Useful Tips

As you can see, there are no special technological difficulties in assembling a block house.

All work must be done slowly and carefully, according to the principle "measure 7 times - cut once!" Also take into account the following helpful tips that were not included in the material already described:

- The moisture content of the material should not exceed KD 8-12%. Otherwise, there is a risk of cracks and deformation.

- If you do not want to use corner fittings, cut 30 ° to the wrong side at the ends of the plank. So, the fit of the boards will be tight.

- In order not to break the edge of the board, sand the butt along the joint with sandpaper.

- Inspect the surface of the product before purchasing. Often there are knots falling out and green bloom, which spoils the appearance of the wood.

- It is advisable to apply varnish to the block house in damp rooms. The stain emphasizes the structure of the wood product.

- To twist the screws, use special "cue balls". They have a magnetized tip.

- Do not use nails when attaching the planks.

- Varnish and stain must be natural.

- Thoroughly wash the roller and brush after each coat of varnish and stain.

Furniture and plumbing

Furniture is of particular importance today. It is the accent of the interior of any room in a private house. It is these elements of the interior arrangement that indicate the desired style and hint at the well-being of the home owners. The priority is the emphasis on functionality. Any item in the interior composition of each room in a log house should be as useful as possible.

This is expressed in the presence of transformation systems, compactness. Manufacturers provide different models, taking into account the design features of the premises. For example, for bay window ledges, you can order special sofas that can occupy a rounded wall as tightly as possible.

Bedside tables have been developed for bedrooms and living rooms. They are distinguished by good functionality at a minimum size. Even for the bathroom, you can choose products taking into account the peculiarities of the layout. On sale there are corner and straight type bathtubs, options for one, two users, seating products with different bowl shapes. The streamlined shape allows for the safe operation of the premises.

Sinks for private houses made of wood are chosen lightweight. Stone countertops are undesirable here: they will create a large load on the foundation. Toilet bowls can be with microlift or heated. The presence of a frame installation will contribute to the reliability of fastening products. A metal heated towel rail will be a useful purchase. It weighs a little, but brings organization into the room.

Views

The main criterion based on which the classification of a block house is carried out is the raw material used for the production of such panels. Products are made from wood, metal or vinyl.

For the production of wooden products, preference is given to coniferous and deciduous types of wood, among which pine, spruce, cedar and so on can be distinguished.

The production of such panels is carried out using the following technology:

- the log is cut according to a special method, during which four elements are formed;

- the resulting products go through a drying process, which can last about 14 days;

- after which the material corresponding to the required properties is given the appropriate configuration, which allows them to finish the buildings.

Taking into account the quality of wooden lamellas, there are several categories of wooden block houses:

- category "A" - products of this group may contain defects in the form of 1 knot, 2 cracks and resin pockets for 1.5 m of material;

- products with up to 4 knots and 2 pockets are categorized as "B";

- category "C" includes products on the surface of which there may be defects that make up no more than 5% of the panel length.

The positive qualities of wooden products include the following material properties:

- high level of resistance to mechanical stress;

- maintainability of individual components of the structure;

- ease of installation and low weight of products;

- environmental friendliness of products;

- panels allow the bases to "breathe" and provide thermal insulation;

- aesthetic appeal.

The metal block house is notable for several positive qualities.

- The raw material for production is zinc-coated steel sheet.

- The inside of the panel is primed and painted. A certain pattern is applied to the outside, which imitates wood.

- The material stands out for its durability and resistance to temperature extremes. In addition, unlike wooden counterparts, the products are not subject to deformation from contact with moisture.

Metal gives the panels high strength, and the cost of metal products is always an order of magnitude lower than a block house made of wood. In addition, steel panels do not need to be processed and are not classified as fire hazardous construction products.

Vinyl products contain special additives that provide them with high quality and durability. Products on the market today are distinguished by a wide range of colors and low cost.

Vinyl panels perfectly imitate wood trim, among the advantages of the products it is worth noting the following characteristics:

- the material does not require specific maintenance - there is no need for processing or painting over time;

- according to consumer reviews, a vinyl block house has a long service life, which exceeds that of wooden products;

- products have a minimum weight, which eliminates the presence of additional load on the foundation of the building after the facade cladding;

- panels have a high level of UV resistance.

