How is the bandaging performed?

To obtain greater strength, the masonry dressing method is used. If you follow the instructions, even a beginner can handle this process. Used to stabilize transverse and longitudinal seams. This involves erecting a row so that each segment falls on two or three lower ones. In construction, the following masonry stands out:

- One-level. Dagger and spoon rows are laid out alternately.

- Multilevel. First, several rows of one type sit on the solution, and then the same amount of another.

- Three-level. Every 3 rows of the long side are replaced by 1 short one.

Backfill brick is often a substandard type, which, due to its low price and high strength, is an indispensable option in construction for the construction of the main frame of a building. However, before laying out, it is recommended to study the principles of working with the material in order to competently carry out the construction project of the building.

Properties and characteristics

Rubble bricks have the following features:

- Strength.

- Environmental friendliness.

- Frost resistance.

- Resistant to aggressiveness.

- Bonded strength.

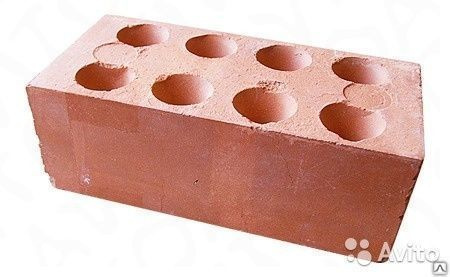

Product marking directly indicates the scope of use, for example, M200 indicates a permissible load - up to 200 kg per 1 cm2. This option is used when erecting the base or load-bearing parts of a building. The M150 or M100 brand copes with less pressure, therefore it is better to select it when building a one-story structure. In the presence of voids in rubble brick, thermal conductivity is significantly reduced.

When manufacturing, the manufacturer focuses on the minimum requirements in accordance with GOST, therefore the backing stone has irregularities, roughness, chips and a not entirely presentable appearance. The size has an error of up to 10 mm. The thickness of the masonry is 2 or 2.5 bricks, so the difference in dimensions does not greatly affect the quality of the work, since you can use the halves. In this case, the main thing is to make an excellent dressing so that the walls do not delaminate.

There is a variety of M125, which is widely used in the construction of cottages, in terms of strength characteristics it is better than M100. The building itself turns out to be more beautiful and more durable. Such walls perfectly cope with sudden temperature changes, even at -50 ° C they do not lose their good properties.

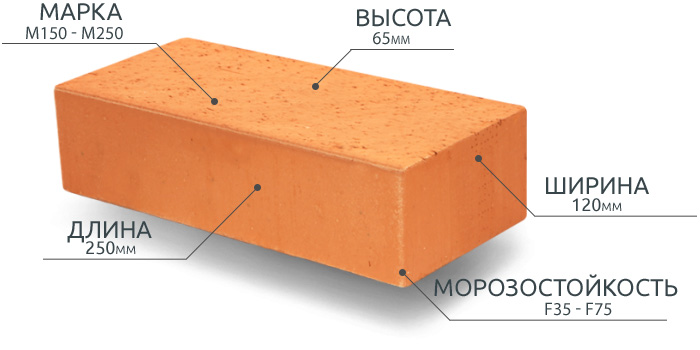

Of particular importance is the frost resistance of the product, indicated in the accompanying documentation. The figure indicates the number of freeze / thaw cycles that the material will cope with and not change its technical parameters. The size of the backing brick is also important, there are several types:

- Standard single - 250 × 120 × 65 mm.

- Double - 250 × 120 × 138.

- One and a half - 250 × 120 × 88.

Based on its size, the manufacturer sets different prices for the brick.

If we compare the usual and backing type, then the latter has a large number of disadvantages. This is explained by non-compliance with technology and free GOSTs. Bricks can be bought with defects, different textures, colors, fuzzy edges, chips, roughness. In most cases, this is due to improper firing.

Tips before buying

In addition to the cost and manufacturer, it is necessary to choose a product according to certain parameters, for example, the absence of:

- strong chips;

- traces of dye;

- different shades;

- inclusions of impurities.

It is better if the entire purchased block was from the same batch, since there is a high probability of getting a product of equal shape and size.Even if there are deviations, they will be the same, which makes the masonry process easier.

You can identify a poor-quality brick by the sound when you hit it. If it is deaf, this indicates insufficient firing. This fact is also indicated by the pale orange tint. If used in construction, there is a risk of rapid deterioration. If the color has a black tint, this indicates that the product is burnt and it is ideal for the construction of drain pits and other structures that do not have a strong load.

