys the weaker one. The principle of compatibility must also be followed when selecting hardware for certain materials. For example, a bond of copper and aluminum is extremely undesirable, while copper behaves quite friendly with other metals.

Related Posts via Categories

- Bolt strength class - how well do the hardware resist shattering?

- Anchor bolt with nut - proven fastening option

- Dowel-nail - which fasteners are of the highest quality?

- Anchor bolts - a special type of fasteners for complex structures

- Bolt designation in accordance with GOST - we are guided in the world of hardware

- How to rivet a rivet - automatic and manual methods for different materials

- Bolt manufacturing - straightforward workflow

- Spring Cotter Pin - Eared Fastener for Mechanical Engineering

- High Strength Bolts - Complete Fastener Information

- Blind rivet sizes - what should you think about when calculating?

Advantages and disadvantages

High consumer demand for blind rivets is due to a number of indisputable advantages of these hardware.

- The ease of installation is due to the need to access the connection only from the front side. This favorably distinguishes these hardware from threaded nuts, for the installation of which access is required from both sides. In addition, threaded fasteners tend to loosen and loosen over time.

- The low cost of blind rivets makes it possible to form a reliable and durable fastener without saving on material.

- A wide range of standard sizes greatly facilitates the choice of fasteners.

- The ability to combine materials of different structure and properties significantly expands the scope of hardware.

- High strength and durability of the connection. Subject to the rules of installation and careful operation, the service life of the rivets is equal, and sometimes even exceeds the service life of the fastened parts.

The disadvantages include the need for pre-drilling, non-separable connection and the application of significant efforts when riveting by hand. In addition, the models are disposable and cannot be reused.

What are they?

Rivets can be not only combined, blind and tight, but also made of a specific material. The technological features of these devices may have various features, which each manufacturer has its own. New types periodically appear on the market, for example, semi-hollow, so the consumer can choose driven, hollow, explosive, countersunk, colored and black, pull rivets. And also a wide range of fasteners allows you to choose the right option for metal, profiled sheet, profiled steel deck.

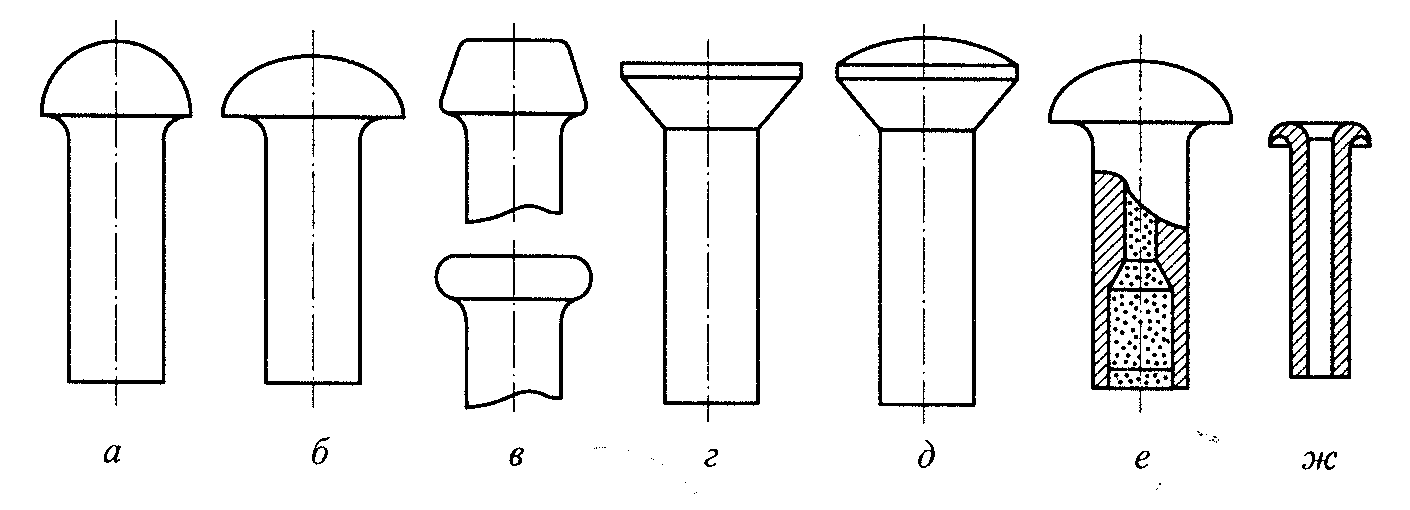

Currently, craftsmen use such types of rivets as:

reinforced - these fasteners are used to connect materials with a high boundary of strength, as a result of using these products, a very reliable connection can be obtained; this type of rivets has found its place in mechanical engineering, aviation;

Regular

One of the first rivets is considered ordinary, they are characterized by a mushroom shape. This type of fixture has a shank with a wide head. Rivets of this type are quite reliable, but at the same time they are characterized by complex installation. The use of this fastener is relevant in the case when it is necessary to connect two surfaces by fixing a through rivet.

