Facade painting technology

- Prepare the surface before directly applying paint. The substrate must be free of dirty or greasy stains, efflorescence or limescale, peeling paint or plaster residues, unused fasteners and other parts that make painting difficult. All noticed surface imperfections should be putty, crumbling or flaking areas should be removed. For sealing, use a mineral external putty.

- Work should be done in dry weather. The recommended air temperature is from + 5 ° to + 30 ° (in fact, at subzero temperatures or sweltering heat, hardly anyone would think of painting a house).

- Scaffolding is usually covered with a net to protect it from direct sunlight and dust-raising winds.

- Before application, white paint must be tinted with special pastes. If the procedure is performed independently, it is necessary to carefully monitor the dosage accuracy, since the slightest mistakes lead to a difference in the shade of the coating.

- Before use, the paint must be thoroughly mixed in the original container. An open container should be covered, the edges must be cleaned of paint, otherwise the lid will dry out (acrylic paint has strong adhesive properties). To obtain the desired viscosity, the material is diluted with an appropriate solvent or water.

- At least two layers are used, the first of them serves for the base coat, and the second, more fluid - the finishing additional. If it is necessary to apply three or more coats (rarely, but this happens), then each subsequent one should be made slightly less viscous to obtain a uniform surface.

- Painting is carried out using the “wet on wet” method, that is, it is not allowed to leave uncoated areas on the same plane. The boundaries of parcels to be covered in one go are along corner edges or decorative elements that intersect the entire surface of the wall.

- The paint is applied either mechanically - with a spray gun, or manually - with a roller or brush. The spray gun is convenient for large areas and wall heights, but it is not always available, so you often have to do it with a roller or, which is somewhat slower and not so neat, with a brush. Basically, a roller is used, and the brush is used only for fine finishing the edges (especially with two-tone coating) or around protruding elements, window openings, etc.

Peculiarities

Acrylic paint belongs to a large water-dispersion group and is a suspension of fine solids in a liquid solution. The division within this group is almost arbitrary, since its solvent is water. Any paint of this type is a thick substance, consisting of different components, due to which it acquires certain properties.

The composition of water-dispersion paint includes elements involved in the formation of a special film on the surface that has a protective function. In addition, it contains fillers, additives and coloring pigments. Fillers can be of both natural origin and synthetic base. Thanks to them, the paint acquires certain properties. The pigment content gives the dye the desired color or shade, and additives improve the properties of the paint.

The difference between the various types of this group lies in the bonding components, scope and price.

Acrylic water dispersion paint differs from other types of this group by the presence of polyacrylates. In addition, it contains copolymers that are directly involved in the formation of a film that protects the surface. This film is vapor-permeable, which means that the material under it "breathes". The formation of mold and the development of pathogenic bacteria under the condition of a vapor-permeable surface is practically impossible, and therefore it is not at all dangerous not only for healthy people, but also for individuals suffering from allergies.

All components contained in the paint are non-toxic, and since the basis of acrylic dyes is water, and not a solvent, there is no pungent smell. And there is nothing to ignite here, so an important advantage of acrylic paint is its fire safety.

The film created on the surface of the material is resistant to moisture, in addition, the painted surface is perfectly washable. These properties are also inherent in latex-based water-dispersion paint, but they are absent in the species with PVA in its composition.

An important advantage of an acrylic-based dye is the rapid drying of the painted surface, provided that the prescribed temperature and humidity conditions are observed. In addition, the components in the composition of the paint mask small cracks well, and the surface itself is resistant to mechanical stress.

The service life of acrylic paints is long, the surface that has been painted will have a presentable appearance for at least 8-10 years without cracking, despite the influence of not always favorable external factors.

It is a pleasure to work with acrylic paint. It not only fits well on the surface, but also does not require special protective equipment. All kinds of masks and respirators used when working with solvent-based paints are not needed here, since there are no gases poisonous to the respiratory system. And in case of accidental contact with the skin, it is easy to wash it off, because the basis is water.