It is worth paying attention to the reputation of the manufacturer / supplier, the distance of delivery (it can greatly affect the final cost), the method of transportation, etc. It is not recommended to purchase from the first comer, it is better to compare several firms with each other

Backing price

Depending on the region of the Russian Federation, the price tag for the product will differ slightly. This factor is influenced by the manufacturer, quality and method of firing, type (hollow or solid).

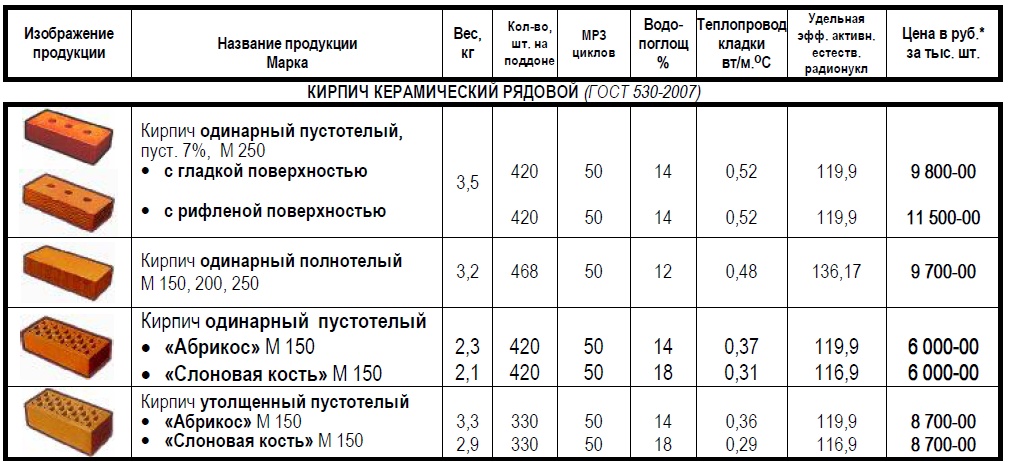

| View | Peculiarities | Price rub / pc |

| Single grooved | M100 | 9 |

| Single grooved | M100 | 8 |

| Single with voids (gas firing) | M150 and M175 | 9 |

| Single corpulent (gas fired) | M125 | 8 |

| Single smooth | M125 | 8 |

| Single regular | M100 | 7 |

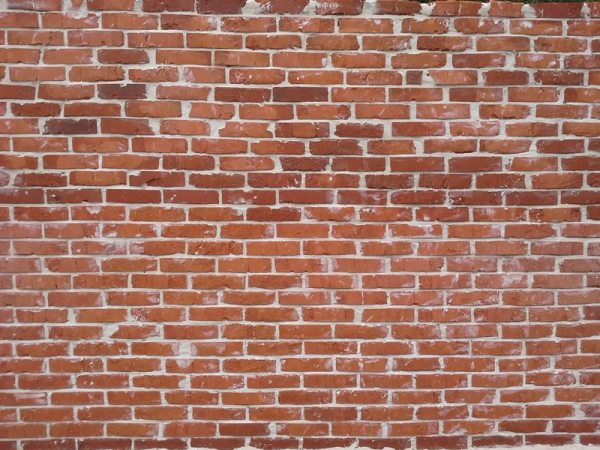

Brick walls

08.07.2011 20:29

Building bricks have certain dimensions based on

which, a decision should be made about the thickness of the walls of the house. In Soviet times, the thickness of the walls was usually two or two and a half bricks, which is equivalent to 0.5-0.75m. Today, this is not the most popular brick wall thickness. Often the limit is 1.5 bricks, that is, 0.4m. This fact is due to the emergence of a variety of heaters, which are widely used in the construction of country houses. The difference in cost between the insulation and the main material used can significantly save on construction. Thus, the thickness of the walls according to the new, so-called, European standards is minimized, while the missing wall thickness to provide the necessary heat and sound insulation characteristics of the structure is obtained by insulation. This is not to say that this new and widely used standard is better. Judge for yourself, in European countries, from where, in fact, it began to spread, there is no such harsh climate with sharp temperature changes. Applying this technology, do not forget what climatic conditions you live in. The so-called savings, thanks to the use of insulation, can grow into high costs for eliminating the consequences.

As for, directly, the varieties of bricks used in construction, then it can be conditionally divided into two types according to the scope of application:

- Backing brick

- Facing bricks.

Backing brick is a kind of ordinary brick

white and red. With the use of this material, the construction of the walls of the house for plastering is usually carried out. Ordinary brick strengthens the walls of the house, due to its ability to absorb moisture. Plaster adheres better to red bricks. White brick is more often used if neither wall plastering nor cladding is envisaged. To ensure visual appeal and reliability, the seams in the white brick walls from the outside are processed to create a pattern using a special tool. Pattern options can be different and are chosen at the discretion of the customer.

Facing bricks are used for laying walls with certain

nuances. The outer walls are made of facing bricks so that the joints in the masonry structure are even and the masonry looks neat. The facing brick is placed under the bar. Internal walls, as a rule, are made of backing bricks. The facing brick is tied up with the backing brick using a reinforced mesh.Reinforced mesh with a diameter of about three to four mm is laid through 3-4 rows of bricks over the entire width of the masonry. The width of the backing brick is 0.25-0.4 m. An opening of 0.05 m is left between the rows of facing and backing bricks. In some cases, the opening is filled with expanded clay. Expanded clay helps to retain heat in the structure. But this technology has a big drawback: if moisture penetrates into expanded clay, this can first cause it to swell, and subsequently lead to the formation of cracks in the walls. When laying a reinforced mesh, a maximum permissible vertical error of 0.01m by 6m is possible.

It is better to produce clak during daylight hours and at a positive temperature. In addition, masonry should not be carried out during precipitation. And in order to prevent moisture from entering the structure after the end of the working day, a prerequisite is to cover the structure with a waterproof material (Article prepared by ASK Aegida).

Material characteristics

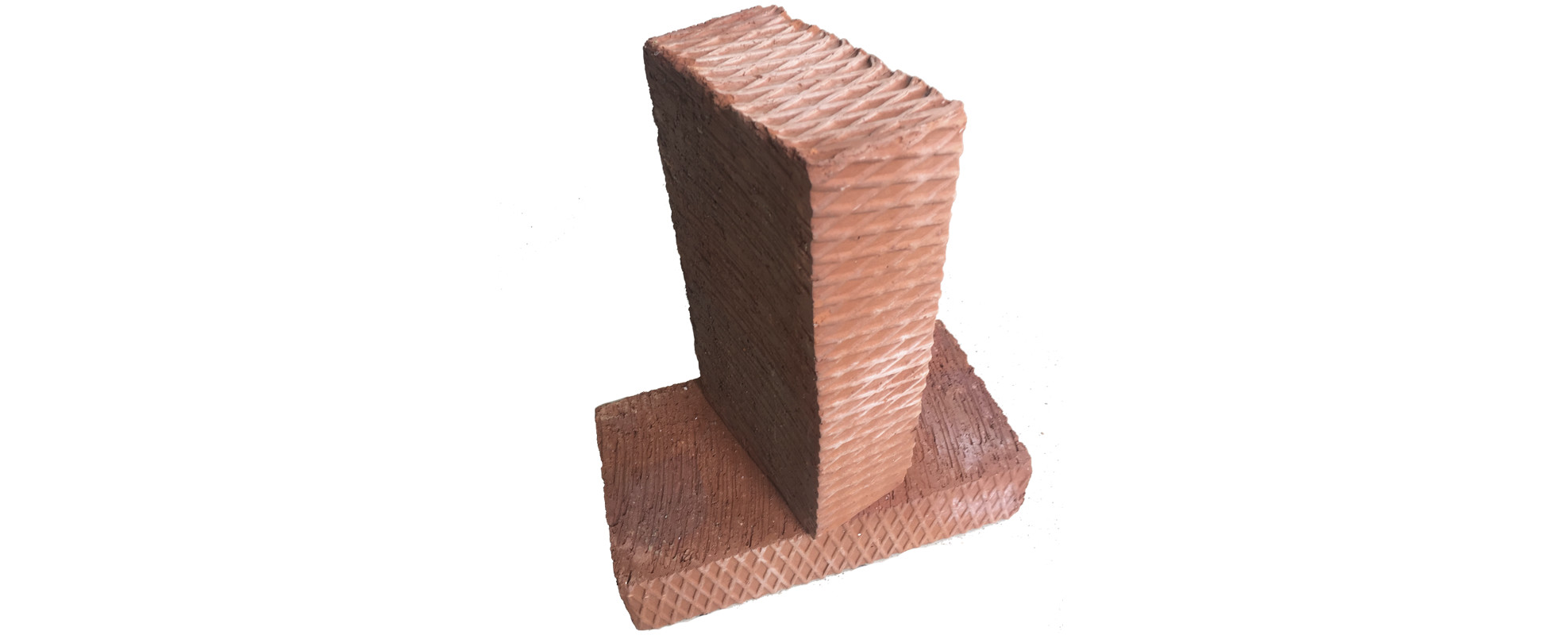

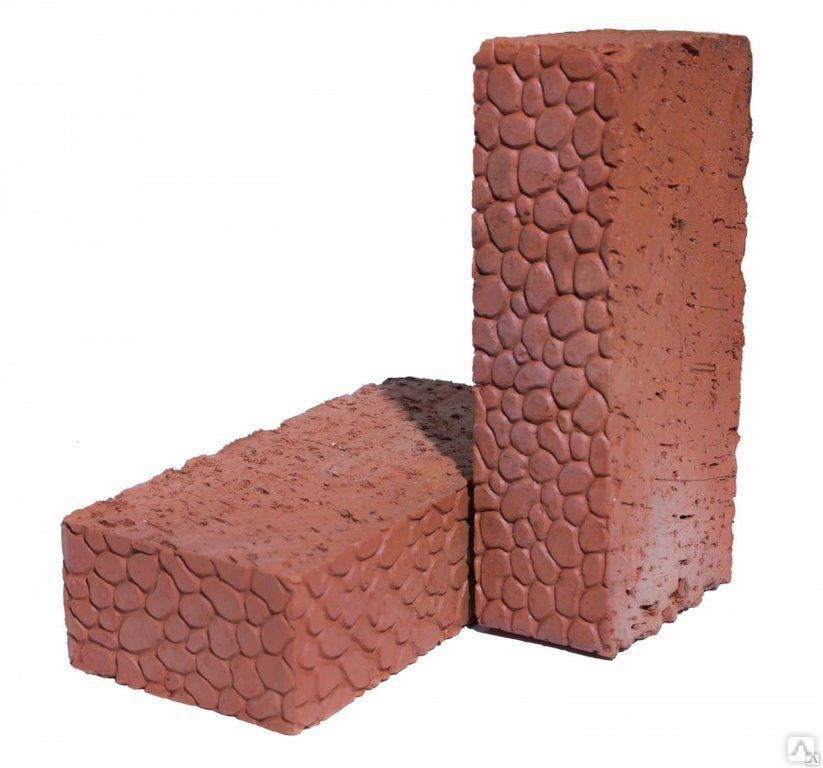

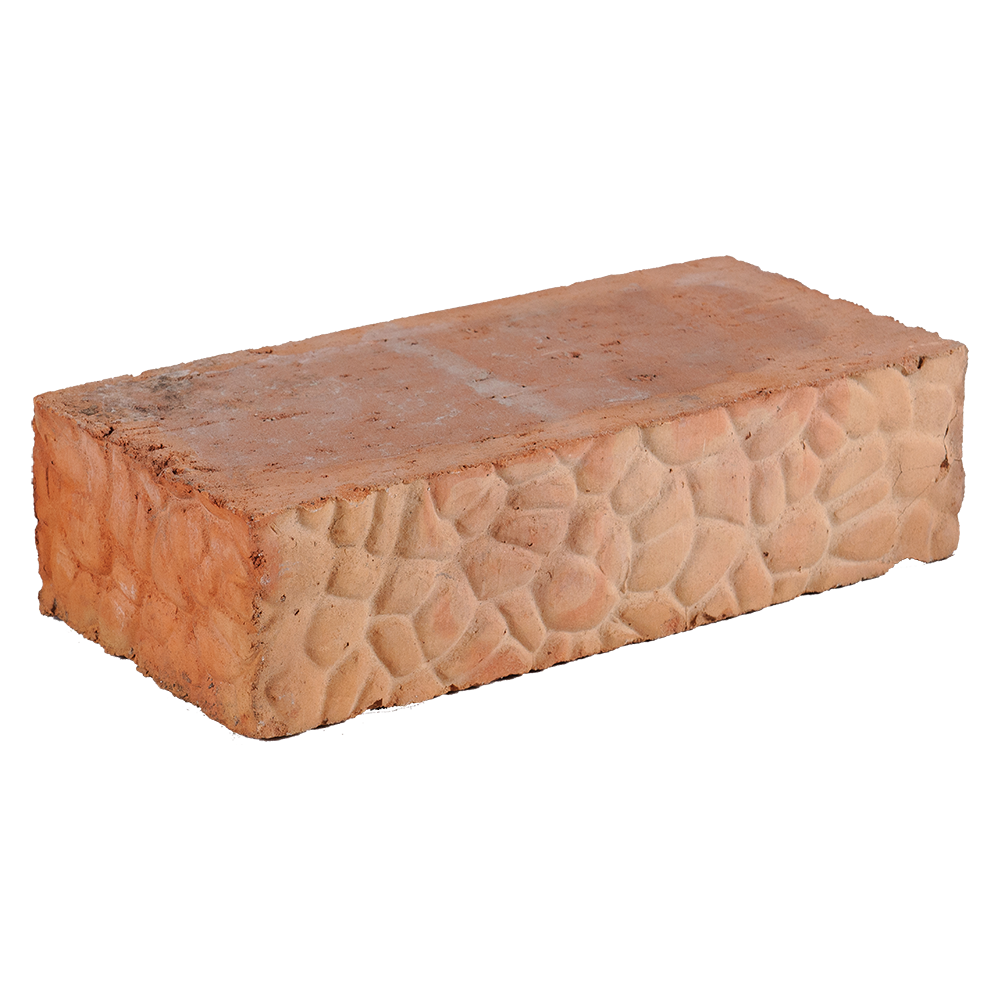

In the photo there is a rubble brick wall.

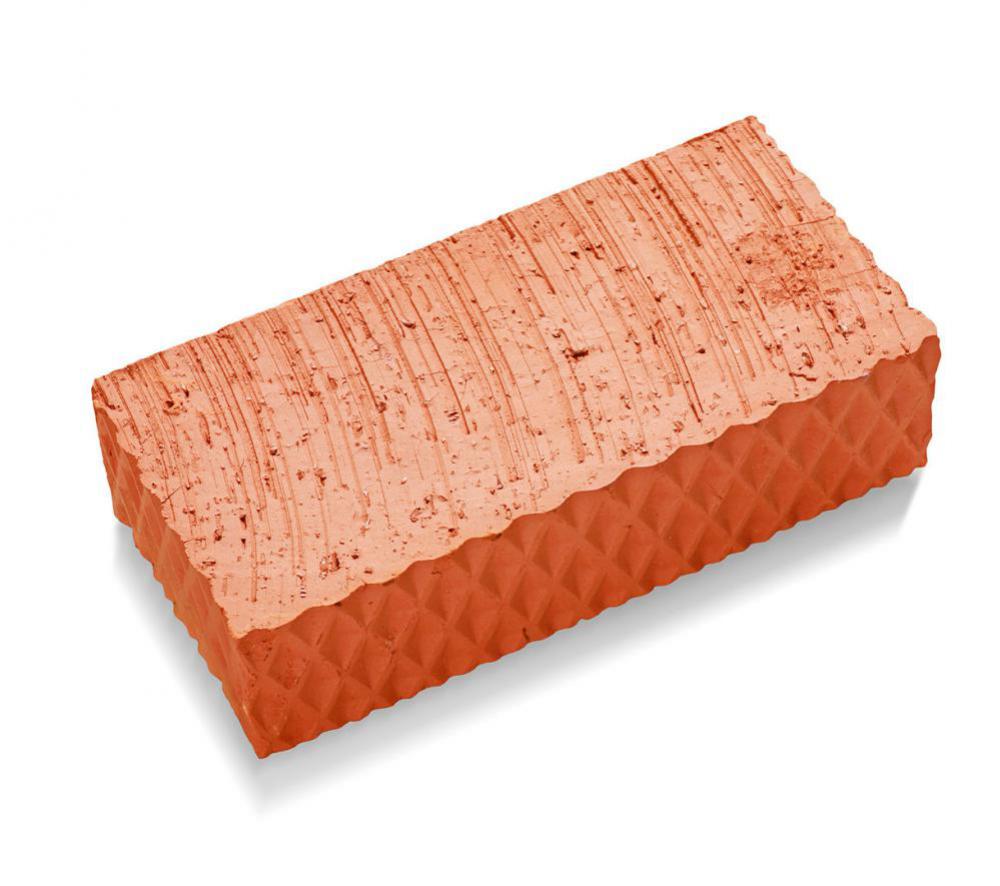

The GOST requirements for the external parameters of the backing brick are minimal: chips, surface roughness, curvature (but not more than 1 cm) are allowed, and there may be unevenness of shade or color. For better adhesion to the mortar, the side edges (spoon and poke) can be grooved.

Such deviations are allowed on the basis that it will subsequently be hidden under plaster or other finishing materials, including it may be revetted with decorative finishing. Sometimes for this, double silicate brick M 150 is used, and often - decorative facing brick.

Purposefully, enterprises are very rarely engaged in the production of such products, the exceptions are cases when clay of a low grade is used in production. Thus, the manufacturing technology corresponds to the manufacturing technology of high-quality products, but the main methods are plastic molding and semi-dry pressing.

Basically, ordinary building bricks are used for backfilling, which have some surface roughness, or the temperature parameters of firing were violated during production, etc. But the substandard appearance does not affect the mechanical and physical properties of the material, and the price is much lower, therefore, its use can significantly reduce the total cost of building an object.

As a result, some of its disadvantages become an advantage. For example, roughness during finishing works provides a more reliable adhesion to mortars.

Product labeling

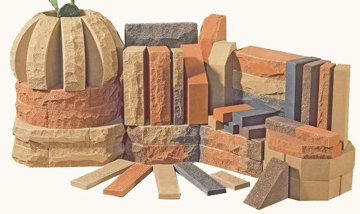

Photos of varieties of backing stones.

The designation of ultimate strength has alphanumeric marking, for example, M150 indicates that for 1 sq. cm should account for no more than 150 kg of load. Marking is needed to determine which brand of rubble brick should be used when erecting a structure.

For example:

- solid brick of the M200 and M150 brands is suitable for laying the foundation,

- M100 can be used for a one-story building,

- for multi-storey buildings, use M125 or M150.

Linear dimensions according to GOST

All products are manufactured in accordance with GOST 530-2007 and have the following dimensions:

- 250 mm × 120 mm × 65 mm - single;

- 250 mm × 120 mm × 88 mm - one and a half;

- 250 mm × 120 mm × 140 mm - double.

Frost resistance

An important characteristic for our latitudes is frost resistance, which affects the durability and timing of the structure. It indicates the number of cycles of saturation with moisture, followed by freezing and defrosting, which the material can withstand.

Backing ceramics brands

Before choosing a backing brick for construction, you need to decide on the marking. Brick blocks are marked depending on their strength.

The bricks indicate the pressure that brickwork can withstand per square meter.

M-100 is the cheapest backing brick suitable for small buildings. It is most often used for the construction of one-story or two-story private houses. Since the brick is distinguished by good frost resistance, even with the M-100 marking, the house will be able to stand for decades and not crack.

M-125 is used as an intermediate type of material between two other types of backing bricks. It is suitable for the construction of low-rise buildings and is slightly stronger than the M-100.

Backfill brick marked M-150 is used for the construction of high-rise buildings. The blocks are suitable both for building foundations and for erecting load-bearing walls.

Backbone brick

A backbone brick is an ordinary (red) building brick that has disadvantages in appearance. External walls are usually not built from it, as they will not look very beautiful. After all, it can have chips, roughness, oblique lines of edges, inhomogeneity of color and texture. It can be either with voids or solid. Its sizes can be very different, but the most common are brick 250x1250x65 mm. and 250x120x88 mm.

However, the disadvantages of the backing brick are at the same time its advantages: due to flaws, it costs an order of magnitude cheaper. And this is very often the main factor when choosing a material for construction.

It can be used for the construction of walls, which will later be sheathed with other materials or revetted or decorated. Then all chips and flaws will be hidden under other materials.

A building built of backfill bricks will look impeccable when using special cladding bricks. The aforementioned roughness, although it has a repulsive appearance, but due to the irregularities it has good adhesion to the cement.

Poor appearance and small defects in manufacturing does not mean that this is associated with some additional risks. Because there are very specific GOST requirements. They guarantee that the structure of such bricks will last for a long time.

Usually backfilling bricks are not made on purpose, but are a by-product of production.

However, they have the same characteristics:

- good frost resistance,

- strength,

- sizes convenient for construction.

There are various markings "M100", "M200", "M150", etc.

The number after the letter M indicates the ultimate load:

- For example, M200 means that 1 cm2 can have a load of no more than 200 kg. It is perfect for building a foundation.

- And M150 and M100 can be used to build a one-story building.

The presence of voids reduces thermal conductivity, which greatly enhances heat retention in the home. So this is another plus in favor of using backing bricks in the outer walls.

In the end, I would like to note that the disadvantages of appearance are more than offset by the cost. And the appearance of the walls can always be corrected by various methods.

You can find out about the features of backing bricks by watching the following video.

Interesting in the section "Brick"

How much cement is needed per cube of concrete? Expanded clay concrete - the main characteristics Expanded clay and its fractions One-and-a-half brick Brick size 250x120x65 Brick ШБ (refractory chamotte)

All rights reserved, 14+

Specifications

The dimensions of the window and door openings are selected based on the values of the products that will be installed in them. However, now the mass construction of houses is being carried out according to individual projects. In such apartments and houses, openings and partitions are made only after the premises are sold and the new owner draws up the layout.

It also happens that the dimensions of the frames of doors and windows are already known at the time of construction, then the opening is made for the given dimensions. Then a stock of several centimeters is necessarily taken, which will later be filled with polyurethane foam.It is also necessary for making adjustments to the structure. Only with this size of the opening is it possible to carry out high-quality installation work with window and door frames.

- Building bricks. There are several types of it, which differ in thickness: single, one and a half and double.

- The solution on which the stones are laid. There are several varieties of masonry mixes. The differences lie in their composition and properties. Each type has its own name.

Cement mortar is one of the most durable. It has a fairly long service life. Its composition is very simple: quartz sand, cement and water. Lime mortar contains lime instead of cement. Clay is made from clay with sand. A mixed solution combines the qualities of several types, because contains various components such as clay, sand, cement, lime, water and various chemical compounds. They have great mobility and accessibility.

Ceramic brick weight

Ceramic or red brick is the standard and most widely used type. It is made from varieties of clay, by burning in a kiln. This species has very good characteristics. Houses made of this material are comfortable and safe.

Red brick weighs

slightly, but its weight may fluctuate. Average -it's 4 kg .

Hollow brick

weighs less. This is due to the voids inside it, which can be of completely different sizes depending on the manufacturer.

Ceramic hollow brick:

- single - 2.5 kg;

- one and a half - 3.3 kg;

- doubled - 5 kg.

Ceramic solid brick:

- single - 3.6 kg;

- one and a half - 4.3 kg;

- doubled - 6.6 kg.

Facing brick:

- one and a half - 1.32 - 1.6 kg;

- doubled - 2.7 - 3.2 kg.

Varieties

The popularity and huge demand for double brick is due to its high performance. It can differ in texture, size, number of slots and shapes of voids. There are two types of blocks depending on the raw materials used for manufacturing.

Silicate

Their main feature is that the production is carried out from a mixture of 90% sand and 10% water. In addition, the product also contains additives that increase its quality. This is an absolutely environmentally friendly material that looks like natural stone. The process of making double silicate bricks is carried out by pressing a moistened mixture of lime and sand, after which various pigments are added to it, and sent for steam treatment. It can be either hollow, slotted or porous. By strength, silicate blocks are divided into grades from 75 to 300.

These blocks are most often used for laying out internal and external partitions. It is impossible to use silicate brick for the construction of basements and foundations of buildings, since the product is not resistant to moisture, and in the absence of a waterproofing layer, it can be subject to destruction. It is not recommended to make double silicate bricks and laying pipes, ovens. It will not withstand prolonged exposure to high temperatures.

As for the advantages, this product has excellent sound insulation and has the correct geometric shape. Despite the large weight of such bricks, their laying is quick and easy. In terms of their density, silicate products are 1.5 times higher than ceramic ones, therefore they provide durable and high-quality masonry. In addition, silicate double blocks are 30% cheaper than other types.

Ceramic

They are a modern building material that is used in almost all types of construction work. Its feature is considered to be large, which is usually 250 × 120 × 138 mm. Thanks to such non-standard dimensions, construction is accelerated, and the consumption of concrete pouring is significantly reduced.In addition, double ceramic bricks are in no way inferior in strength to conventional blocks, so it can be used when erecting load-bearing and self-supporting structures in buildings no more than 18 m high.The product is also characterized by high thermal insulation, the buildings laid out of it are always warm, and they are constantly maintained optimal microclimate.

The main advantage of double ceramic bricks is its affordable cost, while many manufacturers often make good discounts when purchasing blocks for the construction of a large object. These blocks, in addition to high quality, also have an aesthetic appearance. Usually brick is red in color, but depending on the additives, it can also acquire other shades. The product is environmentally friendly, and even with prolonged use and exposure to the external environment, it does not emit harmful substances.

These blocks are transported on pallets, where they usually fit up to 256 pieces. As for the marking, it can be different, more often everyone chooses M-150 and M-75 bricks for the construction of objects. In addition, double ceramic blocks are subdivided into solid and hollow; not only their price, but also their heat capacity depends on this parameter. Hollow bricks cannot be used for the construction of load-bearing walls, in this case only solid bricks are allowed. Despite the fact that the first is lightweight and significantly reduces the overall load on the foundation, the inherent cracks in it affect the thermal conductivity.

In addition, double bricks are subdivided into the following types.

- Private. These blocks are ideal for laying stoves, fireplaces and foundations. The only thing is that the front layout requires additional finishing.

- Facial. It is produced in clinker and hyper-pressed versions. It can be either solid or hollow bricks. Unlike ordinary blocks, face blocks are produced in curly, trapezoidal, rounded and twisted shapes. As for the color, it is dark brown, gray, red, yellow and brown.

Where can you use it?

Backfill bricks are not used for the construction of the external walls of the building, as they will look unsightly. Brick of this type is chipped, it is rough, with oblique edge lines, and the color and texture are heterogeneous. Also, this building material can be solid or hollow. If we consider the sizes, then they are diverse, but dimensions of 25x12.5x6.5 and 25x12x8.8 cm are considered more popular.

Backfill brick buildings must be covered with facing material.

But these disadvantages of the backing brick are at the same time its advantages, since the flaws reduce the cost of the material, which is considered one of the main characteristics when purchasing. For example, it is bought if the walls after construction are sheathed, revetted or decorated with other material, because after a number of works have been completed, all flaws will hide under the top layer.

If you build a building from such a brick, then it will have an impeccable appearance, but only on condition that it is subsequently lined with a special material. I would like to note that such a minus as roughness makes it possible to obtain excellent adhesion to the solution. From this we can conclude that if defective products come out during the manufacture of bricks or they have a bad appearance, this will not add additional risks to the construction, since absolutely all work is carried out in accordance with SNiP and GOST. On the contrary, the building will stand for many years.

Specifications

Backing stone can have various shapes, textures and colors. The shade depends on the color of the clay used to make it. The appearance cannot be called beautiful.You can use such a brick in all types of external work and has proven itself very well in the construction of load-bearing walls, foundations, arches and columns. At the last stage of construction, it is most often subjected to a cladding process.

It is of high quality, made using environmentally friendly materials and has a low cost. The brick has excellent characteristics that significantly distinguish it from other types of bricks:

- high density;

- good frost resistance;

- not exposed to aggressive environment;

- retains its appearance for a long time in any weather;

- has a special relief pattern, which creates a good adhesion to the mortar and ensures reliable and high-quality masonry.

Several brands of backing ceramic stone are produced: M-100, M-125, M-150. This variety allows you to choose a building material for specific tasks. This mark displays the strength level of the brick. The higher the grade of the backing brick, the more floors it can withstand. Most often, M-150 and higher is used for the construction of multi-storey buildings.

Several brands of backing ceramic stone are produced: M-100, M-125, M-150. This variety allows you to choose a building material for specific tasks. This mark displays the strength level of the brick. The higher the grade of the backing brick, the more floors it can withstand. Most often, M-150 and higher is used for the construction of multi-storey buildings.

The most affordable and popular is the brick of the M-100 brand. Mostly private houses and cottages are erected from it. He is not afraid of temperature drops. Even at -50 degrees, the brick feels good.

From M-125, this is how you can build cottages and low buildings. In terms of strength and reliability, it is better than the M-100. And at home, using it, it turns out pretty nice and durable.

Backing roughing M-150 has an excellent strength indicator. Any supporting structures and foundation can be folded from it.

The frost resistance of bricks is of great importance. The marking of this indicator indicates how many cycles of freezing and defrosting a wall made of this material can withstand without destruction.

When purchasing a brick, you should pay attention to its quality: it should be smooth, without stains and chips and cracks

The variety of backing bricks allows you to choose the most suitable material for the construction of exactly the building that is planned. And in order to avoid unexpected surprises during construction, it is necessary to carefully study the characteristics of the building material.