Case - how to make an accurate calculation of consumption

Take KNAUF Concrete Contact as an example. Consumption figures declared by the manufacturer: 0.35-0.4 kg / 1 m 2 Let's check them in practice.

Professional builders recommend applying a test coat with measurements. To do this, take exactly 1 m 2 of the surface on which the primer will be applied. Ours is a cleaned wall with old plaster. You can draw a square with chalk. For convenience, we limit it with masking tape. Take a jar with a tool (for us it is a brush). We put it on the scales. We pour enough Concrete Contact into the jar so that the total weight is 1 kg - for ease of calculation.

We apply the primer, painting the entire square with high quality without gaps. We weigh again. On the scales 620 g.

Consequently, 380 g of soil was used for 1 m 2. That is, the real consumption for this wall is 0.38 kg / m 2, that is, it corresponds to the declared one. Multiplying the resulting figure by the area of the walls in the repaired room, you can find out exactly how much concrete contact is needed.

Maybe dilute a little with water?

Concrete contact is made on the basis of acrylic additives, therefore to dilute it with water to save money is completely useless and even harmful.

Water will make the solution non-uniform and it will lose its properties. The price of Concrete Contact should not suggest savings, because it holds building surfaces much stronger than conventional primers, even of deep penetration. Therefore, it should not be diluted with water.

Fictitious savings will result in real financial losses. Cracking of plaster, and peeling of layers and falling off of pieces of the wall will definitely not please you. Don't risk it!

And if you spread it thinner?

If you try to reduce the consumption of Concrete Contact by applying a thinner layer, then the subsequent adhesion of the coating to the working surface will also decrease. In addition, the waterproofing properties of the layer will also deteriorate.

If there are no “unpainted” spots left on the working surface at the visual level, priming can be considered complete.

Concrete contact dries at room temperature in 2-4 hours. You cannot apply the primer at zero or sub-zero temperatures, just as you cannot let it dry in the cold. But at the same time, the finished surface can withstand five freezing cycles down to -40 0 C.

After drying, the surface can be processed further - plastering, laying tiles, gluing wallpaper or vinyl film. Do not leave the primed surface for a long time, so that dust does not settle on it.

Consumption of concrete contact: how much does it take for 1 m2?

For most people, the word "repair" is unlikely to cause at least some positive emotions. Usually this process is associated with huge expenses: effort, money and time.

One of those tasks that sometimes cause torment even for people with repair experience, albeit not professionals, is the need to increase the adhesion of certain materials. This is where the concrete contact primer will help.

Concrete contact is a special type of primer that can turn absolutely any surface from perfectly smooth to as rough as necessary.

It consists of a very strong adhesive, as well as acrylic and quartz sand. Apply concrete contact for external and internal work. The main manufacturers of this material include Knauf, Prospectors, Master.

Advantages:

- The main positive side of using this primer is that you don't have to remove old coatings from where you want to apply it before applying it.

- You can not use a reinforcing mesh during plastering work, and using a concrete contact on the plaster will increase its strength, since the solution penetrates into the plaster coating and holds it together.This means that after using the concrete contact you can, for example, drill or perform other similar work without fear of significant damage to the finish.

- When working with this substance, you may not use special protective equipment, because it is an environmentally friendly substance, which does not contain any solvents or other harmful substances that can harm your health.

- Walls treated with concrete contact will not stop "breathing", and mold and other types of fungi will never appear on them.

You may find it useful to know how to prime the walls under the wallpaper. Read this article.

Disadvantages:

- You cannot store this material in the cold because it will lose its properties.

- If applied incorrectly, it will not fulfill its basic properties.

Consumption rates

Despite the fact that the name of this material contains the word "concrete", concrete contact can be used on completely different surfaces.

Accordingly, the rate of its consumption will be completely different. It depends, first of all, on the porosity of the surface on which you apply it.

And although the simplest and most reliable way to determine the rate of consumption of concrete contact is simply to apply it to a part of the desired surface, an area of one square meter, let's still consider the approximate rate of consumption of this material.