Almost the only drawback of this paint is the price. It is slightly higher than that of the water-based analogue.

Sometimes water-based paint is equated with water-based paint. But this is not entirely true, since they differ in composition. Despite the fact that both types are based on water, the basic components of water-based paint can be either chalk or slaked lime. It also contains PVA. The components directly affect its properties: it deforms faster and has a short service life.

This is interesting: How to choose water-based polyvinyl acetate paints?

Water based paints

The basis of this variety is water, which dilutes all kinds of thickeners, pigments, polymer compounds. The whitening component is zinc oxide, styrene acrylate forms a protective film. Purpose, product characteristics depend on the percentage of components. The viscosity is changed by the amount of solvent.

Improving the versatility of the finished product, manufacturers add resins:

- mineral;

- acrylic;

- silicone.

The specific gravity of the formed protective coating is 1.4-1.5 kg, the consumption of such products is 210 ml per 1 sq. meter. This indicator is changeable, changes from such data:

- type of surface to be painted;

- the amount of added solvent;

- how much the base absorbs;

- other.

Advantages:

- environmental safety, no smell, no harmful fumes;

- ease of use, the choice of any known method;

- color change is carried out by adding pigment;

- availability, low consumption.

There are several types, differing in composition, scope, characteristics, properties:

- silicate;

- acrylic;

- mineral;

- silicone.

The acrylic variety is versatile, it paints glass, metal, brick, concrete, wood and surfaces from them equally well. Silicone and mineral solutions are of good quality, but expensive; silicate types are used in rooms with high humidity.

Types and application

Latex paint has a wide range of uses. Depending on the variety, it can be used for exterior decoration or for indoor work. Facade paint products have a special compound that protects the surface from the formation of mold and mildew. For painting surfaces indoors, the following paints are suitable:

- acrylic is a good solution for painting wood;

- vinyl - ideal for painting ceilings and walls;

- dense - designed exclusively for ceilings;

- textured - an excellent solution for creating a relief print, embodying the most daring design ideas;

- drip-free - allows you to hide various kinds of irregularities and cracks.

Depending on the appearance, acrylic paint is divided into several types:

Matte is ideal to hide some imperfections on the surface. It perfectly masks small irregularities. Such a tile is not afraid of exposure to sunlight, since it practically does not heat up. Its disadvantage is that it gets dirty quickly enough. It requires careful and frequent maintenance, but it has excellent resistance to contact with water and abrasion.

- Glossy is a good solution for decorating a room inside or outside. It allows you to visually increase the area of the room. This paint practically does not get dirty. Its disadvantage is that it can be used exclusively for painting a flat surface.

- Semi-matte - acts as the golden mean between matte and glossy paint. It combines the advantages of the above types.

There is another classification of latex products, which depends on the additives introduced into them.

Polyvinyl acetate

This paint is made on the basis of PVA (vinyl acetate polymer). It is also often called water-based or water-dispersion.

Advantages of polyvinyl acetate paint:

- does not contain solvents;

- there is practically no smell;

- has good adhesion to the surface;

- easily washed off hands if not completely dry;

- affordable price.

But water-based paint can be washed off even after complete drying, therefore it is not recommended to use it for external work. It has a chalky effect and can stain your clothes if you touch it.

This paint is ideal for painting ceilings as it is ideal for hard-to-reach areas in dry rooms.

Styrene-butadiene

This type is considered by many to be water-based latex paints. The difference is that styrene-butadiene paint is characterized by excellent moisture resistance and increased wear resistance. It is inexpensive, so it is in demand.

Its disadvantage is low lightfastness. When exposed to sunlight, it changes color very quickly. It can be safely used for interior work. It is ideal for a hallway, corridor or storage room.

