Bolt designation

For a long time, competing manufacturers used their own standards. This system has undergone a number of major changes, after which all parts began to correspond to certain parameters and are marked according to them. This provision was necessary in a rapidly developing industry, in which the lack of standards complicated the production process.

At the moment, there are three unified standards according to which markings are applied to bolts for ease of use:

- GOST;

- ISO;

- DIN.

The recommended designation scheme for bolts and screws according to GOST is used in the CIS countries. The requirements of the quality standards apply to food, manufactured goods, clothing, etc. ISO is an international metric system adopted in 1964. At the moment, this standard is used in many countries around the world. DIN is adopted and used in Germany. This system has several standards.

Description

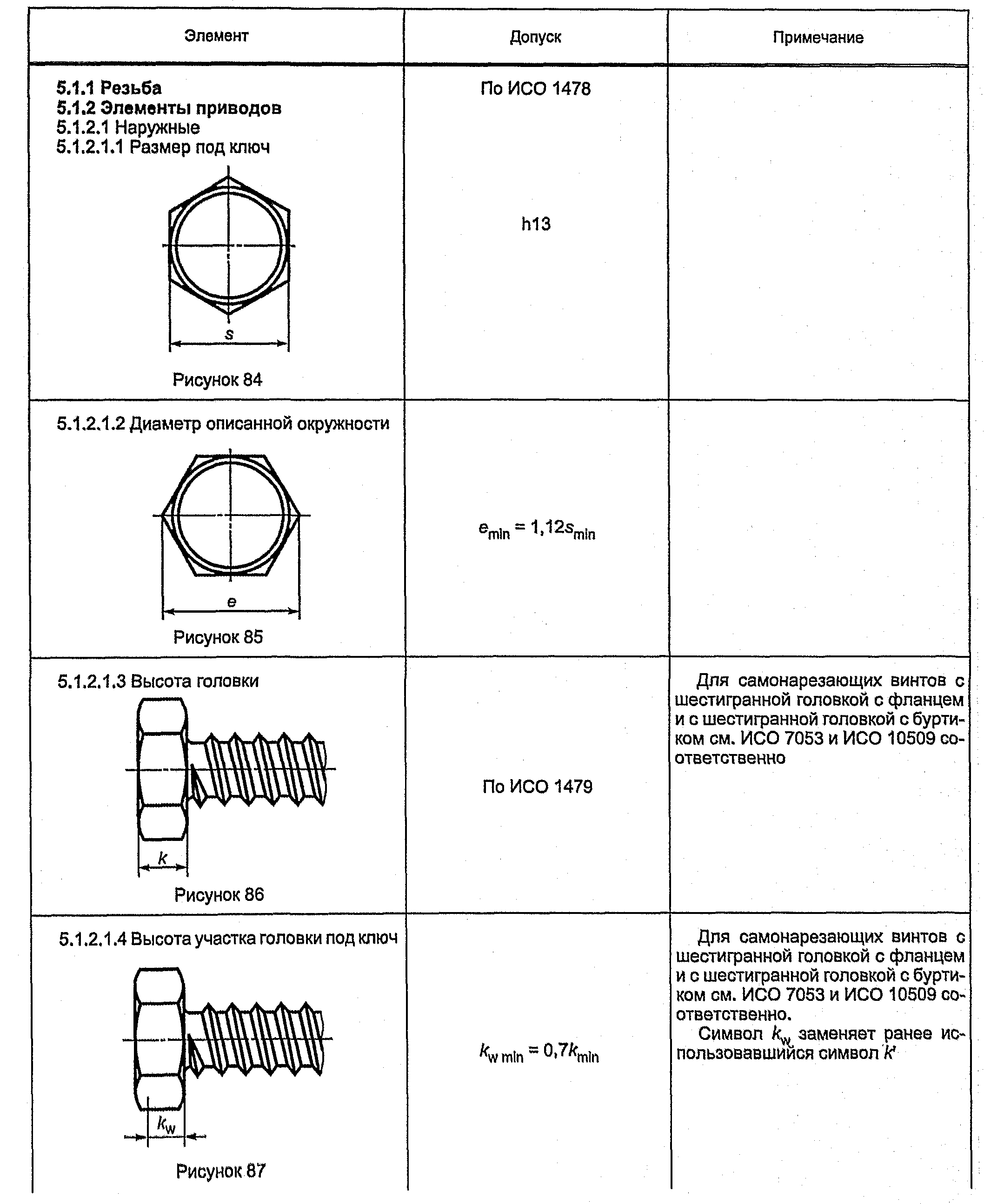

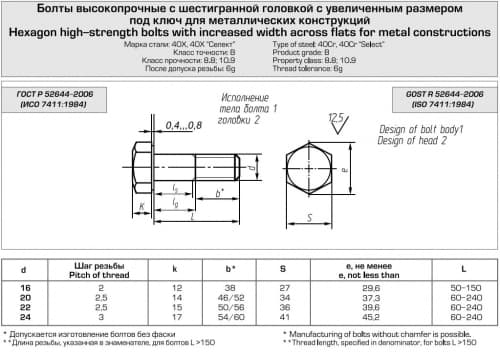

For high-strength bolts there is an official valid GOST 52644-2006. This act standardizes:

-

bolt dimensions;

-

the length of the thread of such a fastener;

-

variations of structural elements and designs;

-

twisting coefficients;

-

theoretical weight of each product.

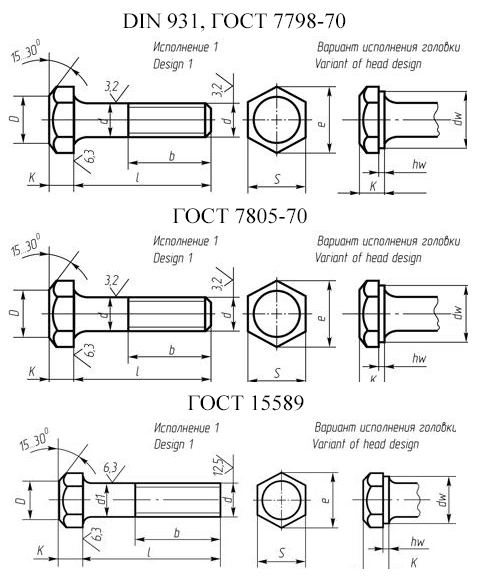

They are also covered by the DIN 6914 standard. By default, this product has a hex head for a wrench. It is intended for highly stressed steel joints. The diameter of the fastener can be from M12 to M36. Their size ranges from 3 to 24 cm.

Such bolts can be used in mechanical engineering, in engine building. They are also useful for areas where strong vibration is active; finally, they can be used in building structures of various kinds. However, the correct tightening torque plays an important role. Too little pressure often leads to premature destruction of the connection, too strong can damage the fasteners or the structures to be connected.

5 How are bolts tensioned?

The tension force of the VPB can be adjusted in several ways. We list them below:

- By the number of impacts of the wrench.

- By the axial tension of the fastener.

- By the angle of rotation of the nut.

- By the moment of twisting.

Here you need to know that regardless of the tightening option for high-strength fasteners, it is imperative to use tie bolts. At the initial stage of tension, the VPB head should be held. The process itself is performed from the hardest part of the connection or from its middle. A torque wrench is used to tighten the bolt for a certain amount of effort. This tool allows you to clearly determine the tightening torque (coefficient) of the connection.

The procedure for tightening the connection with a torque wrench is as follows:

- the package is tightened with fasteners;

- all bolts (including tie bolts) are tightened to a given force;

- the plugs are knocked out, VPB are mounted in their place.

After that, the installed fasteners are tightened to failure with a wrench. M24 bolts are often tightened with a wrench, which is calibrated by turning the nut at a certain angle. Such a tool allows a tightening torque of at least 1600 Nm to be obtained. Calibration of the device for M24 bolts is carried out before starting work. The described nutrunner can be equipped with replaceable tapered heads. They are overweight. As a result, it is possible to reduce the power loss due to twisting. The heavy weight of the heads is not their only feature. In addition, they are necessarily subjected to heat treatment. Moreover, it is performed so that the replaceable devices have a hardness on the HRC scale in the range of 35–45 units.

Tightening the high strength bolts

Tightening the high strength bolts

M24 bolts can be tightened not with one wrench, but with two at once. This technique makes it possible to obtain the most accurate torque. It is used quite often. In this case, the first key (called the small key) creates a torque of no more than 200 Nm. After that, take the second tool (large). And with this key, the final tightening is performed. It provides a torque of 1600 Nm. The tension of high-strength bolts M20, M16, M30 and so on (all except M24) is carried out in most cases with a reference to the axial force. The operation is performed with an electric or pneumatic key. It must be tared before assembling the metal structure.

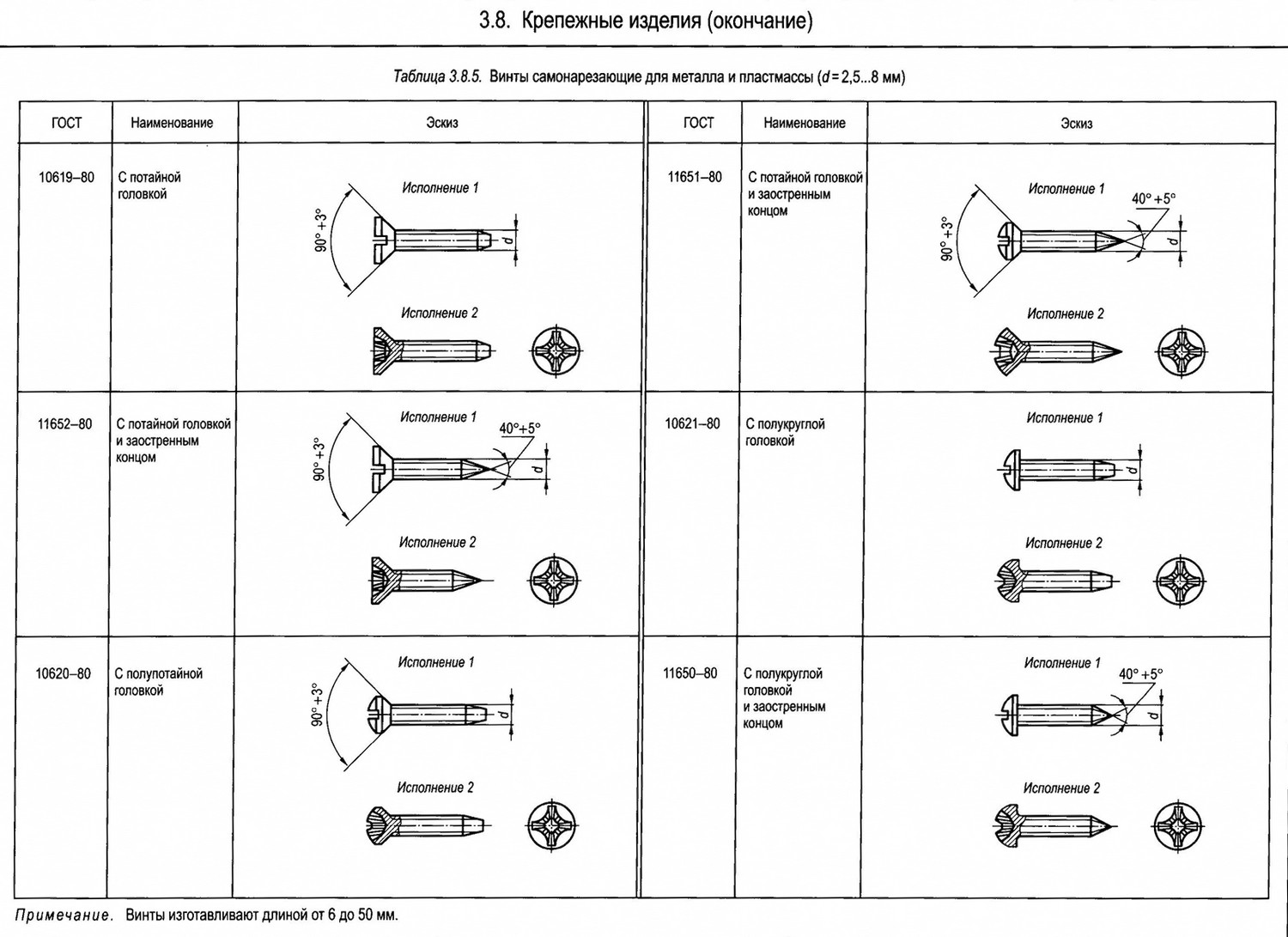

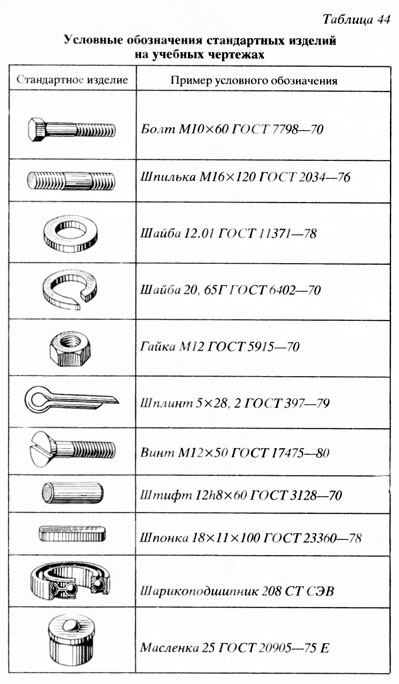

Product 2М12х1,50LH-5gx50.66.А.047 GOST 7798-70

- Product. In this place, they write the name of the part: bolt, screw, hairpin, etc.

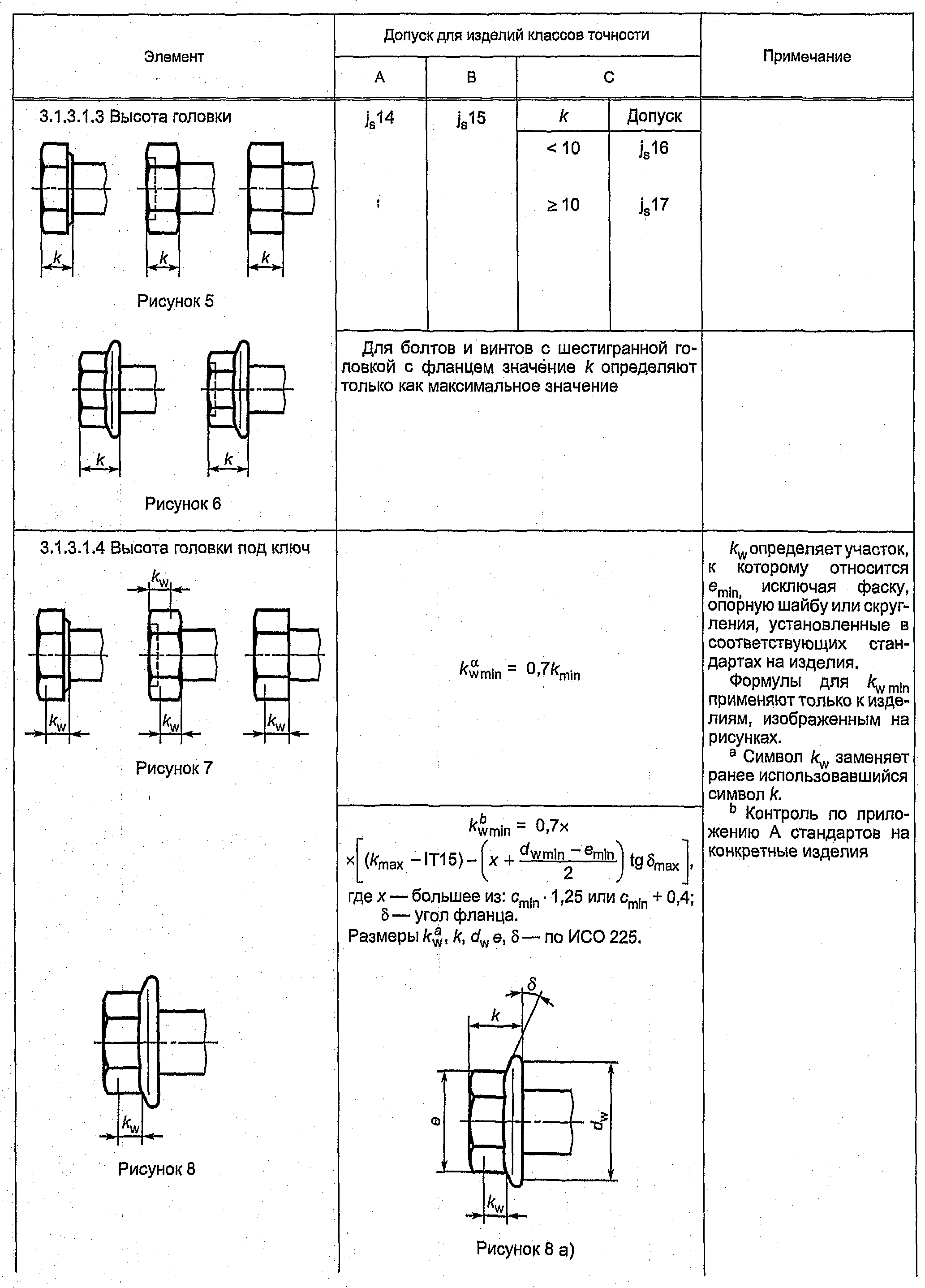

- The quality class is dictated by GOST, therefore it may not be specified. There are three classes - A, B and C, where the designation A speaks about the highest accuracy of the part.

- Number 2 denotes performance. There are only four types of performance. Execution 1 is not specified by default.

- M is the designation for the type of thread. The first letter of its name is indicated: metric, conical or trapezoidal.

- 12 - bolt diameter in millimeters.

- 1.5 - thread pitch, may not be specified if it is basic for a thread of a given diameter.

- LH - designation that this bolt has a left-hand thread. If the product is made with the main (right) thread, then this will not be indicated.

- 5g indicates which grade of precision the thread was cut. Classes can be numbered from 4 to 8, with 4 being the most accurate grade.

- 50 - bolt length (designation in millimeters).

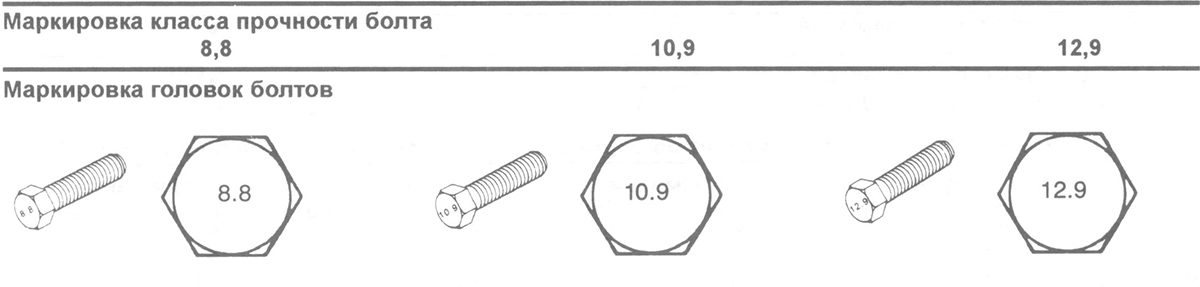

- 66 - product strength class. On the head of the bolt, these indicators are put with a dot between the numbers. Do not put a dot in the legend.

- A - the characteristic used for the manufacture of steel. In this case, it is indicated that the bolt was cast from free-cutting steel. The letter C says that the part was made of calm steel. This parameter characterizes the strength class of the bolt. This means that the class is higher than 8.8.

- 047 indicates the type of coating and its thickness on the product. There are several types of coating - from 01 to 13. In this case, the type of coating is 04, and its thickness is 07 µm.

The symbol of bolt fasteners allows you to meet the requirements for a specific product and design as accurately as possible. Compliance with quality standards is the key to successfully meeting project requirements. A note that the product complies with GOST allows you to study the properties of the part according to these documents and means its full compliance with standards. GOST standards correspond to other unified systems. To transfer from one system to another, it is enough to use the metric conversion table.

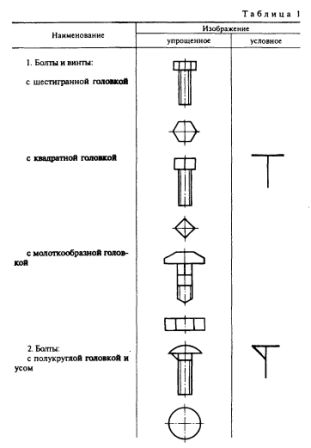

2

The symbol for hardware appeared in the USSR at the beginning of the last century. In the full designation, absolutely all parameters are indicated, starting from the name of the hardware and its strength class and ending with the number of the standard. It consists of 13 positions. The name of the product is indicated first, followed by the accuracy class. The third position is occupied by the execution of the product. Depending on the state standard, it can be in 4 versions. If version 1 applies, then it is not indicated. Products of version 2 have a hole for a cotter pin at the end of the threaded part, and 3 - a pair of through holes in the head. Hardware version 4 does not have any additional holes.

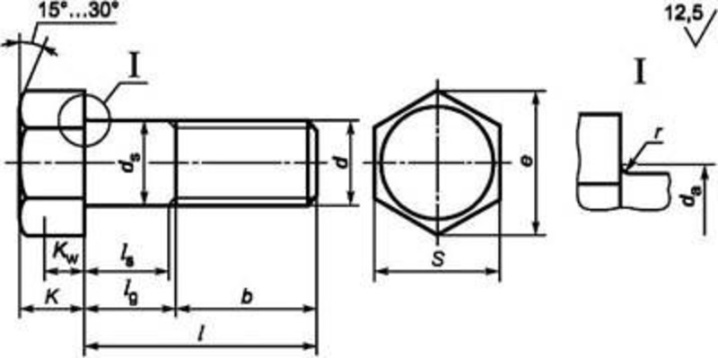

In the drawings placed in the reference books, such parameters as the length, diameter of the rod and thread for each type of hardware are marked. Further in the designation, the nominal diameter, pitch, direction and tolerance of the thread are specified. The eighth position is occupied by the length of the product. The strength class is indicated behind it. Moreover, in this case, the values of the nominal ultimate resistance and the yield point may not be delimited by a point.The following is an indication of the use of stand-alone or quiet steel. This is followed by the grade of the material. The last two positions are occupied by coverage information and the state standard number.

How are high strength bolts different from ordinary bolts?

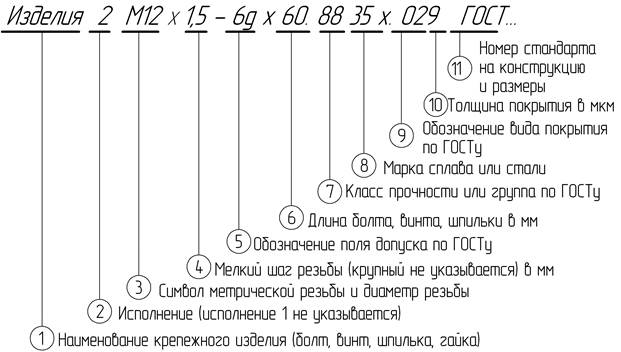

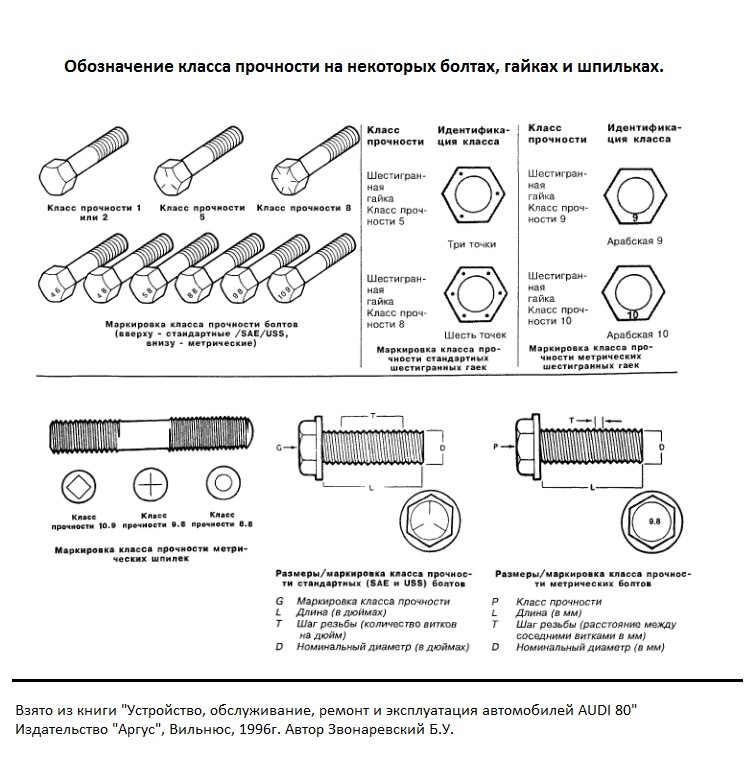

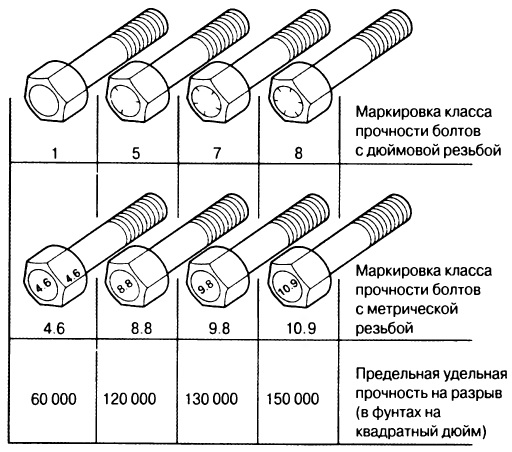

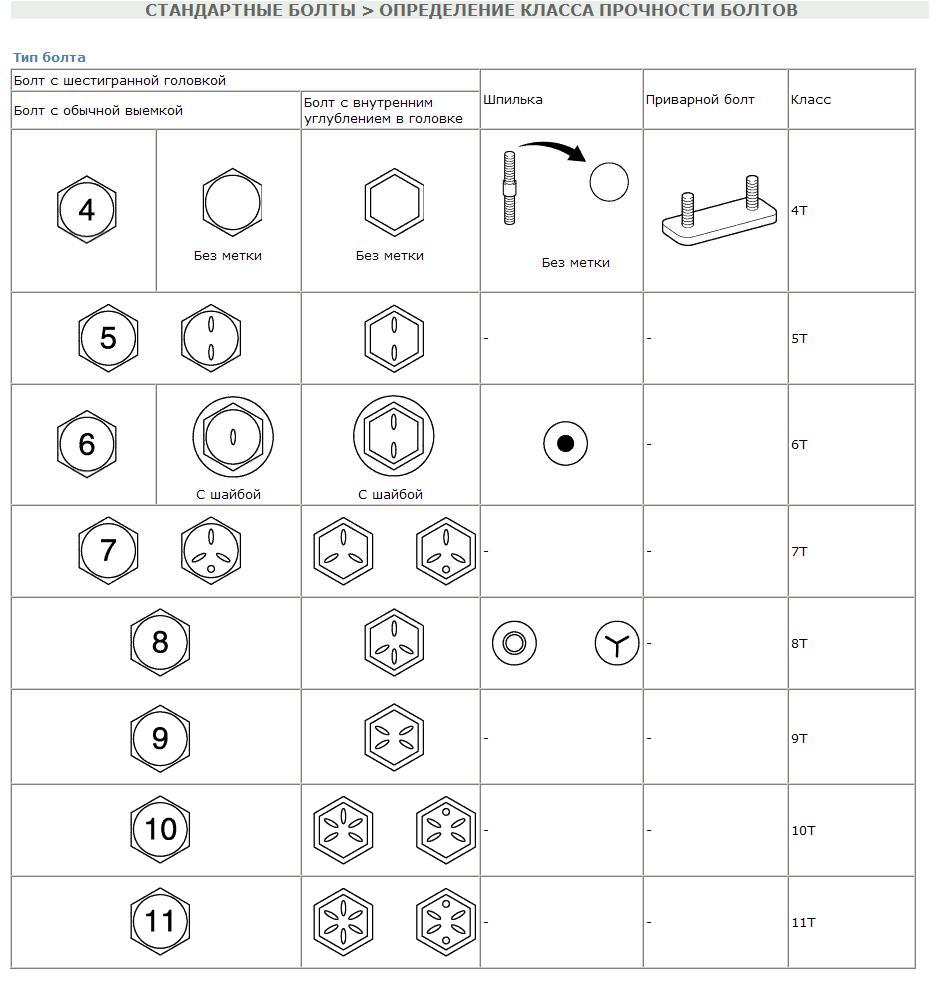

All fastening elements must comply with the strength class specified in the current GOST standards. There are 11 marking categories of strength class. Marking numbers indicate strength. Multiplying the first figure by 100 - we get the ultimate strength. Multiplying the second digit by 10 - we get the correlated tensile strength in interest rate.

High strength bolts are classified as grade 9.8, 10 and above. The main difference between ordinary bolts and bolts with the maximum strength class is the physical and mechanical feature that allows the fasteners to take a heavy load. Operation of high-strength bolts can take place in a harsh climate (Marking "ХЛ"), at an average cold temperature (Marking "U"). Bolts are made with thread m12 - m36.

4.5. Acceptance and sealing of connections subject to their complete disassembly

4.5.1. No matter the way

tension, the controller must first of all make an external inspection of all

high strength bolts supplied and ensure that all bolts are

the established markings, washers are supplied under all heads and nuts; speakers

outside the nut, parts of the bolts have at least one thread above the nut and

two under the nut; the assembled unit bears the stamp of the brigade that carried out these

work ().

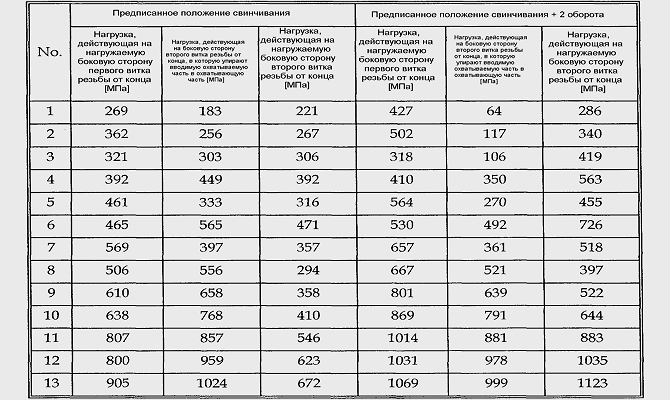

4.5.2. The number of bolts in the unit,

subject to control is indicated in table. 3.

Table 3

|

Quantity |

Quantity |

|

Before |

100 |

|

6-20 |

5 |

|

21 |

not |

4.5.3. If the results do not match

control to the requirements of clause 3.5.1. for at least one bolt, double

number of bolts. If in this case a defective bolt is found,

all bolts of a given connection are monitored.

Rice. 3

4.5.4. Control results

regardless of the method of tension should be recorded in a special log ().

4.5.5. Responsibility for

the quality of the bolt setting is borne by the contractor.

4.5.6 Package screed tightness

checked with a thickness gauge. 0.3 mm against the tightened bolt in the area,

limited by the washer. The stylus must not pass between the assembled parts into the area

limited by the washer (hereinafter the resulting washer).

4.5.7. At every connection like

as a rule, a core mark is applied to the team that performed the connection and the person

who made the control. The number of the stamp is assigned by order for the unit,

making connections. If the bolts are prepared using the waxing method,

the letter "P" is put with the stamp.

4.5.8. After accepting the connection

controller, all joints along the contour must be primed. If in the project

the object does not have a brand of primer, it is allowed to use primers

FL-03K, GF-021 with the addition of dry pigment to a consistency that excludes

flowing of the primer into the package.

4.5.9. Tension tool

bolting and surface preparation is adopted according to

«Application Guide set instrument for staging

high-strength bolts ". MMSS USSR Moscow 1985 ().

1

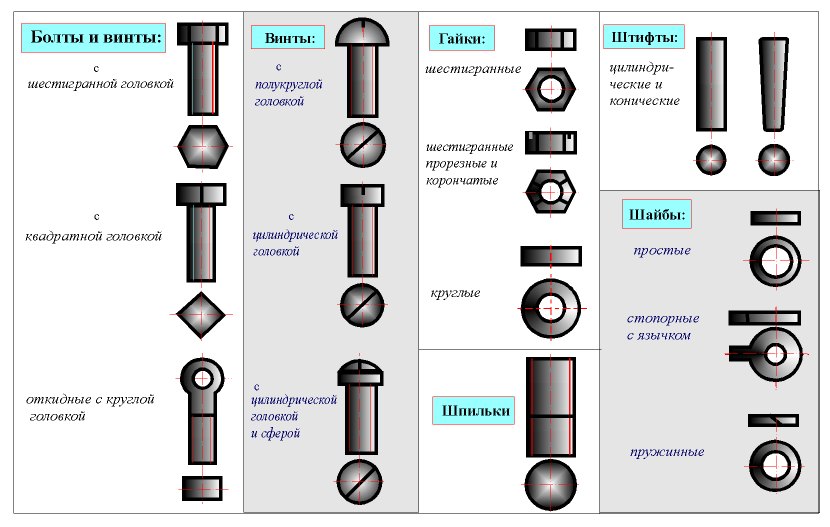

This fastener has found its wide application. It is impossible to imagine an industrial area that does not use bolts. Construction, aviation, mechanical engineering, shipbuilding, and just everyday life - in all these areas they are irreplaceable. With their help, you can get a strong, reliable and, which is very convenient, detachable connection. This fastener consists of two parts - a rod on which the thread is applied, and a head. It most often has a hexagonal shape.

Hardware are classified depending on the purpose, shape and strength of the product. Let us dwell on the concept of strength class in more detail.This characteristic determines the mechanical properties of the fastener. There are 11 classes in total. They are designated by two numbers, delimited by a dot. The first number multiplied by 100 corresponds to the nominal temporary resistance. For example, for fasteners with an accuracy class of 3.6, it is 300 N / mm 2. And multiplying the next figure by 10, we find out the nominal yield strength. For the above bolt, it will be 60 N / mm 2.

Furniture bolt

There are special ones with a strength class of no more than 5.8. They are used primarily in the construction and furniture industries. But plowshares and road fasteners can already have a higher strength class - 8.8. The first found their application in the installation of attachments for agricultural machines. The highest strength class (up to 12.9) is possessed by mechanical engineering products, since it is they who are involved in the assembly of critical structures.

The bolts are hinged in shape, manufactured in accordance with GOST 3033–78. Their feature is the head, made in the form of a movable part of the articulated joint. But the upper part of the eye-bolt, with the features of which you can get acquainted in more detail, having studied GOST 4751-73, is a ring. These products are especially relevant for the installation of installations, unloading and loading operations, for towing. And all thanks to the unique design. The bolt rod is screwed into the bore hole, and a hook can be hooked onto the ring, a rope can be tied.

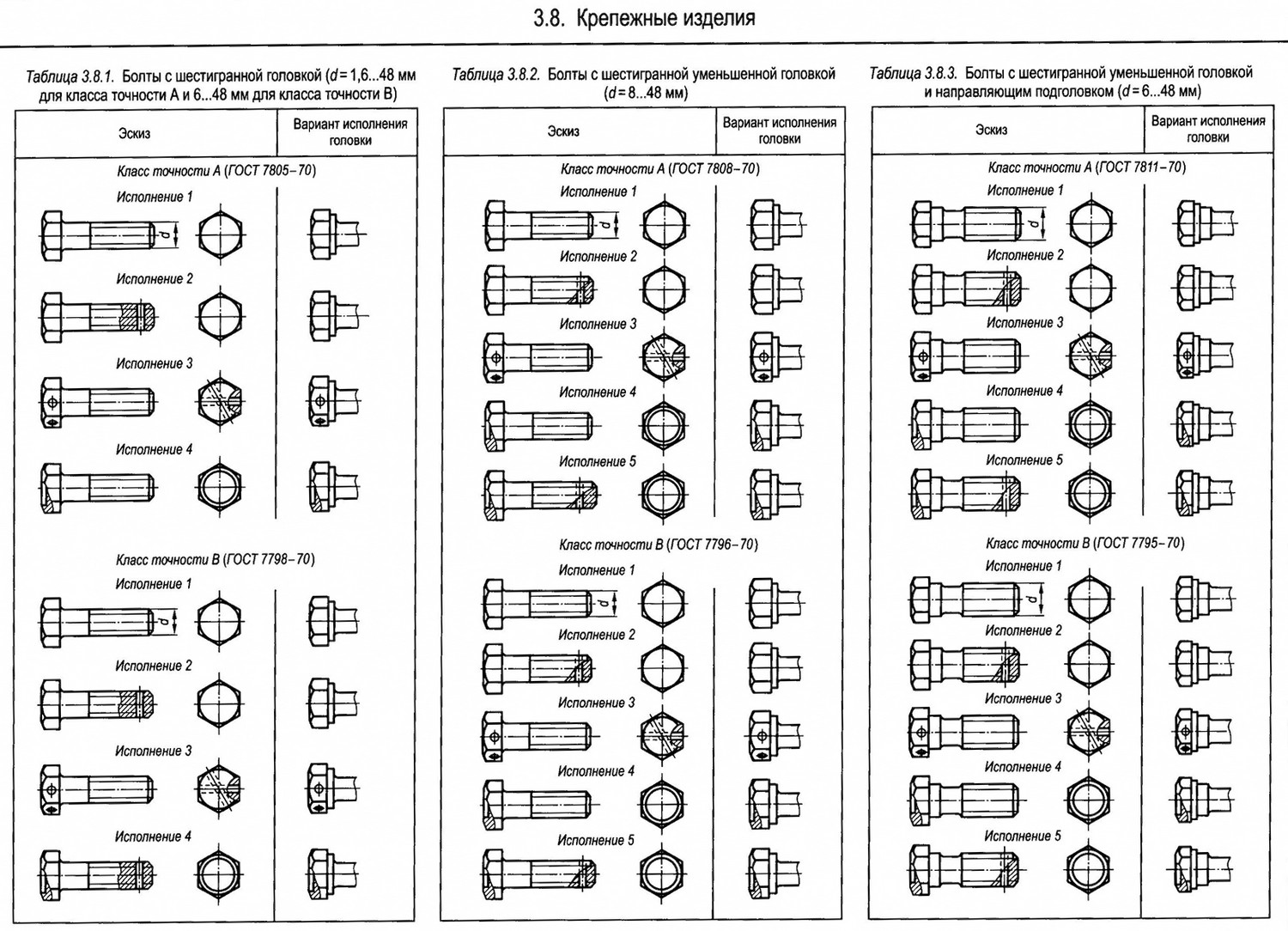

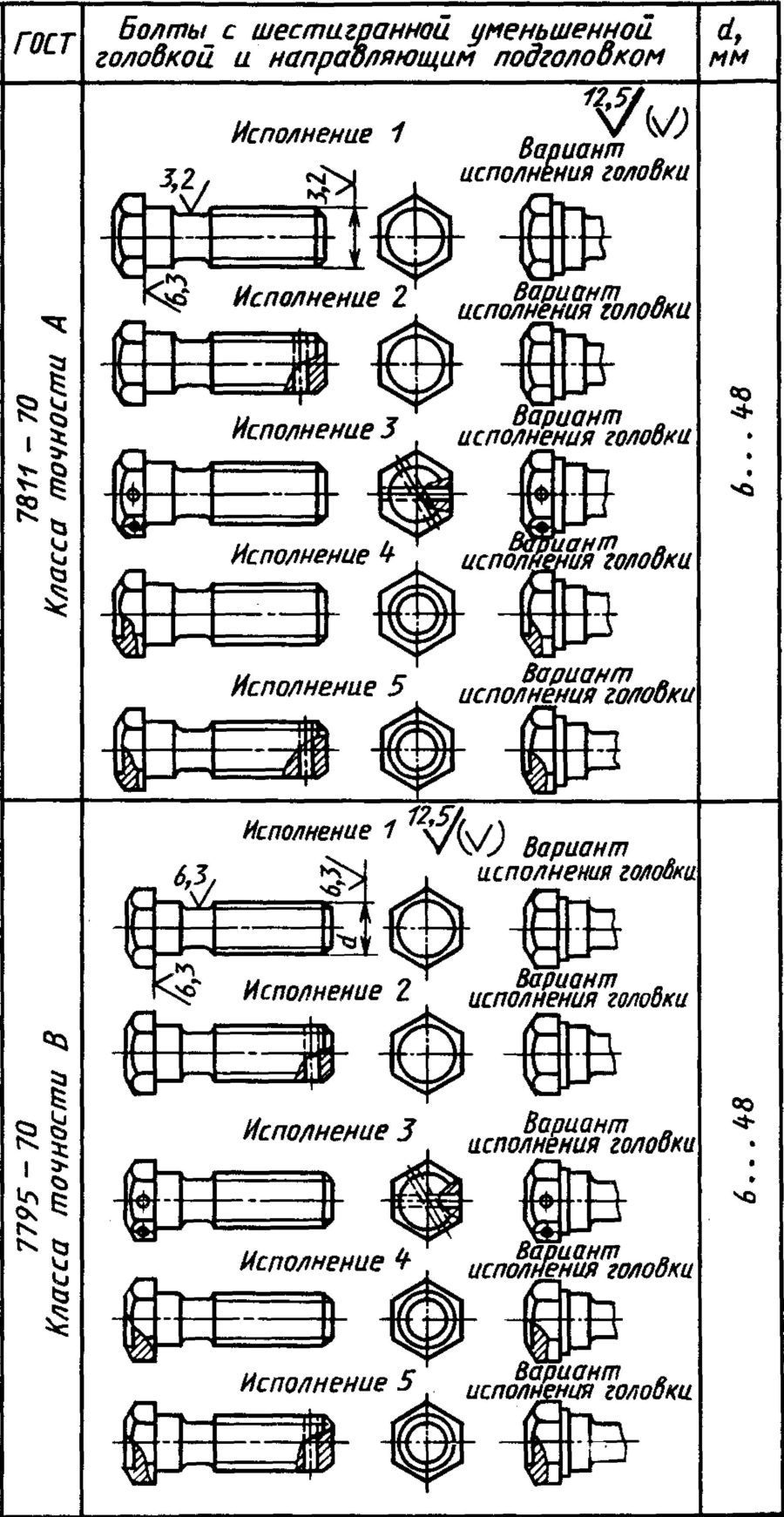

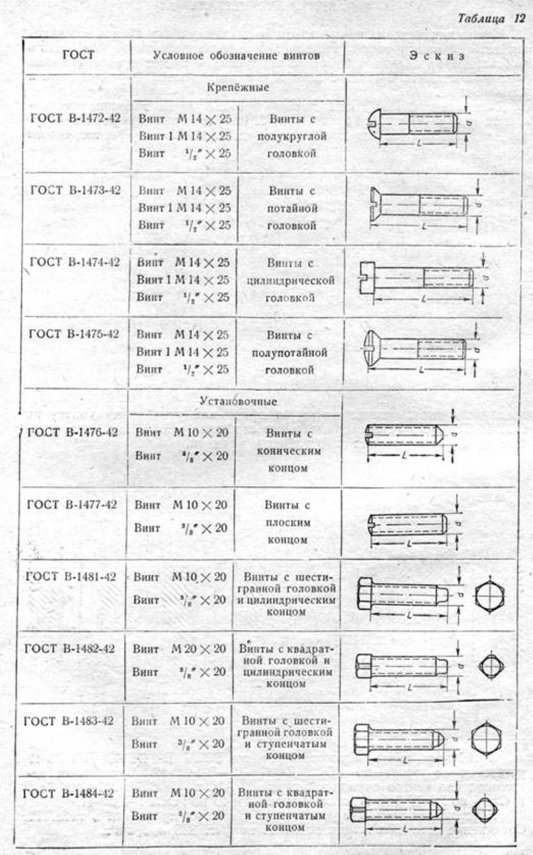

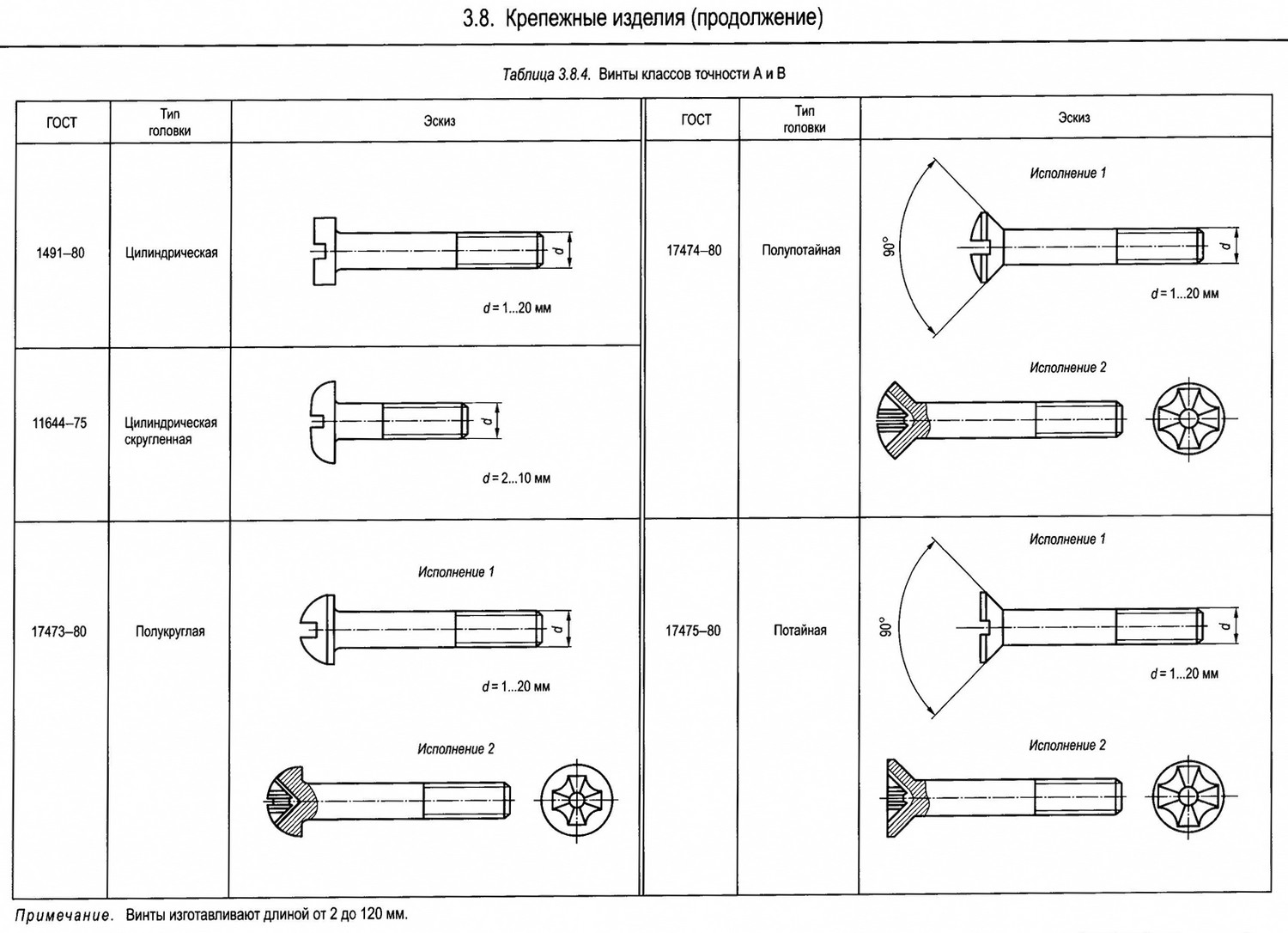

Bolt heads can be different. The most common one can rightfully be called a hexagon, which ideally fits a wrench. These products are manufactured in accordance with the requirements specified in GOST 7798.7817–80, 10602–94 and 18125–72. But there are also hardware with semicircular and countersunk heads (GOST 7783–81, 7801–81, 7802–8 and 7785–81, 7786–81, 17673–81). Noteworthy are products with a flange. Structurally, they resemble standard parts, only they have an additional flange. It looks like an ordinary nut.

Decoding numbers

The most complete marking of the mounting bolts is given in the table. It has both an alphabetic and a numerical meaning, and all these symbols are located in a strictly defined GOST order. If you indicate such a marking in the specification of a construction or installation project, any engineer can easily understand what kind of hardware is in question and what characteristics they have.

As an illustrative example, consider the designation of a hardware, for which the marking is located on the head: Bolt A3M12x1.50LH-4gx60.66. S. 097.

- The first is the product name. The word "bolt" can be replaced by the name of another product, which is subject to marking.

- The letter A denotes the accuracy class of the product. In total, there are 3 classes of accuracy: A, B, C. A means that the accuracy of the bolt is high.

- Number 3 tells us about the type of product execution. According to the standards, there are 4 types of execution, but type 1 is not indicated in the marking.

- The next letter M informs about what type of thread on the bolt shank. The type of thread is distinguished by conical, metric or trapezoidal. The letter M stands for metric.

- The number 12 indicates the diameter in millimeters at the bolt shank. It is noteworthy that only class A products have the M12 marking.

- The number 1.50 gives information about the pitch at which the bolt is threaded. If the thread pitch is standard for the diameter, it is not indicated in the marking.

- The letters LH indicate that the bolt has a left-hand thread. In the case where threading is done as standard right-handed, this is not displayed in the marking.

- The 4g designation indicates the accuracy class. The thread is cut with an accuracy on a scale from 4 to 8. The lower the indicator, the more precisely the thread on the hardware is made.

- The number 60 indicates the length of the bolt. In this example, it is 60 mm.

- The number 66 speaks of strength. These temporary hardness parameters are separated from the length by a dot.

- The next letter denotes the grade of steel alloy from which the bolt is made. The letter C means that the hardware is made of so-called calm steel. If the letter A was in the marking, it would mean that the steel is automatic.

- The numbers 097 show what kind of coating the hardware has. In total, 13 types of coating are distinguished, with the number 9 marking galvanized hardware. The number 7 denotes the thickness of the coating in microns, in our case the thickness of the galvanized coating is 7 microns.

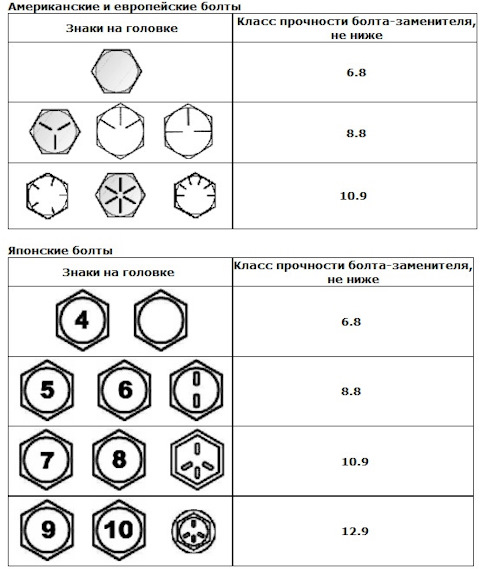

Uniform requirements for hardware and their marking, adopted in our country, make it possible to accurately and quickly select fasteners. For products of European or American production, the marking is different, since the dimensions are indicated in inches. Conversion tables are used to read inch designations.

All about bolt marking in the video below.

2 Nuts and Bolts Standards in Brief

At the moment, all threaded connections are unified according to international and state standards (ISO, GOST, DIN). The need for such a unification was obvious from the beginning, but not all manufacturers of nuts and bolts were striving for it. It was more profitable for them to have their own production standards.

The first unification system was invented by Vitvoort in 1841 in Britain. It is used by the British to this day. The following bolt thread standards also apply:

- the American carving system created by Sellers in 1864;

- a unified system (used in English-speaking countries), based on the Sellers and Whitworth systems;

- DIN - German system (there are standards DIN EN, DIN ISO and others);

- ISO is the metric standard system used since 1964 in many countries.

In the 1970s, ISO was upgraded by the US National Institute to ANSI / ISO. Now it is she who is considered the most common standard for threaded connections.

In the Soviet Union, and now in Russia and the CIS, GOSTs are more often used - mandatory state (interstate) standards.

How to properly tighten and unscrew the bolt

Most often, when tightening bolted connections on various structures in the household, ordinary wrenches are used - socket, open-end and ring wrenches. However, in this case, it is difficult to accurately determine the tightening torque, therefore, in industrial production and repair shops, experienced locksmiths use special torque wrenches or pneumatic wrenches, the main advantage of which is the ability to set the required tightening level, depending on the type of mechanism.

To unscrew the bolt, use the same wrenches, but in older designs, most often the bolts "stick" strongly to the nut due to corrosion. For safe unscrewing, several simple methods are used:

- use of penetrating grease WD-40 aerosol type;

- slight tapping on the rusty bolt with a hammer to break the rust in the profile of the threaded connection;

- turning the nut slightly in the direction of tightening (only a few degrees).

Areas of use

Several areas of use for extra strong fasteners have already been mentioned. But it can be used not only for metal structures in construction and mechanical engineering, as is often thought. These products are also needed for agricultural machinery and rail fastenings. The main feature is the suitability for such assembly joints that are exposed to very heavy loads, and where therefore standard fixing methods cannot be used. Such fasteners are in demand even in the most "heavy" construction - in the construction of bridges, tunnels, high towers and towers.

Any parts of high-strength bolts, of course, must have increased reliability and mechanical strength. All connections where such fasteners are used are classified in the shear-resistant category. When using such fasteners, you do not need to drill or clean the holes. You can screw a high-strength bolt not only into metal, but also into reinforced concrete.Separately, it should be said about the hexagon bolts.

There are also products with a reduced head height (and one of their subspecies is designed for small keys). However, products with an internal hex are good due to:

-

more convenience;

-

increased strength;

-

optimal reliability.

4.2. Assembly of connections on high-strength bolts when it is necessary to completely disassemble the connections

If necessary, complete disassembly

connections should be removed from the design load on a specially designed

project and restore the node using the following technology:

4.2.1. Technological process

assembly of connections provides:

- inspection of structures and verification

their compliance with the requirements of the project and the chapter of SNiP III-18-75 (in terms of the accuracy of manufacturing structures);

- alignment of holes and fixation

in the design position of elements and connection parts using mounting plugs

(10% of the number of holes, but not less than 2 pcs.);

- installation in free from traffic jams

high-strength bolt holes;

- checking geometric

dimensions of assembled structures;

- tight screed of the package;

- tension of the supplied

high-strength bolts for the force provided by the project;

- removal of plugs, setting in

the freed holes of high-strength bolts and their tension to the design

efforts.

4.2.2. Difference in thickness

elements overlapped by overlays, determined before placing overlays with

using a ruler and a feeler gauge, should not exceed 0.5 mm.

4.2.3. With a difference in planes

parts to be joined from 0.5 to 3 mm to ensure smooth bending of the lining

the edge of the protruding part must be smoothed with an emery stone at a distance of up to

30 mm from the cut of the part with a slope not steeper than 1:10. With a plane difference of more than 3

mm, gaskets should be used. The use of gaskets must be agreed

with a design organization.

4.2.4. Bolt lengths

are selected depending on the thickness of the package ().

4.2.5. When drilling holes

in elements with treated surfaces, cooling must not be used

liquids containing oil.

4.2.6. The assembly of the connections should be

produce directly on high-strength bolts and plugs. Applying other bolts to

assembly quality is prohibited.

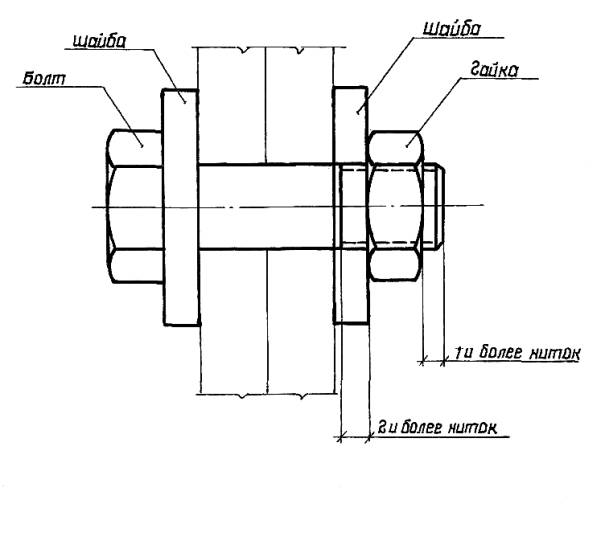

4.2.7. Every bolt

is installed in connection with two high-strength washers (one is placed under

the head of the bolt, the other under the nut).

4.2.8. Nuts tightened on

design effort, nothing is additionally fixed.

4.2.9. At the time of installation

high-strength bolts, the nuts should be free (by hand) screwed on the thread.

Otherwise, the nut or bolt should be replaced, and rejected bolts and

send nuts for re-preparation.

Material

The strength of the fastener is one of the most important parameters characterizing hardware. The strength of the fastening directly depends on the type of material from which it is made. Depending on the strength characteristics, the metal for production and the mode of its heat treatment are selected.

Most commonly, standard bolts are made from alloy and non-alloy steel. But in some cases, they can be made of other metals, such as copper, aluminum, which are used in cases where there is no need to achieve high strength of fasteners. For jewelry making, fasteners can be made from precious metals such as gold, silver, and others.

Very often, to improve the technical characteristics of hardware, a special coating is used that protects the fastener from environmental influences (humidity, water, temperature range, chemicals).

Among the most common coatings, the following varieties can be distinguished:

- Zinc. The thickness of the zinc coating can vary depending on requirements. For bolts used in household appliances, the thickness is usually small. But for industrial fasteners, it is usually up to 25 microns.

- Cadmatized.Not a very common type of bolt due to the toxic properties of cadmium. Therefore, they are used in rare cases when the coating from other materials does not allow achieving the desired performance characteristics.

- Nickel. Typically used for fasteners used in furniture manufacturing. Nickel increases only decorative characteristics, practically does not change the operational characteristics.

- Phosphating and oxidation. They are used to create a protective layer on the surface of bolts due to the oxidation of the base metal.

- Zinc lamellar. They are becoming widespread, as they can increase the service life of fasteners several times.

3 Connections at VPB - key provisions of SNiP III-18-75

The specified Sannorms describe the rules for the production of metal structures. They cover all existing high-strength bolted connections:

- With bearing hardware. In them, the transfer of shear forces is carried out through crushing, shearing and friction.

- Frictional. In this case, the forces are transmitted exclusively through friction.

- Bolt-welded, bolt-riveted and bolt-glued.

- Flanged. Such high-strength bolt connections are used in structures in which the fasteners work only in bending (flexible flanges) or in tension (rigid flanges).

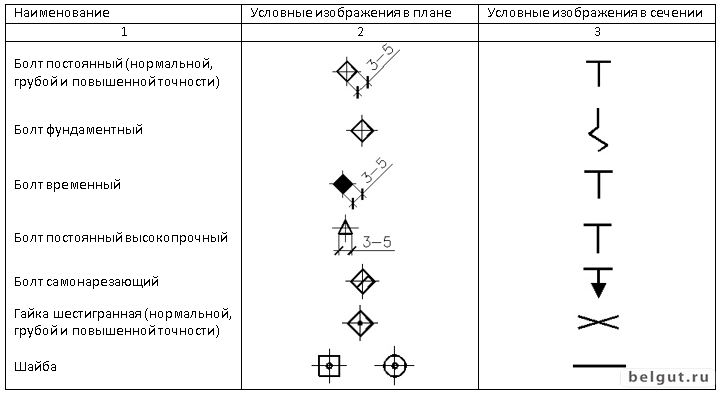

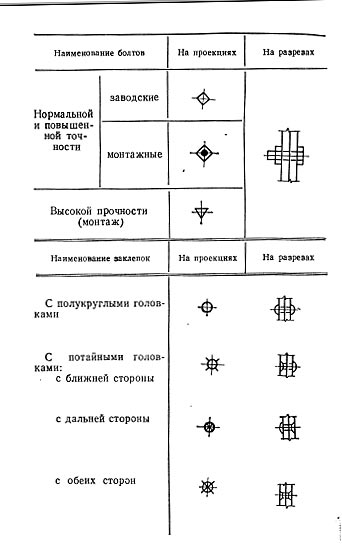

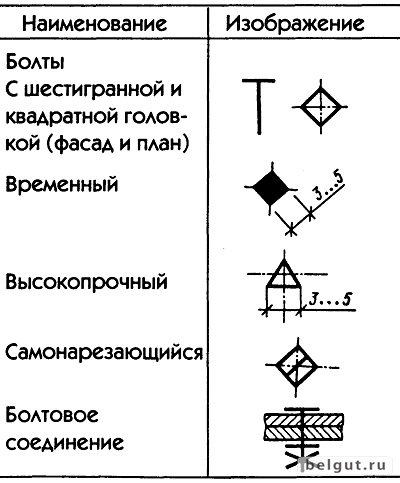

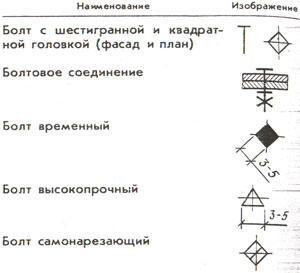

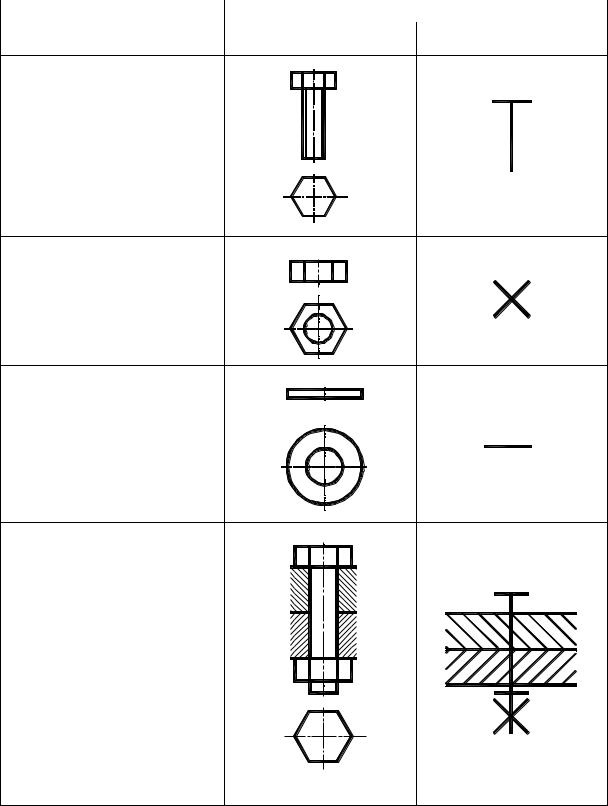

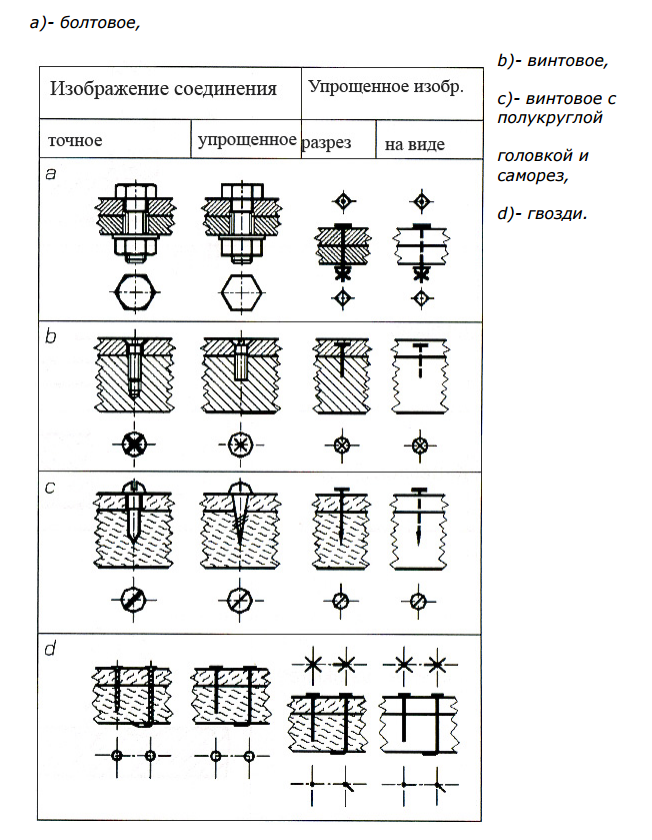

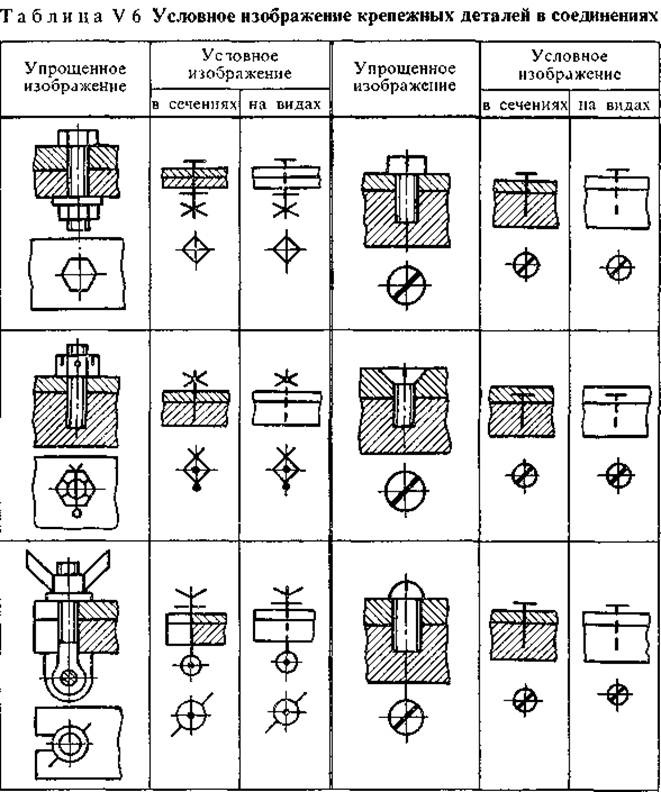

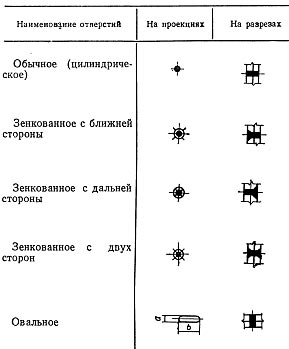

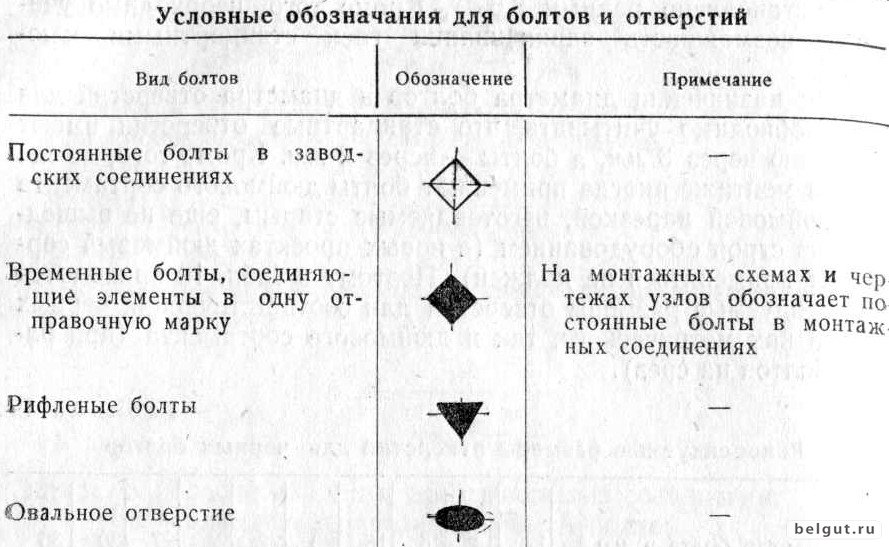

Separately, we note that any friction connection is designed according to special standards. They are set out in SNiP II-B.3-72. Other types of connections are developed according to the technical specifications of a specific manufacturer of work. They can be different. All bolted connections have their own designation in the drawings. It has remained unchanged since 1968, when State Standard 2.315 was put into effect.

Fastening high strength bolts

Fastening high strength bolts

The designation of VPB with a frictional connection has the form of an ordinary triangle. In the drawings of metal structures, which are assembled using VPB, the methods of drilling holes and their nominal cross-sections, as well as the type of connection, are indicated. This data is present in the first place. In addition, SNiP drawings require the following characteristics to be indicated:

- the grade of the alloy from which the bolts are made (40X Select or other steels), as well as GOST for the manufacture of the latter;

- axial force and method of tensioning the VPB;

- coefficient of friction;

- processing option for contacting parts;

- specification of bolts, washers and nuts;

- coefficient of resistance (temporary) to rupture of fasteners.

SNiP put forward special requirements for the sending parts of metal structures, which are connected by the bolts considered in the article. They are usually assembled in devices designed for this (most often in conductors) with fastening clamps. Holes for mounting hardware are drilled for the design section of the VPB (it is indicated on the drawings). Hole diameters are selected taking into account the operating conditions of the structure

Also in this case, the coefficient of shear stability of structures is taken into account.

Conclusion

For fasteners, GOST 27017-86 establishes terminology for various design forms. The nomenclature of fasteners established by the standard is mandatory for use in all types of documentation and literature using these standards. However, the definitions of various types of fasteners established by GOST are allowed to be supplemented by introducing derivative signs and characteristics of fasteners into them, revealing the meaning of the terms used in them, indicating the objects included in the scope of the defined concept.

Bibliography

- Iosilevich GB, Stroganov GB, Sharlovsky Yu. V. Tightening and locking of threaded connections .. - M.: Mashinostroenie, 1985. - 224 p.

- Gould D., Mikich M. Contact areas and pressure distribution in bolted joints // Design and technology of mechanical engineering. 1972. No. 3 ... - P. 99.

- Retscher F. Machine parts: in 2 volumes .. - M.: Gosmashmetizdat. 1933-1934

By accessing this page, you automatically accept