Mounting

It is also necessary to install the drive-in fasteners correctly. For work, you will need a drill, a drill - its diameter is selected according to the size of the outer part of the anchor.

Let's analyze the correct procedure.

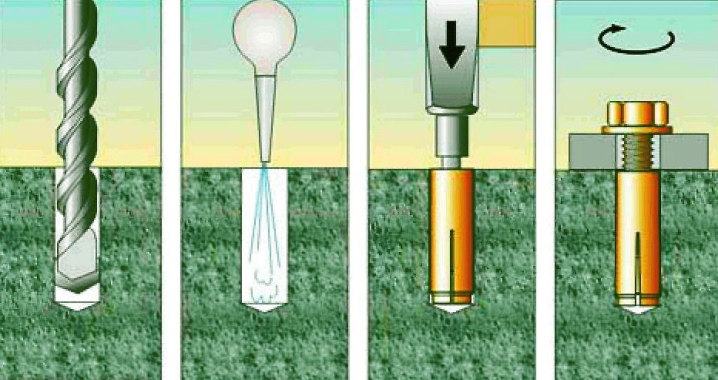

Using a drill, a hole is created on the surface of the wall. If the diameter is large, it is worth taking a diamond bit. In other cases, a victorious drill for concrete will be enough.

The hole made is cleaned from the inside of debris. It can be blown out if a lot of dust has accumulated after drilling.

The anchor is inserted into the prepared hole

It is important to point it perpendicularly wall or ceilingto avoid skewing.

Hammer blows - manual or pneumatic - fix the product inside the material. Once the bushing is unfolded, it locks securely into place, providing a strong connection.

Fasteners can be used as intended

It is loaded by securing the structures to be hung.

Correctly installing drop-in anchors is a snap. It is enough to use the suggested recommendations for the installation to be successful.

What is a drop-in anchor, see below.