The disadvantages of vinyl products include the heterogeneity of the structure, as well as sensitivity to temperature fluctuations, due to which, according to experts, they should not be used for all types of buildings, including frame-type houses or buildings made of aerated concrete.

Care Tips and Tricks

Service life, appearance depend not only on the initial choice of building material, its correct installation, but also on subsequent care and respect. Simple steps to care for the casing will protect it from external factors and deformation. After installing the panels, they are covered with a primer, then a varnish with a wax base is applied.

During operation, periodically remove dust from the surface with a vacuum cleaner, carry out wet cleaning. It is recommended that coverage be renewed every five years. This procedure will not only increase the service life, but also renew the look and shine of the panels.

Types of blockhouse for interior decoration

When choosing a blockhouse for a room to be renovated, you should pay closer attention to the size, grade and appearance. The wooden panels used for interior decoration are an order of magnitude smaller, that is, the width of one board is approximately 9 cm, but there are other options for every taste

Such parameters present the room in a favorable light, visually expanding it. If you nevertheless decide to use wide panels, then this can spoil the impression, since they visually reduce the space and in some cases create discomfort.

Division of material into categories:

- Extra class.There are no cracks, irregularities or scratches on the surface of the finish. It is mainly used in rather expensive houses and luxury hotel complexes;

- Grade A. Usually, due to high-quality performance, this option is used for the treatment of residential and business premises;

- Grade B. This type of wood already has visible defects on the obverse. As a rule, this material is chosen for arranging steam rooms and dressing rooms;

- Grade C. It has a rather unsightly appearance, therefore it is more suitable for utility rooms - storerooms and basements.

On the market, you can often find combined types of panels, for example, A-B or B-C. Before making the final choice, you should familiarize yourself with the storage conditions of the panels. If the place where the panels are located does not comply with the norms and standards adopted in this area, this can affect the installation of the blockhouse - the tree can split or crumple.

Varieties of material

In the modern construction market, you can find many varieties of block houses, which differ in some parameters and characteristics. The main classification implies the selection of several types of material, depending on its quality.

- "Extra". "Extra-class" panels do not have significant defects, are of excellent quality and high cost.

- Category "A". Panels in this category are of good quality. A small presence of healthy knots, resin pockets and traces of pests (wormholes) with a width of no more than three millimeters is allowed.

- Category "B". The material may have more significant surface defects. However, flaws should not spoil the performance and decorative characteristics of the panels.

- Category "C". Products of this class are distinguished by low cost and the worst quality. The material has an unpresentable appearance and needs additional processing. Panels of this class can be used to decorate the walls of utility rooms.

The operating characteristics of a block house are influenced by the type of wood from which the material was made.

- Pine. On such a surface, there are usually traces of knots, which create an interesting pattern. The material can be used for both interior and exterior decoration of houses.

- Siberian fir. This material stands out among other conifers with the smallest weight. Fir contains little resin, so such wood is prone to decay and requires additional treatment with an antiseptic.

- Spruce. This material has a nice texture. Unlike pine, spruce has a lighter shade.

- Cedar. Such wood has a pleasant aroma and has a good effect on the indoor microclimate.

- Larch. This material is highly durable. Larch contains a large amount of resin, which protects the material from decay.

- Alder. This type of wood is considered one of the most durable and moisture resistant. The performance of alder panels only improves over time.

- Linden. Such a coating is practically not exposed to high temperatures. Most often, a linden block house is used for cladding bath rooms.

- Birch. The wood has a homogeneous structure and is easy to process with paints and varnishes. With the help of birch panels, you can create an imitation of almost any expensive wood species.

- Aspen. Such panels are not subject to decay, they tolerate moisture well and are highly durable.

Wooden panels can be of different lengths, widths and thicknesses. Standard material thicknesses are 20, 30 and 36 millimeters. The width can vary from 90 to 190 millimeters. The intermediate values of the width of the released material are usually 120, 140 and 160 millimeters. The panels are usually two or six meters long.

Preparation and accessories

Before the start of installation work, the block house should be prepared. For this, a short period of time is allocated for the acclimatization of the material. This usually takes several days. At this time, insulation, waterproofing is laid outside the walls, and the material is calculated in a cube.