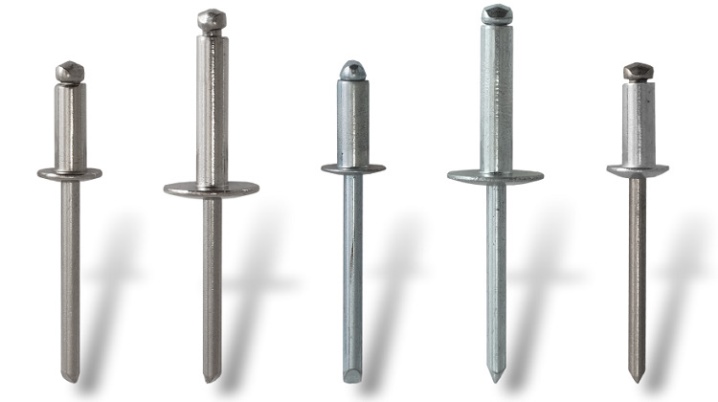

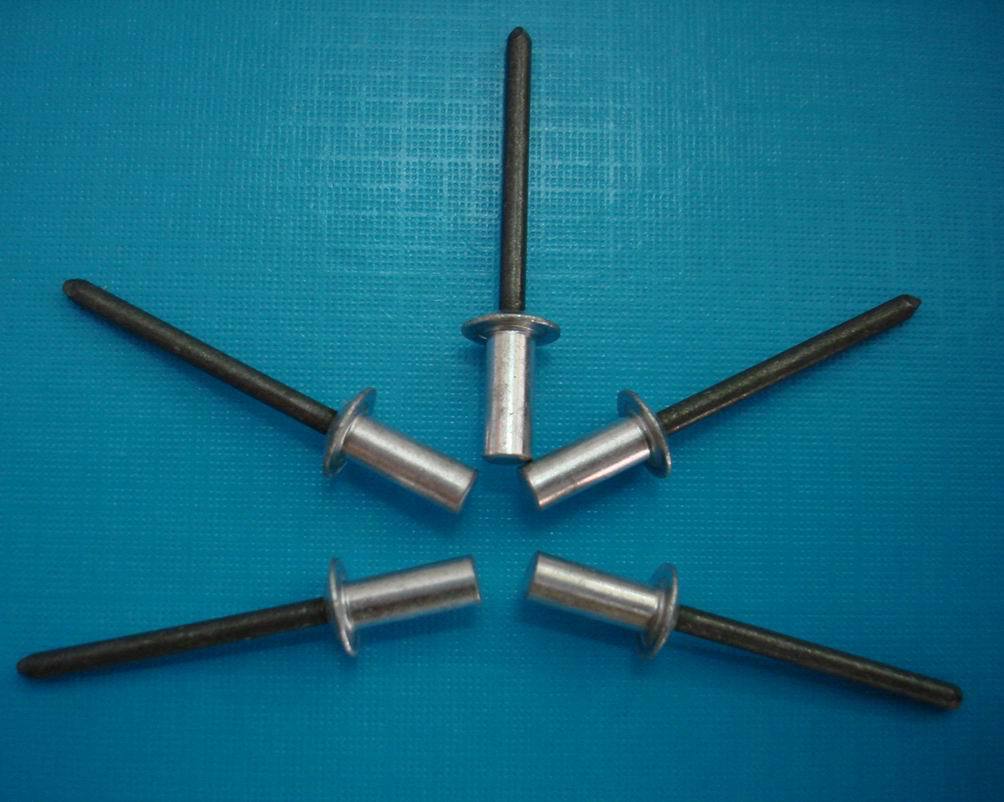

Fume hoods with tail

The use of pulling devices is in demand when joining two metal sheets. These fasteners contribute to secure fixation, even if the master has access to only one side. In order to work with blind rivets, an air or mechanical pistol is required, and you can also use a special attachment for a screwdriver.

The exhaust type of devices has the form of a long metal rod, at the end of which there is a tubular aluminum sleeve. It is also possible to use other soft material in the manufacture of these goods. By pulling the steel rod, the craftsman can detect the deformation of the sleeve rod, the reason for this situation is the presence of a small head that prevents the exit.

The popularity of blind rivets is due to the ease of installation, as well as the low cost of equipment. This fastener is appreciated for the ability to connect thick and thin parts, even if the sleeve height is low relative to the thickness of the workpieces. Insert the workpiece and then tighten the tail. As a result of these manipulations, you can get a full-fledged reliable connection. There are two types of pull-out hardware.