Peculiarities

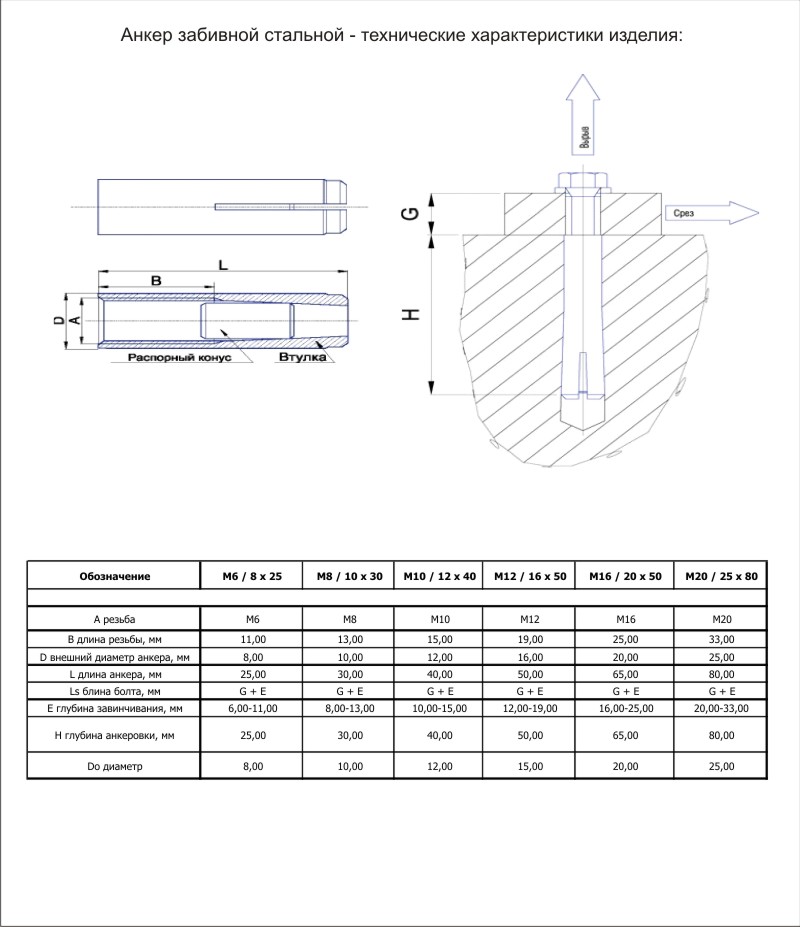

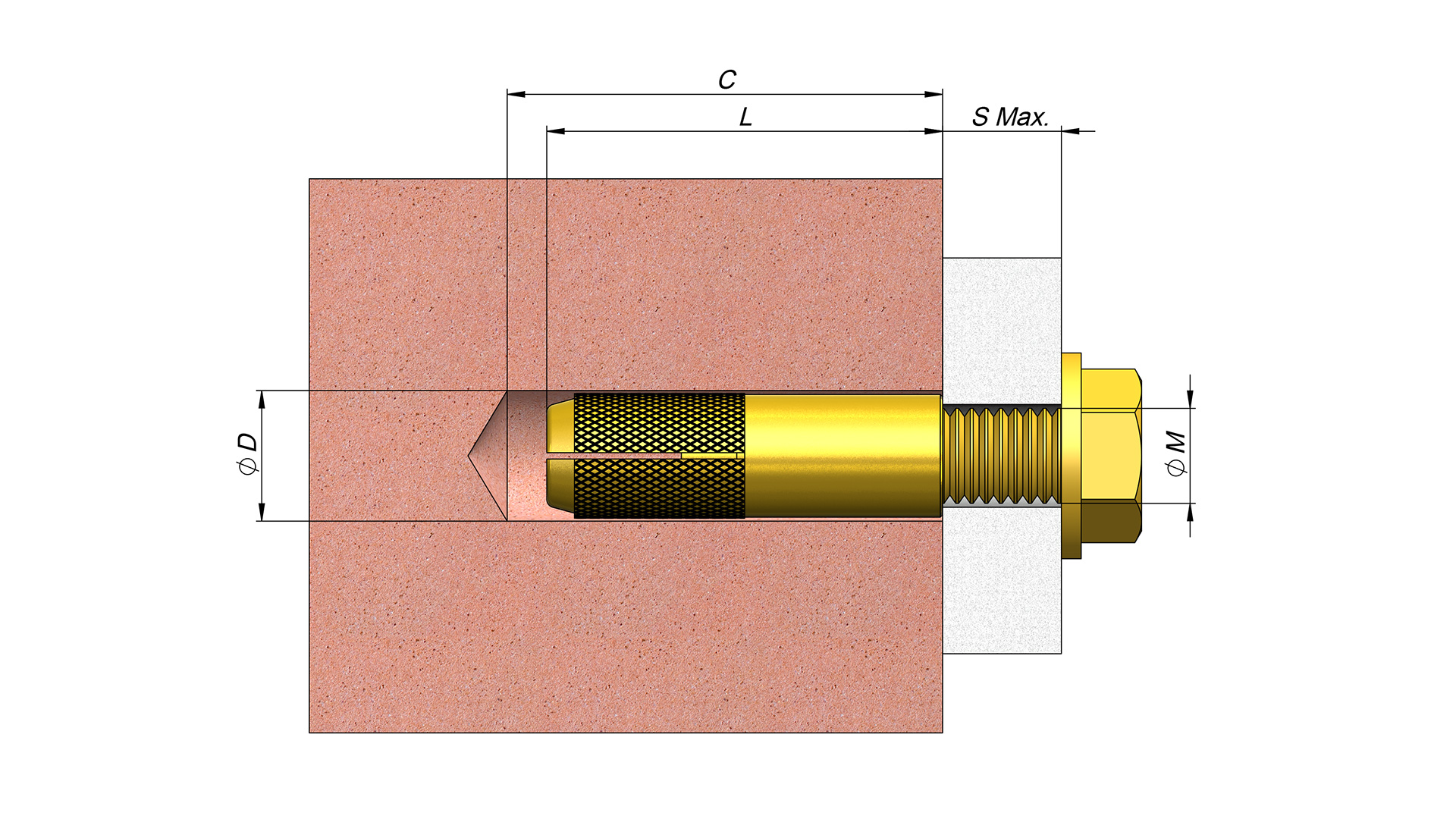

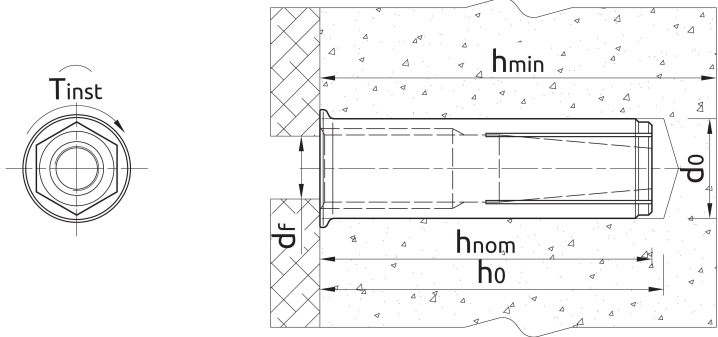

A drop-in anchor is a type of fastener placed inside the main walls and other vertical structures made of brick and concrete. Its main difference is the fastening method. The collet is fixed at the moment when the rod element is driven into it.

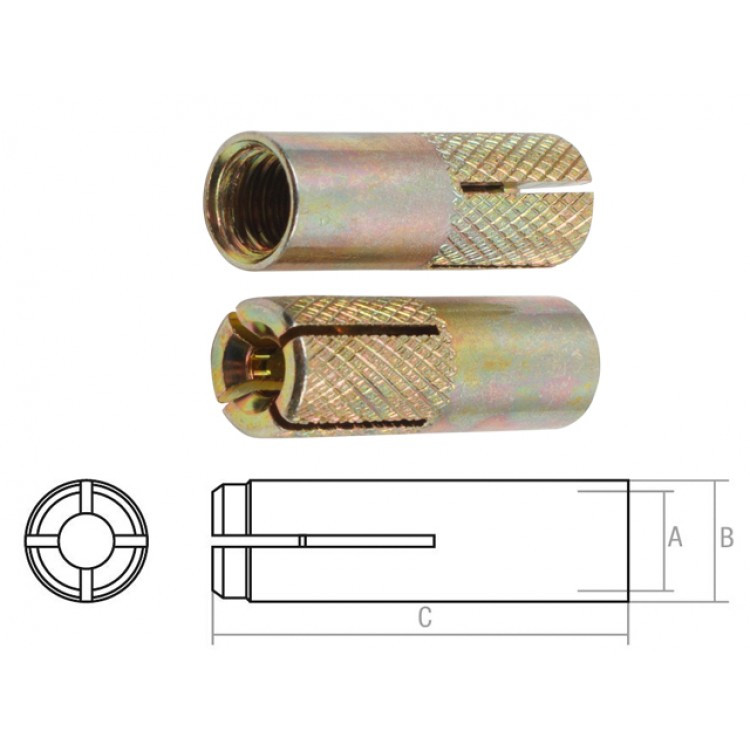

The design includes two components.

- Tapered bushing. There is a thread on one side. On the other, there is a split element with 2 or 4 parts and an inner conical element.

- Wedge-cone. It enters the inside of the sleeve, opening it and creating a wedging force.

During the installation process, the wedge itself is inserted into the bushing, and then, with a hammer, it goes deeper into it. If there is a stop at the bottom of the hole, the impact is applied directly to the anchor. The element is fastened to a concrete or brick surface due to frictional force, and in some cases by means of a stop, using a hand or pneumatic tool. The finished mount receives a fairly high strength, suitable for use under strong and medium-intensity loads.

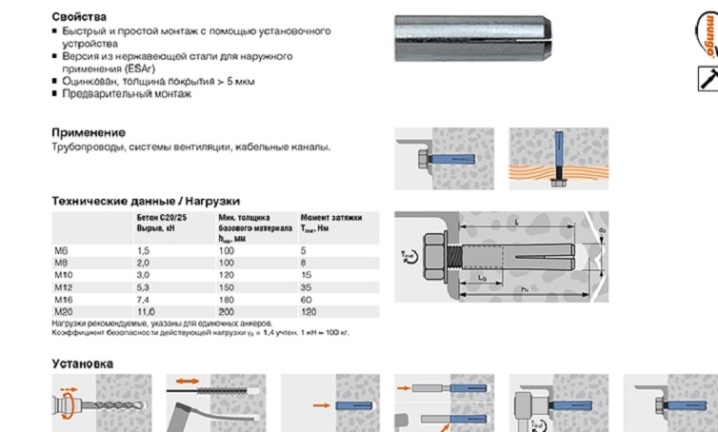

Drop-in anchors are intended for installation in walls made of natural stone, solid brick, high-density concrete monolith. They are not used in surfaces with a cellular, porous, combined structure. Such fasteners are suitable for fixing lighting fixtures, cable cables, hanging and console furniture, wooden and metal suspensions for various purposes.

Selection Tips

When choosing the right anchors, it is very important to pay attention to a number of key points.

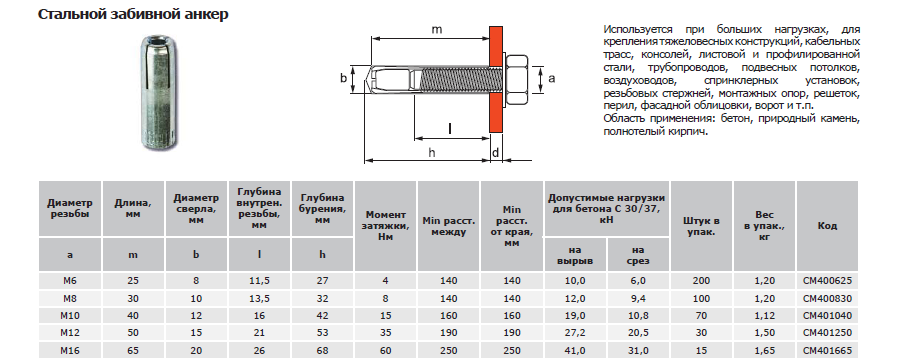

- Place of installation. Lightweight anchors are suitable for the ceiling, since the load on them is usually not too great. For walls, especially if the hardware has to withstand a significant mass, reinforced options are chosen from structural stainless or galvanized steel.

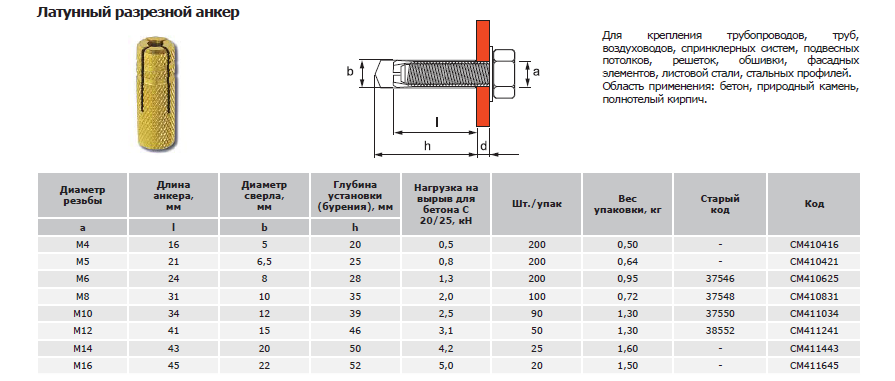

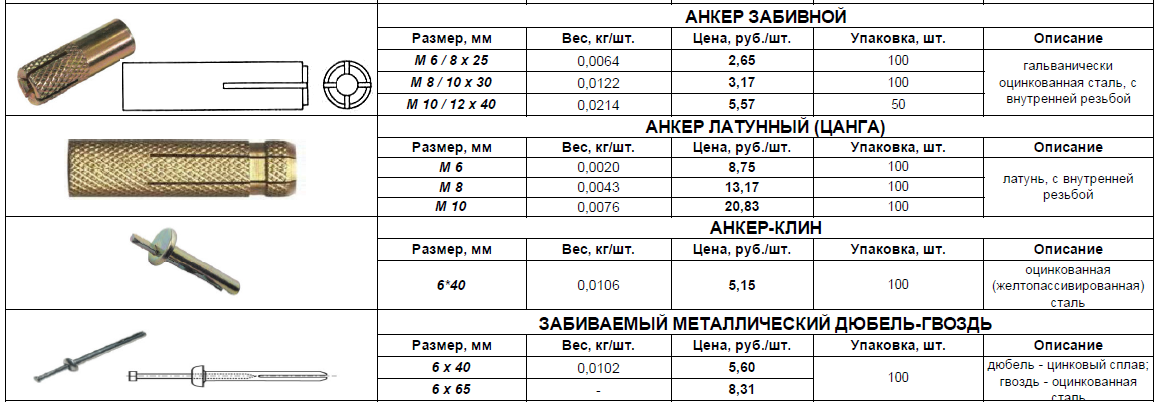

- Type of anchor material. Brass products are the least loaded, they can be used to fix wall lamps, light ceiling chandeliers. Steel options are stronger and more reliable, capable of withstanding pieces of furniture, shelves, and other furnishings.