Also, the installation of panels provides for the assembly of vertical battens from slats or bars. The distance between the frame elements should be 70 cm. To provide the necessary waterproofing, a thin frame is additionally attached to the self-tapping screws over the insulated lathing.

To install the boards, you need to purchase certain components.

- Universal planks.

- Hanging profiles. They are usually fastened over window openings to protect the finish from moisture. If the facade consists of several levels, then the profiles are used between the transitions.

- Starting bar. It is necessary for mounting the bottom row of boards.

- Finishing profile. It is placed along the edges of the wall to secure the last panels.

- Connecting strips and corners.

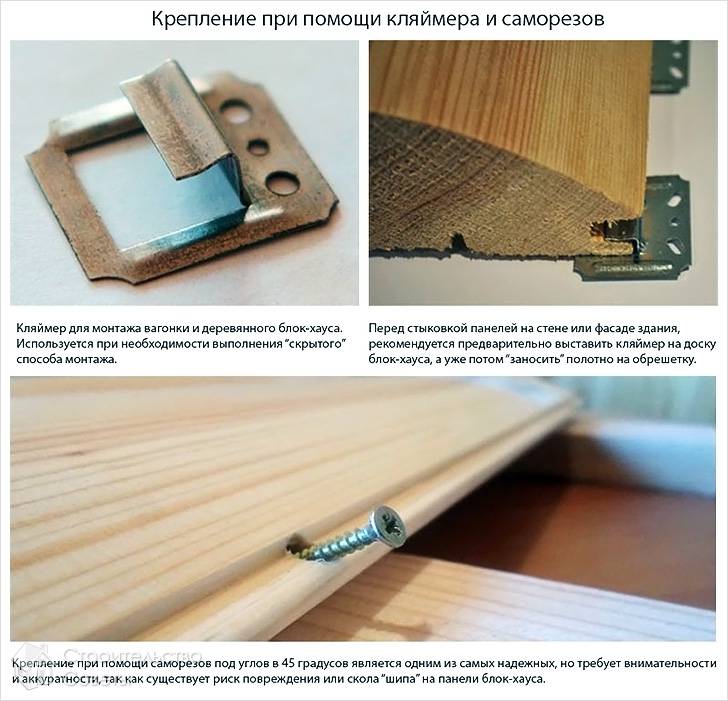

- Special fastening elements (kleimer and self-tapping screws).

Installation tools should consist of a standard set including tape measure, level, screwdriver, hammer and drill.

Material selection

You can get attractive and high-quality cladding only if you choose the right material. For the interior decoration of rooms, a block house is chosen from both coniferous and deciduous species.

The former contain a large amount of resins and essential oils in their composition, which provides a natural antiseptic effect. In addition, they bring the unique aroma of the coniferous forest into the house. Usually, spruce is used, which has a large number of knots, which creates an interesting pattern. Pine pleases with an attractive amber-gold hue; a room decorated with such material looks warm and cozy.

When choosing a coniferous block house, it should be remembered that it is not suitable for rooms with high temperatures (bathroom, sauna, steam room), since when the temperature rises, resin is released. It can cause burns when heated.

Hardwood is also popular. It is necessary to choose its varieties that demonstrate strength, resistance to decay, warping. These include oak, aspen, linden.

As for the appearance, the block house can imitate a bar or a log. The first in section forms a square, the second - a circle. A block house under a log allows you to imitate the surface of natural log walls and looks very original.

For interior decoration, panels with a width of about 8-10 cm are usually selected, while for external cladding - a wider option, that is, 20 cm.However, this is not a mandatory rule, and if necessary, you can choose a wide block house for a room ...

The standard length of the material ranges from 2-6 m, it should be selected based on the ease of installation and design features. So, with the help of long and thin light strips, you can visually make the room larger. The cost of the material depends on the length parameter - the longer the bar, the more expensive it is.

As for the thickness of the material, 2 cm will be enough for indoor use.In general, the strips can have a thickness of 2-4.5 cm.

Having decided on size and appearance panels, it is necessary to find out what class they belong to, since this largely determines the quality of the products.