Acrylosilicone

This option is ideal for painting facades. It is resistant to moisture and light, and is also characterized by increased vapor permeability. This paint acts as an excellent substitute for silicate and silicone. It has similar properties as silicate, but it is cheaper, so the demand for it is always great.

Acrylic

This option is expensive, but has excellent performance. It can be used to decorate building facades or as interior enamel. It retains its attractive appearance under all circumstances.

Many buyers agree that it is better to buy an expensive acrylic paint and paint the room once for a long time than to buy a cheap analogue and paint again every year.

Latex paints are versatile because they are suitable for painting a variety of surfaces. They fit well on drywall, foam concrete, plaster, even on plastic window sills.

Composition of paints

Both acrylic and latex formulations are composed of the following main components:

- Binder ingredients. This is one or more polymers. The service life of the painted coating, adhesion to the surface, abrasion resistance and other physical and mechanical properties depend on the quality of the binder.

- Pigments. Serve to give the desired color.

- Fillers. These are substances that make the painted surface glossy or matte, give strength to the paintwork.

- Solvent. It is a liquid base for the dispersed phase.

- Surfactants and additives. These are components that give the paint mixture certain properties so that it is possible to apply them to various materials - wood, glass, concrete, wallpaper, plastic and others.

Working with paint

It is not difficult to paint the wall yourself with acrylic water dispersion, but in order to obtain a flawless result, it is important to properly prepare the surface for finishing. The degree of complexity of this task always depends on the initial state of the walls or ceilings.

Preparation

- Wash and clean all dirt.

- If there is an old coating and its condition leaves much to be desired (cracks, bubbles, peeling layer), then all this must be removed with a spatula or scraper. In especially difficult cases (oil paint on concrete), a construction hairdryer, a drill with an attachment in the form of a crown or a wire brush is used, you can also purchase a special tool for removing old paint (remover). We also recommend that you familiarize yourself in more detail with the question of whether acrylic paint can be applied to oil paint.

- Existing flaws (cracks, chips, potholes) need to be covered with putty, wait until dry, and wipe the irregularities with fine-grain sandpaper.

- Clean the surface completely from dust and cover with a layer of primer. It is good if an antiseptic is present in its composition; this will provide additional protection against mold and other harmful microorganisms.

Painting

To work with water-dispersion paint, a spray gun is often used. With the help of this tool, you can significantly speed up the process, but it is quite realistic to get by with a set of the simplest devices:

- paint brushes and roller,

- tray,

- masking tape.

Paper adhesive tape is used to protect surfaces that cannot be painted or to mark the boundaries between areas that are painted in different shades.

The material is first applied with a brush to hard-to-reach places: corners, joints, etc. To start working with a roller, its coat must be properly impregnated with a coloring agent, and then the excess must be removed by rolling on a special ribbed surface of the tray.

The wall is painted by rolling the roller up and down and left and right alternately, thus applying the most uniform and high-quality first layer. When it dries up, they act on the same principle a second time, but now it will go faster, and the paint consumption will be reduced by almost a third.

Two layers are usually enough to get an even and rich tone, but if you wish, you can put a third one. It is possible to diversify the decor using textured rollers, stencils and other devices.

Acrylic water-dispersion paint is a very convenient material for realizing creative ideas for improving the interior and renovating facades.

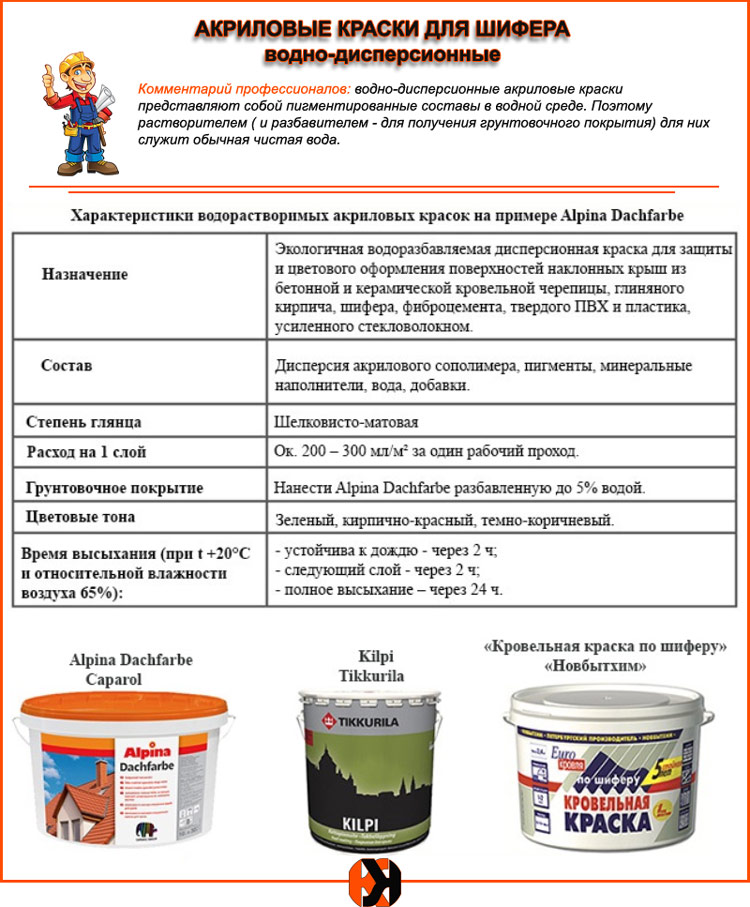

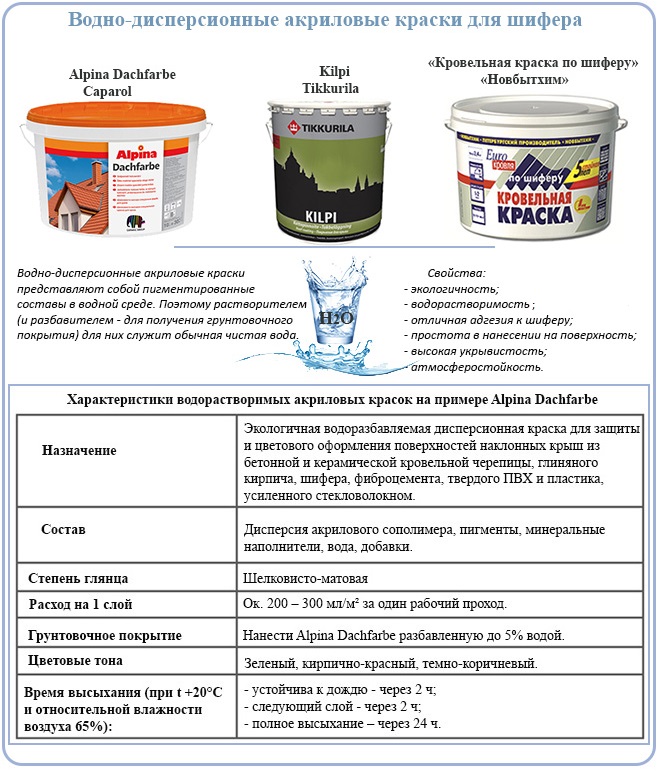

The main types of water-dispersed paints by bases and their characteristics

The developers annually offer dispersions with new inclusions and binders.Relatively new proposals include some decorative emulsion and water dispersion paints that form an unusual texture, for example, imitating a stone. They can be applied to any primed substrate, including wood and metal.

Modern water-based enamels are classified by type of application:

- Facade;

- Interior.

They contain common components, for example, to protect against mold and mildew, all differ in composition and characteristic properties. There are also latex and hammer formulations with a special effect.

The developers annually offer dispersions with new inclusions and binders.

Polyvinyl acetate

PVA-based paints are characterized by low hydrophobicity, so they should not be used in a damp room. They are suitable for painting plastered ceilings in an apartment with a stable temperature regime. This is a budget option for redecoration.

They are suitable for painting plastered ceilings in an apartment with a stable temperature regime.

Acrylate

Dispersion paint with the addition of acrylates remains the most demanded, due to the optimal ratio of price and quality. It is resistant to UV rays, therefore it is recommended as an interior design, even on the south side. A vapor-permeable elastic coating is also guaranteed.

The water-resistant composition is easy to use, the layer does not crack even with a noticeable temperature drop. But this does not mean that you can experiment as facade coatings, if the packaging says “for interior work”. The advantage is a perfectly flat surface after painting, regardless of the base material.

The water-resistant composition is easy to use, the layer does not crack even with a noticeable temperature drop.

Latex or styrene-butadiene

Styrene-butadiene dispersed compositions are moisture-resistant, but their pigment quickly burns out under the influence of sunlight. The interior is the place. These are latex formulations based on synthetic and organic resins such as rubber that look great after drying.

Application - washrooms, baths and showers, as they excellent resistance to moisture and wash well. It is possible to paint insulated attics, cellars and wine cellars. The walls of glazed loggias and balconies are quite acceptable, provided that a dull shade is used (the polymer quickly burns out in the sun).

Application - toilets, bathrooms and showers, as they perfectly resist dampness and wash well.

Silicone

If we talk about what silicone water-dispersion paint means, then it is worth focusing on its specialization. It is known to specialists as a façade dye of excellent quality. These mixtures are distinguished by the property of repelling dirt and water, cleansing the wall during rains. Therefore, the building by the road will remain clean even in bad weather.

The coating will protect the walls from any impact, while maintaining high aesthetics and uniformity of processing. With this composition, specialists work on basement and facade surfaces - on brick, concrete and plaster. It is noteworthy that matte and glossy variations are offered for facade work.

The coating will protect the walls from any impact, while maintaining high aesthetics and uniformity of processing.

Dispersion-silicate

Silicate dyes are also water-based. Liquid glass and sodium ethyl silicate in its composition explain their name and classification - mineral paints. Main varieties:

- Dispersed silicate (acrylic added);

- Silicate silicone.

The basic requirements for compositions and their properties are regulated by GOST.

Silicate dyes are also water-based.

How to work with the material?

It is quite easy to use an acrylic water-dispersion paint and varnish material.In order for the result at the end of finishing work to be flawless, you need to take care of thorough preparation of the base before applying paint. The complexity of such processes depends on the state of the surface. If she does not need preparation, you will have to stock up on patience and perseverance.

Preparation

First you need to remove dirt, thoroughly wash the surface. If there is old paintwork material (eg bubbles or cracks), clean it with a scraper or trowel. If the case is especially difficult (for example, an oil-based paint has been applied to a concrete surface), clean the coating with a wire brush, drill, or hair dryer. You can also purchase an optional remover to help remove old material from the substrate faster and easier.

Putty should be applied if there are defects on the surface (potholes, chips, cracks). When the finish is dry, remove any unevenness using a fine-grained emery cloth. Then remove all dust from the surface, apply a primer to it. It is better to choose a primer with an antiseptic: it will prevent mold.

Look for a liquid with a higher penetrating power: it will make the surface structure uniform

Application of the coloring composition

The most suitable device is a spray bottle: with its help water-dispersion acrylic paints and varnishes materials can be applied as easily and quickly as possible. However, you can easily choose simpler tools. To apply the coloring composition, you will need to prepare:

- masking tape;

- roller, brushes;

- tray for paint.

To protect areas that you do not intend to process from paint ingress (or to delimit areas that will be painted in different shades), use adhesive tape made of paper. First you need to paint over hard-to-reach areas (joints, corners). It is better to use a comfortable brush for this. Then you can move on to using the roller. Before this, his fur coat should be thoroughly impregnated with paint and varnish material.

Remember to remove excess paint from the tool first. To do this, roll the roller on the tray (this is especially convenient if it has a ribbed surface). When applying paint and varnish material, roll from right to left, from top to bottom. So the first layer will be of high quality and uniform. Dry completely before applying the next coat. The second time, the staining will be carried out much faster, and the dye composition will need much less.

Professional secrets for interior work

The interior painting of living quarters has its own nuances. During work with the VDK, the air humidity increases greatly. To create a safe and comfortable environment, it is advisable to install forced ventilation. In this case, the paint and varnish material will dry out faster and better.

For a perfect finish, follow these guidelines:

- You need to start applying paint parallel to the frame structure, from the side of the window.

- The first time it is better to paint over with a brush, a composition diluted in a ratio of 0.5 liters of water to 5 liters of paint. Subsequent layers are applied with a roller to achieve a leveled surface.

- Each coat of paint is applied at intervals of 3 hours.

- The sprayer will significantly speed up the painting of the walls. It can be applied at a distance of a meter from windows.

- If the surface is highly absorbent, it may be necessary to apply three coats to obtain a quality finish.

- It is better to dismantle or cover skirting boards with masking tape before painting the interior walls.

- If, according to the design concept, it is required to paint one wall in two different colors, which will visually divide the room into zones, for example, for working at the computer and relaxing in front of the TV, use the same masking tape.

- Always consider the natural light factor. The last coat of paint on the ceiling will look better when applied perpendicular to the wall with the light source.

Water-based paint and textured stencil rollers will help create stylish and bright interior elements.

Properties of water dispersion paint

In addition to water, the composition of dyes includes fillers, pigments, binding polymers and substances that give the material additional properties. Aqueous dispersion formulations are often sold as a liquid paste that is diluted with water just before use. It is recommended to dilute water emulsions with oily solvents: linseed oil or turpentine.

Main components

Water-based paints are formulated with materials that determine their performance and performance characteristics. These include the following components:

- Fillers - the smallest marble chips, talc or powdered chalk. These components are responsible for the hardness, wear resistance and other performance properties of the coating.

- Pigments - define colors and shades.

- Binders and film formers are polymers that hold all components together and create a surface layer of paint after the water evaporates.

- Solvents: water - for an aqueous dispersion system, water and oil - for a water-based dye.

- Supplementary components - substances that give the necessary performance properties and improve the technical characteristics of the coating.

Depending on the additional additives, a distinction is made between aqueous dispersions based on polyvinyl acetate, latex and acrylic.

Paints containing PVA perfectly fit on plastered surfaces, wood and concrete. They are inexpensive, easy to apply and dry quickly, but are not suitable for outdoor use and rooms with high humidity, as they are poorly resistant to pollution and weathering. Polyvinyl acetate stains are excellent for indoor walls and ceilings with moderate humidity.

Latex coating is more resistant to moisture and abrasion, is not afraid of dirt and can be used for painting kitchens and bathrooms.

Acrylic dyes have the best protective properties and resistance to external influences. They are not afraid of moisture and dirt. Acrylic compounds can be used indoors with high humidity and for painting exterior walls made of wood, brick and concrete.

Specifications

In addition to the composition, which largely determines the operational properties of the paint and varnish layer, the main characteristics of water-based paints are:

- viscosity;

- consumption to cover one square meter;

- temperature conditions during storage and application of paint;

- drying speed.

Viscosity determines the fluidity of a material and depends on the concentration of water. The viscosity index of the dye for application with a brush or roller should be about 40-45 St, and for a spray gun - about 20 St.

Viscosity determines the fluidity of a material and depends on the concentration of water. The viscosity index of the dye for application with a brush or roller should be about 40-45 St, and for a spray gun - about 20 St.

Material consumption per square meter determines the ability to completely paint over the surface in one layer. Water dispersions have good hiding power, so an average of 170 to 220 ml is consumed per square meter. The indicator depends on the viscosity and characteristics of the painted surface.

Water-based paints must not be frozen and used at sub-zero temperatures. It is undesirable to work with the material at temperatures below five degrees Celsius and at high air humidity.

Water-based dyes dry quickly. After 30-45 minutes, the surface layer no longer sticks, and after 8-12 hours the coating dries completely.

Types and characteristics

Many types of water-dispersed paints are produced, so the scope of their application is very wide. In terms of resistance to moisture, water-dispersion solutions are divided into washable, moisture-unstable and moisture-resistant.

The dispersed mixture is subdivided according to the main composite polymer component:

- polyvinyl acetate;

- acrylate;

- latex or styrene-butadiene;

- silicone;

- dispersive silicate.

The component in PVA mixtures is polyvinyl acetate, which does not tolerate moisture and is easily washed off.Such cheap mixtures are suitable for painting dry ceilings or bedroom walls. Acrylate dispersions contain acrylic, which is characterized by moisture resistance, resistance to mechanical stress, resistance to sunlight without discoloration. Unlike PVA, these materials are expensive.

A mixture with acrylic is classified by purpose:

- interior.

- front.

Acrylic paint can be washable or dry mechanically cleaned. According to the type of painted surfaces, compositions for plaster, wood or metal are distinguished.

Latex paint is similar in its properties to acrylic composition. The difference is that latex turns yellow under the influence of ultraviolet radiation, therefore it is not used to paint the external parts of buildings and rooms where direct sunlight penetrates. A type of latex mixtures is a rubber paint with a high latex content, which has the properties of rubber when applied in 2-3 layers. It creates an elastic, durable layer that is not afraid of abrasion, water, high and low temperatures.

Latex mixtures with the addition of vinyl versatate have recently appeared on the paint and varnish market. This substance imparts stable fire-fighting qualities. On its basis, fire-retardant coloring materials are made. An intermediate link between acrylic and latex compounds is acrylate-latex. Mixing latex and styrene allows you to change the final price of products and improve quality. The price of such mixtures is lower compared to pure acrylic material.

Water-dispersed silicone paint with silicon resins is capable of painting any material, since silicone masks coating defects. It is possible to apply on a damp surface: for example, high quality characteristics allow painting rooms with high humidity levels, and making external finishing of buildings. A special feature of silicone paint is its ability to not absorb dirt and dust, ensuring cleanliness during use. Silicate compounds are made with the addition of liquid glass, so they acquire especially strong properties. Ideal for painting facades, creating a high-density protective coating. Only mineral surfaces can be painted: concrete, clay, plaster, gypsum.

All production of water-dispersion mixtures is regulated by GOST.

When choosing products, the following technical characteristics are assessed:

Colour

The color characteristic is of great decorative value. Initially the mixture is white due to the titanium dioxide pigment

The desired shade is achieved by applying a color scheme. The whiter the dispersion at first, the richer the desired color will be.

Uniformity. The diluted solution should be free of clots and solids. When applied, it should form a smooth layer.

Wear resistance. This performance depends on the strength of the finished layer.

Material consumption. An important parameter that depends not only on the surface to be painted, but also on the quality of the raw materials, on the density of the solution. Solutions, which weigh one and a half kilograms with a volume of one liter, are usually distinguished by good coverage. The average consumption of dispersion compositions is 130-180 g / sq. m. The approximate consumption is indicated on the label.

- Moisture resistance. The degree of moisture resistance depends on which formulations can be used under various humidity conditions.

- Resistant to light. The appearance of the coating depends on the lightfastness. UV resistance is determined by the components of the composition. Acrylic and polyvinyl acetate tolerate light exposure well, they will not fade.

- Frost resistance. The low temperature resistance parameter is determined by the number of freezing cycles.