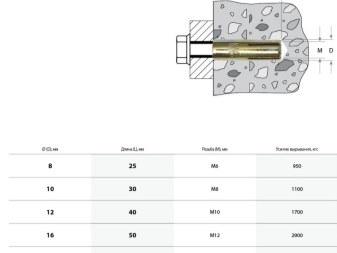

- Surface type. For concrete of not too high density, it is worth choosing the most reliable fasteners of the "Zikon" type; under certain circumstances, such products are suitable even for cellular materials. For bricks, products are chosen no more than 8 mm in diameter.

- Size range.Products are selected based on the required load intensity. In the absence of depth restrictions, it is better to give preference to fasteners with a small margin of safety.

- Operating conditions. For open air and wet rooms, it is worth choosing drop-in anchors with a stainless or galvanized coating.

Species overview

The classification of driven anchors implies their division according to several criteria. It is worth considering that this element has a lower bearing capacity than embedded fasteners and other types of clamps.

The hammered anchor is most in demand in everyday life when hanging structures on the ceiling and walls.

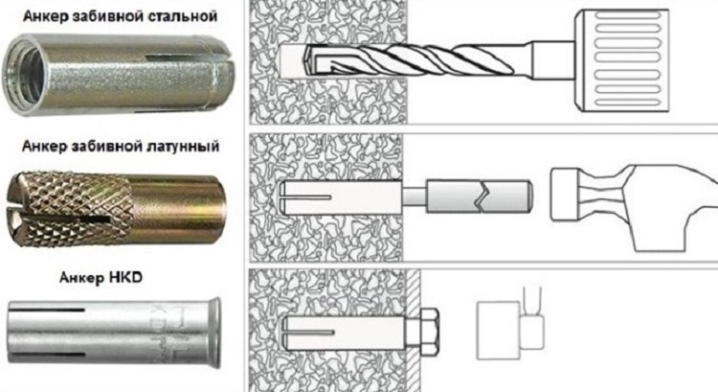

By the type of material of manufacture, these fasteners are of several types.

Steel, sheet metal. They are designed for light loads.

By the peculiarities of manufacturing, this type of hardware also has its own classification. Ceiling options are not wedged with a special element, but with a nail. Special anchors are hammered by direct contact with their body - it is put on a prepared wedge. Variants with external and internal threads are considered more durable and reliable. Those in which it is present only in the bushing itself are designed for minimum loads.

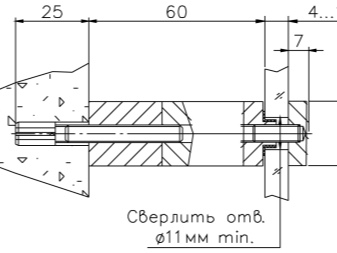

Separately, it is customary to consider a variety of driven anchors such as "Tsikon". Outwardly, its design differs little from the traditional one. There is a bushing with 4 slots here, a wedge made of structural alloy steel. Only the installation principle of the product is different. First a straight hole and then a tapered hole are pre-drilled. A wedge is inserted into it, onto which the bushing is pushed, there is a bursting and strong fastening of the product in the hole.

Popular brands

Among the popular brands of drop-in anchors, the most common are the brands of the leading companies from the EU. The recognized leader is Fischer from Germany, it was this company that developed the Zikon-type anchors, which are popular with professional builders. The brand uses sheet, stainless steel, structural steel in the production

The company is famous for the quality of its products, pays great attention to their compliance with established standards

The price range is above average, it is definitely not possible to call cheap fasteners from Switzerland.

Koelner is a company from Poland with a loyal pricing policy. Products are made from inexpensive galvanized steel, but there are also stainless, brass options. All of them are delivered in packs of 25 and 50 units - this is beneficial if serious construction is underway with a large number of hanging elements.

Among the relatively inexpensive brands, Sormat also stands out. This manufacturer is based in Finland and standardizes its products according to the requirements set in the EU. The range of products is as large as possible, here are both acid-resistant stainless anchors and simple galvanized ones.