- Open - these are standard devices that have a through hole in the body. They are quite similar to hollow goods. They are used in the case when high requirements are not imposed on installation regarding reliability and strength. Such products are among the most demanded goods on the market.

- Closed ones are used when the fasteners must be as tight as possible. These rivets prevent moisture, dust and debris from entering the fasteners.

Threaded

Threaded rivets are among the most expensive. This fastener is in the form of a hollow threaded sleeve. The sleeve is inserted into the prepared hole and the rod is twisted. Usually, these devices are made of aluminum, but there are products made of copper and brass. For a high quality connection, it is worth not violating the direction of the pull. The work should be done with a special pistol, but, alternatively, you can use a bolt and nut. This type of rivets is characterized by minimal trauma. Often, the threaded form of rivets is used during the mechanical engineering process, as well as during the manufacture of the body part of electrical equipment.

According to the design features, this hardware is divided into many varieties. For example, the spacer version holds soft and loose surfaces well. The multi-clamping product comes in handy when working with parts of different thicknesses. In this case, the formation of a universal node occurs.

How to use?

It is not too difficult to use rivets - for cylindrical products, you can even do without a special tool, an ordinary hammer is enough. You can work very successfully even in the "field" conditions, not to mention a full-fledged workshop. The largest steel rivets are used in the assembly of bridges and overpasses. Smaller products are in demand in mechanical engineering, instrument making

Important: riveted joints are not tight enough by default, and it is possible to seal them properly only when using sealants and special brands of rubber

A hole is usually drilled beforehand. If a countersunk rivet is used, countersink is recommended. The process in the case of a blind rivet is something like this:

- insert a rivet;

- pull together the necessary details;

- form a closing head (using a tool);

- check the readiness of the connection, if necessary, clean it.

For information on how to make a steel rivet with your own hands, see the next video.

What it is?

Rivets are fasteners that are used to connect two or more surfaces of materials when needed. These devices are inserted into the holes of the workpiece, which have been formed in advance in the form of a line. The fastening element has the form of a rod, which, when deformed, is able to cover the walls of the hole and hold on to them using the friction force.

According to consumers, rivets are reliable fastening methods that have been used for many years. Nowadays, they are also in great demand, in particular in those places where fasteners must be made as responsibly as possible.

The advantages of using this type of connection are as follows:

- simplicity of design;

- the ability to connect materials of different types;

- reliability;

- resistance to vibration and shock loads.

The negative aspects of such fasteners include the following:

- the need for labor and material costs;

- the possibility of destruction of the connection if the hole diameter is incorrectly selected;

- decrease in the quality of tightness after a certain period of time.

Riveting is the procedure for joining parts by forming a series of rivets. In this case, the connection is called a riveted seam. Depending on the hardware, the craftsmen can carry out hot and cold riveting. The first involves the use of a plastic material, but the second is usually based on the use of a hard type of steel.

2 Device and design features

Exhaust hardware consists of a body and a rod. A body is commonly referred to as a body, sleeve, sleeve, or cylinder. It is the body that is the fastening element that performs the load-bearing function. The body consists of a head (side) and a flat hollow cylinder. In sealed hardware, the end of the cylinder is sealed tightly. By the type of head (side), hardware is divided into hardware with a high side, with a wide side and a secret side. The wide side, as well as the high side, ensure the implementation of a strong riveted fastening. Such fasteners are visible from the side and form "bulges" on the surface of the part. The concealed rim provides an almost smooth surface at the attachment point, however, it is less reliable. The countersunk side has a flat flat surface and a thickness of about 1 mm, in this case the main massive part of the head is inserted into the mounting hole.

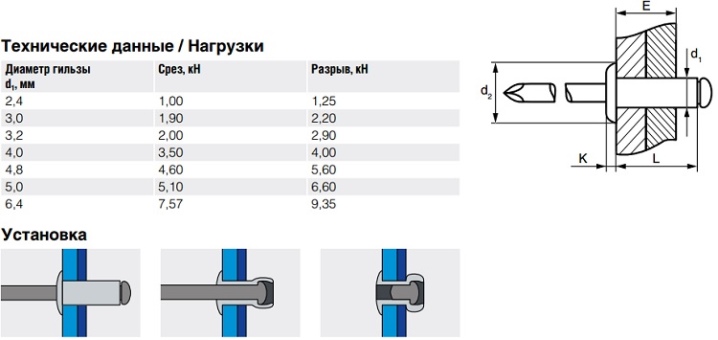

The rivet cylinder can be of different lengths and thicknesses. It is by the outer diameter of the cylinder that the diameter of the hardware is indicated in the name when ordering. Cylinder sizes are the most important of all hardware sizes. It is the dimensions of the cylinder that are decisive when choosing rivets. The essence of the fastening boils down to the fact that the fastening element must provide a movable / fixed connection of several parts or elements. The length of the cylinder is calculated by the formula: thickness of the riveted material1 + thickness of the riveted material2 + riveting thickness (specified by the manufacturer) + 0.5-1 mm (for a movable joint).The diameter of the cylinder is taken equal to the required diameter of the holes for fasteners (usually the hole is larger by 0.1-0.2 mm - for free installation of hardware into it).