- On surfaces with high porosity, such as concrete slabs, bricks or special porous stones, you should apply 0.5 kg per m2.

- For materials with medium density, such as concrete monolith or concrete tiles, you will need 0.3 kg per 1 m2.

- Low-porous surfaces (ceramics, tiles) will require at least 0.15 kg of concrete contact per 1 m2.

DIY primer application

First you need to clean the surface of debris and dirt, dust and everything else. Next, you need a roller or brush.

It is necessary to carefully place the concrete contact in the container and apply it with a roller in an even thin layer on the wall. Corners and hard-to-reach places are primed with a brush.

When performing work, you need to monitor the temperature in the room. It should not be lower than +5 ° C.

Now the main thing is done and you can rest a little. You must wait until the concrete contact is completely dry

This is very important, because if it is even slightly damp, it will significantly reduce the quality of adhesion.

Complete drying of the concrete contact usually occurs in 5-6 hours. After this time, you can proceed to further finishing.

It is impossible to delay with the continuation of finishing work, because after more than two days the surface will dry out and become dirty.

Now that you know about this wonderful type of primer, your renovation will be easy and enjoyable.

Video review of concrete contact primer.

What types are there

Choose a primer based on the material of the base (wall), purpose and type of subsequent finishing. Let's consider all types in more detail.

Acrylic deep penetration

The white translucent deep-penetrating solution has no unpleasant odor and dries quickly.

One of the most commonly used type of wall primer. The penetrating universal acrylic-based compound removes dust from the surface, strengthens old and loose plasters, improves adhesion, slightly reduces the water absorption of walls and ceilings and thereby prevents moisture from leaving the applied plasters.

Consumption largely depends on the porosity of the walls, on average 100-200 g per square meter.

Ingredients: water and acrylic polymers. Antibacterial and antifungal components may also be present

It is important to pay attention to the amount of dry residue in the composition of the acrylic solution. In good wall primers this value should be less than 10%, in floor materials - 15%

The solution dries up in 2.5-3 hours.

Manufacturers: Ceresit CT 17, Unis, Prospectors, Optimist, Bolars, Lacra, etc.

Adhesive quartz-primer of the "betonokontakt" type

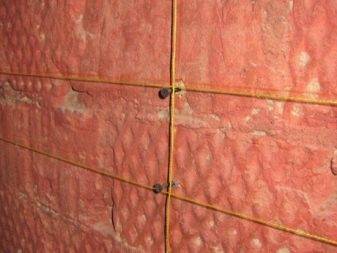

Concrete contact significantly improves the adhesion of the wall and finishing materials. The dye in the primer helps to control the uniformity of the application.

Betonokontakt is an excellent option to improve the adhesion of concrete and any sheet materials: drywall, fiberboard, chipboard, OSB boards before applying gypsum or decorative plaster.

Primer composition: acrylic dispersion (more concentrated than universal), quartz sand, dyes.

After the concrete contact dries, the wall or ceiling becomes rough due to the applied sand. This allows even smooth surfaces, including painted walls, to be plastered or tiled.

Consumption: 200-300 g per 1m2 when applied with a roller.

Manufacturers: Ceresit CT 19, Alpina Expert Quartz-primer, KNAUF Betokontakt, Farbe, Tex, etc.

Anti-mildew and mildew primer

Anti-mildew soil

Serves for antifungal and antibacterial protection of wood, as well as for treating walls in damp rooms and basements.

Antifungal primers are made on the basis of universal acrylic with the addition of an antiseptic. Therefore, they have the same technical characteristics: consumption and drying time.

Examples of manufacturers: Alpina Expert Bio-Stop, ECOTERRA, Gunstig, Lakra, Areal, etc.

Alkyd (glyphtene)

Alkyd primer

It is mainly used to protect metal from rust, wood from decay. Also, GF-primer is used on surfaces made of plastic, chipboard, fiberboard, glass or fiberglass as an intermediate layer before painting.

Alkyd compounds are applied in any convenient way - with a roller, brush, spray. Dilution of the solution with white spirit is allowed.