Panels belonging to the "Extra" class are distinguished by premium quality. They have no knots or internal pockets and are cut exclusively from the middle of the trunk. As a rule, such finishing is used in elite premises, and its cost is high.

Panels of class A, B demonstrate fairly high quality. They have a small number of knots, darkening, but at the same time suitable for finishing, look neat and noble, have a more affordable price.

There is also a class C material that is not suitable for use as a finishing material.

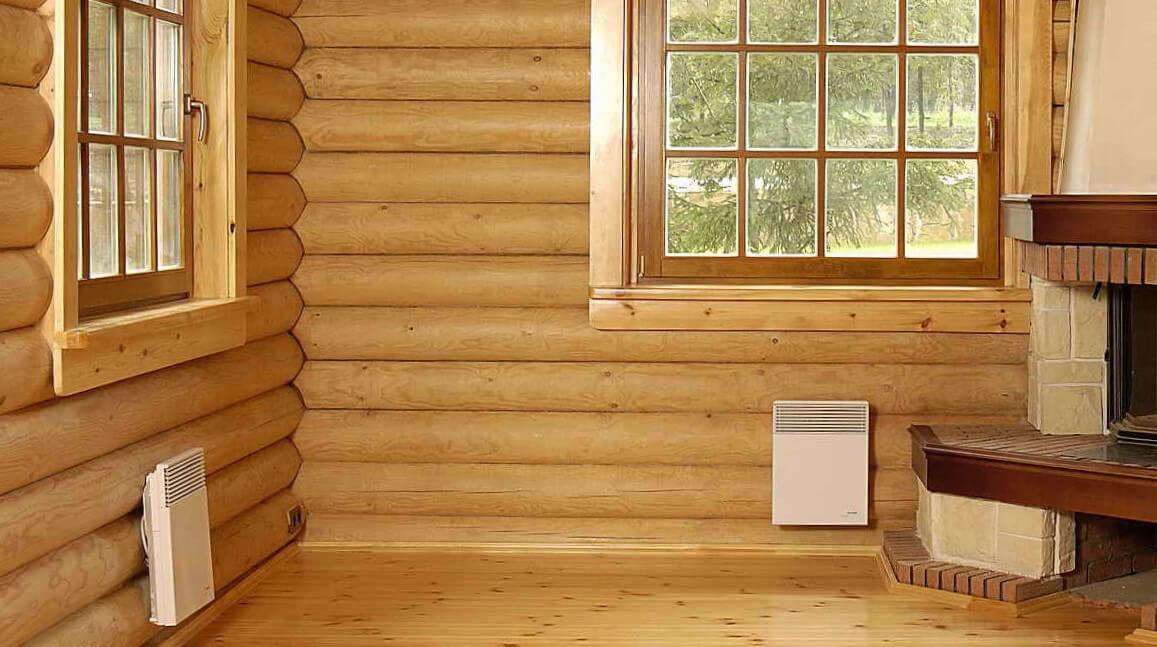

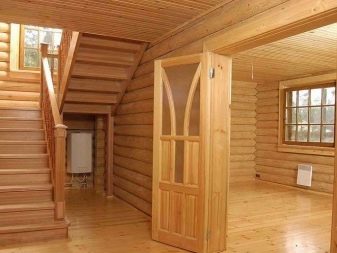

Room decoration ideas

Today there are many ideas for using a block house in the interior. This material is often used in combination with bright paint or decorative plaster and wallpaper. Cladding with natural stone and paneling will allow you to make high-quality repairs, which you will not have to think about for many years.

Wooden panels, placed on one of the walls in the bedroom, look especially beautiful. Thus, the sleeping area acquires an interesting design, it combines style and utility at the same time. Wood fills the room with a pleasant scent and creates an excellent environment for relaxation. The corner lined with a block house looks unusual in the interior of the bedroom. In order not to disturb the unity of the image, it is recommended to decorate the ceiling with boards. An interesting decor option can be obtained by decorating one of the walls of the bedroom with a block house, and the other with clapboard.

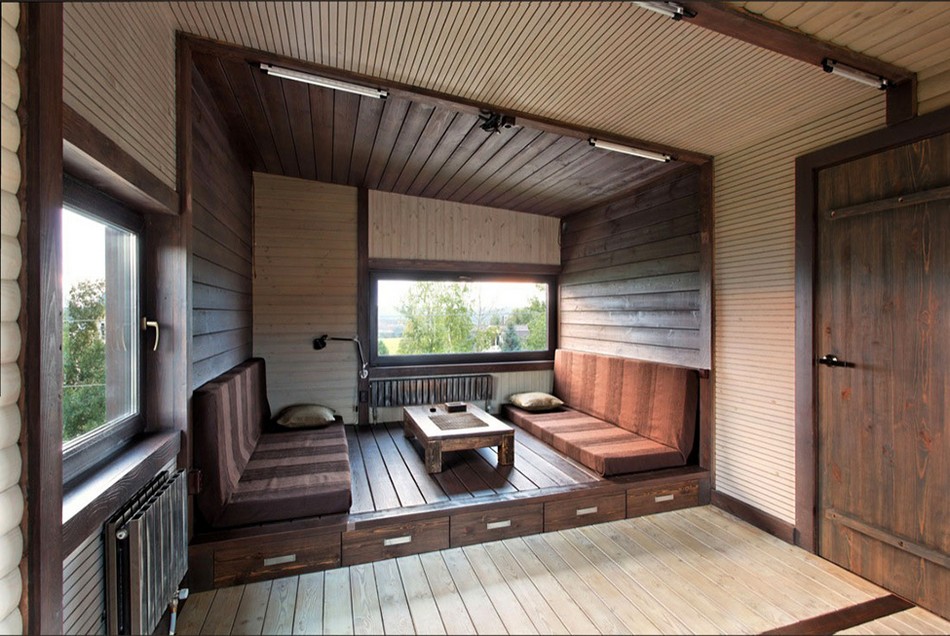

In the event that you need to create a Provence style, then in an apartment it is best to use natural wood panels for interior decoration, giving preference to light shades. In this case, the installation site for them can serve not only a wall, but also ceilings or furniture. Thanks to the play of colors and the use of boards of different textures in the rooms, it is possible to create an atmosphere that will resemble a merchant's or noble house.

The living room is considered the face of the owners, therefore, its design must be appropriate. To fill this room with chic and beauty, it is enough to sheathe the walls and ceiling with expensive wood species. It is advisable to choose panels with an imitation of the natural pattern of the array in the form of knots. At the same time, one wall, sheathed with wooden panels, looks good, while the others are decorated with decorative plaster. This idea allows you to avoid monotony in the interior and fill the space with natural motives.

A special place in the interior is occupied by the design of the corridor or hallway. For these rooms, you can combine a block house with clapboard in the wall cladding. This will create an interesting transition in lines and colors. If the corridor and hallway are small, then it is necessary to choose light shades of the panels. Both brown and gray are suitable for this. In the event that the area of these rooms is large, then it is recommended to decorate them in country style and try to use the maximum number of colors in the cladding. In the cladding of the corridor walls, a combination of wood panels with metal, stone and glass is also allowed.

The block house has found its place in the décor of the kitchen. For this room, you can choose boards of various colors. The kitchen in the style of Provence and Katri looks especially exquisite. The house block is installed on walls, ceilings, partitions are made of it and all surfaces are painted with paints of warm shades. An original solution will be the processing of semi-antique boards, after which they will acquire roughness and cracks. If the kitchen is decorated in the style of a "Russian hut", then you can dilute its interior with artistic painting.

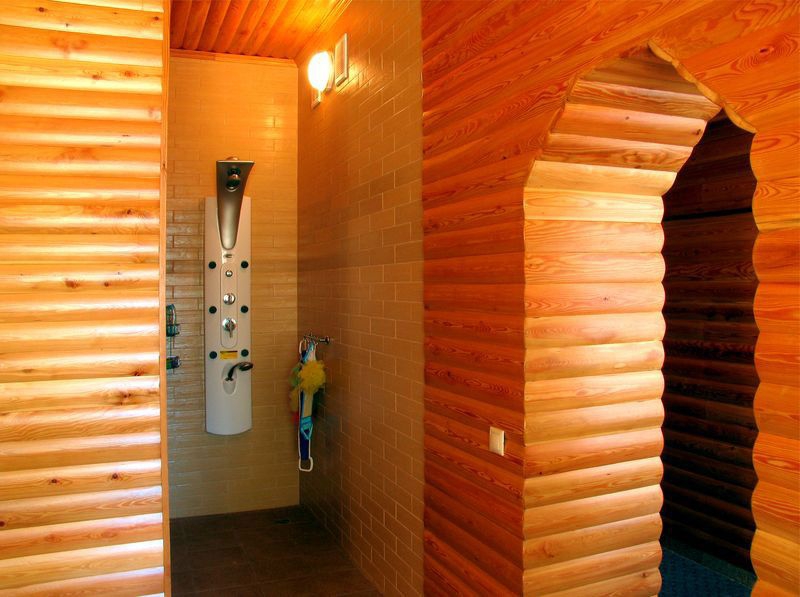

In the interior of the bathroom, it is important to create a feeling of coziness and comfort, therefore, when covering walls and ceilings, you need to choose the right color for the block house. Chocolate, white, gray, beige and resinous-black shades of wood will look good in the bathroom

In this case, decorative finishes should be complemented with carvings and patterns. In addition, cold or neutral shades can be used in the bathroom interior. The block house in this room is best installed on one of the walls, as well as decorate the washbasin area with cladding.

It is worth paying attention to the fact that the color of the furniture, ceiling and flooring should be in harmony with the wood panels.

You can learn more about the block house for interior decoration from the following video.

Advantages and disadvantages

Like any other building product, the block house has its own positive and negative characteristics.

The widespread use of this product in the interior decoration of premises is due to its advantages.

- Environmental friendliness. The panels are made exclusively from natural raw materials. For this, high-quality wood is selected, which undergoes preliminary processing and drying. In addition, the blockhouse made of coniferous wood creates a good microclimate in the rooms. As for the boards made of deciduous trees, they have high hardness and moisture resistance.

- Strength. The material can withstand the effects of various environments. It is UV resistant and does not lose its original appearance and quality over time.

- Aesthetics. The excellent appearance of the boards allows them to be used for various decoration of rooms, further emphasizing the beauty of the interior. The material is produced in a variety of colors, so it fits perfectly into any room design.

- Light weight and easy to install. Installation work is carried out quickly and does not require a special tool, so it is quite possible to do it yourself, without resorting to the help of specialists. In addition, the light weight of the panels does not require additional reinforcement of the surfaces and foundations of the house.

- Thermal insulation. Wood retains heat well.

As for the disadvantages of the block house, they can be attributed to them.

- Insufficient vapor permeability. The surface trimmed with this material "does not breathe", so condensation can accumulate on it. Most often, a similar problem is observed in rooms where there is no constant temperature regime. To avoid this, it is enough to install a good ventilation system or make wall lathing with a pitch of 50 mm between the beams.

- Flammability. Since natural wood is usually used for the production of a block house, it is worth worrying about protecting it from fire and treating it with a refractory mortar.

Advantages and disadvantages

Among the advantages are:

- Environmentally friendly - impregnation and other chemical agents are not applied to the wood during manufacture;

- Soundproofing - wood absorbs and attenuates noise;

- Thermal insulation - although it is not a heater, it perfectly insulates cold walls;

- Lightness and strength - it will not create a load on the walls and foundation;

- Ease of installation - installation will not cause difficulties and even a layman can do it. The main thing is to set the level correctly;

- Combines with other finishing materials.

Disadvantages include:

- The wood burns, so it is imperative to process it with a special compound;

- Even with a slight impact, dents can appear;

- Weak vapor permeability. Without good ventilation, mold or mildew can develop underneath.

Mounting

Finishing a block house inside the house must be approached responsibly and carefully. The duration of the service life of the material and the quality of the cladding depend on the preparatory work. For a wooden blockhouse, there are a number of features that must be taken into account during installation. Required tools for installation work:

- level;

- self-tapping screws and screwdriver;

- antiseptic;

- brush;

- drill;

- hacksaw.

The first step is surface preparation. The walls must be treated with a special disinfectant primer. For each type of walls, a separate type of impregnation is selected. Consult with experts when buying a building material, they will tell you which type is better to buy for your coverage.

Next, clean and level the walls of the room. Since the panels will be installed on the frame, careful alignment is not required. The room in which the finishing work will be carried out should not be with high humidity. The panels must be acclimatized, for this leave them for several days in the room where the installation will be carried out.

The installation of the frame is the next stage of finishing the house with a blockhouse.Before installation, wooden profiles must be treated with special agents to protect them from moisture. We install the beams with a step of 50 cm. The walls can be insulated if necessary. The thickness of the profiles should be no more than 25-30 cm. The direction of the profiles should be perpendicular to the panels.

The next step is to install the panels. The cladding must be started from the bottom up. The first panel is fastened with bolts, the subsequent ones snap onto each other and are also fixed with self-tapping screws.

Corner docking can be done in two ways:

- cut the ends of the panels at an angle of 45 degrees and connect them without auxiliary elements;

- using corners.

After the walls are finished, the panels must be sanded. Then the surface is treated with stain. There are various colors of the protective antiseptic that you can choose based on your preference.

Features of interior design of country houses

The concept of the interior of a country villa includes the arrangement of a garden-vegetable garden, external, internal decoration. Interior finishing is the final stage of any construction project. The style of design is approximately chosen according to pictures from the Internet, glossy magazines. Materials are selected based on the previous experience of the owners, if they have ever been involved in renovation, on the advice of friends, and sometimes on the recommendations of finishing specialists.

It is better to think over the general design concept at once - after all, all architectural elements, buildings, interiors are developed in a complex. The right approach will turn a modest nondescript house into a luxurious home, a cozy villa, where no generation can enjoy a vacation.

Since this place is intended for the leisure of the whole family, perhaps sometimes with relatives, friends, the house is planned to be very extensive - there will be a kitchen, a living room, an entrance hall, a nursery, a bathroom, bedrooms, workshops, a swimming pool. You also need to take care of utility rooms, outbuildings - if it is supposed to keep animals, store garden equipment, etc.

How a house block is mounted in an apartment, indoors

First you need to prepare the walls. Their surface is coated with a deep penetration impregnation with disinfecting properties. This is necessary so that the cladding of the house inside the block house does not lead to mold and rotting of the walls. The choice of the impregnation itself depends on the material.

If on the surface of the walls there are any serious potholes, irregularities, you can walk on them with plaster, but "without fanaticism" - it is not at all required to level everything to the ideal. It is necessary to remove dust, dirt, remnants of the old cladding from the walls. It is good to cover the boards used for the lathing with a special water-repellent compound for wood.

How to put the frame

If there is a desire and need, then the frame can be supplemented with a layer of steam and heat insulating materials - a vapor barrier film, expanded polystyrene or mineral wool plates. For the construction of the lathing, a beam is used, whose thickness does not exceed 25-30 mm. Photos of the interior decoration of the block house, for all their usefulness, will not tell you about the important role the dryness of the material plays.

This is necessary so that during the drying process it does not deform and spoil the overall appearance.

If the attic is being finished with a block house, you can see in the photo that a distance of half a meter is maintained between the individual elements of the crate. The same principle applies to cladding and other objects. Plumb line, level, square and answers will help you find out how correctly the frame is set.

If the cladding panels will be installed vertically, then the sheathing beams are placed horizontally. The interior decoration of the blockhouse does not require the obligatory treatment of the lathing with a water-repellent primer, but it can still be done. But in baths, saunas and other rooms with a high level of humidity, this stage is required.

How to mount the cladding

On the instructions in the form of a photo, a block house inside the house begins to be done by attaching the starting bar with self-tapping screws, then going from the bottom up. The self-tapping screw cap should go 2-3 millimeters deep: this will allow you to cover it with a special plug or a PVA ulem to match the panel.

When the house is finished with a blockhouse, the boards are placed so that the spike looks up, after which the next slats are placed. They are connected to each other using grooves and spikes on the edges. In the places of corner joints, special corners can be attached.

If the finishing of the block house inside the house is done correctly, it guarantees a wonderful - cozy, healthy - environment.

Interior decoration block house PHOTO: