Advantages of Lego bricks

Lego brick as a business has a wide range of advantages:

- the popularity of this building material, associated with its design features - it looks like toy bricks familiar to everyone, it has grooves and guides, due to which it becomes possible to lay stones without developed skills and even without cement;

- as a consequence of the previous point, the dynamics of sales of Lego bricks is growing steadily;

- due to the novelty of production technology, there is little competition on the market now;

- general demand for bricks;

- stability of demand for products;

- great business prospects;

- no need for large financial investments for the opening of production.

Lego bricks are made not from clay, but from a concrete mixture, thanks to this, not only do you not need kilns for firing, but the raw materials will be much cheaper.

Lego bricks are made not from clay, but from a concrete mixture, thanks to this, not only do you not need kilns for firing, but the raw materials will be much cheaper.

Thus, the production and sale of Lego bricks is a great opportunity for an entrepreneur to start a business that is not particularly difficult to implement and will certainly pay off all costs if done correctly.

What assortment to offer to consumers?

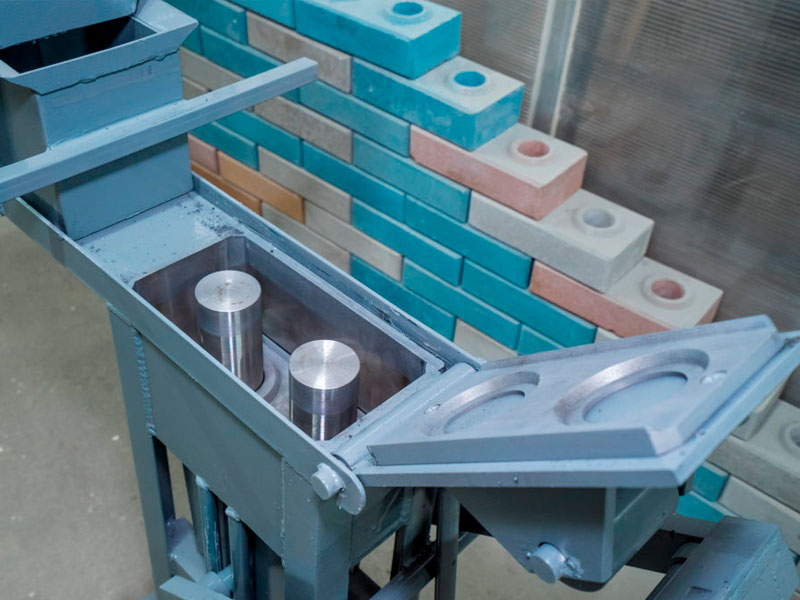

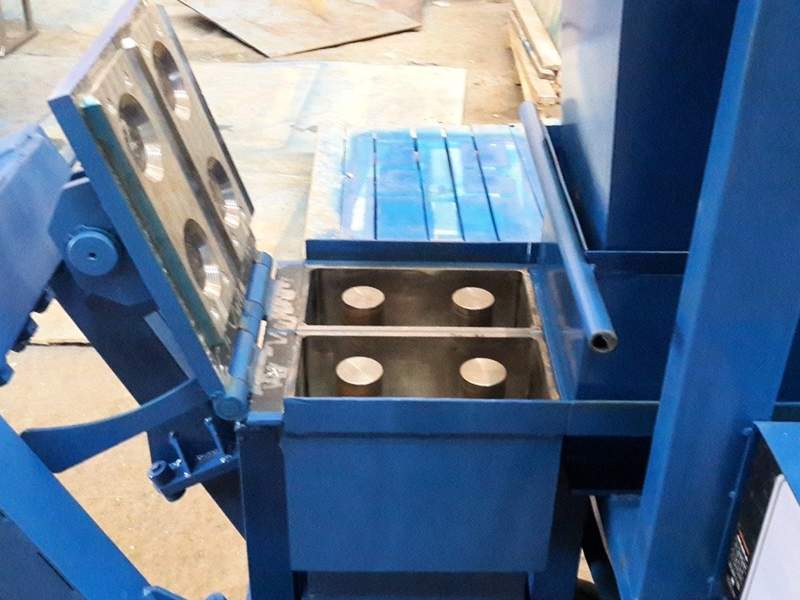

Whichever manual press for Lego bricks is chosen, it will be equipped with special dies. And it is from these matrices that what shape, what size and what kind of finished products will be produced will depend.

Matrix for Lego bricks will allow the entrepreneur to offer consumers a complete range of manufactured blocks. By replacing the molds on the machine, the following types of products can be obtained at the output:

- Standard brick This is the most popular type of all possible. And the sale of machine tools today, basically, is carried out precisely for such bricks. Even if there is no extra money for the purchase of additional dies, blocks of a standard form must be present in the assortment.

- Fitting brick. The dimensions of Lego bricks are exactly the same here, only they can be connected to each other with the side parts, and not just the upper and lower parts.

- Rail-like brick. Such blocks are stacked like rails. Among professional builders, such Lego bricks are quite in demand. Therefore, if you want to enter a large market with your own products, you must definitely acquire such matrices.

The price of the matrix is quite high - 25,000-50,000 rubles. But it is quite reasonable, given the technology of their manufacture and the raw materials used (high-quality hardened steel 54-65 HRC)

And when ordering this "detail" from a supplier, it is important to know what types of matrices are in general:

- Simple. Such matrices are intended for the manufacture of bricks by the piece. This is the simplest option available to many at its cost.

- Combined. The dimensions of the matrix in this case are designed for the simultaneous release of 2-3 bricks

- Original. Such matrices are made to order according to individual measurements. It makes sense to purchase such "templates" only when there is a specific order for a specific brick. And keeping such matrices in reserve is absolutely useless - an extra waste of money.

When deciding where to buy matrices for Lego bricks, it is worth considering that you need to choose them especially carefully. To last as long as possible, they must meet all quality standards. Otherwise, even a couple of technological cycles of the matrix will not last.

Equipment

The construction machinery market offers a wide range of equipment for making Lego bricks. Here you will find both large lines and mini plants for organizing a workshop in a small room.

Equipment price for lego brick making depends on the power, output and pressure that is applied to the raw material during the formation of the block.

From technology, you will need a crusher, a vibrating sieve, a mixer, a hopper, a dispenser, a hyper press, a mold for the production of Lego bricks and a steaming chamber.

The best equipment for making Lego bricks

We will look at the best installations that are suitable for organizing mini Lego brick production.

Below are both cheaper mechanical (manual) and hydraulic (semi-automatic) machines, the price of which is an order of magnitude higher. These installations are produced in many cities of Russia. You can buy a machine for the production of Lego bricks in Saratov, Krasnodar, Kirov, Blagoveshchensk, etc.

1. Hydraulic machine "Lego 180" - $ 2,540, manufactured by LLC "TechTron", Kirov; Allows to make bricks in the following sizes: length - 250 mm, width - 125 mm, height - 65-90 mm. The weight of the block depends on the raw materials used - 3.5 - 4 kg.

Specifications:

- Dimensions: 150 by 65 by 120 centimeters;

- Weight: 202 kilograms;

- Motor: 3 phase, 380V;

- Productivity: 180 pieces per hour, 1440 pieces per shift (3.8 m3);

- Product pressure: 8-10 tons (adjustable).

2. Mechanical machine "Lego 120" - the cost of 680 dollars was produced by LLC "TechTron", Kirov. Allows to make bricks with the following parameters: length - 250 mm, width - 125 mm, height - 65-90 mm. The weight of the block depends on the raw materials used from 3.5 kg.

Specifications:

- Dimensions: 160 x 50 x 110 cm;

- Weight: 89 kg;

- Productivity: 120 pieces per hour, 960 pieces / shift (2.5 m3);

- Product pressure: About 2 tons.

3. Mechanical machine cost - $ 630, manufactured by LLC "Stanki-Saratov", Saratov. Allows to make bricks with dimensions: length - 250 mm, width - 125 mm, height - 65 mm.

Specifications:

- Dimensions: 20 x 50 x 14 cm;

- Weight: 99 kilograms;

- Hopper volume: 40 liters;

- Productivity: up to 1000 pcs / shift;

- Pressure: 2 tons.

4. Hydraulic machine for Lego bricks SGU-2000 - $ 2,370, manufactured by Ferrum LLC, Kirov. Allows to make bricks with dimensions: length - 250 mm, width - 125 mm, height - 65 mm.

Specifications:

- Occupied area - 3 sq. m .;

- Productivity: up to 130 pcs / hour;

- Product pressure: 20 tons;

- Power consumption - 7.5 kW;

- 12 months warranty

5. Hydraulic machine for making Lego bricks - $ 6,360, manufactured by "ImportTechKom-invest" LLC, Blagoveshchensk. Allows to make bricks with dimensions: length - 300 mm, width - 150 mm, height - 100 mm. / Length - 250 mm, width - 125 mm, height - 75 mm.

Specifications:

- Machine type: hydraulic;

- Productivity: up to 1900 pcs. per shift;

- Size: 350 * 500 * 1000 millimeters;

- Pressure: 80 - 100 kN;

- Weight: 450 kg.

6. Hydraulic machine 5BRICKS40S - $ 4,650, manufactured by GlobImport LLC, Krasnodar. Allows to make bricks with the following parameters: length - 250 mm, width - 125 mm, height - 75 mm.

Machine parameters:

- The machine is hydraulic;

- Productivity: 200 bricks in 1 hour;

- The kit includes tooling for the manufacture of 3 types of products;

- Dimensions - 0.94 x 0.65 x 1.45 m;

- Hopper volume - 95 liters;

- Weight: 198 kg.

Premises and equipment

The production of Lego bricks can be organized in a room that meets certain requirements. The most important criteria include:

- Availability of ventilation, electricity, water and sewerage.

- Adequate lighting.

- Convenient transport access for loading / unloading.

- A place for a warehouse for finished goods and raw materials.

The location doesn't matter. The premises for production can be both within the city limits and outside the settlement.

The main equipment for making Lego bricks is a machine. It is not a problem to buy special equipment in Russia, because there are many offers from suppliers

When choosing, you should pay attention to the level of automation, productivity, availability of additional options and dimensions. An important criterion is the price

In terms of cost / quality, machines from the following manufacturers have proven themselves well - Atlant, Condor, AKS, Bricks.

The most important characteristics are the power and dimensions of the machine. So, if the room for the production of Lego bricks is small, it makes no sense to clutter it up with large equipment. The same applies to the power parameter.At the initial stage, there is no need to spend money on a high-performance line, because it will take a long time to recoup it due to the lack of stable orders.

The cost of the machine depends on the technical characteristics. So, a unit of small capacity, capable of producing up to 500 bricks per shift, will cost 400-450 thousand rubles. (for example, UGK-25 or AKS-1). The more efficient the device, the higher the price. So, a machine capable of producing 2.5 thousand products per shift will cost from two million rubles (for example, AKS 7, LY1-10).