Consumption: 100 g / m2. Drying time is 24 hours.

Examples of manufacturers: Otex, Lakra, Tex GF-021, TURY.

Silicate

This material is based on liquid potash glass. The primer is used for interior decoration and facade work to strengthen the surface, protect against aggressive environments and precipitation, and prepare for painting with silicate paints. Suitable for sand-lime bricks, concrete, cement-sand and lime plaster.

Consumption when applied in one layer is 200-250 g per m2.

Producers: Caparol Sylitol-Minera, Derufa Silicate Primer, Ceresit CT 15.

Working with soil

The instruction states that any primer should be applied to a clean, dust-free surface, if possible. As already mentioned, the temperature should be above +5 ºС. The solution is liquid, conductive and it is advisable to de-energize the room before starting work.

The composition enters the distribution network ready-made and does not require additional actions, except that it must be thoroughly mixed with your own hands before work. It contains sand, which has the peculiarity of settling, so it is necessary to mix not only before use, but also during work.

In order for the primed surface to differ from the general background, the solution is tinted, as a rule, in pink. Drying time can vary from 2 to 4 hours, depending on the air temperature and the level of ventilation in the room.

Work as a baker.

Consumption of the composition

The consumption rate of concrete contact per 1m2 no longer depends on the type of base, but rather on its porosity, that is, on the ability to absorb moisture.

Below we present the averaged data obtained empirically.

- The porous material has high moisture absorption characteristics, 0.35 - 0.5 kg of soil is consumed for it. This includes pre-grinded concrete, hard putty, sand concrete, building bricks and some types of natural stone. Before using concrete contact, these surfaces are recommended to be treated with some kind of deep penetration soil. If a tree is processed, then an antiseptic is applied.

- Materials with medium porosity absorb moisture less and the rate of consumption of concrete contact is 1m2, respectively, lower, from 0.2 to 0.35 kg.These include monolithic blocks of high-grade concrete, most self-leveling floors, concrete tiles and some types of facing bricks.

- The primer is especially appreciated for the ability to process low-porous and smooth surfaces, they consume approximately 0.15 - 0.25 kg per 1m². These can be worn out concrete monoliths, grouted concrete screed, ceramic or tile tiles, old stubborn paint, and even glass.

Roller application.

How to reduce the consumption of the composition

To put it simply - then nothing. Experts do not even advise to experiment in this direction. The price of a concrete contact is quite loyal and there is no need to try to remove the foam from places where it is not accepted to remove it, such attempts can be more expensive later.

At a minimum, the plaster layer can crack and lose its dignified appearance, but it can even reach complete peeling of the coating. This type of soil, in addition to actually increasing the adhesion, also has decent waterproofing characteristics. And most of the plasters and putties are diluted with water.

If a wet composition is applied to a poorly primed surface, moisture from the solution is absorbed into the base and the hardening process stops, and shrinkage continues. As a result, the plaster layer cracks and falls off. The highly porous base literally sucks out water, and the concrete contact prevents this process.

Deep penetration soil.

The video in this article provides additional tips on the topic.

How to prepare surfaces for processing?

Before application, the surface must be thoroughly cleaned of dust and dirt, if it is a floor, then it must be vacuumed. If there are places on the surface that exfoliate or crumble, then it is better to remove them immediately, and plaster the irregularities with cement mortar. Priming is carried out after the plaster has completely dried. Concrete contact does not stick to oily surfaces, and if there are such areas, they need to be thoroughly washed, only after degreasing they start processing.

Places with paint before priming are washed with a damp sponge and after drying, concrete contact is applied. We recommend pre-treating surfaces that cannot be thoroughly cleaned with an ordinary primer. This procedure will reduce the consumption of material, due to the fact that ordinary soil will fill large cracks and roughness. After processing, small blockages are removed, and the concrete contact will adhere more strongly to the surface.

Top manufacturers

There are many different manufacturers of concrete contact on the market now. The cost usually ranges between 300-600 rubles for five kilograms. If you wish, you can find more expensive, but not the fact that it is of better quality. The scope, consumption of the mixture or ready-made solution is indicated on the package.

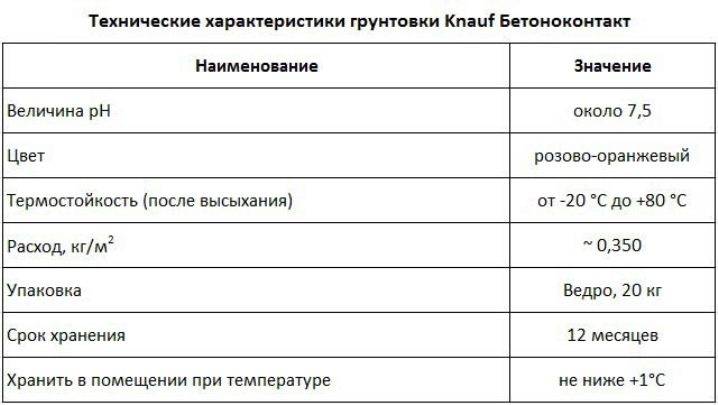

KNAUF

It manufactures products for the treatment of any surfaces, the solution is intended for both manual and mechanized work. Consumption approx. 0.35 kg / m2. Color - pink to control the uniformity of the application. Curing time - 12 hours. Price 20 kg - 3330 rubles.

Acrylic-based primer Beton Kontakt - recommended before laying tile or porcelain tiles, applying finishing decorative plaster, putty, and further pouring the floor.

Rotband-grund - is produced as a mixture, without solvents, modified dispersion. It is intended for processing porous substrates with increased moisture absorption, as well as in preparation for subsequent leveling with other types of plasters.

"Prospectors"

The primer contains BASF latex. Suitable for interior work, including crumbling walls with old plaster. Available in different sizes: 3, 8 or 16 kg buckets. Consists of copolymer acrylic dispersion, sand, water and various useful additives.

Used for walls, ceilings in rooms with normal or high humidity. 5 kg - 315; 8 kg - 725; 16 kg - 1350 rubles.Temperature limits during work - from +5 to + 30 ° С. Short shelf life - no more than 6 months from the date of issue.

There are ready-made solutions for deep penetration - up to 10 cm in a 20 kg package, which is enough for 67 m2 of base. These are quick-drying mortars that allow further finishing work in 2 hours. Minimum consumption - 0.2 kg / m2. The operating mode is in the range from +5 to + 25 ° С. Expiration date - 12 months.

Ceresit

Produces material for application on smooth surfaces, suitable for external and internal use. Consumption 0.3-04 kg / m2. Dries about three hours, pink. 5 kg - 465; 15 kg - 1265 rubles.

- CT 19. Provides surface frost resistance during operation. Allowed 5 freezing cycles for up to two weeks at a temperature not lower than -40 ° C. Conditions for carrying out finishing activities at an air and base temperature from +5 to + 30 ° C, air humidity should not exceed 80%. The adhesion of the mortar to the concrete base after a week is not less than 0.5 MPa.

- CT 17. Deep penetrating primer containing antiseptic.

"Phoenix" concrete contact

A primer on quartz sand creates a uniform rough layer. The mixture has a strong sticky property. Suitable for interior renovations with different types of surfaces. Consumption 0.2-0.3kg / m2. Do not freeze under any circumstances, store in a tightly closed container. Packing of 20 kg - 1200 rubles, enough for 67-100 m2. Application temperature range from +5 to + 40 ° С.

VGT

The company produces a coarse dispersion primer for treating poorly absorbent plaster substrates. Often used before laying ceramic tiles. Full hardening time is about 24 hours. Consumption - 0.25-0.5kg / m2. Price for 3 kg - 315; 8 kg - 725 rubles.

How to use concrete contact, the specialist tells in the next video.

Application and characteristics

You can use the material once after shaking. It is recommended to use it to:

- prevent paint degradation on dry plaster;

- facilitate plastering;

- improve the adhesion of tiles to concrete walls;

- close seams and cracks;

- reduce premature shedding of finishing materials.

The Knauf brand primer contains acrylic, which makes it highly resistant to moisture. At the same time, the quality of surface preparation is not worse than that of most other auxiliary materials (and sometimes even better).

Issued by:

- both a universal mixture and adapted directly for interior work;

- both large and small fractions.

A carefully thought-out formulation and production technology allows the primer to remain unharmed for many decades.

The German concrete contact is colored pink. It is designed to impregnate substrates that are not able to absorb glue or leveling compound. The polymer dispersion composition helps even in cases where the previous finish is not dismantled, but overlapped.

The concrete contact is suitable for lubrication:

- tile tiles;

- expanded polystyrene;

- drywall.

The leveling mortar, placed on the primer, dries evenly. Thanks to pre-treatment, it will be possible to reduce the amount of plaster or paint used. Concrete contact has antiseptic properties. It effectively suppresses the emergence of foci of any pathological microflora. When using it, the permeability of the intermediate layers of finishing increases, and because of this, ventilation of the premises, their exchange of air with the outside world, is facilitated.

Knauf has a neutral acid-base balance. It retains its positive characteristics even in freezing temperatures of -40 degrees, and in temperatures up to +60 degrees. Due to the absence of toxic components, Knauf concrete contact can be used even where ventilation is unsatisfactory - there will be no harm to the health of household members.

In a container of the most practical capacity (5 or 20 kg), the primer retains its characteristics for up to 1.5 years, unless the tightness is broken.

More about primer concrete contact Knauf

- in the next video.

Consumption of the mixture

The consumption of high-quality concrete contact Knauf per 1 m2 is a very important and urgent issue. Professionals, and even those who have worked with such compositions at least once, will say for sure that this indicator is determined by the type of surface, its initial state and the level of moisture absorption.

When analyzing construction practice (on average), the following figures were obtained:

- Consumption for brick, sand concrete and porous concrete is 500 g per 1 sq. M. You can reduce costs if you use impregnations that penetrate deeply into the material.

- First-class cast-in-place concretes are primed in the amount of 350 g per 1 sq. M, provided that the pore size is medium.

- When there are few pores or the surface is already covered with paint, you can spend only 150-250 g of primer to cover 1 sq. M.

In order to fully ensure adhesion, the condition of the original wall surface must also be taken into account. If in the process of work gaps are found or the base very greedily absorbs the finishing material, you can cover it again, but only after the initial mixture has dried completely.

Determining exactly how much primer will have to be spent is not so difficult. Its small volume is weighed in a pallet and distributed over an area of 1 sq m on walls and ceilings.

Home craftsmen and even experienced professionals are naturally interested in whether it is possible to deviate from the recommended numbers, to use a smaller amount of concrete contact. As practice shows, this is a big mistake: the cost of buying a primer is relatively small, and its lack worsens the quality of preparation. The created layer will be fragile - it can crack and delaminate. The worst part is that it will not be possible to achieve a normal level of adhesion with the main finish afterwards.

Then even the best primer will not be able to prevent plaster shedding or cracks in the paint. We'll have to redo all the work, re-invest in the purchase of finishing and preparatory materials.

At first, concrete contact can be mixed with deeply penetrating mixtures, and then it is permissible to use it only in its pure form. When using a spray gun, the total consumption of the primer increases slightly. The manufacturer recommends waiting for drying for 12 hours (this time is the maximum). If the temperature and humidity conditions are favorable, you can wait only 3-4 hours. When using hand tools, the concrete contact must not be diluted with water, but if it is sprayed mechanically, the solution is made in a 2: 1 ratio.

The proportions of the consumption of acrylic composition

Acrylic primer is sold in stores in two forms: ready-made liquid mixture and powder. If your choice fell on powder, then you should know that a significant amount of water is needed to prepare a powdery substrate. As a rule, manufacturers indicate on the packages exactly how much water is needed to prepare the mixture.

The ready-made solution is used for interior decoration, but not in black color, since the acrylic primer itself has a characteristic whitewash structure, and in case of contact with a dark surface, it leaves stains.

The soil in question is used to prepare the working area (wall or ceiling - it doesn't matter) for covering with plaster, putty or wallpapering. In addition, the acrylic primer is excellent for surface finishing before painting with acrylic paints.

For 1 m2 of working area, approximately 130-150 grams of soil are consumed, depending on the characteristics of the surface.

Summing up, we note that no matter what type of primer mix you would choose, the determining factor of consumption in proportion per 1 m2 will always be the objective circumstances of the finishing work.The data given in the article (as well as the proportions on the packages) will be only reference points for you, which will help you determine the calculation of the required amount of the mixture.

Consumption

Many people wonder what are the costs of a primer? The consumption of high-quality concrete contact Knauf per 1 m2 depends on several parameters. Experts say that the consumption of the mixture is determined by the absorption rate of the substrate, the type of surface, as well as its condition. The average soil consumption is as follows:

- when applied to porous concrete, sand concrete and bricks, the cost is 500 grams per square meter. By using impregnations that penetrate deeply into the substrate, costs can be reduced;

- with an average porosity of monolithic concrete, the consumption is 350 grams per square meter;

- with a minimum number of pores, as well as in the case of application to a painted surface, the costs will be approximately 150-250 grams per square meter.

For maximum adhesion, the condition of the substrate must be taken into account. If gaps begin to appear during priming, and also if the walls absorb the primer mixture very quickly, it is advisable to prime in two layers, the second layer can be applied only after the first layer has completely dried.

To understand how much primer will be consumed in general, it is necessary to conduct a test. For this, a small volume of the mixture is weighed and the concrete contact primer is distributed on m2 of the ceiling or wall. After that, the total number of square meters that need to be primed is calculated. Thanks to this sample, you can easily calculate how much material you need to buy.

Many people are interested in whether it is worth saving concrete contact and using it less than the manufacturer recommends? Experienced craftsmen have made sure in practice that it is unacceptable to save soil. This often leads to a significant deterioration in the quality of base preparation, as a result of which the surface will be fragile, adhesion to the finish will be insufficient. The finishing material can begin to flake, crack and crumble.

It is also very important to consider how to properly dry certain materials. For example, if the sand concrete is dried at the wrong temperature, and it is not moistened in time, the walls will dry out, as a result of which even a sufficient layer of soil will not save from the appearance of cracks and shedding of the plastered layer

This will lead to additional costs and rework of the entire work. To avoid this, the manufacturer's recommendations must be strictly followed.

Mixing of concrete contact with deeply penetrating soils is allowed, but then it must be used undiluted. If you apply the primer mixture with a spray gun, then the consumption will increase slightly. Knauf recommends waiting 12 hours after applying the primer for it to dry completely before applying the finishing material. Drying time at normal temperature and humidity is 3-4 hours.

If you use hand tools such as a brush, roller or brush to apply betokontakt, it must not be diluted with water. And when spraying mechanically, you can dilute the soil in a ratio of 2 to 1.

The modern construction market offers a huge selection of finishing materials. In order for your repair to be of high quality and unique, you need to purchase good materials for it. One of these finishing materials is concrete contact. We will talk about it in this article.

Thanks to the concrete contact, the smooth surface of the wall can be roughened. The interior will turn out to be individual and decorated at the same time. This material is popular both among beginners who carry out repair work with their own hands, and among specialists who have extensive experience in priming and puttying. Concrete contact primer does not contain a lot of consumption.

Priming walls with concrete contact

Concrete contact primer is considered a versatile finishing material. Has a number of advantages:

- The finished coating dries quickly. 2 hours after applying the mixture, you can already start with another finishing material.

- Thanks to the concrete contact, the surface (walls, floor, ceiling) has good adhesion to paints or varnishes.

- Moisture resistant. After the mixture dries, a waterproof film forms on the wall, which does not allow moisture to penetrate the wall. High rate of exploitation. A wall treated with concrete contact can last 60 years

- Can be colored in any color. Has a wide range of colors.

- It is applied to the wall with a spray gun, roller, brush.

- Manufacturers produce dry mix and ready-made solution of different weights.