Unscrewing

So, how to unscrew a universal screw with a countersunk head or a self-tapping screw with torn off edges, or worse, without a cap at all.

The first thing to do is to inspect the tool used for turning out and replace it with a suitable one. The tip of the tool should fit snugly into the slot and not be worn out.

To remove the screw, the screwdriver must fully match the shape and dimensions of the slot. If the replacement did not work, we use other methods. Self-tapping screws for drywall are most often possible to unscrew by using thin sheet rubber, laying it between the screwdriver and the slot.

When unscrewing from a board and other wooden products, it is effective to hit the head of the screw, followed by tapping on the screwdriver at the moment of application of force. If the universal screw with a semicircular head is not completely wrapped (protrudes above the surface by at least a millimeter) or the design of its head allows this, then using pliers or a gas wrench, try to unscrew it.

A few drops of brake or lubricating fluid, kerosene will make the screw scroll. You can heat the hardware, it will expand and deform the surrounding materials, and cooling will allow you to turn it out.

It is possible to use adhesives (superglue, "liquid nails", "cold" welding, and if time permits, then epoxy compounds), soldering or, if the fastened parts allow, then welding. If the self-tapping screw does not begin to twist, proceed to radical measures.

Carpentry Tricks. 10 Methods for Removing a Broken Screw.

Bolt unscrewing methods

Below are the most effective ways to remove damaged bolts and screws.

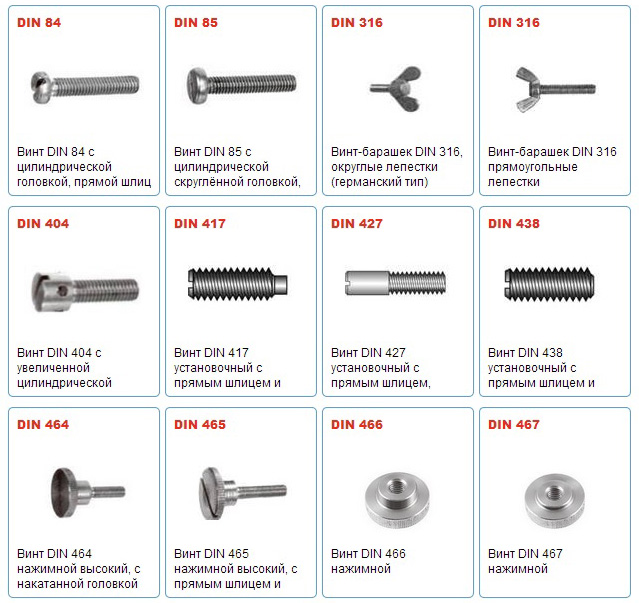

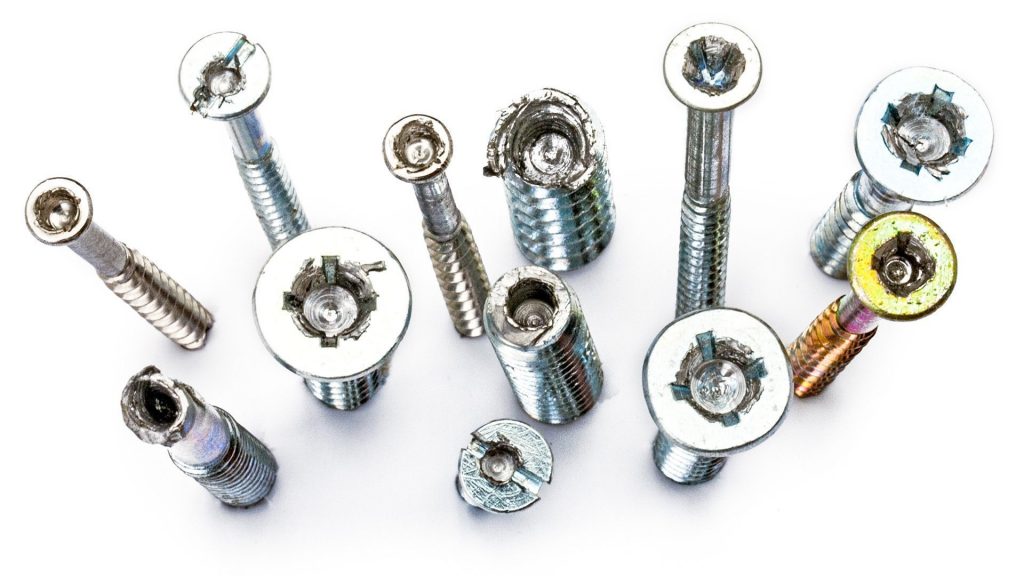

With tainted edges

When deciding how to unscrew a bolt with a torn off edges, you need to consider whether you have access to it, its location, and what tool you can use. Based on these factors, you can apply one of the following methods:

- Using a chisel. This method is suitable for large bolts that are easily accessible. All you need is a hammer and chisel. The chisel is applied tangentially to the head and sharp blows are applied to it. The method is simple, but it rarely achieves the desired result. It should only be used when there is no other tool at hand.

- If there is easy access to the location of the fasteners, you can use the universal adjustable key. Even a round head can be clamped securely with this tool. If you use small cobra wrenches, which have sharp notches on the working surfaces, you can unscrew the smallest bolts. Such a tool can help out in many cases, but it must be new. With a worn tool, the notches can no longer provide reliable adhesion to the metal, and the key will slip.

-

If the edges are not severely damaged, then the heads for the spanner wrench can help out. For these purposes, the profile of the spanner wrench must have 12 edges (there is an asterisk inside the head, not a hexagon). Unscrewing is performed as follows. Choose a head one size smaller than the size of the bolt, and press it onto the torn edges with a hammer, then unscrew it in the usual way.

- This method consists in using a hacksaw for metal, with which a cut is made on the head of the bolt for a flat screwdriver. The cutting depth should not be more than 75% of the height of the bolt head; at greater depth, one of the halves may break off.

- If you have a file or a grinder at your disposal, then you can restore the turnkey edges of a smaller size. If you have an open-end wrench, it is not necessary to cut out the hexagon; it is enough to make two parallel faces.

- If welding can be used at the location of the attachment, then this will greatly facilitate the task. In this case, you can put a nut of a suitable diameter on the head and weld them together, and then use ordinary keys.

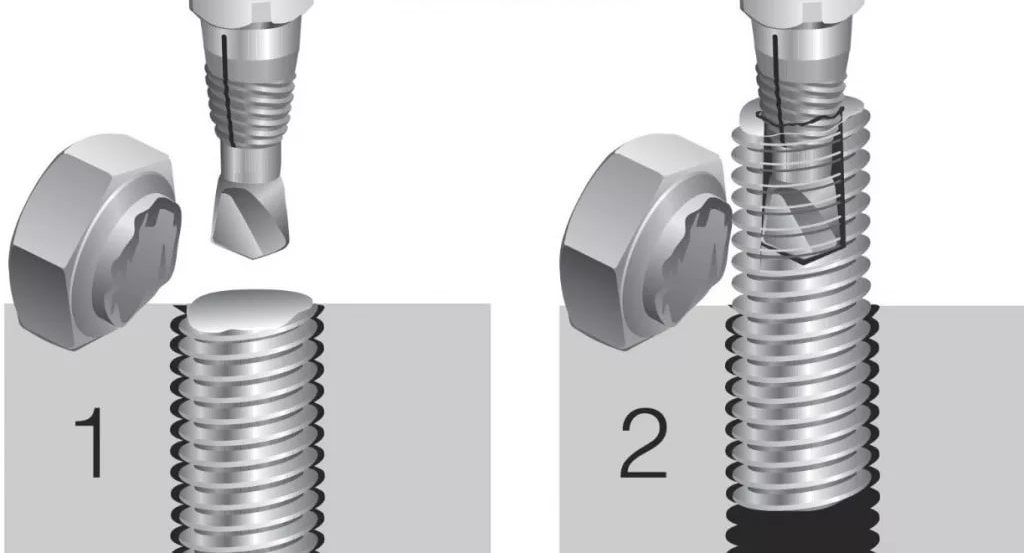

With a torn off head

Very often, disassembling old threaded connections, you can not only damage the edges of the bolt, but also tear off the head. Then the question arises: how to unscrew the torn off bolt. If you have disconnected the parts, and the stripped bolt protrudes from the body of the part, then you can use all of the above methods.

But how to unscrew a bolt with a torn off head if the bolt body does not protrude from the part? There are several options for solving this problem.

- It is best to use a special tool - an extractor. The extractor is made of a cylindrical metal rod, at one end of which there is a tapered thread of the opposite thread, and at the other end there is a square shank. To use it, a hole must be drilled in the center of the bolt. The hole diameter is 2-3 mm less than the thread diameter. After that, you need to take an extractor of a suitable size and hammer it into the hole with a light blow. Turning the extractor by the shank, unscrew the rest of the bolt.

- If there is a left-hand thread tap, you can successfully use it as an extractor. The only difference is that the hole diameter must be the same as for threading. The exact value can be found in the corresponding tables.

- If you still can't unscrew the chip, you can try to remove it in this way. Drill a hole in the bolt with the largest possible diameter, taking care not to damage the threaded connection. Then take the appropriate tap and cut a thread in the hole. During this process, the threads are cleaned and the remnants of the bolt are removed.

Ways to pull out a screw with a torn cross

If the edges of the fastener are torn off or licked, then there are several ways to unscrew such a screw or self-tapping screw.

Crimping protruding thread head

In the event that a part of the self-tapping screw protrudes above the surface, you can unscrew it by squeezing the head with pliers. For this, it is best to use thin pliers (platypuses). With their help, they clamp the tip of the screw and begin to rotate it counterclockwise. Instead of pliers, you can use a drill chuck. They squeeze the head and unscrew the self-tapping screw.

With a drill chuck, crimp the head of the self-tapping screw and unscrew it

Restoration of splines

If you cannot grab the head with pliers, and the screw rises slightly above the surface, then the slots can be restored. To do this, use a grinder or a hand saw for metal. With their help, a cut is made on the head, it should not be deeper than 2 mm, otherwise the head will weaken and break. After that, unscrew the screw with a flat screwdriver.

The cut on the head should not be deeper than 2 mm, otherwise it will weaken and break

Drilling a hole in the head

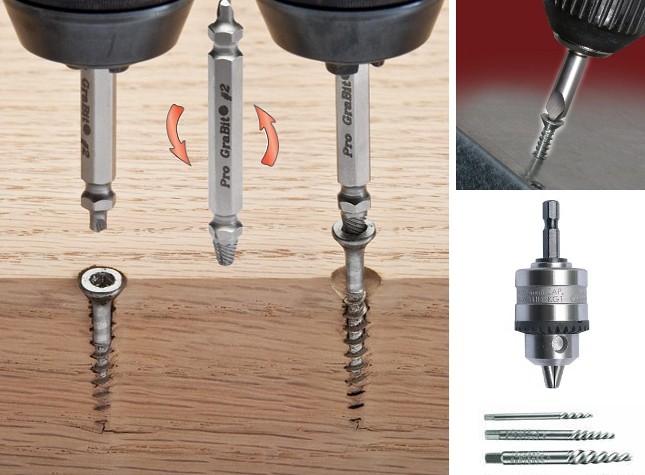

A left hand drill can be used. In the store, in addition to the usual drills, there are those with a spiral stroke from left to right. Using such a tool, a hole is made in the head of the screw. When the drill reaches a certain depth, it gets jammed and the self-tapping screw begins to unscrew with it.

When the drill reaches a certain depth, it gets jammed and the self-tapping screw begins to unscrew along with it.

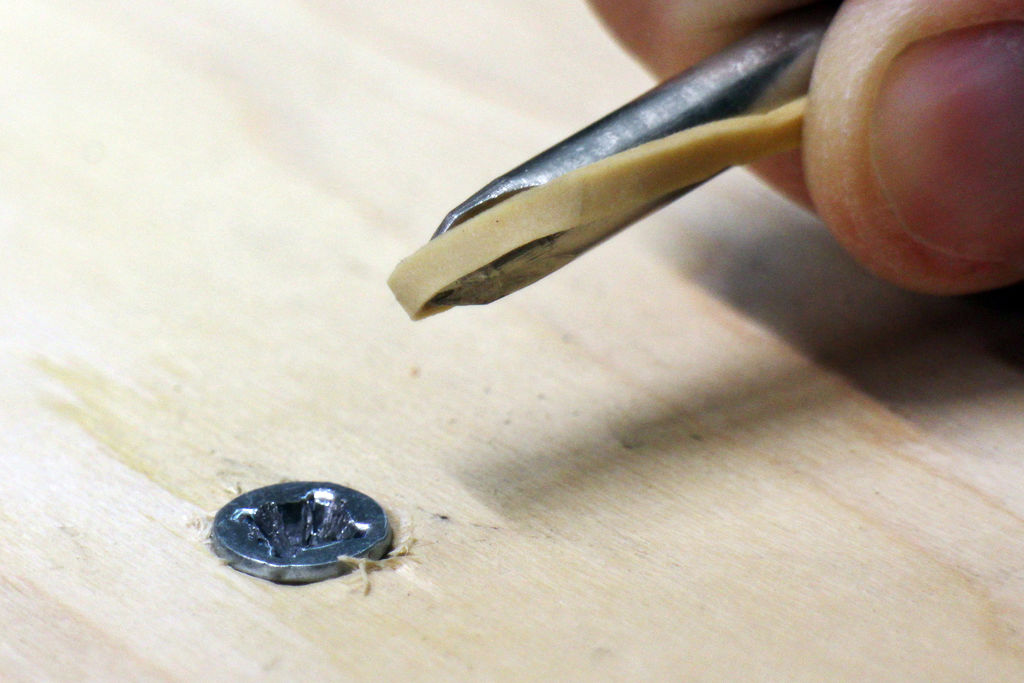

Use of rubber

For this method, you need to find a piece of medical harness or dense rubber, for example, a camera from a motorcycle. A screwdriver is selected that fully matches the slots on the head of the self-tapping screw.A piece of rubber is placed between it and the head and, pressing hard on the screwdriver, unscrew the problematic fasteners. Rubber helps to increase the coefficient of friction, and the tip fits snugly into the slots on the head, so the screwdriver does not slip.

A piece of rubber is placed between the tip of the screwdriver and the head of the self-tapping screw and, pressing hard on the screwdriver, unscrew the problematic fasteners

Heating fasteners

This option works well when the fastener is screwed into plastic. Using a soldering iron, heat the screw head. The high temperature softens the plastic and weakens the fasteners. After that, you need to quickly, until the surface has cooled down, unscrew the self-tapping screw. If the screw is in wood, then it is heated and waited until it cools down. This allows the fastener to be slightly loosened, after which it is easier to unscrew the fastener.

Extractor application

An extractor is a tool designed to unscrew screws, bolts and self-tapping screws with broken heads. First, using a drill, the diameter of which is less than the diameter of the head, a recess is made in it. After that, take a conical extractor of the appropriate diameter, screw it into the recess and unscrew the fasteners. You can use the extractor immediately if the depth of the slots is sufficient for screwing it in.

Usually self-tapping screws and screws are right-handed, and the extractor left-handed.

There are slotted extractors. They are made in the form of a nut, to which there is a slot instead of an internal thread. A slotted extractor is put on the screw head, and then the slot is screwed into it.

With a core and a hammer

The core has a sharp end, therefore it provides reliable engagement with the head of the screw or screw. In order to unscrew the problematic fasteners, the core is abutted against the head at an angle of 45o, after which it is gently hit with a hammer in the direction opposite to screwing. As soon as the fastener is loose, the screw is unscrewed with a screwdriver.

Using an impact screwdriver

The peculiarity of the impact screwdriver is that it has a strong handle that can be hit with a hammer. Take such a tool so that its tip matches the slots on the screw. They insert the sting into the slot and make several blows on the handle, after which they try to turn the fasteners. Such actions allow you to loosen the fastening, after which the screw or self-tapping screw is simply unscrewed.

Using glue

For this, epoxy glue is usually used, as it provides a very reliable connection. After the screw head has been greased with glue, a nut is placed on it and wait until it adheres well. After that, using a key, turn the nut and at the same time unscrew the problematic fasteners.

How to remove a rusty screw?

How to remove a rusty wood screw from a board?

How to remove a rusty screw from a concrete wall?

Tips for removing different screws from different materials:

- Blow - it is necessary before you try to unscrew it, hit the screw head through a spacer, preferably copper or brass, you can also use bronze, if there are none, then through mild steel so that the blow goes through the entire screw and there is no recoil. The point is to "rip" rust from the place where it adheres to the surface of the threaded joint ...

- Impact tool - you can use an impact screwdriver, both manual and mechanical. The meaning is the same - “to rip from the place of rust ...

- Heating - pre-heat the screw before unscrewing it, you can use different heating options - fire, electricity, heat transfer from one object to another. The point is that the metal will first expand, and then take on its basic size, while crumbling the rust ...

- Rust converter - you can use a chemical method, pre-treat the screw with an active chemical liquid, such as a rust converter, WD-40 and its analogues, Coca-Cola and others. The method may not be effective if the liquid does not get into the rust.The point is that chemicals "eat away" rust ...

If the screw is just old and rusty, then it is worth lubricating it with a WD-screw or oil, wait a little and unscrew it with a screwdriver. And if the screw is stuck, then a common way to deal with this trouble is to soak it in Coca-Cola. We often use this driver with experience, when the wheels do not unscrew on old VAZ cars. The third method, which I personally tried, was to hit a screw.

Recommendations

A tool useful for unscrewing different types of screws is best purchased in advance and kept close at hand. This moment is especially relevant for owners of garages and personal vehicles. Here, an extractor for unscrewing broken hardware will be most useful - it is better to choose a universal type of construction, with a shortened working part. With it, it will be possible to unscrew the problematic fasteners even in hard-to-reach places.

There are some simple tips to help you reduce the chances of edges or splines breaking off.

- Select exceptionally high quality fasteners with a hardened head.

- Securely fix the tool tip in the slots. When a screwdriver or bits slip, the protruding edges are erased - it will be more difficult to turn out such a hardware.

- Maintain the tool in working order. On a key or screwdriver, the edges also often turn out to be licked, which greatly interferes with the normal unscrewing of the fasteners.

Considering these tips, you can avoid the occurrence of problems with unscrewing screws for various purposes from the parts fastened by them.

In the next video, you will learn how to remove any screw.

How to unscrew?

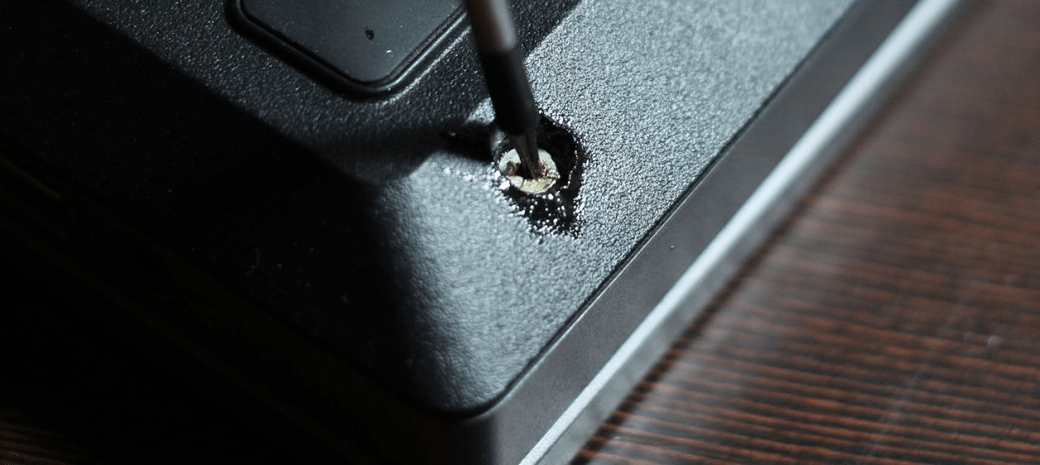

Each laptop model has its own disassembly diagram, which shows the unscrewing sequence. You can find it on special sites and forums, sometimes it is in the user manual. After familiarizing yourself with the diagram, pick up a screwdriver.

- With a plastic sting. It is needed for delicate disassembly, since it does not damage the splines and does not scratch the case. If it does not help, steel is used.

- With a hardened steel blade. It is needed if the slots are "licked", the edges are torn off, it is impossible to unscrew the screw. It can slip off and damage the part, so you need to act carefully.

If the screw comes loose, you're in luck. And if you need to unscrew the licked bolt, do the following:

- drip silicone grease on the thread or head (industrial can corrode plastic);

- warm up the head with a soldering iron; if the screw is screwed into the plastic, the soldering iron must be impulse;

- make new slots - for this, take a flat sharp screwdriver, attach the sting to the place of the old slot and hit the end of the screwdriver with a hammer; you need to beat lightly, otherwise the connection will deteriorate; if you do it right, the head is deformed and you get a new slot, of course, such a screw will need to be replaced with a new one;

- a screw with torn off edges can be unscrewed by cutting new slots with a file; To prevent sawdust from getting inside the case, use a vacuum cleaner during work, after cutting, wipe this place with a cotton swab.

The following video shows you how to remove a screw from a laptop.

Ways to unscrew bolts, screws, screws with lapped edges

If in the usual way it was not possible to unscrew the fasteners whose edges were licked off, you can use one of several proven options.

Gas wrench

This method is used when loosening bolts, since they have a head protruding from which you can grab. For this:

- Clean the head of the bolt.

- Lubricate the junction with kerosene or diesel fuel, a liquid such as WD-40 helps well, and leave for 15–20 minutes.

-

Unscrew the bolt. This is done with a gas wrench. With its help, a great effort is created and even a round head can be well gripped.

The disadvantage of this method is that it is not always possible to get close to the desired bolt with a gas wrench.

Slicing new faces

If the bolt is large, then with the help of a grinder, new faces can be cut on it. It is enough to make only 4 of them and unscrew the bolt using a smaller wrench. It is possible to cut new faces on the bolt with a file, but this is more difficult and takes longer. On the head of a screw or screw, you can make a cut with a hacksaw for metal or a grinder.

A deeper cut can be made on the head of a screw or screw for a screwdriver

Hammer and chisel or impact screwdriver

This option is more suitable for lapped nuts or large enough screws. The chisel rests on the head of the fastener and, striking it with a hammer, gradually turn the screw or nut. Small screws or screws can be removed with an impact screwdriver and hammer. After loosening the fastening, the work is done with an ordinary screwdriver.

An impact screwdriver can be used to unscrew small or lapped screws

A tourniquet or piece of rubber

In this case, use a small part of a medical tourniquet or a piece of dense rubber. The selected material is placed on top of the head of the screw or screw, after which it is pressed with a screwdriver and gradually turned. The presence of rubber will help increase friction and solve the problem.

The harness is laid between the screwdriver and the head of the screw or screw

Extractor

An extractor is a special tool that is used to loosen screws, bolts or screws with lapped or broken heads.

Extractor - a tool for loosening screws, bolts or screws with lapped or broken heads

The order of its application:

- Using a thin drill, a small hole is made in the head. In some cases, the extractor can simply be driven into the lapped screw slot.

- An extractor of the required diameter is selected. Drive or screw it into the prepared hole. It depends on whether you are using a conventional tool or a screw tool.

-

Unscrew the bolt.

Video: unscrewing a licked screw with an extractor

Conventional or left hand drill

Left hand drills with counterclockwise rotation are available. They improve the centering of the tool and reduce the stress on the drill, which results in higher productivity and accuracy of drilling. By inserting such a tool into a drill, you can unscrew the screw or screw with a licked head. If a left-hand drill is not available, you can try drilling out the jammed fasteners with a regular drill. In this case, you need to take a drill, the diameter of which is less than the diameter of the bolt or screw.

It is necessary to act carefully so that you do not have to cut the threads for the new fastener later.

The drill should have a smaller diameter than the problematic bolt

Glue

A nut of the appropriate diameter is fixed to the head of the problematic screw or screw using epoxy glue or glue called "cold welding". After the glue securely fixes it, turn the nut with a wrench and unscrew the screw or screw with it.

With the help of glue, the nut is fixed to the licked head, and then the screw is unscrewed with it

Welding

If there is a welding machine nearby, then you can fix a new nut on the head of a bolt or screw by welding it.After that, it can be unscrewed immediately.

A new nut can be welded to the problematic bolt or screw.

Solder and soldering iron

If you need to unscrew a small screw or screw, use a soldering iron and solder:

- The heated solder is dripped onto the head of the fastener with lapped edges.

-

Until the tin has solidified, a screwdriver is inserted into it and wait a few minutes.

- Unscrew the problem screw and clean the tip of the screwdriver from the solder.

Methods for loosening sour bolts

Motorists, namely, they most often have to deal with stuck bolts, know how to unscrew a sour bolt. Several methods of loosening are used, including the use of physical and temperature exposure, chemical compositions.

Tapping and physical impact

Impact with a hammer and chisel helps to break the adhesion of materials, corrosion, as a result of which the bolt yields and twists out.

Tapping. A preparatory measure that helps break down oxides. In mild cases, after tapping, it is possible to unscrew the hardware. It is enough to hit the fastener 2-3 times with a hammer using a copper adapter.

Loosening. Like tapping, it is aimed at breaking down rust. You should not unscrew, but on the contrary, tighten the bolt even tighter, and only then try to unscrew it.

Lever arm. It is advised to use it as a key tool at hand. First, the hardware itself and the area around it should be cleaned with a metal bristle brush. Then a spanner wrench is put on the head of the fastener, and a pipe is put on the wrench. The lever increases the force of impact, but it is not recommended to apply excessive force, as this leads to licking the edges of the nut and breaking the key.

Chisel. Using this effective technique, rust can be broken up and fasteners can be lifted off the ground.

However, in this case, it is important how the chisel is installed. It should be placed closer to the edge of the bolt / nut, at an angle, in the direction of unscrewing

A sharp and powerful blow with a hammer should be applied to the blunt side of the chisel.

WD-40 and Penetrators

WD-40 is a popular tool used by almost all motorists. If suddenly it was not at hand, other liquids, such as gasoline, kerosene, white spirit and the like, will help unscrew the bolt due to the high penetrating power and properties of the solvent. They soften dirt, rust, penetrate deep into the threads, acting as a lubricant. The application is simple: you need to clean the area around the acidified compound and fill it with the selected agent. After 10-15 minutes, the deposits will soften, the grease will seep into the smallest gaps - the bolt can be unscrewed.

Warming up

Under the influence of high temperature, the metal expands, therefore, in order to unscrew the bolt, you need to warm up the nut or the part into which the hardware is screwed, and if this does not help, then the fastener itself, since the fluctuation in size will help destroy the rust. Heating can be done with a tool such as a gas torch, soldering iron, or even a lighter.

A special device for heating corroded and stuck bolts and nuts is an induction bolt heater. The heated part is placed inside the induction field, the spiral, and as a result heats up. The advantage is that heating is carried out from all sides at once, and not from one side, as in the case of using a burner or other tool. This device is small, convenient, operates on a 220 V network. You can assemble it yourself from available tools.

While the nut is hot, unscrew it with an open-end or socket wrench. If it was not possible to unscrew it immediately, repeat the procedure and use combined methods (lever, tapping, loosening).

Acids

Acids are used to loosen bolts and nuts. A well-known remedy is table vinegar. After moistening the cleaned compound with vinegar or covering the rusted area with a rag soaked in vinegar, wait about 30 minutes for the rust to soften. Then the hardware can be twisted.

In addition to vinegar, phosphoric acid is used, and in particular Coca-Cola, which contains it in an amount sufficient for a positive result. The procedure remains the same: it is necessary to clean the area surrounding the fastener and fill the fastener with a drink. He should get wet. Periodically, they try to unscrew the bolt. Phosphoric acid is used to degrease and dissolve rust.

A special agent that is made on the basis of acids is a rust converter. Before using it, the surface must be cleaned and degreased with a solvent. Then a small cloth is moistened with the converter and placed directly on the rusted joint. Rust is destroyed - the hardware is unscrewed.

How to prevent rust

As you know, it is easier to prevent a problem than to fight it hard later. Among the many drugs for corrosion protection, the following can be distinguished:

- Long acting inhibitor. After processing metal products with this tool, you do not have to worry about accidentally forgetting them on the street. Let them lie there for a whole year. Now they are perfectly protected from the effects of any bad weather that can cause a corrosive process.

- Lithium preservative grease. It is used to process door hinges, various chains and cables. After application, a thin film appears on the surface, which is not afraid of exposure to the atmosphere and does not allow rust to develop.

- Silicone grease. Since the grease is made on the basis of silicone, it can be easily applied to any metal products, even if they have partially plastic, rubber or vinyl inserts. When the grease dries, a thin, transparent, non-stick protective layer forms on the surface of the product.

- Anti-corrosion spray. Used when it is necessary to process areas with difficult access. The spray penetrates deeply into the product and prevents rust from appearing on it. A very popular tool for threading fasteners.

- Rust stain remover. The composition contains non-toxic substances. It can be used not only for cleaning construction products, but also for cutlery.If they handle all the table knives in the house, then they will certainly never suffer from rust. It is enough to wait about five hours, then rinse the solution with a cleaning compound.

All methods have proven themselves quite well. You can use any of them, although often one is not enough and you have to use all of them. In any case, masters have been using them for a long time and quite successfully. But most importantly, remember that it is better to initially protect yourself from rust, and not fight it.

Causes of the problem

Rust can destroy any surface, especially metal.

It appears if the part is in contact with water for a long time, salt and various contaminants get on it. Even ordinary dust can cause friction between the elements and aggravate the situation. Any metal product has a special protective coating. If it has been damaged, then corrosion forms, due to which the mount ceases to perform its functions. Some metals do not react well to contact with oxygen or chemicals, as a result of which rust also appears.

To unscrew the mount, you need to create microscopic cracks in the rusty crust.