During the production process, additional equipment will be required for the production of Lego bricks:

Matrices - needed to define the size and shape of the product

The appearance of the Lego brick depends on the quality of this node.

When choosing, it is important to pay attention to the surface on which there should be no burrs or roughness. In the process of making dies, steel should be used, and the optimal wall thickness is 6-8 mm.

Automatic mixers of solutions

The cost of products is at the level of 60-70 thousand rubles

and more. Special attention should be paid to the blades, which must be of high quality and withstand increased loads. The larger the blade area, the more efficient the work.

Transport belts. With this equipment, the workpiece is fed into the mixer or transported to the hopper. There are two types of ribbons - vertical or horizontal. Price - 100-130 thousand rubles.

You will also need a tool, without which it will not be possible to optimize the Lego brick production process:

- Shovels for dry material.

- Pallets for folding the finished product.

- Container for water and cement.

- Brushes for cleaning the belt, hopper or tray.

Despite such an impressive list of equipment, 2-3 people are enough for servicing. One must work with the machine, the second feeds the mixture, and the third controls the process.

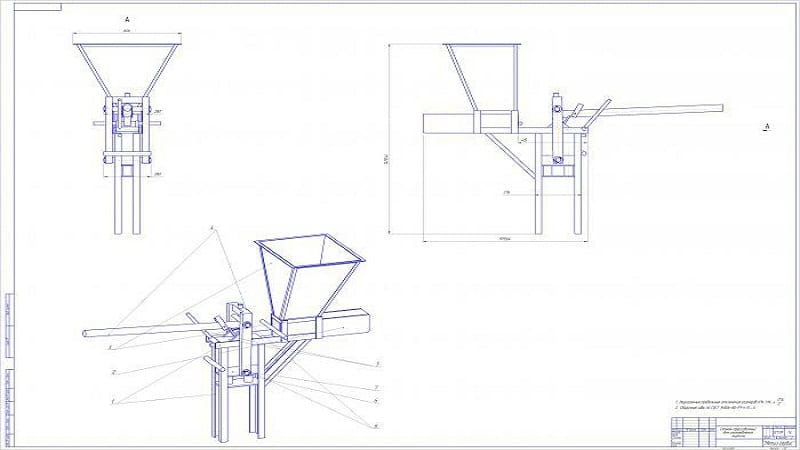

Making a brick machine yourself

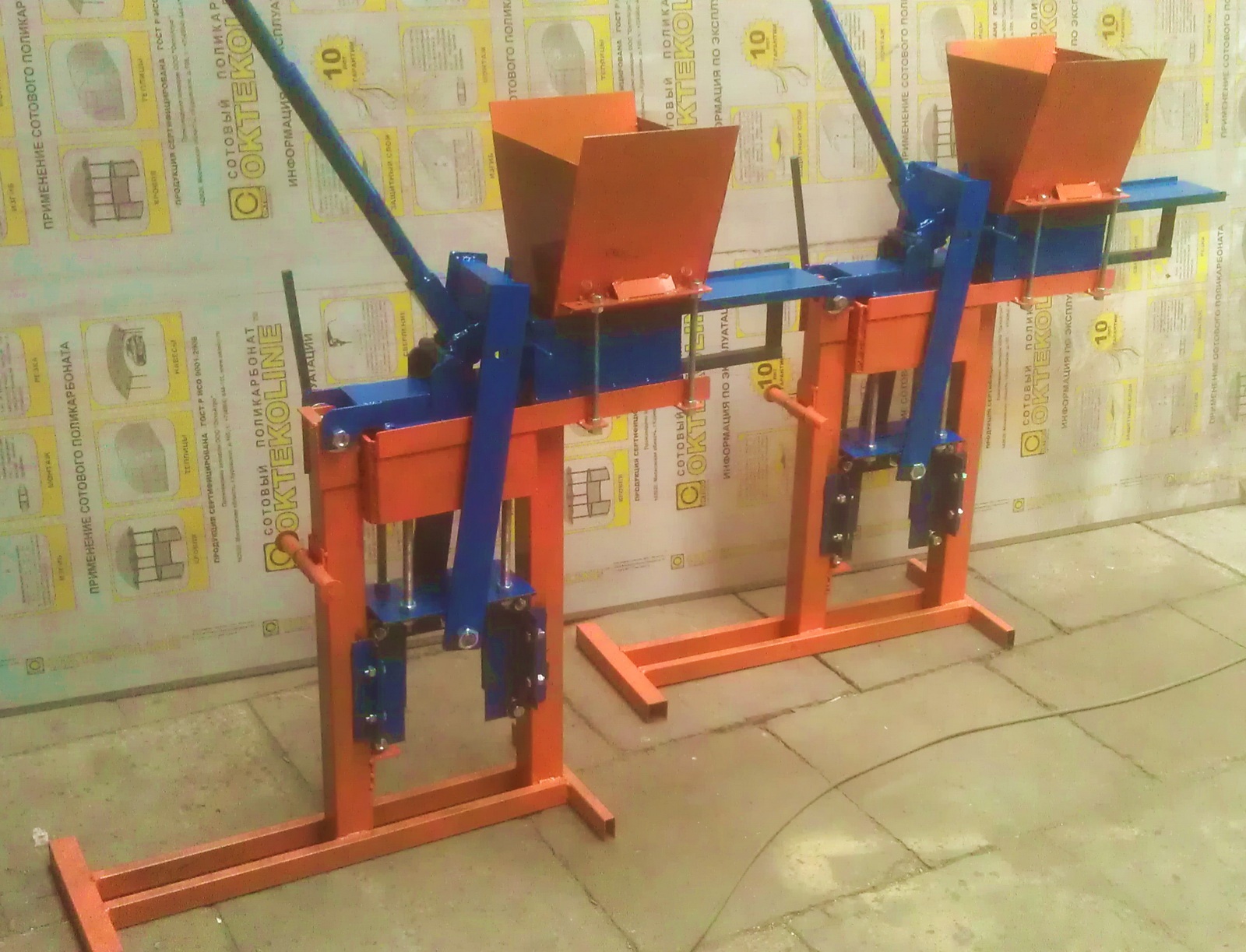

First you need to decide on a specific type of machine: with a manual or electric drive. The first option is much easier to manufacture and requires less costs from the entrepreneur.

It is important to note that the strength of such products is significantly lower than their more technological counterparts. According to experts, self-production of an automatic machine is not profitable for novice entrepreneurs.

In this case, you will need to purchase electric drives and other units, the cost of which is quite high.

It should also be noted that home-made machines make it possible to manufacture products that have a low margin of safety. Such products cannot be used in the construction of load-bearing structural elements, due to the high risk of cracking in severe frosts. The reason for the appearance of cracks is the high humidity of the manufactured bricks.

Waste from crushing limestone rocks, volcanic dust or sand are suitable as raw materials for Lego bricks.

Waste from crushing limestone rocks, volcanic dust or sand are suitable as raw materials for Lego bricks.

Required tools and accessories

To create a machine, you will need several sheets of steel, differing in thickness. The steel will be used to create the walls of the press. You will also need to purchase a channel and metal corners. In addition to all of the above, you will need thick-walled metal pipes for the manufacture of the piston and handle.