For example, aluminum rivet AlMg2.5 4x10. This means that the type of alloy is indicated here, the number 4 is the indicator of the outer diameter in mm, 10 is the length in mm.

Aluminum rivet AlMg2.5

Kernel. Carries out the function of riveting. Usually made of steel, which is much stronger than the body. At the end of the rod there is a head that rivets the inserted end. During installation, the rod is pulled out with a special tool (pneumatic riveter) or, if there are few fasteners (1-3), you can also use ordinary pliers. However, in the latter case, you will have to apply decent physical strength.

The main advantage of the design of blind rivets is that they allow one-sided installation (access to the fastening is required only from one side), acting like anchors.

A more durable rivet - a threaded one - differs from a pull-out rivet by the presence of a thread inside the cylinder. The cylinder of the threaded fastener has a screwed-in rod that does not pull out forcibly, but twists out. To strengthen the connection, a screw or bolt is screwed inward. Thus, a conditionally "closed" fastener is obtained. It is sometimes called blind rivet.

After the dimensions and material for the rivets, as well as the type of side, have been determined, you should decide on their type.

1 Materials for making

Blind rivets are made from a wide range of materials. This allows the use of such fasteners in almost all types of work. In addition, the blind rivet itself can be painted in one color or another. Colored hardware is widely used in light industry (textile), where color matching is required.

The choice of rivet material depends on the material of the fastened parts and the environment in which the fastener will be located. The materials for making rivets can be as follows:

- Aluminum. Pure metal and its variants are possible: anodized, varnished.

- Cink Steel.

- Stainless steels. A2 - resistant to rusting, A4 - resistant to corrosion and acidic environment (found wide application in the chemical industry). Or imported counterparts, for example, DIN 7337. Stainless steel is one of the most common and durable materials.

- Copper.

- Copper-nickel alloy (monel). Contains 70% Nickel, 30% Copper.

- Polamide. A relatively fragile material, it has found application in the manufacture of clothing and various textile products.

All materials from which fasteners are made are regulated by GOST.

Fasteners

When selecting a material, it is extremely necessary to carry out a careful selection of materials of hardware with fastened materials - due to the fact that the fastening can be destroyed. The destruction of fasteners occurs due to the formation of a galvanic pair of hardware - part. In a humid environment or when wet, a current begins to flow through the galvanic vapor, which destroys the mount.

For example, when aluminum and steel come into contact, there is a very rapid oxidation of aluminum and, as a result, destruction. Therefore, for fastening steel parts, it is better to use stainless steel rivets A2, A4 or DIN 7337. Steel rivets are recommended for use most often, because they have very high strength. But the steel-galvanized rivet is less common. The reason is that the zinc coating wears out rather quickly, especially if one of the fixed elements is mobile. Copper and copper alloy rivets are the most versatile hardware. Copper only conflicts with aluminum, and fasteners with other metals are safe to make. The main disadvantages of copper are the high price and ugly color after oxidation (some time after the fasteners are installed, a green coating may appear - oxidized copper), although this does not affect the strength of the joint. Polamide is the most versatile material.Such a rivet will allow you to connect anything you like, but this connection cannot boast of special strength.

When ordering rivets, it is very important to indicate the material in the specifications, and to do this in detail if there are several types of alloy (for example, when ordering an aluminum rivet, indicate the alloy AlMg2.5, or AlMg3.5)

What material should the rivet be of

Rivets are usually taken from the same material as the parts to be joined - this avoids electrochemical corrosion

Pay attention to the strength characteristics. But, as a rule, when connecting aluminum parts, the strength of aluminum hardware is sufficient

In general, rivets are made from the following metals:

- steel:

- ordinary - grades St2, St3, St10;

- corrosion-resistant Х18Н9Т;

- galvanized;

- alloyed (stainless) - 9G2, 304, 316.

- copper MT and M3;

- aluminum alloys (more often AD1, D18);

- aluminum-magnesium (AlMg2.5; AlMg5; AlMg3),

- brass (L63).

When connecting copper parts, the installation of brass and copper is permissible. Aluminum is bonded with aluminum alloys. Steel sheets - corresponding grades of steel rivets. There are also mixed hardware - from two different metals (chemically non-conflicting). Most often, there are aluminum-steel.

For the installation of facade elements, slopes, ebbs, metal tiles and profiled sheets, blind rivets made of galvanized painted steel are usually used. Coloring - in tone with the details.