To work with sheet steel, you will need a welding machine and a grinder. In addition, you will need to purchase several discs to work with different metals. The press is attached to the corners with bolts and nuts. This means that you will also need a drill and special drills that can handle thicker steel.

Step-by-step sequence of work

To make a press, you will need to make a cylinder from steel sheets. The dimensions of this cylinder must correspond to the volumes of the manufactured products. Next, you need to divide the channel into two segments one meter long. Press stands will be made from these sections.Two metal rectangles must be placed between the tops of the rack to create a cross-section. These rectangles are welded to the uprights.

A channel is installed on top of the resulting structure. Its length should be seventy centimeters. The channel is welded with ribs pointing up. One of the parts of the channel should protrude beyond the structure itself. Supports are welded to this part. At the end of the welding work, a hole is cut out inside the cylinder.

For the manufacture of the hopper, pre-prepared metal sheets are used. The dimensions of the hopper outlet must be equal to the dimensions of the product. To attach the hopper to the protruding part of the structure, special legs made of metal strips are used. When attaching the legs, it should be borne in mind that the shape itself should easily slide along the edges of the rail.

For the manufacture of the piston, rectangular metal sheets are used. Through these sheets it is necessary to pass two pipes that will be used as a handle to open and close the lid. Bolts are used to fasten the handle to the main structure. The corners are used to make the base of the unit.

Lego brick is a simple and ingenious solution in construction

Lego brick is a simple and ingenious solution in construction

Technological nuances

A hand-made Lego brick machine will be inferior in strength to those products that are made in the factory. In order to better understand all the features of this production, let's get acquainted with the technological process. A mixture of clay, cement and sand is used to create raw materials. The mixed raw material is poured into the hopper.

Further, a special dispenser takes away part of the mixture required to create one product. This mixture goes to the die of the press, where the brick itself is made. The bricks produced must be thoroughly dried in natural conditions. Drying time depends on the quality of the raw materials used. As practice shows, when choosing raw materials, one should take into account the characteristics of the existing equipment. Complete with industrial equipment, there is a user manual, which lists all the basic requirements for the materials used.

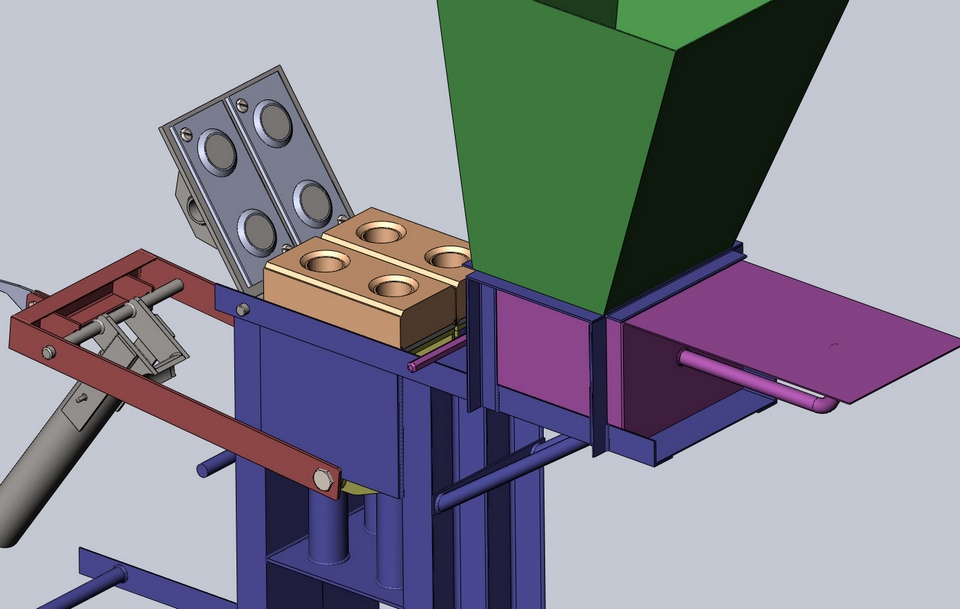

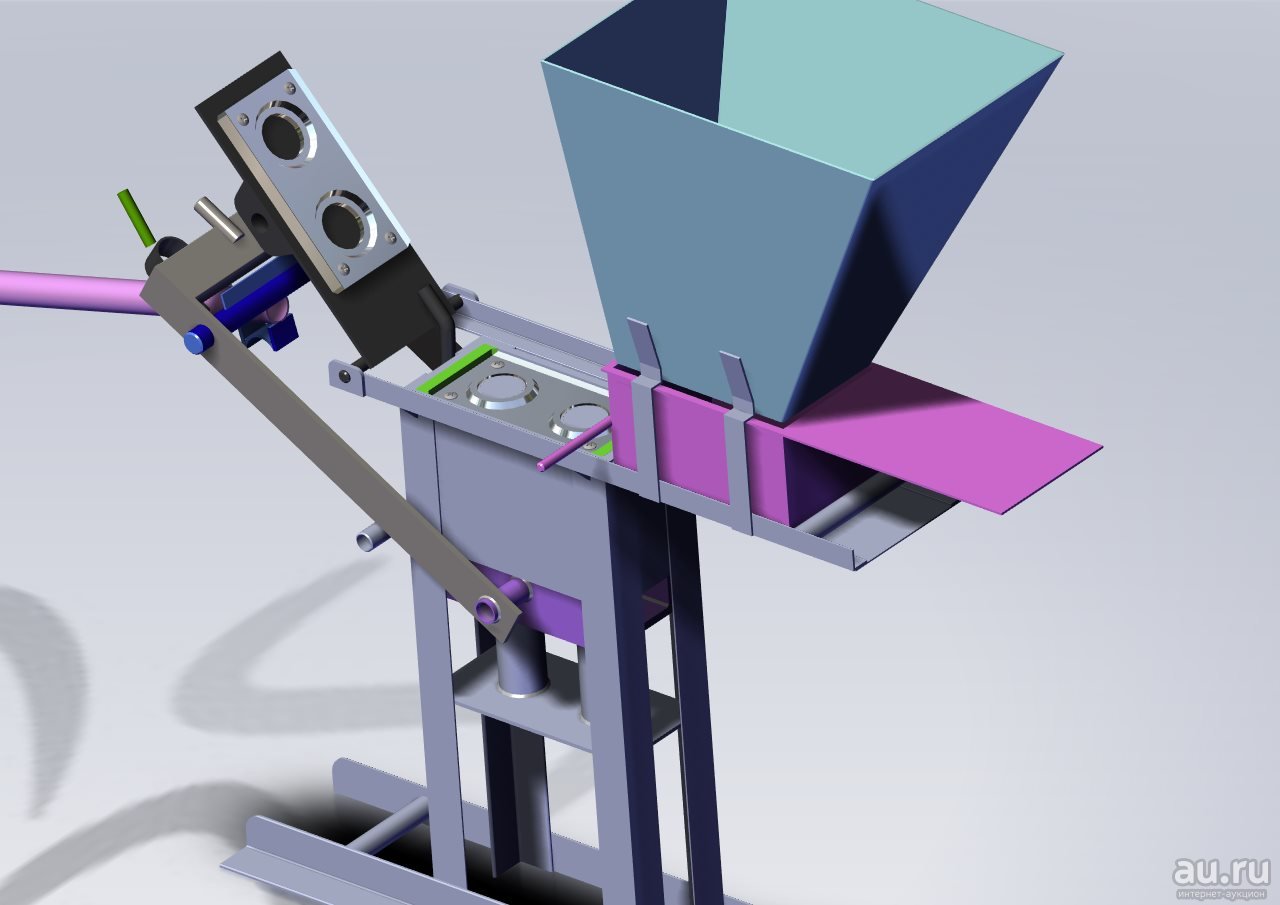

Description of equipment

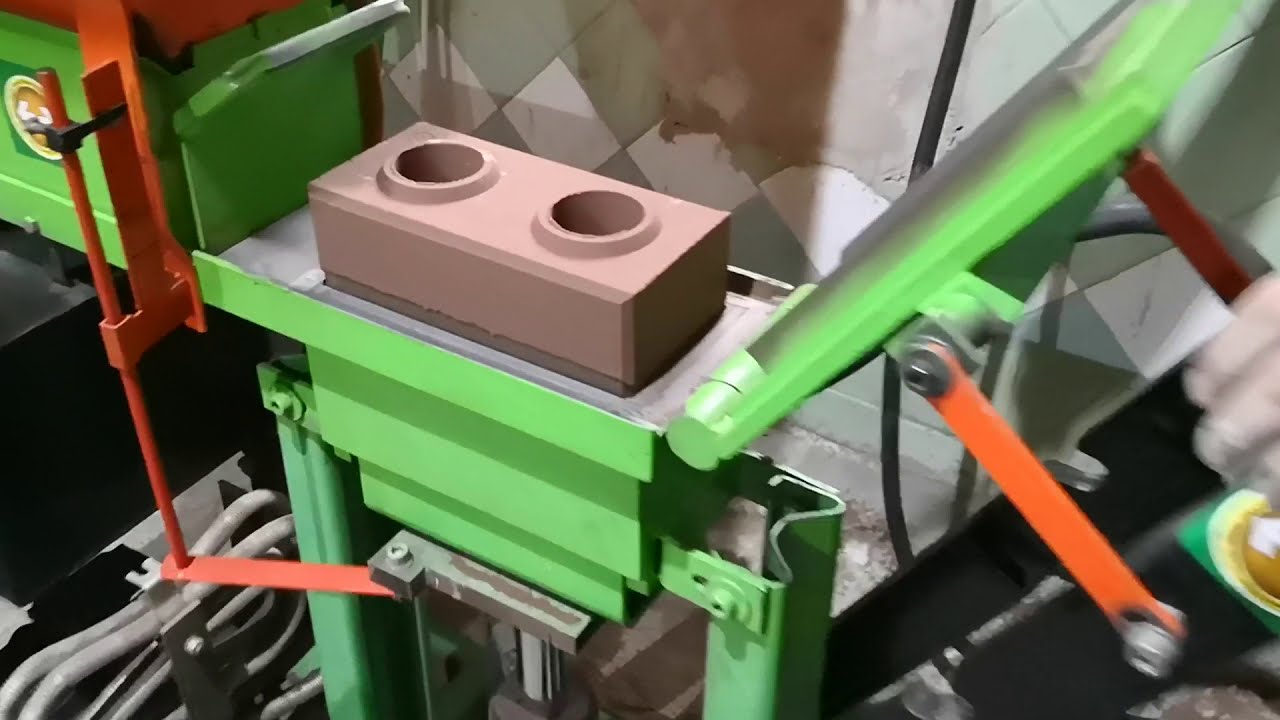

A lego brick making machine is a structure that includes certain units mounted on a metal frame. The Legostanok considered here allows semi-automatic production of Lego standard bricks.

The unit allows you to obtain Lego bricks by pressing under high pressure, without subsequent firing in thermal furnaces.

Operating principle

The prepared mixture for the formation of bricks enters a special hopper, then, with the help of a dispenser, the mixture enters the molding space, then with the help of a hydraulic press, the mixture is compressed under high pressure, as a result a finished product is obtained.

The machine is equipped with a three-phase electric motor and an oil pump to pressurize the hydraulic cylinder.

Unlike analogs with a manual pressing mechanism, Legostanok using a mechanized compression process allows you to achieve higher pressure and increase the productivity of the process.

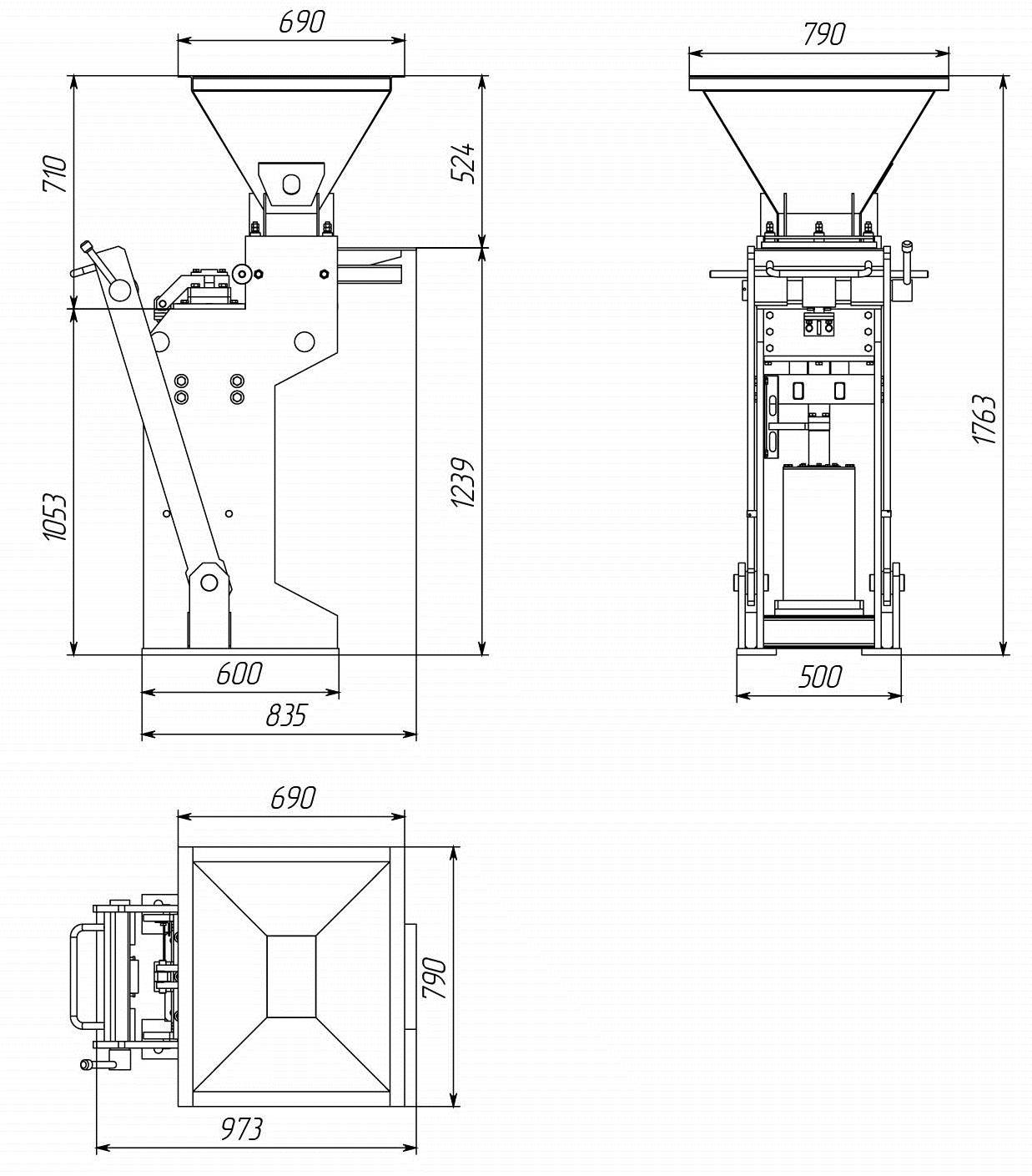

Specifications

The parameters of the machine are optimal for its placement in a limited area. The correct organization of labor and preparatory processes in obtaining the mixture allows you to achieve high performance.

- height - 1200 mm;

- length - no more than 800 mm;

- width - 650 mm;

- hydraulic pump drive of the press - electric (manual);

- electric motor power - 3000 W;

- required power supply - 380V, 3-phase connection system;

- the maximum developed pressure by the press is not less than - 40 kg / cm2;

- average time of brick formation in the press chamber - 10 s;

- the maximum amount of finished product output with timely loading of the receiving hopper is about 200 bricks / hour (for machines with a hydraulic drive).

The main components of the machine include:

- loading hopper;

- manual mixture dispenser;

- forming chamber;

- a matrix that allows you to get the proprietary geometry of the holes of the Lego brick (located in the molding chamber);

- electric motor;

- oil pump;

- hydraulic press (powered by oil pumped by a pump);

- machine frame.

Modes of operation

The machine can operate in manual and semi-automatic modes. Manual mode provides for the process of forming products by using a lever mechanism capable of creating the required force in the press sole. The semi-automatic mode of operation allows the operator only to open the valve on the hydraulic line at the right time, forming is carried out using a hydraulic press.

Semi-automatic mode increases the productivity of the machine by 1.5–2 times. The finished product is of a higher quality, since it is possible to achieve the required pressure for the adhesion effect of the substance at the molecular level. Characteristics of bricks that can be produced on the machine

The brick obtained on the machine has two convex spherical holes on its upper plane, and two holes with a concave sphere on the lower plane. This is the hallmark of the Lego standard. This geometry allows you to clearly fix products during construction using adhesive solutions.

Geometric dimensions of the finished product:

- length - 250 mm;

- width - 125 mm;

- height - 45-80 mm;

- weight - 3.5–4 kg (depending on the component composition);

- maximum withstand pressure - 300 kg / cm2.

The material from which the products are made usually has the following varieties:

- clay-cement composition (90% clay, 8% cement and water);

- clay-sandy composition (35% sand, 55% clay, 8% cement and water);

- composition based on various screenings (85-90% screenings, 8% cement and water).

Production planning takes into account the availability of raw materials. The bricks obtained by the pressing method require raw materials of a fine fraction, this must be taken into account in order to achieve the required strength.

Products made from screenings have the highest strength characteristics. High sand content degrades the strength index due to the presence of coarse sand fractions.

The production of lego products should include the presence of special molding dies, with the help of which a surface with the required smoothness and specified geometric dimensions is created.

For a full-fledged production, it is necessary to have the entire set of matrices that allow you to obtain halves of bricks and fitting products used in finishing work.

Brick making technology

To understand the key subtleties of making bricks, pay attention to the key components of the machine. They include:

- hopper for dry mix;

- dispenser;

- a brick formation chamber with a matrix that determines the future shape and dimensions;

- electric motor (it is absent in manual models);

- oil pump and hydraulic press;

- the frame of the entire structure.

Design features may vary depending on the model and type of equipment, but the main components look exactly like this.

The production technology itself consists in the use of high pressure, which acts on the loaded mixture, while the filler is literally sintered with cement and water. This method is commonly referred to as "cold welding".

The production technology itself consists in the use of high pressure, which acts on the loaded mixture, while the filler is literally sintered with cement and water. This method is commonly referred to as "cold welding".

The production principle is as follows:

- The entire dry mixture is placed in the hopper, which is thoroughly mixed.

- Then the working mixture is transferred to a special container - a tray.

- After that, it falls on the matrix, and the press acts on it from above for several seconds.

- At the next stage, the platform with the brick moves up, and the press goes back.

- The worker can now remove the finished product and transfer it to a pallet for subsequent steaming or drying.

- The finished product must be placed in a separate room for several days, where strength will be gained. The exact drying time is determined by the type of equipment.

Lego Brick Making Machine

To develop your own business or meet your own needs, you can purchase completely different machines for making Lego bricks: manual, energy-free and electrical, with high performance.  Lego brick machine price and performance:

Lego brick machine price and performance:

- Low productivity machines are about 1000 pcs. per shift, these include manual and electric with low power, the price for them starts from 78,000 and up to 300,000 rubles.

- Medium category machines produce about 2,000 pieces in one working day, the cost is from 350 thousand rubles.

- Industrial machines and mini-factories can produce 750 bricks in one hour, but the price will also be high - over 2 million rubles.

For small volumes, a small machine with a weight of 750 kg is suitable. Its dimensions are: height - 2 m, width - 1 m, length - 1.5 m. As you can see, it will need a small room, 9 sq.m. is enough. But if you buy more powerful equipment, then you will need additional space.

When buying a machine, pay attention to how many work cycles it can withstand: for a manual machine it is 500,000 cycles, and for an electric one the value will vary from 600,000 to a million. The next parameter is the amount of time it takes to make one brick, the average is 15-30 seconds, it also matters how many bricks can be obtained at a time, usually from one to 6-8 pieces

This increases productivity and the cost of the machine will pay off faster. A lot of pressure is required to obtain a stronger brick. Some machines only exert a pressure of two tons, for the construction of some buildings this may not be enough. In order to obtain a brick suitable for the laying of load-bearing walls, a pressure of 30 tons is required.

- The Dobrynya construction equipment plant, their machines are called "Hammer" and "Bulava", are intended mainly for the manufacture of large batches in a short time.

The Legostanok company specializes in equipment for the production of Lego bricks. All equipment is made from Swiss steel.

LLC "Artel Builders" will provide a wide choice for the purchase of machines designed for small production.

The Zeus group of companies offers to purchase machines with the same name, their purpose is small production.

Foreign manufacturers are represented by countries such as Brazil, Turkey, Italy and Spain. Their machines make bricks under pressure no higher than 18 tons. This is due to the fact that the climate in these countries is very warm, therefore materials with less frost resistance are suitable for construction. China uses the developments of European countries, so their products are quite competitive in the Russian market, especially since the equipment is distinguished by low prices. But for all products of foreign suppliers, you can find both positive and negative reviews, but all buyers agree on one thing - their cost is much higher than that of domestic counterparts.

How to start a Lego brick making business - where to start

Any business starts with an idea and financial calculations.

After that, we open production.

Step 1. Register a business

Before starting commerce, choose the form of a new organization. LLC and individual entrepreneur produce products in the same way, however, each type of business has its own characteristics.

Let's highlight the main ones:

- Individual entrepreneur keeps simplified accounting records, pays less state fees. Such an organization is the company of one particular person.It cannot accept other founders. Personal savings or property of the citizen who organized the IP are accepted to correct the financial mistakes of the organization.

- LLC maintains reporting in full. Terms of registration of the company 2.5 months. The organization is owned by 1-50 people. The company is responsible for financial mistakes only with its property (authorized capital).

Please note: IP cannot be sold. With this form of organization, only material values are sold (equipment, raw materials, finished products)

A business with a full package of documents for a company can only be sold by an LLC.

Step 2. We select a room

A big plus of the Lego release is the minimum space requirements for the production line. Small machines are placed on the construction site, in the garage, in the backyard, etc.

When a line with a capacity of more than 600,000 pieces / year is launched, the workshop is equipped.

Basic requirements for the production facility:

- an area of more than 100 m² (including premises for storing raw materials and finished products);

- the height of the ceilings is calculated as the height of the equipment + an increase in loading (with a horse feed of raw materials);

- operating communications (electricity, water, heating);

- good ventilation.

Step 3. We buy raw materials and equipment

Having determined the budget of the enterprise, they proceed to the purchase of machine tools and additional equipment.

The main parameters for choosing a machine:

- productivity (manufactured quantity per cycle / day / month / year);

- time of one cycle;

- pressure;

- number of matrices;

- mold thickness;

- operating mode (manual, automatic).

Without good equipment, the quality of the products will be low. Study the offers on the market in detail and compare them with your requirements.

When choosing between a machine that presses bricks faster and compresses the shape more strongly, choose the latter. It is better to make fewer products that customers will buy than to make mountains of scrap.

Environmentally friendly raw materials are available in all regions.

To select it, they evaluate:

- customer preferences;

- the price of the main material;

- the cost of the binder, plasticizers and dyes;

- availability;

- quality.

The production line is designed for repeated changes in raw materials and recipes. At the preliminary stage, several options for the starting material (filler) are selected: sand, clay, dolomite, marble chips, slag, etc.

How to choose a machine for the production of Lego bricks - useful tips and tricks

The quality of the manufactured products affects the company's profit.

To reduce the number of rejects, product returns and losses during exchange, follow these simple rules:

Choose machines manufactured in climatic conditions close to us. Equipment manufactured in warm regions (Turkey, China, Spain) is not designed for the humidity and frost of our country. It develops less pressure. The masonry obtained on such a machine will not be of high quality. This will be seen by consumers and the demand for such products will be low.

Do not use cementless clay mixtures in regions where the air temperature drops below -20 ° C, or subject it to additional processing. Without further firing, such masonry will crack in frost.

Install the machine with a pressure force of 50 t. The higher this indicator, the better the product

Pay particular attention to the mass that presses on the raw mix to form

Strength, moisture resistance, frost resistance depend on it.

This is especially important if the product will no longer be processed in any way (steam, autoclave, etc.). Don't buy homemade machines

Their drawings are widely available on the Internet. Amateur engineers are mastering the independent production of such equipment. Their machines are cheaper than industrial designs, but they do not guarantee either long-term operation or high quality of products.Remember, a miser pays twice, and you will have to return money for crumbling masonry.

Do not use bricks immediately after making them.

The strength of the manufactured product depends on the preparation of the product after leaving the press:

- No further processing. Such a product reaches 40-50% of the strength of the formulation used.

- Survival. In a well-ventilated place, finished products are stored without transportation. Thus, a strength of 70-80% is achieved.

- Steaming at + 70 ° C for about 7-9 hours ensures maximum strength.

Practical tips for making Lego can be found here: